K-WANG

ABB UNITROL® 6000 Excitation systems

ABB UNITROL ® 6000 Excitation systems

System Overview

ABB UNITROL ® 6000 excitation system is a benchmark product in the field of power generation, which has set the industry standard in terms of progressiveness technology and operational availability. As a core component of many power generation units, it can help power plant owners and operators achieve reliable operation, stable performance, and fast transient response of assets, fully meeting the requirements of the power grid for power generation equipment.

The system has a wide range of applications, covering various power generation and industrial scenarios:

Generator field: Suitable for generators in steam, gas, nuclear, and hydroelectric power plants, including nuclear emergency diesel generators.

In the field of electric motors, they can be used in places such as steel mills, pulp and paper mills, chemical plants, natural gas production plants, refineries, etc.

System version and features

UNITROL ® The 6000 excitation system is divided into two versions, Medium and X-power, each with its own characteristics for different scale application scenarios.

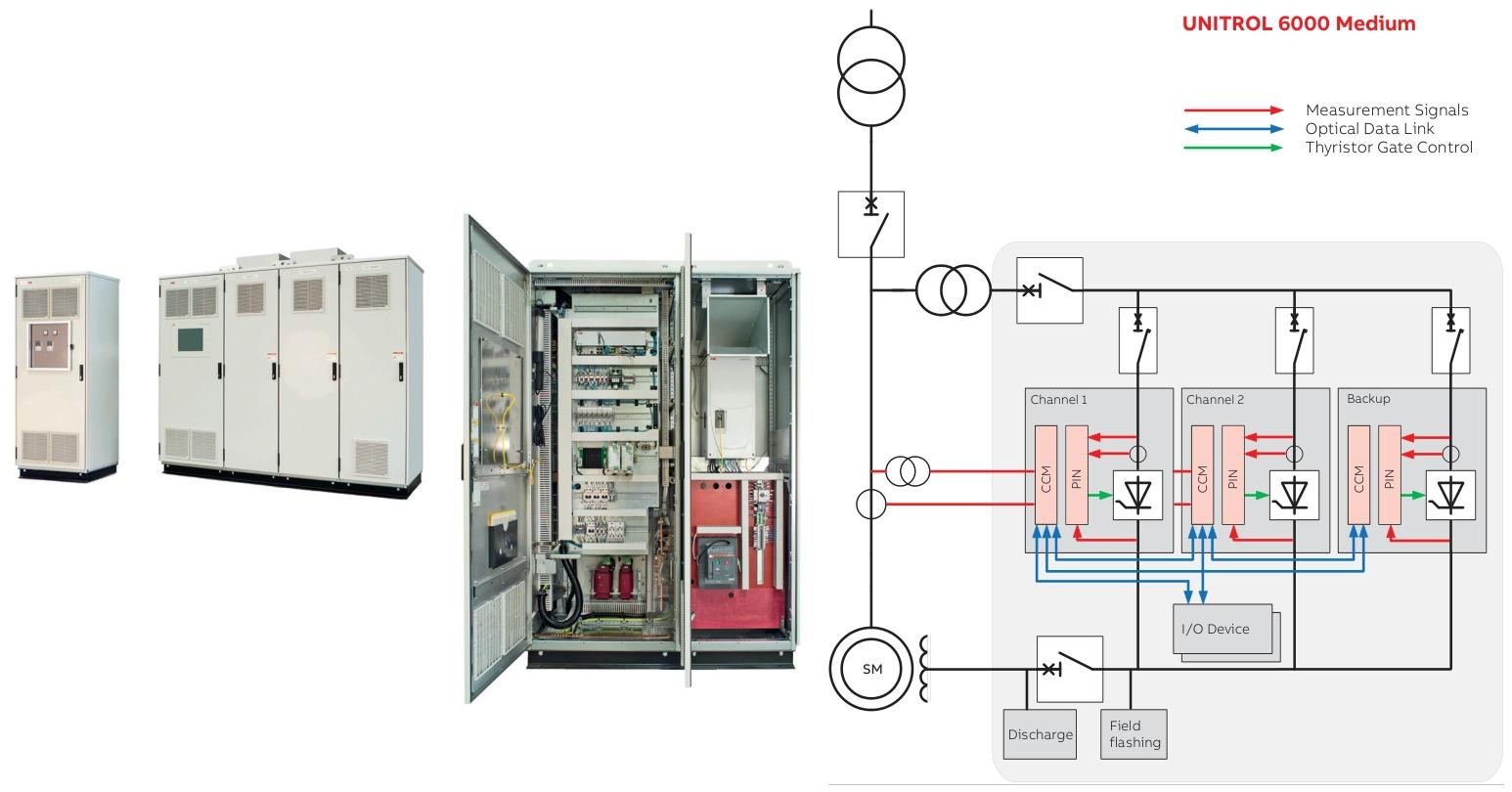

(1) UNITOL ® 6000 Medium

This is a customizable solution designed specifically for small and medium-sized static excitation systems, setting a benchmark for flexibility, reliability, and connectivity in brushless and critical steam generator sets.

Configuration and selection:

Supports single/dual channel configuration, with additional backup channels available upon request.

Provide a variety of thyristor bridge module options to meet various on-site data and availability requirements.

Typical applications:

Hydroelectric power plants, pumped storage power plants, and combined cycle power plants.

A key steam power plant using brushless excitation, excitation current of 200A, and power supply frequency of 400Hz.

Engineering solution: It has functions such as online power conversion and electric braking.

Main parameters:

DC current range:<1800A.

Converter redundancy: single channel, dual channel, dual channel+backup.

