K-WANG

Baldor-Reliance ® Super-E ® Efficient motor: full analysis of technological breakthroughs, standard adaptation, and industrial applications

Baldor-Reliance ® Super-E ® Efficient motor: full analysis of technological breakthroughs, standard adaptation, and industrial applications

Under the dual drive of global energy transformation and industrial energy efficiency upgrading, high-efficiency motors, as the core power equipment of industrial production, have a direct impact on enterprise operating costs and environmental sustainability through technological innovation and standard compliance. Baldor Reliance, a subsidiary of ABB ® NEMA Super-E launched by the brand ® Series of high-efficiency motors, powered by NEMA Premium ® With high energy efficiency performance, multi scenario adaptability, and strict quality control, it has become a benchmark product for efficient power solutions in the industrial field. This article will deeply analyze the technical characteristics, standard compliance advantages, and industry application value of this series of motors, providing professional references for industrial enterprise selection.

1、 Core architecture of product system: covering industrial needs in all scenarios

Baldor-Reliance ® NEMA Super-E ® The series of high-efficiency motors are designed with the core concept of "full power coverage and multi scenario adaptation", and have built a complete product matrix covering both universal and specialized types, fully meeting the power needs of different industrial scenarios.

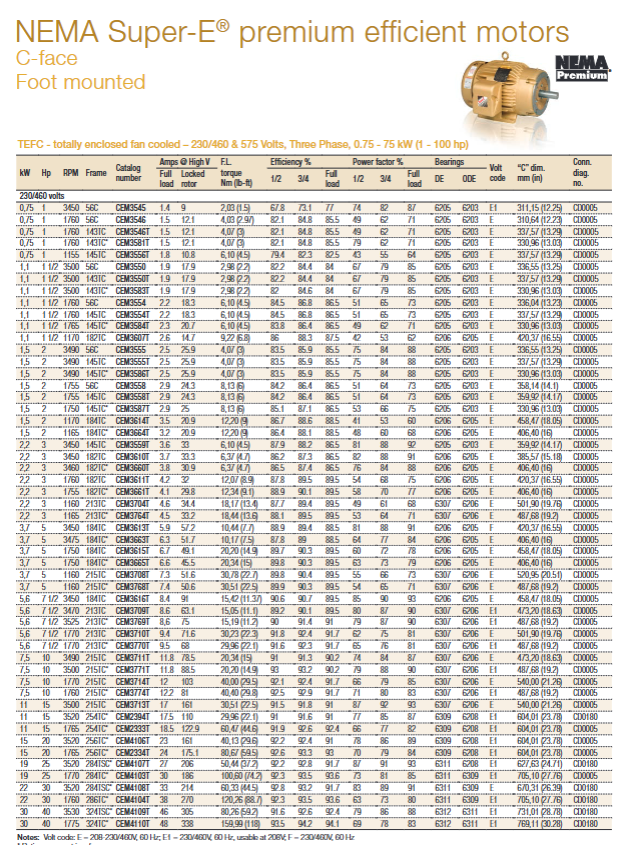

1. Core product classification and parameter range

This series of motors covers a power range of 0.18kW-300kW (1/4Hp-400Hp), with a speed range of 900RPM-3600RPM. The frame size extends from compact models 48 and 56 to large models 449T, forming a seamless connection across the full power range. The voltage adaptation system is flexible and diverse, with single camera models supporting 115/230V, three-phase models covering mainstream voltages of 208-230/460V and 575V, and some specialized models can be customized with 200V special voltage, compatible with most industrial power supply systems worldwide.

The core protection types are divided into two series:

TEFC (Fully Enclosed Fan Cooling) series: including universal, specialized, and braking types, with dust-proof and moisture-proof characteristics, suitable for harsh industrial environments, with a power coverage of 0.18kW-300kW, it is the main product of this series;

ODP (Open Drip Protection) series: covering universal, small motor rules, and elastic base types, with an open heat dissipation design suitable for clean and low dust scenarios, with a power range of 0.18kW-300kW.

2. Scenario based design for specialized models

In response to the special needs of industrial sub sectors, Super-E ® The series has launched multiple customized models for different scenarios, achieving precise matching of performance and working conditions

