K-WANG

TOSHIBA VRF Dx coil interface device Service Manual

TOSHIBA VRF Dx coil interface device Service Manual

1. Basic information

Core equipment:

Dx coil controller: TCB-IFDMX01UP-E (without relay terminal block), TCB-IFDMR01UP-E (with relay terminal block)

Dx valve kit: RBM-A101UPVA-E (diameter Ø 12.7mm), RBM-A201UPVA-E (diameter Ø 15.88mm)

Applicable system: Can connect SMMS-u/∞/e/7 and SHRM-e series VRF outdoor units, requiring on-site preparation of AHU and DX COIL (direct expansion coil)

2. Core technical parameters and configuration

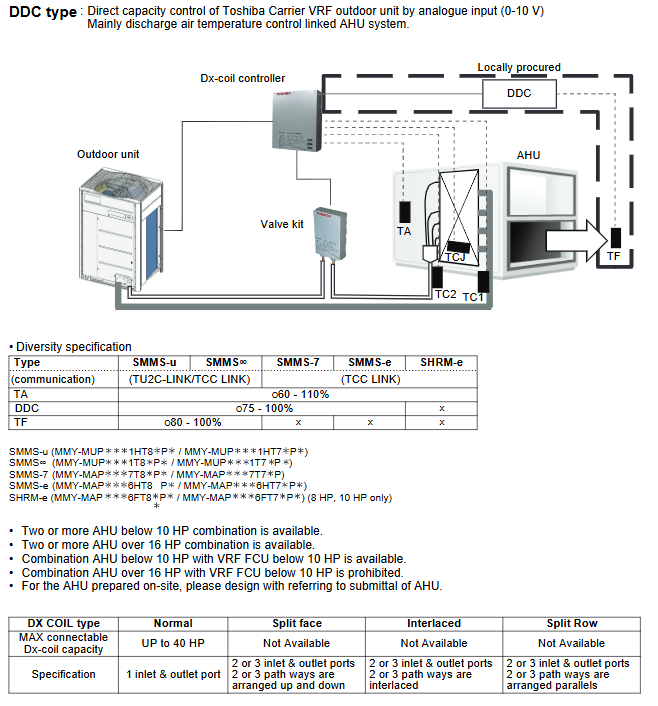

2.1 System Types and Functions

System type Core function Temperature setting range (℃) Adaptation scenario

TA type remote control set return air temperature control for cooling 13-25/heating 18-30 room temperature adjustment

TF type remote control set air supply temperature control 18-29 ventilation system

DDC type 0-10V analog direct capacity control without room temperature control function AHU system linkage supply air temperature control

2.2 Key Hardware Parameters

Refrigerant: Only R410A is supported, and it is prohibited to mix with other refrigerants such as R22. Ventilation is required after leakage (toxic gases are generated in case of fire)

Sensor:

Core sensors: TC1 (gas side), TC2 (liquid side), TCJ (capillary), TA (return air), TF (supply air)

Resistance characteristics: TC2/TCJ resistance is 10.0k Ω at 25 ℃, TA/TF sensor resistance is 12.6k Ω at 25 ℃

Installation requirements: TC1/TC2/TCJ need to be fixed by brazing, with a distance of 50 ± 25mm from the end plate

Pipeline restrictions:

Valve kit to DX COIL maximum actual length: 5m

Total piping length: TA type 200m, TF/DCD type 120m (100m in parentheses)

Maximum height difference: 40m between outdoor unit and indoor unit

2.3 Capacity Adaptation Table (Partial Core Specifications)

DX COIL type controller model, valve kit model, compatible capacity (HP)

Ordinary TCB-IFDMX01UP-E RBM-A101UPVA-E 8-40

Ordinary TCB-IFDMX01UP-E RBM-A201UPVA-E 14-40

Interlocking/facet type TCB-IFDMX01UP-E RBM-A101UPVA-E 42-120

3. Operation and safety regulations

3.1 Personnel Qualification Requirements

Qualified installation personnel: must receive Toshiba Carrier training and possess relevant qualifications for electrical operations, refrigerant operations, high-altitude operations, etc. (in compliance with local regulations)

Qualified maintenance personnel: In addition to the qualifications of installation personnel, they also possess equipment maintenance skills

3.2 Safety Protection Requirements

Required protective equipment for homework types

All homework protective gloves and safety work clothes

Electrical related insulated gloves, insulated shoes, and anti electric shock clothing

Industrial safety helmets for high-altitude operations (≥ 50cm) and ladders that comply with ISO14122 standards

Shoes with anti smashing toe caps for heavy transportation

Electrician specific protective gloves for maintenance operations

3.3 Key operation taboos

Power off requirements: The circuit breaker must be turned off before operation, and a 5-minute wait (capacitor discharge) is required before opening the electrical box cover

Refrigerant operation: It is prohibited to directly recycle it to the outdoor unit, and specialized equipment is required for recycling; Thoroughly empty the air before filling

Modification prohibition: Equipment or parts must not be modified, and replacement parts must comply with the manual specifications (such as relay G2RV-SR700-12DC)

Installation restriction: Indoor unit installation height ≥ 2.5m, prohibited from installation in areas prone to combustible gas leakage

