K-WANG

Baldor Reliability CDPT3320 DC Motor

Baldor Reliance Brushed DC Motor: Technical Parameters, Industrial Adaptation, and Energy Efficiency Upgrade Solutions

In the fields of industrial automation, material handling, precision transmission, etc., DC motors always occupy the core power position with excellent starting performance, wide range speed regulation capability, and stable torque output. The brushed DC motor series launched by ABB's Baldor Reliance brand has become the preferred solution for industrial users with strict manufacturing standards, precise performance parameters, and wide adaptability to various scenarios. This article is based on product technical documents and provides a deep analysis of the core technical characteristics, parameter system, application scenarios, and selection and maintenance points of this series of motors, providing professional references for equipment upgrading and efficient operation in industrial enterprises.

Product Core Parameters and Technical Architecture

Baldor Reliability brushed DC motors are designed with "universal adaptation+precise performance" as the core, and have built a product system covering low-power universal scenarios. Its core parameters and technical architecture highlight industrial grade reliability and adaptability.

1. Basic performance parameter system

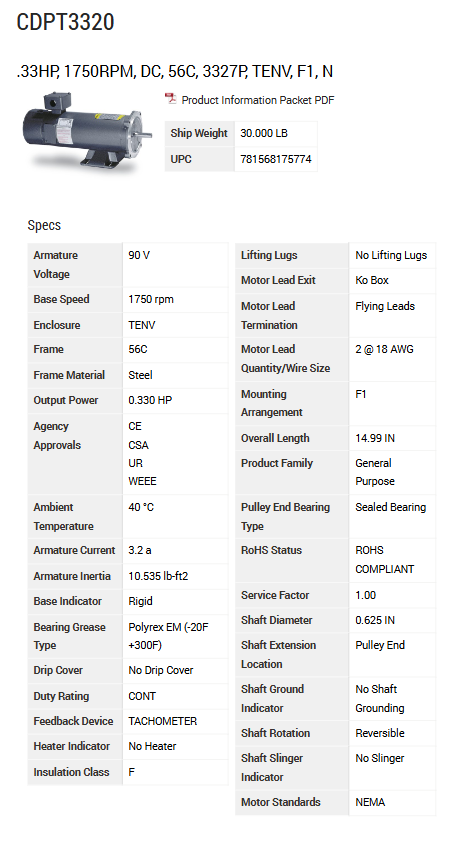

The core parameters of the representative model of this series (CDPT3320) establish the performance benchmark for universal brushed DC motors:

Power and speed: rated power of 0.33HP (0.25kW), base speed of 1750RPM, supporting wide range speed regulation to meet the speed regulation requirements under different loads;

Electrical parameters: armature rated voltage of 90V, rated current of 3.2A, armature resistance of 2.164 Ω, F-class insulation level, able to withstand high temperature operating environment, service factor of 1.00, ensuring stable output under continuous working conditions;

Mechanical structure: It adopts a 56C steel frame, with a total length of 14.99IN and a shaft diameter of 0.625IN. It is equipped with 6203 sealed bearings and uses Polyrex EM long-lasting grease (applicable temperature range -20F~+300F), significantly reducing mechanical wear and maintenance frequency.

2. Protection and compliance design

Protection level: TENV (fully enclosed without ventilation) structure with IP44 protection, effectively blocking dust and splashing liquids, suitable for complex industrial environments;

Compliance certification: Passed multiple international certifications including CE, CSA, UL, and WEEE, compliant with RoHS environmental standards, strictly following NEMA (National Electrical Manufacturers Association) technical specifications, and possessing global market access qualifications;

Safety configuration: Equipped with ISO/ANSI standard graphic warning labels and installation maintenance labels, supporting reversible shaft rotation and F1 rigid base installation, meeting the diverse installation needs of industrial equipment.

3. Load performance characteristic curve

The motor exhibits typical DC motor load characteristics. As the armature current increases from 0.21A to 4.59A, the speed smoothly decreases from 1854RPM to 1526RPM, and the torque linearly increases from 0 to 1.48N · m, achieving an optimized matching of "load increase - stable speed decrease - precise torque increase". This hard characteristic curve enables it to perform excellently in heavy load start-up scenarios, achieving even and smooth stepless speed regulation, fully meeting the core requirements of industrial transmission for load adaptability.

