K-WANG

Tektronix TBS1000 series digital storage oscilloscope

Tektronix TBS1000 series digital storage oscilloscope

Product model and core parameters

The TBS1000 series includes 5 models, and the key parameter differences are shown in the following table:

Model Channel Number Bandwidth Maximum Sampling Rate Display Type

TBS1022 2 25 MHz 500 MS/s color

TBS1042 2 40 MHz 500 MS/s color

TBS1062 2 60 MHz 1 GS/s color

TBS1102 2 100 MHz 1 GS/s color

TBS1152 2 150 MHz 1 GS/s color

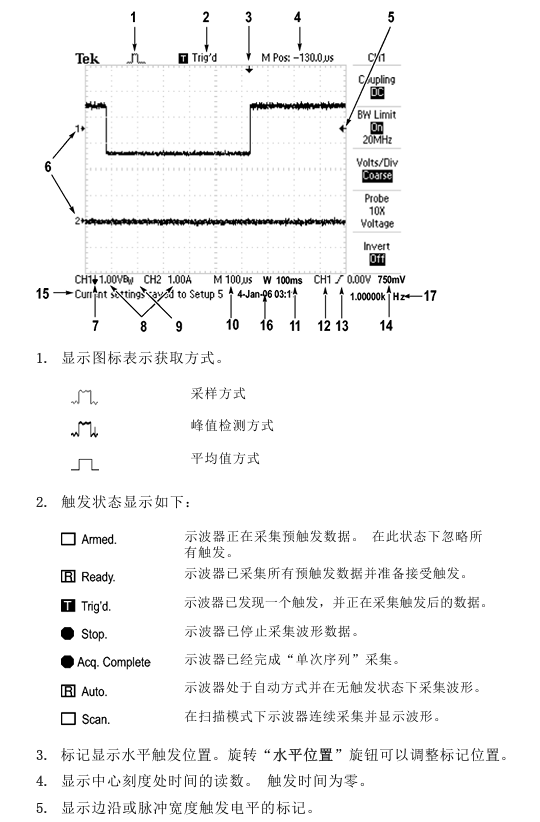

Basic Operation Guide

1. Installation and functional inspection

Installation requirements: The power cord must comply with the specific specifications of the equipment, with a power supply voltage of 90-264VAC (45-66Hz) or 90-132VAC (400Hz); The equipment is cooled by convection, leaving 2 inches of space at both ends and top.

Functional inspection steps:

After booting up, press the Default Setup button to reset to the factory state;

Connect the TPP0101/TPP0201 probe to channel 1, and connect the probe end/reference wire to the "probe compensation" terminal;

Press AutoSet, and after a few seconds, a square wave of approximately 5V peak to peak and 1kHz will be displayed;

Repeat the operation of channel 2 (check channels 3-4 for 4-channel models) and confirm that all channels are functioning properly.

2. Probe calibration and setting

Probe Inspection Wizard: Press the PROBE CHECK button, and the oscilloscope will automatically verify the probe compensation and attenuation coefficient matching (supporting 1X/10X/20X/50X/100X). If it is qualified, it will display "qualified", otherwise it will prompt correction.

Manual probe compensation:

Channel menu → "Probe" → "Voltage" → "Attenuation" set to 10X, P2220 probe switch adjusted to 10X;

Connect the probe to the "probe compensation" terminal and display a square wave according to AutoSet;

Adjust the probe compensation screw until the waveform is "compensated correctly" (no overcompensation/overcompensation).

Current probe settings: Channel menu → "Probe" → "Current" → "Ratio", default 10A/V, need to match the ratio of the current probe.

