K-WANG

ABB UNS0119A-P V101 Controller Module

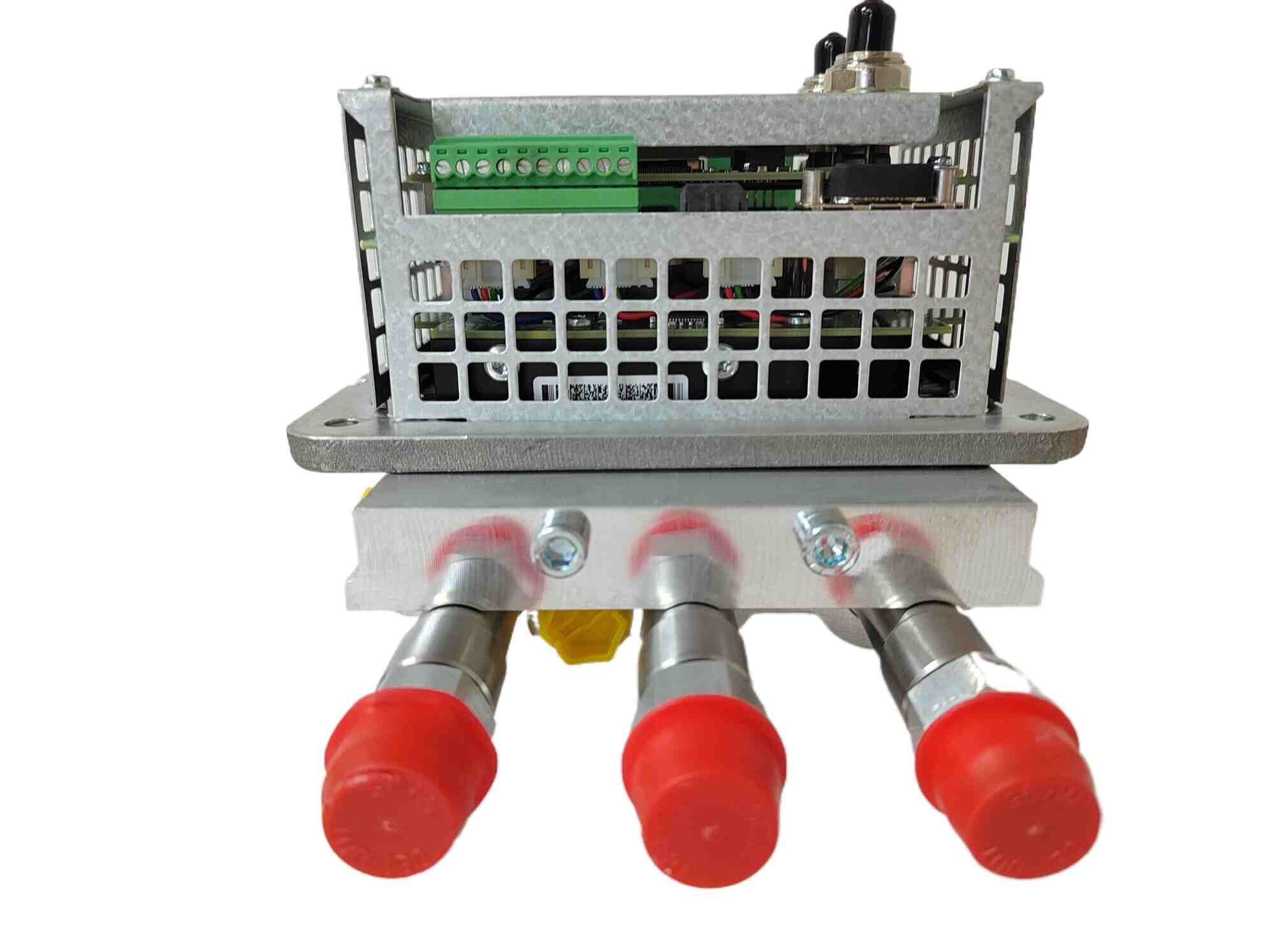

ABB UNS0119A-P V101 Controller Module

Brand background

In the field of industrial control and electrical engineering, ABB is undoubtedly an insurmountable monument. Since its birth in 1988 through the merger of ASEA and BBC, ABB has always adhered to the spirit of innovation and deeply cultivated globally. From being the first to launch a three-phase transmission system and ushering in a new era of power transmission, to developing the world's first self cooling transformer to revolutionize power equipment, ABB's technological innovations continue to reshape the industry landscape. Nowadays, ABB, with operations spanning over 100 countries and 132000 employees, has established a complete technology and service system in various fields such as power and industrial automation. Its profound technical accumulation and excellent brand reputation have laid a solid foundation for the birth and application of the UNS0119A-P V101 controller module.

Product Core Overview

The ABB UNS0119A-P V101 controller module, as an important member of ABB's industrial automation product line, is an intelligent control device that combines advanced technology and high reliability. It is carefully designed for various complex industrial environments, capable of accurately and efficiently handling diverse control tasks, and plays a central nervous system like key role in industrial automation control systems. Through precise control and collaborative scheduling of various devices, this module helps enterprises improve production efficiency, ensure product quality, and promote industrial production towards intelligence and refinement.

Core functions

Super computing and decision-making capabilities: The UNS0119A-P V101 is equipped with an advanced microprocessor, which has high-speed data processing and complex logic computing capabilities. It can collect and analyze massive amounts of data from on-site devices such as sensors and actuators in real time, and make precise decisions and generate corresponding control instructions in a very short time based on preset control algorithms, ensuring that various parameters in the industrial production process are always maintained within the ideal range, providing solid guarantees for the stability and efficiency of production.

