K-WANG

Tektronix TDS3000 series digital fluorescence oscilloscope

Model Channel Number Bandwidth Maximum Sampling Rate Maximum Record Length Typical Application Scenarios

TDS3012B 2 100MHz 1GS/s 10k point basic analog signal debugging (such as audio)

TDS3014B 4 100MHz 1GS/s 10k point multi-channel low-speed signal (such as sensor)

TDS3032B 2 300MHz 2.5GS/s 100k point medium speed signal (such as 100Mbps communication)

TDS3034B 4 300MHz 2.5GS/s 100k point multi-channel medium speed signal (such as CAN bus)

TDS305232 500MHz 5GS/s 1M high-speed signal (such as 500MHz clock)

TDS3054B 4 500MHz 5GS/s 1M point multi-channel high-speed signal (such as PCIe)

Tektronix TDS3000 series digital fluorescence oscilloscope

Basic Information

1. Product model and positioning

The TDS3000 series is a mid to high end digital fluorescence oscilloscope (DPO) launched by Tektronix, featuring high sampling rate and flexible analysis functions, covering multi scene signal debugging. The core models and parameters are shown in the table below:

Model Channel Number Bandwidth Maximum Sampling Rate Maximum Record Length Typical Application Scenarios

TDS3012B 2 100MHz 1GS/s 10k point basic analog signal debugging (such as audio)

TDS3014B 4 100MHz 1GS/s 10k point multi-channel low-speed signal (such as sensor)

TDS3032B 2 300MHz 2.5GS/s 100k point medium speed signal (such as 100Mbps communication)

TDS3034B 4 300MHz 2.5GS/s 100k point multi-channel medium speed signal (such as CAN bus)

TDS305232 500MHz 5GS/s 1M high-speed signal (such as 500MHz clock)

TDS3054B 4 500MHz 5GS/s 1M point multi-channel high-speed signal (such as PCIe)

2. Document and Service Support

Document scope: The manual covers device operation, functional applications, troubleshooting, and is applicable to firmware versions V4.XX and above;

Technical support: Call 1-800-833-9200 in North America, and visit the Tektronix official website for local hotlines in other regions; Support online download of drivers, application notes, and firmware updates;

Warranty Policy: The oscilloscope host comes with a 2-year warranty, and the probe (such as P6139A) comes with a 1-year warranty, excluding malfunctions caused by human damage or unauthorized repairs.

Basic Operation Guide

1. Device initialization and probe settings

(1) Power on and self-test

After turning on, the oscilloscope automatically performs a self-test. If it displays "PASS", it is normal; If "FAIL", check the power connection or contact for repair;

Press the Default Setup button to quickly reset to factory settings (vertical coupling DC, trigger edge rise, time base 200ns/grid).

(2) Probe connection and compensation

Probe selection: It is recommended to use Tektronix specialized probes, such as P6139A (100MHz/10X) and P6249 (500MHz/10X);

Connection steps: ① Connect the BNC end of the probe to the oscilloscope channel, ② Connect the probe tip to the measured signal point, ③ Connect the reference wire to the circuit ground;

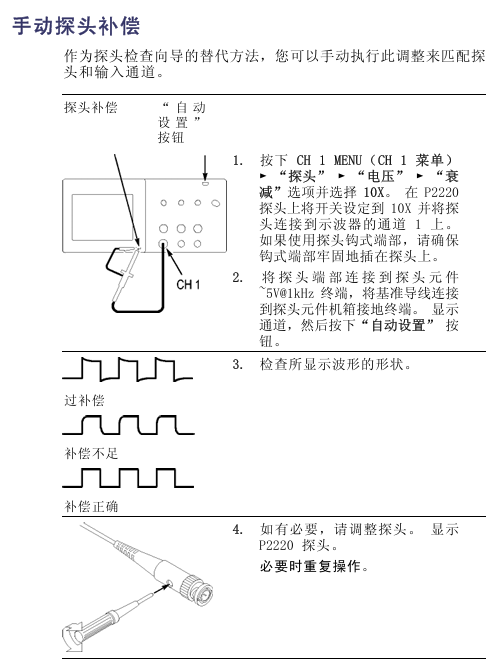

Manual compensation: ① Connect the probe to the "probe compensation" terminal (output 5V/1kHz square wave), ② Display the waveform according to AutoSet, ③ Rotate the probe compensation screw until the waveform is free of overshoot/undershoot (standard square wave);

Attenuation setting: Channel menu ->"Probe Attenuation" Set to 1X/10X, which should match the actual attenuation ratio of the probe (default 10X).

