K-WANG

Honeywell Sieger System 57 Modbus Interface Module Kit Operating Instructions

Model: RS422/485 (05701-A-0312), RS232 (05701-A-0313)

Document Number: MAN0502.PM6 Issue 04 October 99 05701M5006

Manufacturer: Honeywell (formerly Zellweger Analytics Limited)

Honeywell Sieger System 57 Modbus Interface Module Kit Operating Instructions

Basic information

Product Name: Sieger System 57 Modbus Interface Module Kit

Model: RS422/485 (05701-A-0312), RS232 (05701-A-0313)

Document Number: MAN0502.PM6 Issue 04 October 99 05701M5006

Manufacturer: Honeywell (formerly Zellweger Analytics Limited)

Safety Warning and Precautions

Warn

This device is not designed or certified for use in hazardous areas.

Suitable for indoor use only.

Avoid exposure to rain or moisture.

Precautions

Only use components and accessories approved by the System 57 control system.

To maintain safety standards, qualified personnel must regularly maintain, calibrate, and operate the System 57 control system.

Important Statement

Zellweger Analytics Limited shall not be liable for any failure to install and/or use the equipment in accordance with the corresponding version and revision of this manual.

The user of the manual should ensure that its content is completely consistent with the equipment to be installed and/or operated. If there are any questions, they should contact the company for consultation.

The company reserves the right to modify the information in this document without notifying any individual or organization.

Glossary

A1: Low or warning alarm level.

A2: Second warning alarm level.

A3: High or primary warning level.

LED: Light Emitting Diode.

LTEL: Long term exposure limit (8-hour time weighted average).

RFI: Radio Frequency Interference.

RH: Relative humidity.

STEL: Short term exposure limit (10 minute time weighted average).

TWA: Time weighted average.

Main functions and overview

Function: Provides digital communication between the System 57 control system and external computer systems, supports reading configuration, alarm status, and executing calibration programs.

Compatibility: Compatible with 5701, 5704, and 5704F control cards.

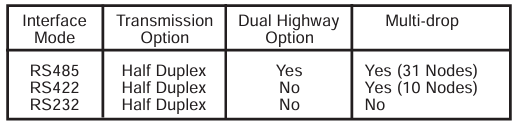

Communication standards: Supports RS485, RS422, and RS232 electrical standards.

Protocol: Operates as a Modbus RTU and supports the 02, 03, 04, 06, and 16 functions of the Modbus protocol.

Data isolation: The data signal is isolated from the System 57 power supply.

Configuration flexibility: Asynchronous serial links can be configured with baud rate, parity, and stop bits.

Way of working

System 57, as a Modbus Remote Terminal Unit (RTU), only transmits data in response to requests from the master device.

The host system (usually a PLC, DCS, or SCADA graphic package) serves as the main device to control the operation of the communication system.

Installation instructions

Preparation before installation

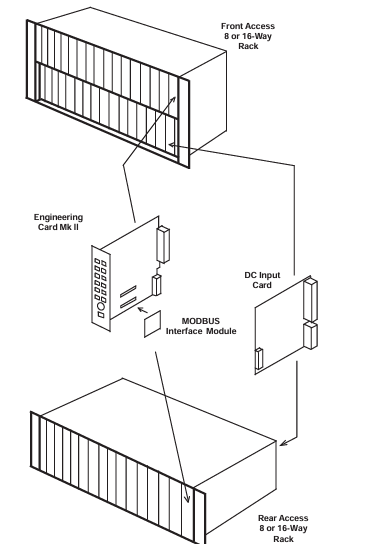

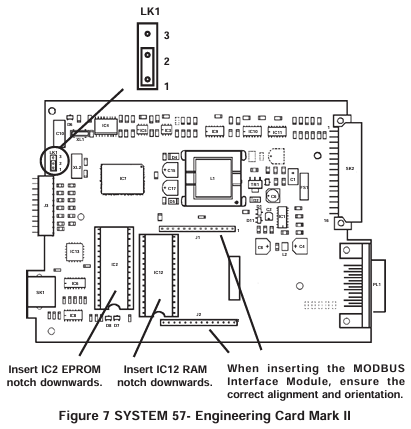

Confirm the type of engineering card, Modbus interface kit can only be installed on Mk 2 engineering cards.

Unpack and inspect the contents of the kit to ensure completeness and no transportation damage.

Installation steps

Cut off all power to the System 57 rack.

Remove the engineering card, insert the software upgrade EPROM integrated circuit into the IC2 socket of the engineering card, and insert the RAM expansion integrated circuit into the IC12 socket.

Replace the short-circuit link LK1 of the engineering card.