Multi communication interaction function: The controller module is equipped with rich communication interfaces, among which the Ethernet interface can easily access the internal network of the enterprise and achieve high-speed data exchange with the upper computer monitoring system, PLC and other devices. Engineers can remotely monitor the module's operating status and adjust control parameters in real time. The RS485 interface provides the possibility for it to connect with numerous smart instruments and devices that support Modbus RTU protocol, easily achieving interconnection and intercommunication between devices, and building a comprehensive and efficient industrial automation communication network.

Flexible I/O configuration capability: In terms of I/O ports, a large number of digital input and output ports can quickly respond to switch signals, used for basic operations such as controlling the start stop and status monitoring of equipment, such as controlling the forward and reverse rotation of motors, detecting the operation/stop status of equipment, etc. The analog input and output ports are dedicated to processing continuously changing signals, such as temperature, pressure, flow rate, and other analog parameters. The module can accurately collect and output analog signals, finely adjust related equipment, and meet the diverse signal processing and control requirements in industrial production.

Convenient programming and customization features: Supports multiple industrial standard programming languages, such as ladder diagrams, structured text, etc., making it easy for engineers skilled in graphical programming or professionals accustomed to text programming to get started. With the visual programming software provided by ABB, users can complete module configuration, parameter setting, and program writing through an intuitive graphical interface, greatly reducing programming difficulty and improving development efficiency. More importantly, users can flexibly adjust module functions and parameters based on actual production processes and control requirements, achieve customized control solutions, and make the controller module perfectly adapt to various complex application scenarios.

Working principle

When UNS0119A-P V101 is put into operation, firstly, various signals from the on-site equipment will be continuously transmitted to the controller module. The analog signals such as temperature and pressure detected by sensors, as well as the digital signals generated by buttons, limit switches, etc., enter the module through corresponding input interfaces. The analog signal is converted into a digital signal by a high-precision analog-to-digital converter inside the module, and then sent to the microprocessor together with the directly input digital signal. The microprocessor performs deep analysis, complex calculations, and precise judgments on these input signals based on pre written and stored control programs and algorithms in memory. After processing, the microprocessor outputs the generated control instructions in the form of digital signals. To control analog actuators such as regulating valves, frequency converters, etc., digital signals need to be converted into analog signals through a digital to analog converter before being transmitted to the actuator; If controlling digital actuators such as relays, contactors, etc., digital signals are directly output to drive their actions. In addition, throughout the entire control process, the controller module continuously exchanges data with other devices through communication interfaces to achieve information sharing and collaborative operations, thereby ensuring the stable and efficient operation of industrial automation systems.

Advantages and highlights

Excellent reliability guarantee: In terms of hardware design, a redundant power supply design scheme is adopted. When one power supply encounters a failure, the other power supply can seamlessly switch and continue to supply power to the module, ensuring its uninterrupted operation. At the same time, through special circuit layout, shielding measures, and filtering technology, the module has strong anti-interference ability, which can effectively resist the interference of complex electromagnetic environment in industrial sites and work stably under harsh working conditions. Moreover, it integrates comprehensive fault self diagnosis functions, which can monitor the real-time operation status of its hardware and software. Once a fault is detected, an alarm mechanism is immediately triggered and corresponding protective measures are taken to minimize the losses caused by equipment failures and significantly improve the availability and stability of the system.

High efficiency and energy-saving features are prominent: in the process of data processing and control instruction execution, the algorithm and hardware architecture are optimized to reduce its own energy consumption. At the same time, with precise control capabilities, the operation status of industrial equipment can be optimized and adjusted, enabling the equipment to operate in efficient and energy-saving conditions, effectively reducing energy waste, and helping enterprises reduce long-term operating costs.

High flexibility and scalability: The flexibility of programming and configuration enables it to quickly respond to changes in different industrial production processes and control requirements, whether it is simple single machine control or complex production line automation control, it can be easily adapted. In addition, the module has excellent scalability, and users can easily add or replace other functional modules according to the needs of system scale expansion or functional upgrade, such as adding communication modules to expand communication protocol support, adding I/O modules to expand port numbers, thereby achieving smooth system upgrade and expansion.

Usage precautions reminder

Strict control of installation environment: To ensure stable module performance and long service life, it should be installed in a dry, well ventilated, and suitable temperature environment. It is generally recommended to maintain the ambient temperature between 0 ℃ and 50 ℃. It is strictly prohibited to install in places with high temperature, high humidity, high dust or strong electromagnetic interference, as these harsh environmental factors may cause damage, performance degradation or even malfunction of module electronic components.

Rigorous wiring operation specifications: It is necessary to strictly follow the product manual for wiring operations, ensuring that each cable is firmly and correctly connected, and resolutely avoiding wiring errors such as short circuits and open circuits. Especially when connecting power and signal cables, carefully check the cable specifications and polarity. If the wiring is improper, it is highly likely to damage the module and cause serious consequences.

Careful and meticulous programming and parameter setting: Before programming and parameter setting, engineers must have a deep understanding of the actual control requirements and the various functions of the module. Be extra cautious when setting parameters, as incorrect parameter settings may cause abnormal device operation or even damage the device. It is recommended to back up the existing parameters before setting important ones, so that in case of any issues with parameter settings, they can be quickly restored to their original state.

Regular maintenance and inspection are indispensable: it is crucial to conduct comprehensive maintenance and inspection of the controller module regularly, including checking for physical damage to the hardware appearance, loose wiring, and normal operation of the cooling fan. At the same time, closely monitor the firmware update information released by ABB and regularly update the firmware versions of modules to obtain the latest functional support, performance optimization, and vulnerability fixes, further enhancing the stability and security of the system.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923