2. Core control system operation

(1) Vertical system

Coupling mode:

DC: AC/DC signal, suitable for DC bias signals (such as power supply voltage);

AC: Block DC components (attenuation<10Hz signal), suitable for AC signals (such as audio);

Grounding: Disconnect the input to determine the zero level position;

Vertical Scale: Range 2mV-10V/grid (1-2-5 sequence), adjustable through the "Vertical Scale" knob; Support "fine adjustment" mode (switch by knob), achieve non-standard stepping (such as 2.5mV/grid);

Channel control: Press the channel button (CH1/CH2, etc.) to turn on/off the channel, move the "vertical position" knob up and down to display the waveform, and support channel overlay display (press Display → "Overlay").

(2) Horizontal system

Time base range: 5ns-50s/grid (1-2-5 sequence), corresponding to the following sampling rate relationship (taking TDS3052B as an example):

Time base setting sampling rate maximum measurable frequency (Nyquist frequency)

5ns-200ns 5GS/s 2.5GHz

400ns-1μs 2.5GS/s 1.25GHz

2μs-50s 1GS/s 500MHz

Sampling mode:

Real time sampling: suitable for high-frequency signals (≤ bandwidth), directly capturing signals;

Equivalent sampling: suitable for ultra-high frequency signals (>bandwidth), reconstructing waveforms through multiple samplings;

Window function: Press Horiz Menu → "Window" to open, define waveform segments and zoom in to view, support switching between main timing and window view.

(3) Trigger system

Trigger type:

Edge trigger: Based on the rising/falling edge of the signal, the source can be selected as CH1-CH4/Ext/Ext 5x/mains power; Coupling supports DC/AC/noise suppression (reducing false triggering of high-frequency noise);

Video trigger: Supports NTSC/PAL/SECAM standards, with synchronization methods including all fields/odd fields/even fields/specified number of lines (1-525 NTSC, 1-625 PAL);

Pulse triggering: triggered by pulse width (20ns-10s), with conditions of>,<,=, ≠, suitable for abnormal pulse detection (such as burrs);

Code triggering: triggered based on logical combinations of 2-4 channels (such as CH1=high, CH2=low), supporting TTL/CMOS levels;

Key operation: Press Set to 50% to automatically set the trigger level to the midpoint of the signal peak to peak; Press Force Trigger to ignore triggering conditions and force collection.

Advanced functional applications

1. Waveform analysis and measurement

(1) Wave Inspector function

Core function: Quickly navigate long recorded waveforms (such as 1M points), avoiding the tedious operation of traditional knobs;

Operation control:

Zoom knob: The inner ring enlarges clockwise and shrinks counterclockwise, supporting separate scaling of X/Y axes;

Translation knob: Move the outer ring left and right to locate the target area;

Marking function: Set the markers (A/B/C/D) according to the markers, and display the time/amplitude difference between the markers;

Example: When analyzing the waveform of a 1M point serial bus, locate a specific data frame by scaling, pan to view the related waveforms before and after, and mark the measurement frame interval.

(2) Measurement function

Automatic measurement: Supports 29 types, with a maximum of 4 displayed at once. The commonly used types are shown in the table below:

Measurement type definition accuracy range

The frequency is calculated based on the first cycle, with units of Hz kHz MHz ± (0.01%+1 count)

Absolute difference between peak to peak maximum and minimum peak values ± (1%+2mV)

The time for the waveform to rise from 10% amplitude to 90% amplitude ± (3%+10ps)

The phase difference between the rising edges of two channel signals, in units of ± (2 °+0.1 °)

Operation steps: Press Measure → "Select Measurement" → Select Source and Type → View Real time Updated Readings;

Statistical analysis: Press "Statistics" to display the average, maximum, minimum, and standard deviation of the measured values (based on 50-1000 sampling points).