Core technological advantages and industry competitiveness

The technological advantages of Baldor Reliance brushed DC motors are mainly reflected in three dimensions: structural design, performance stability, and scene adaptability, forming significant competitive barriers in the global DC motor market.

1. Structural and material optimization

Reversing system: using high-performance molded commutators, optimizing the precision of the brush and commutator coordination, reducing friction losses, improving commutation stability, and extending the service life of the motor;

Insulation system: F-level insulation design reserves additional safety margins, effectively eliminating hot spot issues during operation, adapting to a maximum ambient temperature of 40 ° C, and meeting the requirements of industrial high-temperature working conditions;

Mechanical strength: The steel frame is combined with galvanized hardware, and through rigorous structural strength testing, the vibration peak is controlled within the industrial low vibration standard range, reducing equipment operating noise.

2. Balance between performance and energy efficiency

Against the backdrop of global energy efficiency standard upgrades, this series of motors achieves a precise balance between energy efficiency and performance by optimizing magnetic circuit design and conductor materials. Its operational efficiency fully meets the energy efficiency requirements of general industrial motors, in conjunction with Mobil Polyrex ® The low friction characteristics of EM long-lasting grease reduce mechanical losses by more than 15% compared to ordinary motors, and have significant advantages in energy consumption throughout the entire life cycle. Compared to AC motors, this series consumes less energy in low-speed, high torque, and precise speed regulation scenarios, which meets the cost reduction and efficiency improvement needs of industrial enterprises.

3. Brand and technology endorsement

As a core brand of industrial motors under ABB, Baldor Reliance has established a comprehensive DC motor technology system based on a century of manufacturing experience. The design of its wound magnetic field motor ensures excellent commutation performance across the entire speed range, with a fault free operation time far exceeding the industry average; At the same time, the brand provides complete technical documents such as 2D/3D CAD files, wiring diagrams, and dimension tables, providing comprehensive support for equipment integration and maintenance.

Industrial application scenarios and selection guide

The technical characteristics of brushed DC motors give them irreplaceable advantages in specific industrial scenarios, and scientific selection is the key to unleashing their performance.

1. Core application areas

General industrial transmission: suitable for small machine tools, conveyor belts, blowers and other equipment, with a power level of 0.25kW and a base speed of 1750RPM to meet the power requirements of medium and low loads;

Material handling equipment: supports reversible shaft rotation and precise start stop control, suitable for small conveyors, lifting devices, etc., with stable torque output to ensure smooth material transportation;

Special equipment matching: As a power source for testing instruments, small pumps, and precision transmission mechanisms, it meets the integration requirements of IP44 protection and compact structure adaptation equipment.

2. Core elements of scientific selection

Load matching: Calculate the rated power according to the formula P=T × n/9550 (P is power kW, T is torque N · m, n is speed r/min), and reserve a reasonable load margin based on the motor service factor of 1.00;

Environmental adaptation: TENV protection type is preferred for dust and humid environments. For high temperature scenarios, it is necessary to confirm that the ambient temperature does not exceed 40 ° C. For special working conditions, customized solutions can be consulted;

Electrical adaptation: Ensure that the power supply voltage matches the rated voltage of the armature (90V), and use 18 AWG lead wires for wiring, in conjunction with a tachometer feedback device to achieve precise speed regulation;

Compliance requirements: Export equipment must confirm the certification requirements of the target market, prioritize the selection of models with CE and UL dual certification, and comply with local energy efficiency and safety standards.

3. Differentiated selection of scenarios with AC motors

Comparison dimension Baldor Reliance brushed DC motor ordinary AC motor

Core advantages include wide speed range, large starting torque, smooth speed regulation, simple structure, low maintenance cost, and adaptability to high-temperature and flammable environments

Applicable scenarios include precision speed regulation, heavy load start-up, reversible operation equipment with constant speed operation, high dust and high temperature environment, and large power equipment

Maintenance focus: regular inspection of carbon brush wear, cleaning of commutator debris, routine insulation testing, and maintenance of bearing lubrication

For scenarios that require uniform stepless speed regulation or heavy load starting, brushed DC motors are a better choice; For scenarios with constant speed operation, harsh environments, and inconvenient maintenance, AC motors can be given priority consideration.

Maintenance and troubleshooting

Standardized maintenance is the key to extending the service life of brushed DC motors, and its core lies in paying attention to the characteristics and common fault points of the brushed structure.