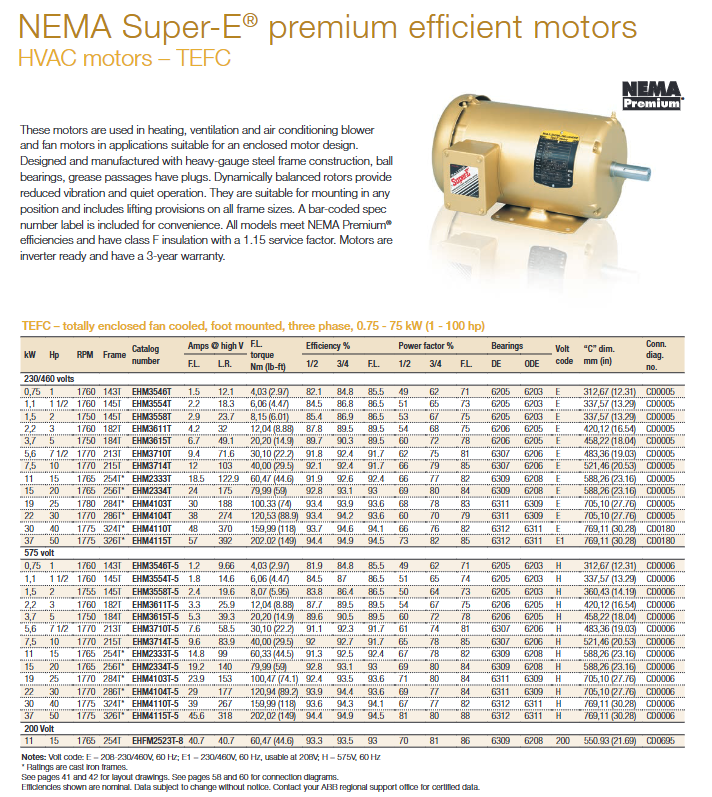

HVAC specific motor: power 0.75-75kW, supports 230/460V, 575V voltage, some models are equipped with AEGIS ® Bearing protection system, Class H insulation level compatible speed regulating drive, heavy-duty steel frame design supporting installation in any direction, meeting the long-term stable operation requirements of ventilation and air conditioning systems;

Refrigeration tower/chiller motor: adopting TEAO protection design, epoxy anti-corrosion coating and double sealed bearing combination, resistant to humid and corrosive environment, suitable for 1200-2000ft/min airflow speed, power 3.7-56kW, specially designed for fluid cooling systems;

Pump motor: Direct coupled design reduces energy loss, vertical P-base model can withstand normal thrust, equipped with AEGIS ® The grounding ring is equipped with Class H insulation and oversized bearings, suitable for fluid transportation scenarios such as sewage treatment and irrigation, with a power of 0.75-37kW;

Unit handling motor: power 0.37-7.5kW, D series brake model equipped with spring brake and manual release lever, accurately adapted to the start stop control requirements of material handling equipment such as conveyors and elevators.

2、 Core technological advantages: triple breakthroughs in energy efficiency, reliability, and adaptability

Super-E ® The market competitiveness of the series of motors lies in their technological innovation in three dimensions: energy efficiency optimization, structural design, and working condition adaptation, which not only meets international high-end standards but also meets the practical application needs of industry.

1. Energy efficiency technology: NEMA Premium ® Energy saving performance

All models in this series comply with NEMA Premium ® The energy efficiency standard is equivalent to the international IE3-IE4 energy efficiency level, and some high-end models have reached the IE5 ultra-high energy efficiency level, fully meeting the energy efficiency requirements of Level 1 and Level 2 in China's GB 18613-2020 national standard. Reduce energy consumption through four core technologies:

Adopting high-grade low loss silicon steel sheets and optimizing magnetic circuit design to reduce iron core eddy current and hysteresis losses;

Select high conductivity pure copper conductors to improve slot filling rate and reduce copper loss in stator and rotor windings;

Standard Mobil Polyrex ® EM long-lasting grease, resistant to high temperatures of 176 ° C, with a lubrication life four times longer than ordinary products, significantly reducing mechanical wear and tear;

Optimizing the design of fans and cooling ribs, TEFC models achieve efficient thermal management through forced air cooling, further improving energy efficiency and stability.

Actual application data shows that compared with ordinary energy-efficient motors, Super-E ® The series can reduce energy consumption by 10% -30%. Taking a 37kW motor as an example, running for 8000 hours a year can save over 10000 yuan in electricity bills, with significant advantages in total cost of ownership (TCO) throughout the entire lifecycle.

2. Structure and Protection: Suitable for harsh industrial environments

Mechanical structure design focuses on durability and environmental adaptability, creating "industrial grade sturdy quality":

The body is made of cast iron or heavy-duty steel frame, with galvanized hardware and anti-corrosion epoxy coating. It has passed the ASTM B117-90 96 hour salt spray test and can withstand complex environments such as dust, moisture, and corrosion;

Dynamic balanced rotor design, with vibration peak controlled within 38.1mm/s, and some high-precision models below 2.03mm/s, reducing operating noise and equipment wear;

Sealed ball bearing configuration, supporting various methods such as foot installation, C-face installation, and footless installation. The frame size is compatible with NEMA standards and adapts to the upgrading and replacement needs of existing industrial equipment.

3. Electrical performance: Balancing stability and compatibility

The electrical system design fully considers the speed regulation and control requirements of modern industry:

The insulation system adopts Class F level (upgraded to Class H for some specialized models), with 200 ° C inverter peak protection capability, in compliance with NEMA ISO14001 Part 31.4.4.2 standard, and suitable for frequency converter speed regulation scenarios;

Silicon free wires and anti corona testing technology reduce harmonic losses and fault risks, and improve electrical system stability;

General models come standard with a service factor of 1.15, while some braking models have a factor of 1.0, supporting short-term overload operation to meet the load fluctuation requirements in industrial production.