3. Core control operations

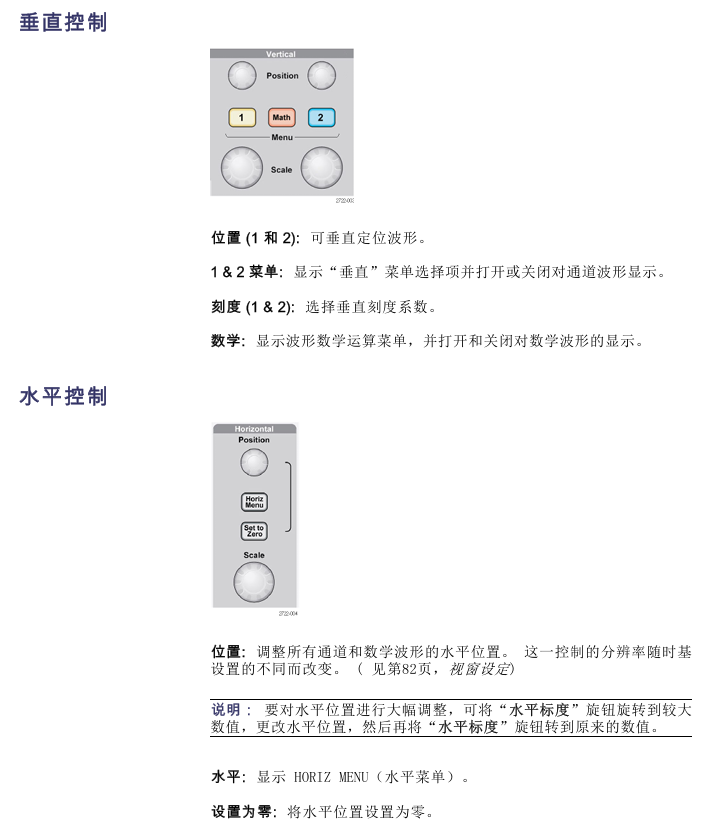

(1) Vertical control

Coupling: DC (AC/DC), AC (DC blocking, attenuation<10Hz signal), grounding (disconnected input);

Bandwidth limit: 20MHz bandwidth limit can be enabled to reduce high-frequency noise;

Scale and Position: The "Vertical Scale" knob adjusts the voltage/grid (1-2-5 sequence, fine adjustment can set small steps), and the "Vertical Position" knob moves the waveform up and down.

(2) Horizontal control

Time base range: 5ns-50s/grid (1-2.5-5 sequence), corresponding relationship of sampling rate is as follows (partially):

Time base setting sampling rate maximum measurable frequency (Nyquist frequency)

5.0ns-250.0ns 1 GS/s 150.0 MHz

500.0ns 500.0 MS/s 150.0 MHz

1.0μs 250.0 MS/s 125.0 MHz

Window function: Open the "Window Settings" through the "Horizontal Menu", define the waveform segment and zoom in to view, supporting switching between the main time base and window view.

(3) Trigger control

Trigger type:

Edge trigger: rising/falling edge, optional source of CH1/CH2/ext/ext/5/mains power, coupling supports DC/AC/noise suppression, etc;

Video trigger: Supports NTSC/PAL/SECAM standards, synchronizes optional scan lines/line numbers/odd fields/even fields/all fields;

Pulse width triggering: The triggering conditions are=(± 5% tolerance), ≠,<,>, and the pulse width range is 33ns-10s.

Key buttons: "Set to 50%" (trigger level set to signal midpoint), "Force trigger" (complete acquisition regardless of trigger conditions), "Trig View" (hold down to view trigger signal).

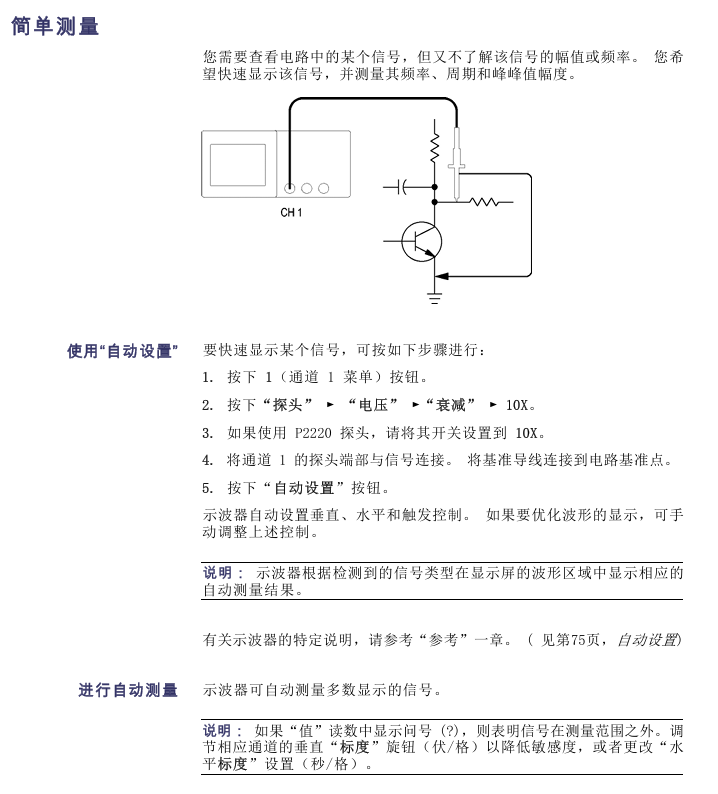

Functional applications and examples

1. Signal measurement

(1) Automatic measurement

Supports 16 measurement types, with a maximum of 5 displayed at once. Some types are defined as follows:

Measurement type definition applicable scenarios

Frequency measurement, first cycle calculation, frequency cycle signal frequency detection

Measurement of the amplitude range of the absolute difference signal between the maximum and minimum peak values of the peak to peak waveform

Evaluation of edge velocity of time pulse signal between 10% -90% rising edge of rising time waveform

Synchronization analysis of phase difference signal between rising edges of two channel phase signals

Determination of pulse signal symmetry based on the proportion of duty cycle, positive pulse time, and period

Operation steps: Press the Measure button → Select the source → Select the measurement type → View the reading (including real-time updates).