Maximum number of converters: 3.

Converter types: D1, D2, D3, D4, D5.

Power System Stabilizer (PSS): 2B/2C.

Adaptive Power System Stabilizer (APSS): None.

PEC controller version: 2nd generation.

IEC 61850 standard: optional.

Excitation circuit breaker: AC or DC.

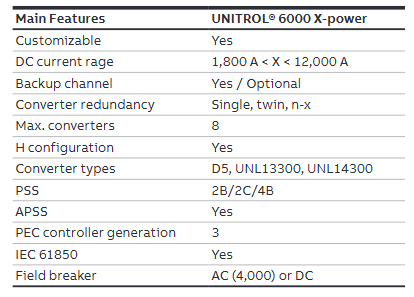

(2) UNITOL ® 6000 X-power

This version is designed specifically for large power generation units, setting new benchmarks in flexibility, reliability, and connectivity.

Configuration and selection:

Supports single/dual channel control configuration and can be equipped with backup controllers according to requirements.

Provide a variety of thyristor bridge module options to meet various on-site data and availability requirements.

Typical applications:

Nuclear power plants with excitation current>10000A.

An underground hydroelectric power plant with an excitation current of 4500A and equipped with a redundant air-water heat exchange system.

A gas turbine power plant (MEGATROL package) equipped with a 15MW static frequency converter for turbine start-up and excitation current of 6000A.

The power part is located in a coal-fired power plant with an IP54 protection level container, automatic voltage regulator cabinet spacing>150m, and excitation current of 3500A.

A hydroelectric power plant equipped with two DC excitation circuit breakers (one for DC backup excitation) and an excitation current of 4000A.

Main parameters:

DC current range: 1800A<X<12000A.

Converter redundancy: single channel, dual channel, n-x redundancy.

Maximum number of converters: 8.

Equipped with H-shaped configuration.

Converter types: D5, UNL13300, UNL14300.

Power System Stabilizer (PSS): 2B/2C/4B.

Adaptive Power System Stabilizer (APSS): Yes.

PEC controller version: 3rd generation.

IEC 61850 standard: standard configuration.

Excitation circuit breaker: AC (4000A) or DC.

Control function

UNITROL ® The control function of the 6000 excitation system is comprehensive and powerful, covering multiple aspects such as closed-loop control, protection monitoring, data recording, and power system stability, ensuring the safe and stable operation of the generator.

(1) Closed-loop control

In automatic mode, equipped with a voltage regulator with PID filter.

In manual mode, equipped with an excitation current regulator with PI filter.

Capable of compensating for reactive and/or active current sag.

Multiple limiter circuits are installed to ensure the safe operation of the generator, including maximum and minimum excitation current limits, maximum stator current limit depending on the temperature of the motor cooling medium, P/Q under excitation limit, volt/hertz limit, etc.

The manual restriction function can keep the generator within a safe range even in manual control mode.

Support power factor/reactive load control.

(2) Protection and monitoring functions

The monitoring and protection functions can be freely configured at three action levels: only issuing alarm signals, switching to redundant circuits, and instantaneous excitation tripping to protect assets.

The main functions include overcurrent protection (instantaneous/inverse time limit), volt/hertz protection, demagnetization protection, rotor temperature monitoring, thyristor conduction monitoring, actual value monitoring, etc.

(3) Data and event recording

The internal event recorder can process and store up to 2000 events, each with a real-time timestamp.

The data logger includes a pre configured section that can record a large number of measurement values and internal signals. It will automatically trigger when a fault occurs, facilitating efficient troubleshooting and continuous improvement to maximize availability.

It also provides a freely configurable high-speed recorder for compliance testing or network event analysis.

(4) System time synchronization

The system clock of all controllers can be synchronized with the time source through the Simple Network Time Protocol (SNTP), with an accuracy of up to 1ms, making it easy to efficiently troubleshoot and keeping the excitation event log consistent with other logs in the power plant, shortening the time for the unit to reconnect to the grid.

(5) Power System Stabilizer (PSS)

The PSS function suppresses power oscillations and improves the stability of the generator and transmission system through excitation. UNITROL ® 6000 optional PSS types include:

Compliant with IEEE Standard 421.5-2016 PSS 2A/2B/2C.

Compliant with IEEE Standard 421.5-2016 PSS 4B/4C.

The Adaptive PSS (APSS) developed by ABB Switzerland can optimize PSS settings based on current network conditions, maximize availability, and avoid tripping due to insufficient damping in weak power grids.

Hardware and software

(1) Hardware components

The system is built on the AC 800PEC high-performance processor family, which is an extension of the ABB 800xA control platform developed specifically to meet the fast control requirements of power electronics.

Control section:

The AC 800PEC control system has extremely high processing speed, providing fast analog and digital process I/O with a typical cycle time of 400 µ s.

Implement fast closed-loop control and conventional process logic in a single controller.

The typical cycle time for low-speed I/O is 10ms.

Ultra fast programmable logic for converter pulse control and optical communication, with a cycle time as low as 25ns.

Power converter:

The power converter for each channel is selected based on the system requirements for maximum excitation current and voltage.

Up to three redundant channels can be equipped, and online maintenance options (optional) are provided to meet strict availability requirements.

ABB has developed a series of thyristor power converters specifically designed for direct (static) and indirect excitation systems, such as D1 to D5, UNL13300, and UNL14300.

The main features of D1 to D5 power converters are: single-phase or three-phase AC power supply voltage up to 1080V; rated power supply frequency 50 to 480Hz (16 ⅔ Hz can be provided according to requirements); The cooling fan has low noise, ≤ 70dB (A); Compact design, fully integrated converter and control, with integrated service panel.

The main features of UNL14300 power converter are: AC power supply voltage up to 1500V; insulation test voltage up to 7.5kV; low cooling fan noise, ≤ 70dB (A); Capable of active current balance control; Optional redundant fans (replaceable during operation) and "pull-out" design (convenient for safe online maintenance and functional testing).

(2) Software functions

The software includes all the necessary regulation, protection, and monitoring functions to ensure the safe operation of the generator as standard features. To meet the specific needs of any application, the software can be easily configured and adjusted.

Simulators and compliance with power grid standards

(1) SMTS-RT 6000 Simulator

SMTS-RT 6000 is a "hardware in the loop" simulator that can simulate generators/motors, their turbines/loads, and the power grid. The simulator is connected to the excitation system for closed-loop testing to analyze its static and transient behavior.

Function: Reduce motor testing time, save costs, and serve as an ideal training tool for maintenance and operation personnel.

Advantage: By using simulators and UNITOL ® Pre adjusting the control parameter set of the 6000 control device can further shorten the debugging time.

(2) Compliance with power grid regulations

UNITROL ® The control function of 6000 can support any grid specification. The extensive testing capabilities and powerful data logger of the excitation control terminal (ECT) are used to test, adjust, and demonstrate the performance of control, stabilizer, and limiter functions.

Testing tool: The built-in white noise generator can quickly and accurately analyze the system frequency response, and perform compliance testing in the least amount of time.

Data storage: Data records are stored in ECT's dedicated memory, which can be easily copied and integrated into electronic documents.

Joint testing: When used in conjunction with SMTS-RT 6000, it can simulate the most critical power plant or grid conditions that are typically not safe to test in actual systems.

Communication function

UNITROL ® The communication function of the 6000 excitation system ensures convenient human-machine interaction and efficient integration with the power plant control system.

(1) Excitation Control Terminal (ECT)

ECT is a user-friendly human-machine interface that supports system operation, monitoring, and maintenance. It is a high-performance industrial grade touchscreen PC that operates independently of the system controller.

Function: Can record events and system data for a long time.

Display: LCD touch screens provide operators with multiple optional screens to display the actual status of the system in both graphical and numerical form.

Compatibility: Running on Windows 10 system, it can also be installed on any PC for debugging.

(2) Integration with power plant control system

Supports Ethernet and fieldbus protocols (Modbus RTU, Modbus TCP, Profibus DP-V0) as well as IEC 61850 as the primary choice for communication with power plant control systems. The emergency control signal can be directly hard wired to the control board.

(3) Remote service

UNITROL ® 6000 supports remote access through ABB RAP platform or customer internal tools. In this way, the local maintenance team can receive necessary support from ABB service experts, which helps to reduce maintenance and service related costs.

Service and Support

ABB for UNITOL ® The 6000 excitation system provides comprehensive services and support, covering installation, commissioning, training, lifecycle management, and other aspects to ensure the reliable operation of the system throughout its entire lifecycle.

(1) Installation and debugging

ABB engineers possess professional competence, extensive experience, and multilingual abilities to ensure satisfactory installation and commissioning of the system.

(2) Training services

ABB University offers services for UNITOL ® The standard and customized training courses for the 6000 excitation system have two options: virtual and on-site training. For a detailed training plan, please visit www.abb.com/abbuniversity.

(3) Lifecycle Management

ABB's excitation system lifecycle management model helps customers extend and maximize the lifecycle of their assets at the lowest cost. Based on the lifecycle stages of the product, service experts will recommend necessary actions and proactively contact customers to inform them of all maintenance, service, and upgrade requirements.

Excitation care plan: comprehensively covering all maintenance needs of customers.

Example of lifecycle services: providing technical support for optimizing reliability, remote services, maintenance and repair, expansion, upgrading, and transformation.

Lifecycle Stage Services:

Active period: The product is available for purchase and provides a complete lifecycle service.

Classic period: The product can be used for power plant expansion, providing spare parts, maintenance, and repair services.

Limited term: As long as materials are available, spare parts, maintenance, and repair services are provided, but lifecycle services are limited.

Elimination period: Due to technical or cost reasons, ABB cannot guarantee the availability of lifecycle services, but will provide technical solutions for asset transformation or upgrading.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector

-

Kollmorgen AKM42G-ASCNR-02 - Servo Motor

-

Kollmorgen DBL4N00750-B3M-000-S40 - Servo Motor

-

Kollmorgen R3-BK23-152B-12-PL-ASE-BS115 - Actuator

-

Kollmorgen MH-427-B-61 - Motor

-

Kollmorgen cr06902 - Servo Drive