K-WANG

TOSHIBA PRODUCT GUIDE Discrete IGBTs

Deep Analysis of Toshiba IGBT Technology Evolution and Multi Field Applications

Insulated gate bipolar transistor (IGBT), as the core device of modern power electronic systems, combines the high input impedance of MOSFET with the high voltage and high current driving capability of bipolar transistor, making it particularly suitable for high voltage and high current load control scenarios. As an important manufacturer in the power semiconductor field, Toshiba's IGBT products are widely used in various fields such as motor drives, uninterruptible power supplies (UPS), induction heating (IH) kitchenware, plasma displays (PDP), flashlights, etc. due to their low saturation voltage drop, high switching speed, high robustness, and diverse packaging forms. This article is based on Toshiba's product guide released in 2011, systematically reviewing its IGBT technology features, product lineup, and development trends, providing reference for engineering selection and design.

Characteristics and Technical Advantages of IGBT Structure

The basic structure of IGBT is a four layer PNPN type, which achieves conductivity modulation through PNP transistors during its conduction period, thereby maintaining a low saturation voltage drop (VCE (sat)) under high voltage conditions. Compared with power MOSFETs, IGBTs have significantly reduced conduction losses at high voltages, especially suitable for medium to high voltage applications ranging from 600V to 1700V.

Toshiba IGBT has the following characteristics:

High speed switch performance: Through carrier lifetime control technology, fast switching is achieved to reduce switching losses.

Low saturation voltage drop: Even in the high current range, maintaining a low VCE (sat) is beneficial for reducing conduction losses.

Built in optimized diodes: Some models integrate fast recovery diodes (FRD) or free wheel diodes (FWD) to improve system reliability and simplify circuit design.

High input impedance, voltage driven: The driving circuit is simple and has strong compatibility.

Diversified packaging: including TO-3P, TO-220, TSON-8, SOP-8 and other packaging options to meet different installation and heat dissipation requirements.

The development trend of Toshiba IGBT technology

Toshiba IGBT has undergone multiple generations of evolution, continuously optimizing its structure, process, and materials

Flat structure IGBT: In the early days, a flat gate structure was adopted to achieve low VCE (sat) by optimizing carrier injection.

Trench Gate structure: introduced since the 4th generation to further reduce saturation voltage drop and improve switching speed.

Thinning and Fine Craftsmanship: After the 6th generation, thinner wafers and finer graphic processes were used to reduce losses and increase current density.

RC-IGBT (reverse conducting IGBT): The 6.5th generation product integrates FWD single-chip into the IGBT chip, reducing external components, lowering thermal resistance, and improving system compactness and reliability.

The following table summarizes the development trend of Toshiba's IGBT at various voltage levels:

Development direction and intergenerational characteristics of voltage levels

1200V 3rd generation: high robustness; 5th generation: trench gate structure soft switch; Generation 6.5: RC structure

900-1500V 4th and 5th generations: trench gate structure soft switch; 6th generation: Thinning; Generation 6.5: RC structure

600V 3rd generation: high robustness; 4th generation: Quick switch; Generation 6: Thinning and Fine Craftsmanship

400V 5th to 7th generation: trench gate structure, suitable for high current pulse applications such as flashlights

300-400V Generation 4-7: Used for PDP driver, gradually optimizing conduction loss and switching characteristics