(2) Cursor measurement

Type: Time cursor (vertical line, measuring time/frequency/amplitude), amplitude cursor (horizontal line, measuring voltage/current);

Example: Measure pulse width → Press cursor → Select "time" from "type" → Move cursor 1/2 to the rising/falling edge of the pulse → Read and display Δ t (pulse width).

2. Advanced analysis function

(1) FFT analysis

Function: Convert time-domain (YT) signals into frequency-domain spectra, supporting 1024 data points (0Hz Nyquist frequency);

Window selection:

Window type characteristics applicable scenarios

Hanning has good frequency accuracy and average amplitude accuracy for periodic waveform frequency analysis

Flattop has good amplitude accuracy, and its frequency accuracy is generally good for measuring the amplitude of periodic waveforms

Rectangular without attenuation, equivalent to windowless pulse/instantaneous waveform

Operation: Math → "Operation" Select FFT → Select source → Adjust scaling (horizontal X1-X10, vertical X0.5-X10).

(2) Data recording and limit testing

Data recording:

Utility → "Data Recording" → Enable → Select Source (Channel/Mathematical Waveform);

Set the recording duration (0.5-24 hours, increments of 30 minutes/60 minutes, or unlimited);

Select storage folder → start collection, and automatically save to USB after completion.

Extreme testing:

Utility → "Extreme Testing" → Define the source and template (internal/external waveform+horizontal/vertical tolerance);

Set violation response (waveform/image storage) and stop conditions (number of waveforms/violation times/time/manual);

Start the test and display the pass/fail statistics after completion.

3. Typical application examples

(1) Capture single pulse signals (such as relay arcing)

Set the expected range for vertical/horizontal scaling, Acquire → "Peak Detection";

Trigger menu → select "Slope" to rise, set the trigger level to the midpoint of the relay switch voltage;

Press Single to trigger the collection when the relay is turned on. After optimizing the settings, collect and observe the rebound of the contacts again.

(2) Video signal trigger (NTSC standard)

Probe connected to video output, AutoSet → "Auto Settings" menu select "Field" → "All Fields";

Trigger menu → "Video" → "Standard" select NTSC, "Sync" select "Odd Field" (only watch odd fields);

Rotate the horizontal scale to display the complete field/line, and the vertical scale ensures full signal display.

Data management and peripheral connectivity

1. USB flash drive operation

Support capacity: ≤ 64GB, file storage capacity (every 1MB): 5 full storage, 16 images, 250 settings, 18 waveforms;

Save function:

Full Storage: Press Save/Recall → "Full Storage" → "Print Button" to set "Full Storage", press the Print Button to save the image+waveform+settings to the ALLnnnn folder;

Save separately: "Save Image" (BMP/JPG format, etc.), "Save Settings" (. SET), "Save Waveform" (. CSV, 2500 data points);

Transfer function: Transfer settings (. SET) or waveforms (to RefA/RefB reference memory) from USB.

2. Peripheral connection

Printer: Connect a PictBridge compatible printer, go to Utility ->"Options" ->"Printer Settings" (ink saving/layout format), press the print button to send the image, and support terminating printing.

PC connection:

Install OpenChoice software (official website download);

Connect the oscilloscope USB device port to the PC using a USB cable;

Follow the prompts to complete the driver installation and transfer data/control the oscilloscope through software.

GPIB connection: Use the TEK-USB-488 adapter, go to "Utility" → "Options" → "GPIB Settings" to set the address (default 1), connect to the GPIB system, and control it through software.

Reference and Appendix

1. Technical specifications (core part)

Vertical specifications: 8-bit resolution (>6.5 bits at 2mV/grid), DC gain accuracy ± 3% (5V-10mV/grid), ± 4% (5mV/2mV/grid);

Horizontal specifications: Long term time accuracy ± 50ppm (≥ 1ms interval), incremental time accuracy ± (1 sampling interval+100ppm × | reading |+0.6ns) (single sampling);

Environmental requirements: working temperature 0-50 ℃, humidity 5% -85% (no condensation), altitude ≤ 3000m.

2. Accessories and Maintenance

Standard attachments: TPP0101 (100MHz)/TPP0201 (200MHz) 10X passive probe, installation and safety manual, customer documentation browser CD;

Optional accessories: RM2000B rack kit, TEK-USB-488 adapter, soft box (AC2100), handling box (HCTEK4321);

Cleaning and maintenance: Use a lint free cloth to remove dust, clean the outer surface with a soft cloth and 75% isopropanol, and avoid abrasive reagents/direct sunlight/humid environments.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923