K-WANG

Toshiba TE3 Series Low Voltage Digital Solid State Soft Starter User Manual

Toshiba TE3 Series Low Voltage Digital Solid State Soft Starter User Manual

The Toshiba TE3 series is a low-voltage digital solid-state soft starter with a current range of 18-1250A, supporting 208-600VAC three-phase power supply. It has core functions such as soft start/soft stop, current limitation, overload protection, etc. It integrates 5 digital outputs, 4 digital inputs, and 1 analog input/output, supports Modbus RTU communication and local touch screen operation, and can quickly adapt to more than 30 application scenarios such as mixers and compressors through Auto Setup. It has multiple protections such as over temperature, phase loss, thyristor fault, etc. The installation needs to comply with NEC standards and is suitable for smooth starting and protection of industrial rotating machinery, reducing starting surge current.

1、 Product infrastructure and specifications

1. Summary of core specifications

Project specification details

Current range: 18A (TE3-18) -1250A (TE3-1250), a total of 12 models

Voltage range: 208VAC, 240VAC, 480VAC, 600VAC, three-phase

Power adaptation for 208VAC: 5-450HP; 600VAC:10-1200HP

Start time 1-300s (customizable)

Soft stop time 0-300s (customizable)

Overload level 10/20/30 (corresponding to different trip curves)

Communication parameters Modbus RTU (addresses 1-32, baud rates 9600-11520)

Weight range 4kg (TE3-18) -181kg (TE3-1250)

2. Input/output interface

Interface type specification parameters

Digital input (DI) 4-channel, supports 110/230VAC or 24VDC, can map start/stop/reset and other functions

Digital output (DO) 5 channels, 240VAC 1A (DO1-DO4), 240VAC 3A (DO5), supporting fault/operating status output

Analog input (AI) 1 channel, 0-10V or 4-20mA, can map current limit, overload and other functions

Analog output (AO) 1 channel, 0-10V or 4-20mA, can output measured current and overload percentage

Special interface PTC thermistor input (PTC+/PTC -), supporting motor temperature protection

2、 Core functions and configurations

1. Start and stop function

Soft start: By controlling the voltage ramp (1-300s), the starting shock is reduced, and the starting base voltage can be adjusted by 10% -100%.

Kick Start: For viscous loads, provide 10-2000ms torque pulses (30% -80% voltage) to assist in starting.

Current limit start: Limit the starting current to 50% -600% of the motor FLA to avoid grid impact, with a limit time of 1-600s.

Soft stop: voltage ramp deceleration (0-300s), supports automatic smooth stop, and prevents water hammer effect on pump equipment.

2. Automatic configuration and application adaptation

Auto Setup: Built in 30+preset application scenarios (such as centrifugal compressors, screw conveyors, submersible pumps, etc.), one click matching of startup parameters.

Parameter adaptation: Automatically adjust the starting base voltage, ramp rate, current limit and other parameters to adapt to different load characteristics.

Quick debugging: Supports parameter backup to USB, batch copying of configurations, firmware can be upgraded through USB.

3. Detailed explanation of protection functions

Protection type triggering condition response method

When the overload protection current exceeds 115% of the motor FLA and reaches the corresponding overload level, the trip time will trip and the machine will stop. Manual/automatic reset is required

Over temperature protection: The radiator trips and stops when the temperature exceeds 90 ℃, and automatically resets after cooling

Phase loss protection: If any phase is missing on the input/output side, it will trip immediately

Low current protection motor current<25% motor FLA, continuous 4000ms (customizable) trip shutdown

Thyristor malfunction: The thyristor is not conducting properly/short circuited and immediately trips. It is necessary to check the resistance of L1-T1/L2-T2/L3-T3

PTC protection PTC thermistor resistance>4k Ω or open circuit tripping shutdown

Voltage imbalance, three-phase voltage difference exceeding allowable range, tripping and shutdown

4. Energy saving and monitoring functions

IERS intelligent energy-saving: dynamically adjust the motor voltage to reduce energy consumption under light load, with an adjustable energy-saving level of 0% -100%.

Real time monitoring: The touch screen displays parameters such as three-phase current, voltage, power factor, radiator temperature, overload percentage, etc.

Log recording: Stores historical data of 10 trip events, peak current at start/stop, and radiator temperature, supports USB export.

Automatic reset: Supports 0-7200s reset delay, 0-10 retries, and can choose to automatically reset for faults such as phase loss and overload.