1. Key points of daily maintenance

Carbon brush maintenance: Regularly check the wear of the BP5011T01 model carbon brush, and replace it in a timely manner when the wear exceeds 1/3. Replace the BP5012A04SP brush spring and 33RK5004SP rocker arm to ensure good contact between the brush and the commutator;

Lubrication management: The bearings use Polyrex EM grease, which is replenished every 5000 hours of normal operation and shortened to 3000 hours in high temperature environments;

Cleaning and maintenance: Regularly clean the dust on the surface of the motor and the carbon powder around the commutator to avoid insulation degradation or mechanical jamming caused by accumulation;

Temperature monitoring: Monitor the temperature of the motor body during operation, which should not exceed 70 ° C, and the temperature of the bearings should not exceed 60 ° C. If there is an abnormal high temperature, immediately stop the machine for inspection.

2. Common troubleshooting

Unstable speed: Check the contact status of the carbon brush, clean the dirt on the surface of the commutator, confirm the stability of the armature voltage, and investigate the problem of poor contact of the leads;

Insufficient torque: Measure whether the armature current reaches the rated value (3.2A), check whether the winding insulation is aging, and confirm whether the load exceeds the rated power;

Abnormal noise: Check the lubrication status of the bearings, check the concentricity between the shaft and the coupling, and confirm whether the friction between the carbon brush and the commutator is uniform.

5、 Industry Trends and Future Prospects

Currently, the global industrial motor industry is undergoing a transformation towards high efficiency, intelligence, and environmental protection. At the policy level, countries are continuously improving their motor energy efficiency standards (MEPS). The IEC 60034-30 series standards have clearly defined the requirements for IE4 and IE5 high efficiency levels, promoting the upgrade of DC motor technology towards low loss and high power density. Baldor Reliance, as an industry benchmark, will further optimize the design of the commutation system in the future, reduce carbon brush wear, and integrate intelligent monitoring modules to achieve real-time warning of operating status and improve the level of motor intelligence.

Under the wave of Industry 4.0, the application scenarios of DC motors as precision transmission core equipment will continue to expand. Baldor Reliance brushed DC motors, with their stable performance, comprehensive certification system, and strong brand support, will continue to provide efficient power solutions for general industry, material handling, precision equipment, and other fields, helping enterprises achieve energy optimization and productivity improvement.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

-

XYCOM XVME-085 - Proto VMEbus Non-Intelligent Prototyping Module

-

XYCOM XVME-100 - PCB Controller Card ROM Board 70100-001

-

XYCOM XVME-103 - VMEbus Board 10103-001

-

XYCOM XVME-110 - VMEbus Memory Module SRAM 70110-001

-

XYCOM XVME-200 - Digital Universal Instruments I/O Module Card

-

XYCOM XVME-201 - Digital I/O Controller PC Board Card 70201-001

-

XYCOM XVME-202 - VMEbus Control Module 70202-001

-

XYCOM XVME-203 - VME Digital Counter I/O Module Board Card PLC

-

XYCOM XVME-203/293 - VMEbus Counter Module w/ Quadrature

-

XYCOM XVME-212 - 32 Channel Digital Input Programmable Scanner Module

-

XYCOM XVME-220 - 32 Point Programmable Scanner Digital Output Module

-

XYCOM XVME-230 - Intelligent Counter Module Bus Board VMS 70230-001

-

XYCOM XVME-240 - Digital I/O Card VMEbus I/O PCB

-

XYCOM XVME-244 - 64-Channel Isolated Digital I/O Module VMEbus Adept

-

XYCOM XVME-301 - Graphics Controller Module 74301-001A

-

XYCOM XVME-400 - Digital I/O Card VME Module 70400-001

-

XYCOM XVME-401 - VMEbus Circuit Board 70401-001

-

XYCOM XVME-404 - VME Disc Drive Controller Module Board Card PLC

-

XYCOM XVME-428/1 - VME Bus Intelligent Asynchronous Serial Communication Module

-

XYCOM XVME-490/1 - VMEbus Card 71490A

-

XYCOM XVME-491 - VMEbus Module 71491A

-

XYCOM XVME-500 - XVME-500/01 Card 70500-001

-

XYCOM XVME-500/1 - VMEbus Card I/O Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923