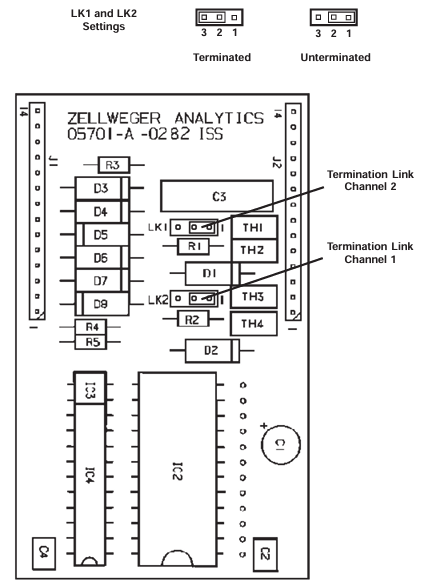

For RS485/422 modules, set the terminal resistance as needed.

Insert the Modbus interface module into the J1 and J2 sockets of the engineering card and reinstall the engineering card.

On site connection

RS485/422 interface: Connect through the auxiliary terminal block TB2 on the DC input card, use shielded twisted pair cable, pay attention to correctly terminating the transmission line, and avoid signal interference.

RS232 interface: also connected through TB2 of DC input card, using high-quality multi-core shielded cable, following the connection specifications of RS232 standard.

Configure Modbus functionality

Host configuration

It is recommended to configure the host to retry at least twice when communication frames are lost.

System 57 configuration

Communication parameters: configurable modes (RS422, RS485, RS232), baud rate, stop bit, parity check, etc.

Address setting: Each rack needs to specify a unique Modbus master address, and when using RS485 half duplex communication and enabling the secondary bus, a secondary address also needs to be set.

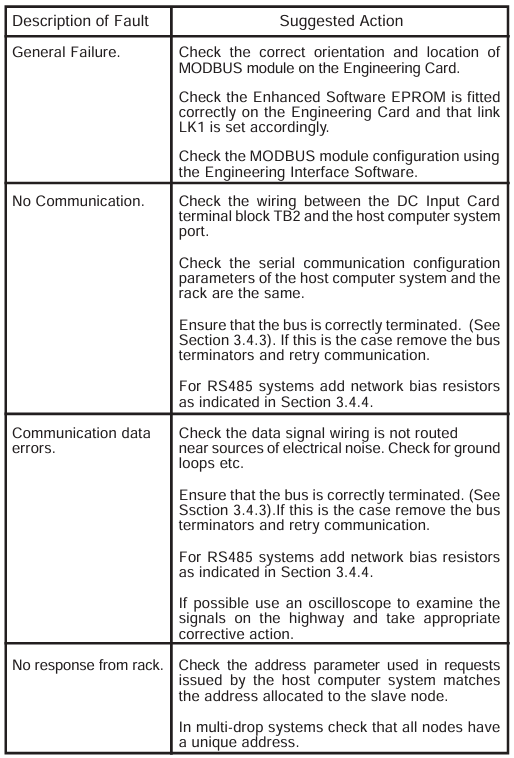

Debugging and Maintenance Instructions

Start program

Ensure that the system power is turned off, reconnect the power, and verify that the LED on the front panel of the engineering card flashes normally and the green POWER ON indicator light remains on.

After the power on suppression time, ensure that the gas detection system operates normally.

Turn on the host system and initiate Modbus master operation.

Simulate alarm conditions, check if the host can correctly detect and take corresponding actions, repeat the test and clear the simulated alarm.

maintenance

The Modbus interface functionality should be regularly tested according to the maintenance procedures in the control system user manual.

Operating instructions

Mainly used to connect gas detection systems to factory control systems, providing centralized monitoring of system status, usually with graphical displays.

The host system needs to be programmed to interpret the signals and status data provided by the System 57 control system.

It is recommended that the host system be programmed to use Function 02 to collect alarm and status data from all channels. If the alarm function needs to be reset, Function 06 or 16 should also be implemented.

