K-WANG

SIEMENS SIMATIC HMI Touch Panel TP 170A, TP 170B Operator Panel OP 170B

SIEMENS SIMATIC HMI Touch Panel TP 170A, TP 170B Operator Panel OP 170B

The SIMATIC HMI TP 170A, TP 170B Touch Screen, and OP 170B Operation Panel User Manual (Order Number 6AV6591-1DC11-2AB0) is a full process guide for three low-level industrial human-machine interface devices. The core covers four modules: installation configuration, functional operation, system settings, and maintenance upgrades. It supports ProTool CS configuration software (V5.2 and above versions), adapts to multiple brands of PLCs such as SIMATIC S5/S7, has 320-768 kByte configuration memory, a 320 × 240 resolution display screen, supports ASCII/RTU transmission, password protection, formula management, trend view, and other core functions. The protection level reaches IP65 (front), and is suitable for machine monitoring and operation in industrial sites.

Comparison of core characteristics of equipment

Equipment model core parameter differentiation function

TP 170A (touch screen) with 320 kByte of memory, 4-color display (320 × 240 resolution), single RS232/RS422 interface basic functions: input/output, status button, bar graph, no recipe/trend function

TP 170B (touch screen) with 768 kByte of memory, 4/16 color display, dual communication interfaces and CF card expansion enhancement features: recipe management, trend view, print output, and multiple languages (5 types)

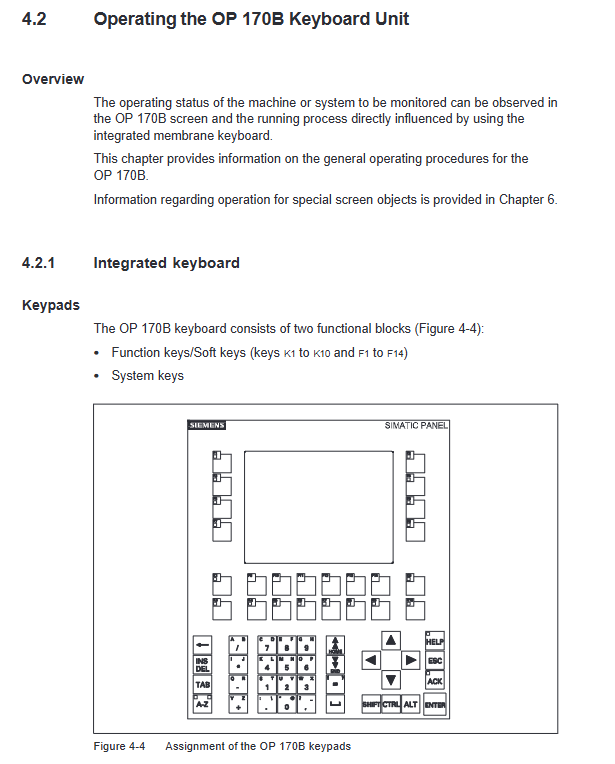

OP 170B (operation panel) configuration memory 768 kByte, 4-color display, integrated membrane keyboard (35 keys)+CF card expansion enhancement functions: soft key customization, batch message confirmation, keyboard shortcut operation

Key hardware specifications

Category specific parameter notes

Display feature resolution 320 × 240, effective display area 116 × 87 mm, CCFL backlight (lifespan 50000 hours) TP 170B/OP 170B supports 16 color display

Communication interface RS232 (9-pin), RS422/RS485 (MPI/PROFIBUS-DP) TP 170A only has a single interface, TP 170B/OP 170B supports dual interface redundancy

Storage expansion TP 170B/OP 170B supports CF card (Compact Flash) for recipe backup and configuration storage

Protection level: IP65 on the front and IP20 on the back, in compliance with NEMA 4 standard (with protective cover)

The power requirement is 24 V DC (18.0-30.0 V DC), with a typical power consumption of 0.24-0.29 A and reverse polarity protection

Environmental adaptation working temperature 0-60 ℃, humidity 5% -95% (no condensation), anti vibration/electrostatic interference in accordance with EN 61000 electromagnetic compatibility standard

Core operating procedures

1. Installation and connection

Mechanical installation

Panel opening size: TP 170A/TP 170B is 198 × 142 mm, OP 170B is 229 × 241 mm

Installation requirements: Panel thickness ≤ 6mm, reserved heat dissipation space (up and down 50mm, left and right 15-70mm)

Fixing method: TP 170A/TP 170B is fastened with side screws, OP 170B supports replacement of function key label strips

Electrical connection:

Power connection: 2-core terminal (+24 V DC/GND), wire cross-section ≤ 2.5 mm ²

PLC connection: Supports RS232 (point-to-point), MPI/PROFIBUS-DP (bus), requires shielded cable

Peripheral Connection: TP 170B/OP 170B can be connected to a serial printer (RS232 9600-57600 bps)

2. Configuration and Debugging

Project configuration:

Software requirements: ProTool CS (V5.2+SP2 and above, TP 170B/OP 170B requires V6.0+)

Configuration process: Create project → Design screen object → Set communication parameters → Download to device

Support functions: multilingual (up to 5 types), password protection (levels 0-9), message alarm (up to 2000 messages)

Download and Upload:

Download methods: manual trigger (startup phase), automatic trigger (runtime phase), supports RS232/SPI interface

Upload restriction: Only TP 170B/OP 170B supports project upload, "Upload option" needs to be enabled

Test modes: offline testing (without PLC connection), online testing (PLC communication verification)

3. Core Function Operations

Key points for operating functional modules and equipment support status

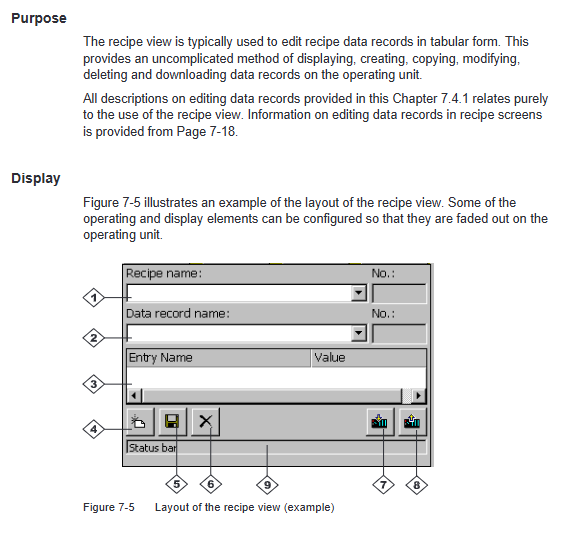

Formula Management (TP 170B/OP 170B) supports 200 formulas/200 data records, can import/export CSV files. TP 170A does not support this

Trend View (TP 170B/OP 170B) can display up to 50 trend curves simultaneously, supporting reading lines and limit value markers. TP 170A does not support this feature

Message alarm supports event messages/alarm messages, 16 confirmation groups, and message buffer storage. All three devices support this feature

Password protection for up to 50 passwords, 0-9 level permissions, automatic logout upon timeout supported by all three devices

Print output (TP 170B/OP 170B) supports screen hard copy and message log printing, but is compatible with EPSON/HP printers. TP 170A does not support it

4. System setup and maintenance

System parameter settings:

Display settings: contrast adjustment, screen calibration (TP series), screen saver (5-minute - permanently turned off)

Language settings: Supports German/English/French/Italian/Spanish, etc., with up to 5 language switches available

Date and Time: Supports synchronization with PLC (S7_CATE-AND_TIME format)

Maintenance and Upgrade:

Daily maintenance: screen cleaning (wet cloth+neutral cleaner), scratch protection (optional protective film)

Backup and recovery: ProSave tool supports Flash memory/CF card backup and batch recovery of configurations

System upgrade: Use PTUpdate tool to update the operating system through RS232 interface (resolve compatibility conflicts)

Fault handling and technical specifications

1. Common faults and solutions

Core causes of fault phenomena and solutions

Project download failed due to communication parameter mismatch and compatibility conflict. Check baud rate/interface settings and upgrade operating system (Chapter 13)

Touch screen unresponsive, uncalibrated, electrostatic interference, screen calibration (Windows CE control panel), grounding treatment

PLC communication interruption cable fault, interface configuration error check shielded cable connection, reconfigure MPI/PROFIBUS-DP parameters

The formula cannot be saved when the storage medium is full. Write protection is required to clear the CF card space and turn off the write protection switch

System message error: Illegal parameters and insufficient memory. Refer to Appendix C System Message Table (error codes 10000-320014) for troubleshooting

2. Key technical specifications

Configuration restrictions:

Number of tags: TP 170A up to 500, TP 170B/OP 170B up to 1000

Number of messages: Up to 2000 event and alarm messages, message buffering supports 64 events

Formula capacity: Up to 200 data records per formula, with a maximum of 60 entries per record

Communication parameters:

Transmission rate: 19200-57600 bps (printer), 1.5-12 MBaud (MPI/PROFIBUS-DP)

Data format: 8-bit data bit, 1-bit stop bit, no checksum (default)

Safety regulations:

Only qualified personnel are allowed to operate, and the power supply must comply with SELV safety ultra-low voltage standards

When used in hazardous areas, turn off the power and then plug and unplug the connector

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

-

KEBA SX TPU 2 16/64 3HAC023195-001 - Teach Pendent Connector Cable 10M

-

KEBA HT4 / HT.4 - Hand Terminal Keypad

-

KEBA KEMRObus-8 22393 - Rack Bus System

-

KEBA FM 265/A 067215 - Kemro K2-200 Module

-

KEBA II030 / II 030 A 22360 - Engel Interface Module

-

KEBA DC 162/IP20 53151 - Controller Module

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA K2 OI280/C - Injection Molding Machine Keypad Film

-

KEBA SR 161 / SR 161/A - I/O Module

-

KEBA i1070 CP031/T CP031/Y - Computer Display

-

KEBA AT-4041 LINZ - Touch Screen Glass Membrane Keypad

-

KEBA E-BT-AN 1866A-1 / 1866D-0 - Circuit Board

-

KEBA PS 244 / PS 244/A / PS 244/E - Power Supply Module

-

KEBA IP 705/IF 21501 - Computer Board

-

KEBA HT4 NEUTRAL 16846/655 - Automation Handheld Keypad Terminal

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad Switch

-

KEBA DO 321 / DO321/16/B - Analog Output Card Controller

-

KEBA Kemro K2-200 DO272/A - Injection Molding Machine Digital Output Module

-

KEBA FX271/A - Controller Module

-

KEBA SC021 / SC021A 2023B-0 - Circuit Board

-

St?rk Tronic ST710-KEBA.43 - Temperature Sensor Cold Storage Controller

-

KEBA DC 661 A 25122 - Controller Module

-

KEBA DC 161 / IP20 17369 - Interface Card

-

KEBA 7" KDT-4908 - Touch Screen Glass

-

KEBA E-SP-CCEC/A/22 479 - HMI Operator Control Panel

-

KEBA 64642 Rev.00 / 2427A - Circuit Board

-

KEBA Kemro K2-200 DM 272/A 070258 - Input Output Module

-

KEBA JB210 / 16299 - Junction Box Module

-

KEBA F-SIC-1/B D1420E - Circuit Board with E-HSI-RS232 RS485

-

KEBA DI 260/A 070257 - Digital Input Module

-

KEBA Ketop IC 205 STB/FA 747228 - Control Cable for CS9 Control 14 Pin

-

KEBA E-3-ACU-10 D16738 - Axis Control Unit Module

-

KEBA Kemro K2-200 LCD - Display Screen Panel

-

Engel / KEBA OP350/W 68334 EC200 - Membrane Keypad Touch Glass Panel

-

KEBA Kemro K2-200 SM210/A - Injection Molding Machine Computer Input Module

-

KEBA E-16-DIGOUT-PLUS / D1456D - Digital Output Board Molding PLC

-

KEBA DM570 97825 - KeConnect C5 Digital Mixed Module

-

KEBA KeTop TT100-Eb0 94461 - 18-Wire Open Ended HMI Cable 10M

-

KEBA SC102 E65100002 - IO Module With Base Board

-

KEBA DC 661/A/25122 - Controller Module

-

Seiko Epson / KEBA Ketop C41 SE TP1 68994/14 - HMI Terminal Control Panel

-

KEBA KeControl C2 102426 - EC-READY Controller Module

-

Engel / KEBA PA 88/2 PA 88d - Control Board

-

KEBA Kemro K2-400 SS 430/A 055823 - Controller Module

-

KEBA Kemro K2-200 OP350/Y-1016 - Membrane Keypad Keyboard Switch Button

-

LTi / KEBA CDB32.004 C37SH / C2.4 SH - Frequency Inverter 10266691

-

KEBA KeView V2 OP350/C-4100 - Computer Display 12.1 inch

-

KEBA G4E606-P PN:G4E606-501G - Industrial Motherboard CPU

-

KEBA AO 240A / AO240A 068371 - Analog Output Module

-

ABB / KEBA STPU3 3HAC023195-006 IRC 5 - Membrane Keypad Switch Touch Screen Glass

-

KEBA KCG075VG2BE-G0 - LCD Screen Display Panel

-

KEBA D1456E-0 - Output Module

-

KEBA KEMRO K2-200 TM 240/A - TM240/A 067111 PLC Module

-

KEBA CP 021/D - KeControl C2 EC-Ready Controller

-

KEBA F-SIC-1 / D1420E - F-Secon-1 Interface Module

-

KEBA AO 240/A 068371 - Analog Output Module

-

KEBA KeTop CB211 - Connection Box

-

KEBA HT4 / 20656 - Kammann Hand Held Keypad

-

KEBA E-CON-CC100/A/ 22178 - Engel Membrane Keypad Panel

-

KEBA Y1-K1-Y2 PA9 - Engel Board Module

-

LTI MOTION CDA32.004C3.0 - Servo Drive 230V AC

-

KEBA E-CG-CONTROL - ECGCONTROL Module

-

KEBA Kemro K2-200 OP350/W 68334 - Engel EC200 Panel Membrane Touch Glass

-

KEBA i1075 - Membrane Keyboard

-

KEBA E-HSI-M - Interface Module

-

KEBA LQ10D321-ERSAT - ZTEILSET FNOB

-

KEBA E-16-DIGOUT/G - Circuit Board

-

KEBA HT4/Neutral/16846 - Mikron Handheld Terminal

-

KEBA KeTop CB310-000 - Connection Box

-

KEBA DC 161/IP20/17369 - Interface Card Module

-

KEBA E-16-DIGOUT-PLUS - Elektronik Bau Linz 262-1456-85-B

-

KEBA HT501 - Handheld Terminal

-

KEBA HT401-4X20 - Teach Pendant

-

KEBA E-3-ACU-10 D16738 - Controller Card Module

-

KEBA 240/A 068371 - Analog Output Module

-

KEBA E-7TEMP D1323E/F/G - Temperature Circuit Board

-

KEBA KeTop TT100-eaa - Communication Cable

-

KEBA E-16 DIGOUT-PLUS D1456D - Engel Output Board

-

KEBA Kemro K2-200 - Touch Panel Glass Digitizer

-

KEBA CC100A03/CAN/4 - PLC Chassis 16-Slot Rack Motherboard 1842E-0

-

KEBA CU 211 - PLC Power Supply

-

KEBA KeTOP CB310-S00 - Connection Box

-

KEBA I/O BUS KOPPLUNG D1547C - Engel Circuit Board

-

KEBA HCS01.1E-W0013-A-02 - Servo Drive

-

KEBA SMC1-Z30 - LTI Security Safety Control

-

KEBA E-PS88-M/C D1527C - Power Supply Board

-

KEBA D1678C / E-SEK - Control Board

-

KEBA 1.83E+02 - Circuit Board Module

-

LUST LTI/KEBA DSM4-05.4-20R.96-W1A - AC Servo Motor

-

Engel/KEBA OP 362-LD/W-5200 - Kemro Ke-200 Membrane Keypad Touch Screen

-

KEBA HT4 24V/0.2A - Kammann Hand Terminal C3052-R47

-

KEBA Kemro K2-200 BL210/B - Injection Molding Machine Controller Module

-

KEBA E-8-ANALOG D1432B - Analog Board

-

KEBA DM272 - Input Output Module

-

KEBA AR161 - PCB ML-EUMIG

-

KEBA E-PS-24V 1825E-1 - Power Supply Board

-

KEBA E-8-THERMO 1770B-1 - Engel Temperature Control Board

-

KEBA HT4-221-20556 - Kammann Hand Terminal

-

KEBA E-10-ANALOG-SUB D1458D - Circuit Board

-

KEBA AC 441 - Control Module 18-32 VDC

-

KEBA KeTop TT050-eaa - Marker Cable

-

KEBA E-ANA-SUB2 D1690C - Analog Submodule Card

-

KEBA Kemro K2-200 OP331/C-1100 - Membrane Keypad

-

KEBA OP 331/C-4400 - Keview V2 LCD Display Screen Panel

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923