3、 Standard Compliance and Certification: Ensuring Global Market Access

Super-E ® The series of motors strictly follow the dual standards of international and domestic standards, and have passed multiple authoritative certifications to provide compliance guarantees for global industrial users, especially in line with the trend of global motor energy efficiency standard upgrades from 2025 to 2026.

1. Adaptation to international standards

Fully compliant with NEMA Premium in terms of energy efficiency ® Standard, equivalent to IE3-IE4 international energy efficiency levels, meeting the energy efficiency access requirements of major markets such as the United States and Europe;

Mechanical and electrical design follows NEMA standards, with standardized frame dimensions, installation methods, and performance parameters, facilitating unified procurement and replacement by multinational enterprises;

Obtained UL/CSA certification, CE certification, in compliance with the IEC 60034 series of International Electrotechnical Commission standards, and has global market access qualifications.

2. Compliance with domestic standards

The energy efficiency level meets the requirements of GB 18613-2020 "Minimum Allowable Values and Energy Efficiency Grades for Electric Motors" at level 2 or above, reaches the IE4 ultra-high efficiency level, and complies with the national energy-saving motor promotion policy;

Adapt to the new standard requirements of GB/T 755-2025 "Rating and Performance of Rotating Electrical Machines", covering new provisions such as variable frequency motor terminology, high-altitude design, insulation level, etc;

Some specialized models meet the GB/T 21707-2025 "Insulation Specification for Variable Frequency Speed Control Motors" to ensure insulation reliability under variable frequency conditions.

3. Quality and warranty guarantee

The product undergoes rigorous factory testing, including efficiency testing (using IEC 60034-2-1:2014 standard loss analysis method), insulation testing, vibration testing, etc., to ensure consistent performance. The entire series comes with a 3-year warranty, and the warranty period for the 841XL series models has been extended to 5 years, demonstrating the brand's confidence in product reliability.

4、 Industry Application Scenarios and Selection Guidelines

Super-E ® The series of motors have achieved large-scale applications in multiple industrial fields due to their wide adaptability and stable performance. Their selection needs to be comprehensively judged based on scene requirements, load characteristics, and compliance requirements.

1. Core application areas

General Industry: General equipment such as machine tools, conveyor belts, compressors, blowers, etc. TEFC universal three-phase motors are recommended with a power of 0.37-300kW, balancing energy efficiency and cost;

Architecture and HVAC: ventilation fans, air conditioning units, heat pump systems, prioritize the use of HVAC dedicated motors with AEGIS ® Bearing protection is suitable for speed regulation requirements and reduces operating noise;

Fluid handling: Water pumps, oil pumps, refrigeration towers, chillers. It is recommended to use direct coupled motors or TEAO protected refrigeration tower motors for pumps to withstand humid and corrosive environments;

Material handling: luggage conveying, elevators, cranes, packaging equipment, using unit handling motor D series brakes to ensure precise start stop and safe operation.

2. Core elements of scientific selection

Power matching: Based on the load torque and speed, calculate the rated power using the formula P=T × n/9550 (P is power kW, T is torque N · m, n is speed r/min), and reserve a margin with a service factor of 1.15;

Environmental adaptation: For dust environments, IP54 or above protection level should be selected. For humid and corrosive environments, TEFC anti-corrosion or refrigeration tower specific models are preferred. For high altitudes (>3300 feet), customized high-altitude adaptation models should be selected;

Control requirements: Select models that support variable frequency drives for scenarios that require speed regulation operation, ensuring that the insulation system meets NEMA ISO14001 Part 31 requirements;

Compliance requirements: Based on the energy efficiency standards of the region, Chinese users must meet the requirements of GB 18613-2020 Level 2 or above, and export enterprises must match the target market NEMA or IEC standards.

5、 Market Competitiveness and Future Trends

Against the backdrop of the global motor industry's transformation towards efficiency, intelligence, and scenario based solutions, Super-E ® The series of motors demonstrate significant market advantages: on the one hand, their NEMA Premium ® Energy efficiency and long-term durability meet the needs of industrial enterprises for cost reduction, efficiency improvement, and sustainable development. According to industry data, the investment return cycle of high-efficiency motors usually does not exceed 2 years; On the other hand, ABB's global service network and Baldor brand's century long industrial manufacturing experience provide users with full lifecycle support from selection, installation to maintenance.

In the future, with the implementation of new standards such as GB 30253-2024 "Energy Efficiency Limits and Grades for Permanent Magnet Synchronous Motors" and the increasing requirements for motor intelligence in Industry 4.0, Super-E ® The series is expected to further integrate intelligent monitoring modules, optimize frequency conversion adaptation performance, launch more efficient permanent magnet models, and continue to lead the upgrading of industrial motor technology.

As the core equipment of industrial power, the selection of high-efficiency motors directly affects the energy efficiency and operational stability of enterprises. Baldor-Reliance ® NEMA Super-E ® The series, with its comprehensive product matrix, leading technological performance, and strict standard compliance, provides global industrial users with energy-efficient and reliable power solutions, making it an ideal choice for industrial energy efficiency upgrades.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923