4. Control Logic and Input/Output

4.1 Core Control Functions

Automatic capacity control: TA type is based on the difference between the return air temperature and the set value, while TF type is based on the difference between the supply air temperature and the set value, as well as the temperature change

Protection function:

Anti cold air emission: Control fan speed based on sensor temperature during heating

Anti freezing control: detect the temperature of the coil during cooling to avoid freezing

Oil recovery control: Regularly recover compressor lubricating oil during cooling/heating

Mandatory function: TF type supports forced constant temperature shutdown (such as fan forced shutdown when TA ≤ 5 ℃)

4.2 Input/output ports (MCC-1777 circuit board)

Analog input: 0-10V (AI1-AI4), 4-20mA (AI1-AI2)

Analog output: 0-10V (AO1-AO2), fan speed output (HH=9V, H=6V, L=2V)

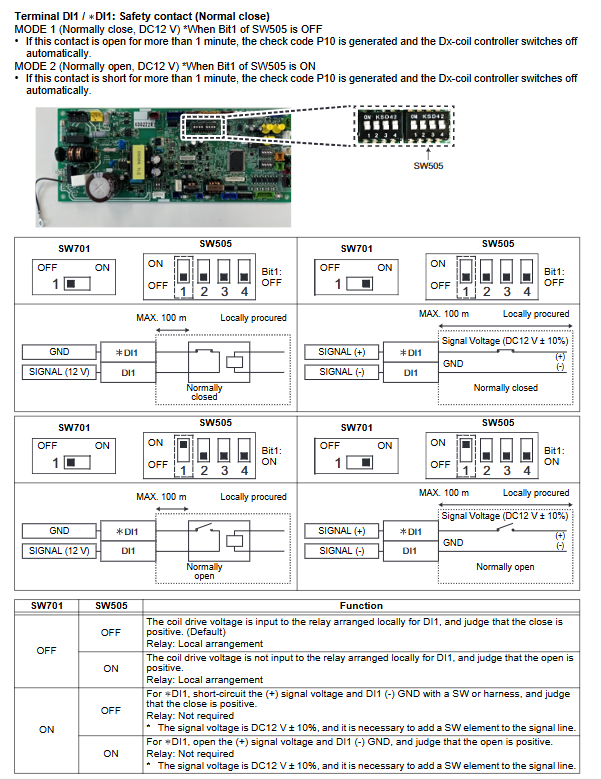

Digital inputs: safety contacts, external fault inputs, operation mode selection (DI1-DI6)

Digital output: operating status, alarm, fan speed, defrost mode (DO1-DOE)

Communication interface: Modbus (supports RS-485, baud rate optional 9600-57600bps)

5. Troubleshooting and maintenance

5.1 Common check codes and their meanings

Inspection code fault type troubleshooting direction

P05 Power supply phase loss/wiring error check power supply wiring and circuit breaker

P10 safety contact disconnection inspection DI1 terminal connection

L30 external fault input check AHU fan operation status

F10 TCJ sensor fault check whether the sensor wiring is short circuited/open circuited

5.2 Maintenance points

Insulation test: After the operation, a 500V megohmmeter should be used to test, and the resistance between the live part and the non live metal should be ≥ 1M Ω

Leak detection requirement: refrigerant leakage must be checked after installation/maintenance

Test Run: Need to enter TEST mode through wired remote control, only supports cooling/heating mode testing

Parts replacement: The controller core circuit board is MCC-1777, and the sensor cable length is 7.5m. If it is insufficient, the optional sensor TCB-IFDES1001P-E (10m) is needed

6. Key settings and calibration

System type setting: configured through SW501 switch (TA type fully closed, TF type only Bit2 on, DDC type Bit3 on)

DN code setting: It needs to be configured with a wired remote control (RBC-ASCU1-E), including device capacity, valve kit type, sensor function, etc. (such as DN11 setting capacity code, DN4AE setting valve kit type)

Modbus settings: configured through SW506 (baud rate) and SW507 (address), supporting up to 16 devices for networking

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB R1091 Industrial Automation Control Module

-

ABB BIO0003 Binary Input Output Module

-

ABB CPU0002 Industrial Control Processor Module

-

ABB M063B Industrial Control Module

-

ABB IMDS003 Control System Module

-

ABB 5SHX08F4502 Power Semiconductor Module

-

ABB RMIO-12C Drive Control Board

-

ABB XO08R1-B4.0 Industrial Control Module

-

ABB 5SGX1060H0003 IGCT Power Semiconductor Module

-

ABB 81EU01E-E Industrial Control Module

-

ABB DSRF197K01 Control System Interface Module

-

ABB TK802F Control System Connection Cable

-

ABB 3BHE039203R0101 Industrial Power Control Board

-

ABB 3BHB004027R0101 Industrial Control Circuit Board

-

ABB 3BHB003154R0101 Industrial Control Circuit Board

-

ABB PM864AK01-eA AC800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Automation Interface Board

-

ABB GCC960C103 Industrial Control Module

-

ABB GVC736CE101 Control System Interface Module

-

ABB PCD244A101 Process Control Communication Module

-

ABB GFD212A Field Device Interface Module

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923