Product lineup and application selection guide

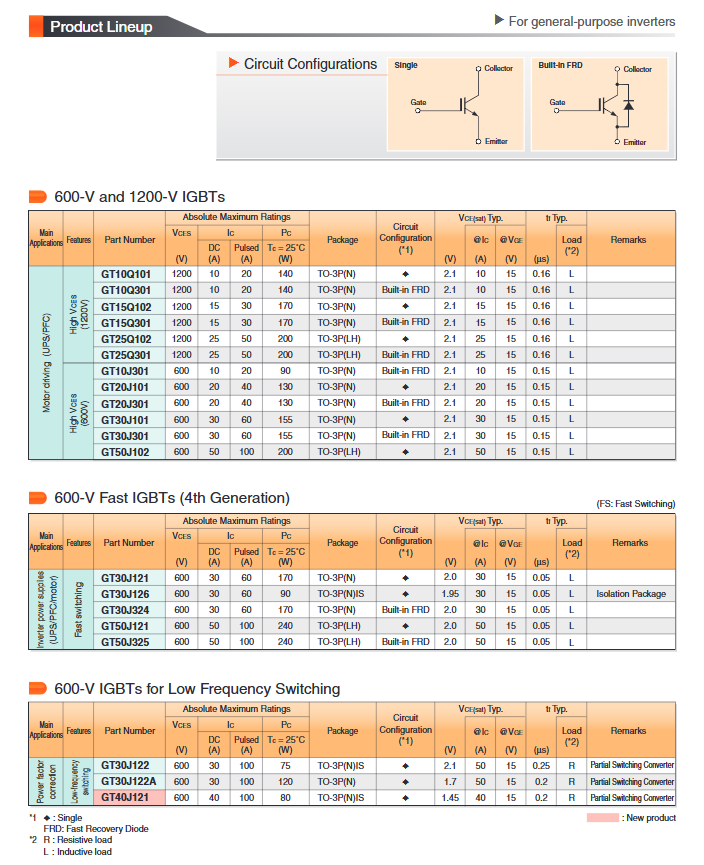

1. Universal inverter and motor drive (600V/1200V series)

Suitable for frequency converters UPS、 In servo drive and other applications, the switching frequency is generally lower than 20kHz (universal type) or up to 50kHz (fast switching type).

High robustness series (such as GT10Q101): Vces=1200V, Ic=10A, built-in FRD, suitable for motor driven U-phase circuits.

Quick switch series (FS series, such as GT30J121): adopting the 4th generation slotted gate technology, with low switching loss, suitable for high-frequency hard switching applications.

Low frequency switch models (such as GT30J122): suitable for scenarios such as some switch converters that do not require high switching frequency.

2. Soft switch application series (600V/900V/1200V)

Suitable for soft switching topologies such as induction heating (IH) kitchenware, microwave ovens, resonant switching power supplies, etc., it can significantly reduce switching losses.

900V series (such as GT15M321): IC=15A, built-in FWD, suitable for 100-120VAC input scenarios.

1200V series (such as GT40QR21): suitable for 200-240VAC input, using the 6.5th generation RC structure, with high integration.

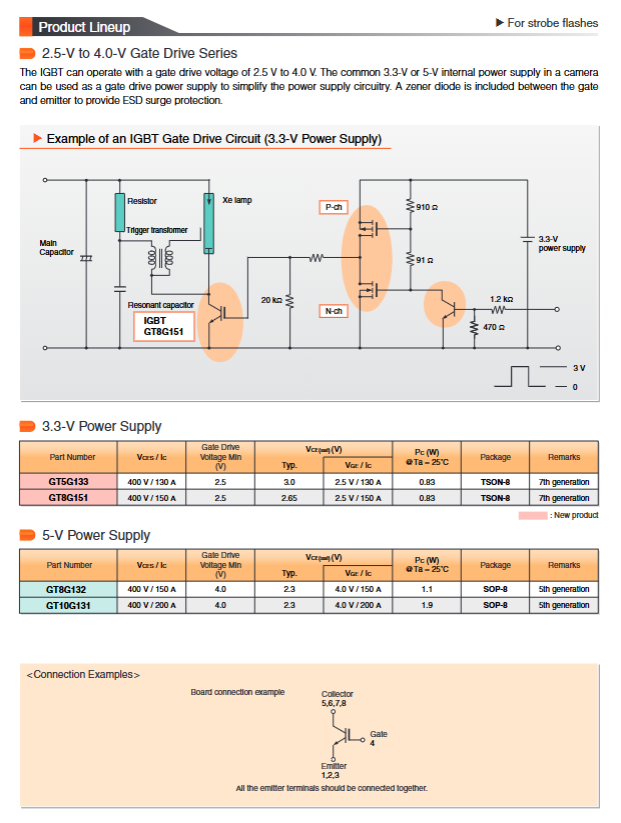

3. Flash application series (400V)

Used for digital camera flash circuits, requiring high pulse current, low gate driving voltage, and small packaging.

Low gate voltage drive series (2.5-4.0V): such as GT5G133 (Vges=2.5-3.0V), can be directly driven by the camera's internal 3.3V power supply, simplifying the circuit.

5V driver series: such as GT8G132, suitable for traditional 5V logic drivers.

4. Plasma Display Driver Series (300V/400V/600V)

Used for PDP scanning and maintenance driving, it needs to withstand high pulse current and low conduction loss.

300V series (such as GT30F124): Vces=300V, Ic=200A, using 6th generation technology with reduced conduction voltage.

400V series (such as GT30G124): suitable for PDP panels with higher voltage.

The 600V series (such as GT30J124) is an early 5th generation product that can still be used in some high-voltage drive applications.

5. RC-IGBT series (6.5th generation new product)

GT35MR21 (900V/35A) and GT40QR21 (1200V/40A), integrated with FWD, are suitable for soft switching and high-frequency applications, with high integration and excellent heat dissipation performance.

Packaging and selection precautions

Toshiba offers multiple packaging options, including:

TO-3P (N)/TO-3P (LH): Suitable for medium to high power, high heat dissipation applications.

TO-220SIS/SM: Suitable for medium power compact installation.

TSON-8/SOP-8: Suitable for low-power, high-density mounting, such as flash circuits.

When selecting, the following factors should be considered comprehensively:

Voltage and current levels: determined based on the system bus voltage and maximum load current.

Switching frequency: For high-frequency applications, choose the fast switch series, and for soft switch topologies, choose the corresponding low loss model.

Thermal design: Evaluate temperature rise by combining package thermal resistance (Rth) with heat dissipation conditions.

Integration requirements: If circuit simplification is needed, built-in diodes or RC-IGBT models can be selected.

Drive voltage: Choose the low Vges series for low voltage logic drive applications.

Discontinuation and replacement suggestions

Toshiba has listed some products that are in the "final stage" or have been discontinued in the product guide (such as MG30T1AL1, GT40M101, etc.), and recommends using new models as replacements. When designing, priority should be given to selecting the current mass-produced series to ensure supply and performance optimization.

Summary and Prospect

Toshiba IGBT continues to improve in terms of conduction loss, switching speed, integration, and reliability through continuous structural innovation and process evolution. From planar structures to trench gates, from discrete IGBT+diodes to single-chip RC-IGBT, its products have covered a wide range of fields from industrial motor drivers to consumer electronic flashlights.

In the future, with the development of markets such as electric vehicles, renewable energy, and high-efficiency power sources, IGBT will continue to evolve towards higher power density, higher frequency, lower losses, and higher intelligent integration. Toshiba, with its years of accumulated technology and product line, is expected to continue playing an important role in the high-end power device market.

For design engineers, understanding the technical characteristics of IGBT, correctly selecting and matching appropriate driving and cooling solutions are the key to achieving efficient and reliable power electronic systems.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

-

KEBA E-CRT D1630D - Circuit Board

-

KEBA DM570 - KeConnect C5 Digital Quantity Mixing Module 97825

-

KEBA KC-E10-3P-63A - AC Charger Accessories Electric Vehicle

-

KEBA G4E606-P - Industrial Computer Motherboard CPU PN:G4E606-501G

-

KEBA KEMROBUS 1842D-0 - Circuit Board

-

KEBA DM262/A - Interface Module K2-200

-

KEBA DI260/A - Controller Module 070257

-

KEBA PS240 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923