3、 Installation and compliance requirements

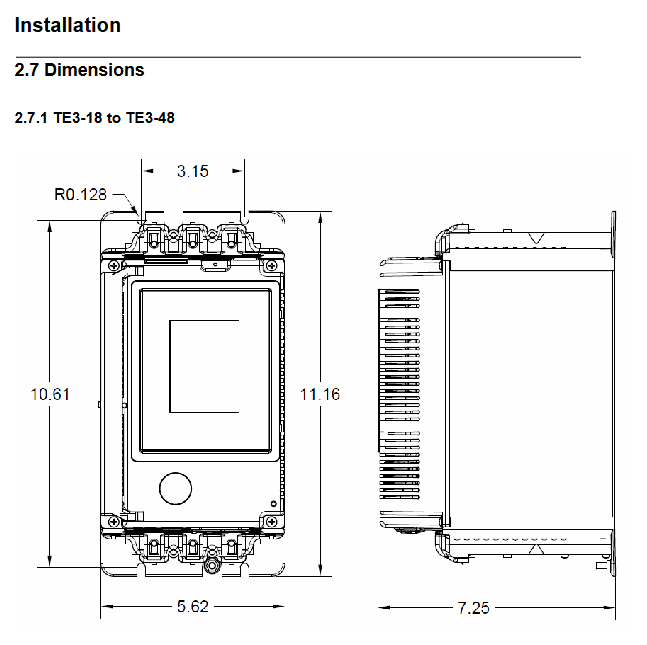

1. Installation specifications

Installation method: Vertically installed on a flat surface, with reserved ventilation gap (minimum 25mm, 127-483mm for high current models).

Environmental requirements: Avoid dust, corrosive gases, and severe vibrations. When the altitude is greater than 1000m, reduce the capacity by 1% for every 100m increase (up to 2000m).

Wiring requirements: The main circuit uses copper conductors with a wire diameter of 0.3-1010mm ² and a wiring torque of 2.8-124.3N · m. The control circuit and the main circuit are wired separately and shielded wires are used.

Short circuit protection: Class J/L/RK5 fuses or circuit breakers with rated currents of 100A-1600A (depending on the model) are required.

2. Compliance standards

Electrical safety: Complies with NEC 70 (NFPA 70), UL508, and cUL508 standards.

Electromagnetic compatibility: EN 55011 Class A, IEC 61000-4 anti-interference standard.

Environmental compliance: RoHS compatible, waste must comply with local electronic waste disposal regulations.

4、 Operation and maintenance

1. Control method

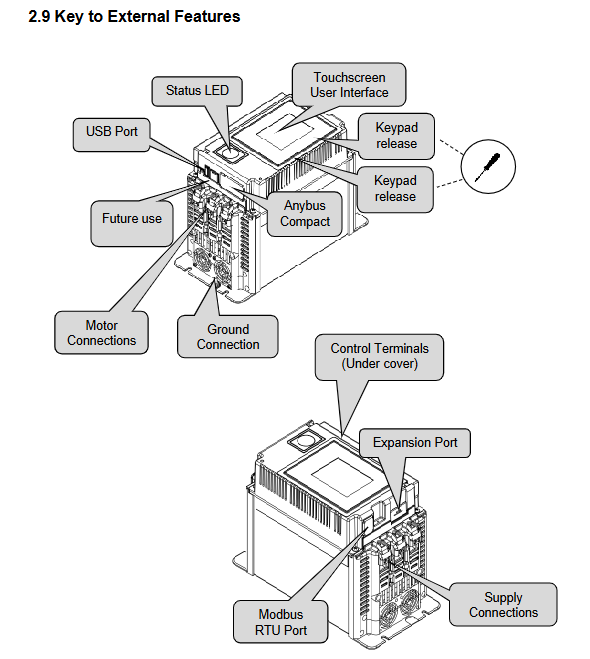

Local control: Supports multi language switching through touch screen start stop, parameter configuration, and status viewing.

Remote control: Two wire/three wire control (DI interface), Modbus RTU communication (supports start/stop, parameter read/write).

Manual/Automatic Switching: Supports Hand/Auto mode, automatically switches to local control in case of communication failure.

2. Maintenance points

Regular inspection: Clean the radiator at least once a year, check the tightness of the wiring, and verify the protective function.

Troubleshooting: Quickly locate the problem (such as 101=input side L1 phase loss) through the trip code (101-2799).

Long term storage: ambient temperature -25 ℃~70 ℃, dry and ventilated, avoid stacking and heavy pressure.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923