(3) FFT frequency domain analysis

Function definition: Convert time-domain (YT) signals into frequency-domain spectra, supporting 1024-1M FFT points;

Window function selection:

Window function characteristics applicable scenarios

Hanning has good frequency resolution and average amplitude accuracy. Analysis of frequency components of periodic signals

Flattop has high amplitude accuracy (± 0.1%), and its frequency resolution is generally calibrated for amplitude calibration (such as signal source output)

Rectangular without attenuation, severe spectral leakage of pulse/instantaneous signals (such as lightning waves)

Operation steps: Press Math → "FFT" → Select signal source → Set window function → Adjust frequency domain scale (Hz/grid).

2. Serial bus triggering and decoding

Supports bus types: I2C, SPI, UART (RS-232/422/485), CAN, LIN;

Trigger settings (using I2C as an example):

Press Trigger Menu ->"Type" select "Bus" ->"Bus Type" select "I2C";

Define SCLK (such as CH1), SDA (such as CH2), and set a threshold (midpoint of the waveform);

Set triggering conditions (such as address=0x50, direction=write), capture the target frame as Single;

Decoding display: Press Decode → "Enable" to overlay color labels on the time-domain waveform (address yellow, data blue, stop red); Support viewing of "event table" (displaying timestamps, types, and values), which can be exported as CSV.

3. Extreme testing and sequence acquisition

(1) Extreme testing

Function definition: Customize "templates" (such as standard waveform contours), use an oscilloscope to compare the collected waveform with the template in real-time, and mark areas that exceed the tolerance;

Application scenario: Batch production testing (such as whether the power output waveform meets the standard);

Operation steps: ① Collect standard waveforms, ② Press Limit Test → "Create Template" → Adjust tolerance (such as ± 5%), ③ Turn on "Test", display "FAIL" and mark the red area when exceeding the tolerance.

(2) Sequence collection

Function definition: Divide long signals into multiple segments (up to 100 segments) for acquisition, with each segment recording a length that is independently set (such as 10k points/segment);

Advantages: Save memory and capture intermittent burst signals (such as pulses with a 1-second interval and a duration of 10 μ s);

Operation steps: Press Acquire → "Sequence" → Set the number of segments and each segment length → Enable acquisition, and after completion, you can view the waveform segment by segment.

Data management and peripheral connectivity

1. Data storage

storage medium

Built in memory: supports 10k-1M point waveform storage, can save 50 sets of settings (. SET files);

USB flash memory: Supports ≤ 32GB, saving formats include:

Image: BMP/JPG (resolution 800 × 600);

Waveform: CSV (including time and amplitude data), TXT (Tektronix proprietary format);

Settings: SET (can directly call up applications);

Save steps: Press Save/Recall → "Save" → Select type/medium/path → Press "Confirm".

2. Peripheral connection

GPIB: Connect to PC through GPIB interface (optional module required) and use TekVISA software to achieve remote control (such as automatic testing scripts);

Ethernet: Supports LXI-C standard, connects to LAN through Ethernet cable, and accesses oscilloscope IP address through browser to achieve remote operation and data transmission;

Printer: Connect to a PictBridge compatible printer, print screen images directly by pressing Print, and support ink saving mode (white background);

PC connection: Connect the PC through a USB cable, install OpenChoice software, and achieve real-time waveform display and data export.

Safety and Maintenance

1. Safety regulations

Grounding requirements: A power cord with a grounding pin must be used, with a grounding resistance of ≤ 0.1 Ω to avoid electric shock;

Overvoltage protection: The maximum voltage of the input channel is ≤± 400V (DC+AC peak). If it exceeds this limit, a high-voltage probe should be used;

Environmental restrictions: working temperature 0-50 ℃, relative humidity 5% -90% (no condensation), altitude ≤ 3000m.

2. Troubleshooting

Troubleshooting steps for possible causes of fault phenomena

There is no display when starting up. The power supply is not connected or the power module is faulty. ① Check the power cord connection, ② Replace the power socket, ③ Contact for repair

Unstable waveform triggers improper settings/poor probe contact ① Reset the trigger level to 50% according to Set to, ② Reconnect the probe, ③ Turn on noise suppression

The measurement deviation is large, and the probe is not compensated/the attenuation setting is incorrect. ① Perform probe compensation, ② Check that the probe attenuation is consistent with the menu settings

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923