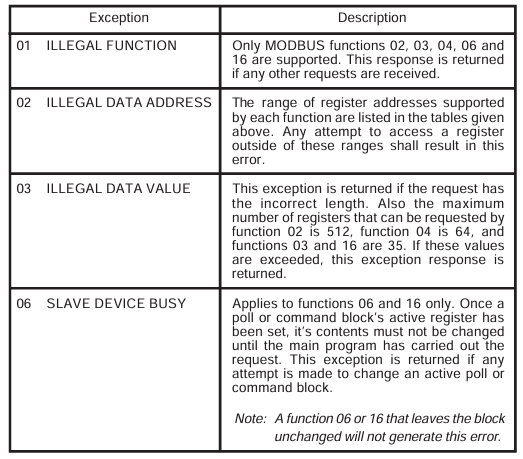

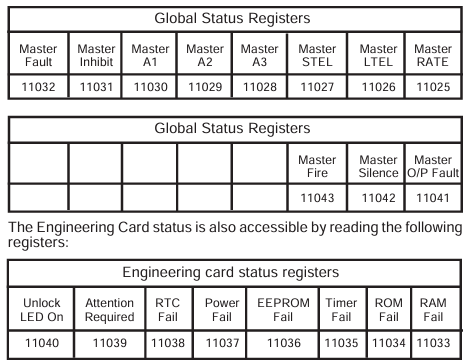

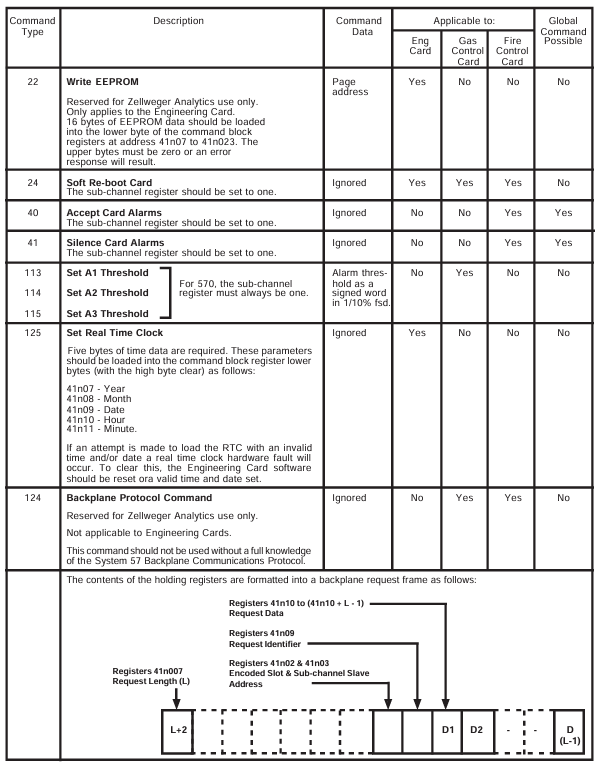

Modbus Function Reference

Supported Features

Function 02: Read input status, can read channel status bits, each sub channel has 11 status bits.

Function 03: Read the hold register. The host can read the contents of the hold register and can read up to 35 registers per frame.

Function 04: Read input registers, with two types of input registers: analog signal value and animation value. A maximum of 64 registers can be read per frame.

Function 06: Preset a single hold register.

Function 16: Preset multiple hold registers, up to 35 registers can be set per frame.

Specification parameters

Environmental parameters

Working temperature: -5 ° C to+55 ° C.

Storage temperature: -25 ° C to+55 ° C.

Humidity: 0 to 90% RH (non condensing).

EMC/RFI compliance

Compliant with EN50081 Part 1 and Part 2 (EMC/RFI Generic Emission) and EN50082 Part 1 and Part 2 (EMC/RFI Generic Immunity).

Serial communication

Format: Asynchronous serial data.

Data bit: 8.

Speed: 19200, 9600, 4800, 2400 baud.

Stop position: 1 or 2.

Parity check: odd, even, or none.

Mode: Half duplex.

Modbus protocol

Mode: RTU.

Supported functions: 02, 03, 04, 06, and 16.

RS485/422 interface module

Power supply: Powered by the engineering card.

Power consumption: maximum 1.5W.

Weight: 30g.

On site terminal: 2.5mm ² (14 AWG), located on the DC input card.

Cable type: It is recommended to use shielded twisted pair cables with separate grounding wires.

Input/Output: Two RS485 transceivers (Channel 1, Channel 2).

Working mode: single RS485 highway, dual RS485 highway (primary and secondary) RS422 highway。

Multi node capability: up to 31 nodes (RS485) or up to 10 nodes (RS422).

Maximum cable length: 1200m (3900ft).

Maximum data rate: 19.2k baud.

RS232 module

Power supply: Powered by the engineering card.

Power consumption: Maximum 0.75W.

Weight: 30g.

On site terminal: 2.5mm ² (14 AWG), located on the DC input card.

Cable type: It is recommended to use shielded multi-core wires.

Input/Output: Two data sets (RXD, TXD) and two handshakes (DTR, DSR).

Maximum cable length: 15m (49ft).

Maximum data rate: 9600 bits per second.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector