K-WANG

WESTINGHOUSE Transformer Product Line

Quality standards: The product strictly follows IEC international standards and Chinese GB standards, and some products can be designed and produced according to customized user needs.

Certification qualifications: Through ISO9001, ISO14001, OHSAS18001 system certification, transformer products have obtained authoritative certifications from KEMA in the Netherla

WESTINGHOUSE Transformer Product Line

Brand and Quality Assurance

Brand Background: Westinghouse was founded in 1886 and has a 130 year history of product innovation. It is a globally trusted industrial and consumer product brand, with business covering multiple fields such as home appliances, consumer electronics, lighting, and power generation equipment.

Quality standards: The product strictly follows IEC international standards and Chinese GB standards, and some products can be designed and produced according to customized user needs.

Certification qualifications: Through ISO9001, ISO14001, OHSAS18001 system certification, transformer products have obtained authoritative certifications from KEMA in the Netherlands and CTQC (National Transformer Quality Supervision and Inspection Center) in China, covering products with different capacity levels of 16MVA-180MVA.

Transformer product system and core parameters

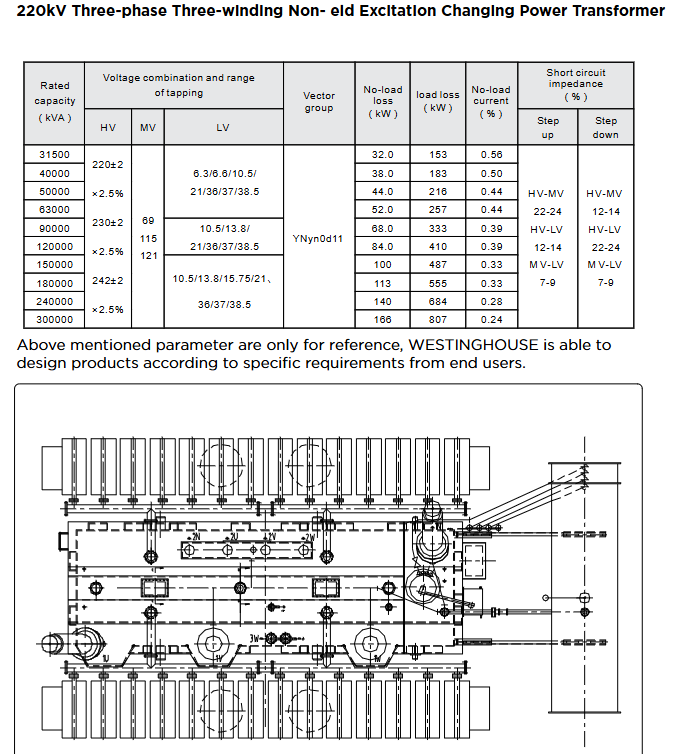

Westinghouse Transformer has a rich product line, covering 16 core products, which can be divided into the following categories according to voltage levels and applications. The key parameters are shown in the table below:

Product Category Voltage Level Rated Capacity Range Core Features Typical Parameter Examples

Power transformers with 220kV, 110/66kV, 35kV, 31500kVA-420000kVA dual winding/triple winding, on/off excitation voltage regulation, oil immersed short-circuit impedance of 6% -34%, no-load loss of 32kW-173kW

Distribution transformers 20kV, 10kV 30kVA-2500kVA have small size, light weight, low loss short-circuit impedance of 4% -6%, and no-load loss of 100W-3960W

Amorphous alloy core distribution transformer 10kV 30kVA-2000kVA is energy-saving and efficient, with no-load loss 50% lower than traditional products, no-load loss 33W-750W, and short-circuit impedance 4% -5%

Dry type transformer 35kV, 10kV 30kVA-25000kVA resin casting, low partial discharge (≤ 5PC), suitable for indoor no-load loss of 190W-27100W, short-circuit impedance of 4% -10%

Special purpose transformer -500kVA-10000kVA designed for specific scenarios, suitable for rectifier transformers with voltages ranging from 10kV to 66kV; Furnace Transformer: Suitable for Metallurgical/Chemical Smelting

Voltage regulating transformers ranging from 2.5kV to 35kV are matched with on load voltage regulation and automatic voltage regulation as needed, with 7-16 steps and a mechanical lifespan of 1 million cycles

Key product classification

power transformer

Covering three core voltage levels of 220kV, 110/66kV, and 35kV, including dual winding, triple winding, and self coupling structures.

Supports on load voltage regulation (OLTC) and non excited voltage regulation (NLTC), with a rated capacity of up to 420000kVA, meeting the high-voltage transmission needs of power plants and large substations.

Typical parameters: 220kV double winding transformer with no-load loss of 32kW-173kW, load loss of 128kW-824kW, and short-circuit impedance of 6% -14%.

distribution transformer

The voltage levels include 20kV and 10kV, with a rated capacity of 30kVA-2500kVA, suitable for distribution scenarios in residential communities, commercial centers, and small and medium-sized enterprises.

The 10kV distribution transformer adopts advanced core lamination technology, with no-load loss of 100W-1960W and load loss of 600W-18000W, low noise, and maintenance free.

Special purpose transformer

Rectifying Transformer: Suitable for scenarios such as electrochemical electrolysis, direct current transmission, and industrial rectification, with a rated power of 800kV-16000kV and a voltage of 6kV-35kV.

Furnace transformer: designed specifically for the metallurgical and chemical industries, used for alloy steel and ferroalloy melting, as well as yellow phosphorus and calcium carbide production. It has a rated capacity of 650kVA-25000kVA and supports overload operation.

Photovoltaic integrated substation: integrating inverters and boosting stations to increase the DC voltage of photovoltaic panels to 11kV/33kV AC voltage, with a maximum output of 3000kW per station.

Other types

Dry type transformer: indoor installation, resin casting process, partial discharge ≤ 5PC, suitable for high cleanliness scenarios, capacity 30kVA-25000kVA.

Column mounted transformer/box type transformer: compact structure, flexible installation, suitable for urban and rural distribution networks, road lighting, with a capacity of 30kVA-2500kVA.

Fully Automatic Protection Transformer (CSP): Integrated with high voltage fuses, low voltage circuit breakers, and lightning protection devices, it has short-circuit, overload, and lightning protection functions.

Operating environment and installation requirements

Temperature conditions: The working temperature of most products is -30 ℃ to+40 ℃, while some products such as dry-type transformers and column mounted transformers have a working temperature of -5 ℃ to+40 ℃, and a storage temperature of -40 ℃ to+70 ℃.

Altitude limit: The default installation altitude is ≤ 1000m, and if it exceeds this altitude, parameters such as temperature rise need to be corrected.

Humidity requirement: The working humidity should be ≤ 90% RH (without condensation) to avoid damage to the product caused by moisture inside.

Installation environment: It should be installed in a location free from corrosive gases, severe pollution, and severe vibrations and impacts. Outdoor products should have windproof and rainproof capabilities.

Application scenarios

Industrial scenarios: power distribution and production equipment power supply for steel plants, chemical plants, metallurgical plants, calcium carbide plants, and large manufacturing plants.

Energy scenarios: Energy conversion and transmission in power plants, substations, distribution networks, photovoltaic power stations, and wind power supporting facilities.

Livelihood scenarios: daily power distribution in residential communities, commercial centers, high-rise buildings, urban and rural buildings, schools, and hospitals.

Key issue

Question 1 (Product Adaptability): What is the voltage level and capacity coverage range of Westinghouse transformers, and what core scenarios can they meet for electricity demand?

Answer: The voltage level of Westinghouse transformers covers 2.5kV-220kV, with a rated capacity range of 30kVA-420000kVA, covering 16 core products. Low voltage level (10kV-35kV) and small capacity (30kVA-2500kVA) distribution transformers/dry-type transformers can meet the daily power distribution needs of residential communities, commercial centers, and small and medium-sized enterprises; Medium to high voltage level (110kV-220kV) and large capacity (31500kVA-420000kVA) power transformers, suitable for the high-voltage transmission needs of power plants and large substations; Special purpose transformers (rectifier, furnace, photovoltaic integration) can meet the specialized electricity needs of industries such as metallurgy, chemical, and new energy generation.

Question 2 (Quality and Reliability): What authoritative certifications have Westinghouse transformers passed, and how do their core technological advantages ensure operational reliability?

Answer: In terms of quality certification, our products have passed ISO9001/ISO14001/OHSAS18001 system certification, and our transformer products have obtained authoritative certifications from KEMA in the Netherlands and CTQC in China. They comply with IEC and GB standards in China, and some can be customized for production. In terms of technological advantages, firstly, the optimized design of the iron core, coil, and oil tank structure is adopted to achieve low loss (minimum no-load loss of 33W), low noise, and small volume characteristics; Secondly, key products have comprehensive protection functions, such as CSP series transformers integrated with high-voltage fuses, low-voltage circuit breakers, lightning protection devices, and furnace transformers supporting overload operation; The third is to adopt advanced production processes (such as resin casting and core lamination optimization), combined with strict factory inspections, to ensure long-term stable operation. The short-circuit impedance is controlled at 3.5% -34%, suitable for different power grid conditions.

Question 3 (Installation and Customization): What are the installation environment requirements for Westinghouse transformers, is personalized customization supported, and what is the scope of customization?

Answer: The installation environment requirements include: altitude ≤ 1000m (adjustable parameters beyond altitude), working temperature -30 ℃ to+40 ℃ (some products -5 ℃ to+40 ℃), humidity ≤ 90% RH (no condensation), and the installation site must be free of corrosive gases, severe pollution, and severe vibration. The product supports comprehensive personalized customization, including voltage level and transformation ratio, rated capacity and short-circuit impedance, winding structure (double winding/three winding), voltage regulation method (on load/off excitation), cooling method (oil immersed/dry/forced air cooling), protective accessories (fuses, circuit breakers, lightning protection devices), cabinet size, material, etc., which can accurately match the specific scene needs of users.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923