K-WANG

TOSHIBA TOSBERT VF-AS3 series

Core positioning: Designed specifically for industrial scenarios, used to control the speed of 3-phase induction motors, built-in permanent magnet synchronous motors (IPMSM), and surface permanent magnet synchronous motors (SPMSM), and does not support single-phase motors

Scope limitation: Not applicable to high-risk or quality control specific scenarios such as power plants, railways, nuclear power, aviation, life support, etc., only suitable for general industrial use

Core identification rules: The model consists of the series name, voltage level, capacity code, and function code (such as VFAS3-6750PC, where 6 represents 500V-690V and 750 represents the corresponding capacity)

TOSHIBA TOSBERT VF-AS3 series

Product basic information

Product Name: TOSBERT VF-AS3 Series Industrial Inverter

Core positioning: Designed specifically for industrial scenarios, used to control the speed of 3-phase induction motors, built-in permanent magnet synchronous motors (IPMSM), and surface permanent magnet synchronous motors (SPMSM), and does not support single-phase motors

Scope limitation: Not applicable to high-risk or quality control specific scenarios such as power plants, railways, nuclear power, aviation, life support, etc., only suitable for general industrial use

Core identification rules: The model consists of the series name, voltage level, capacity code, and function code (such as VFAS3-6750PC, where 6 represents 500V-690V and 750 represents the corresponding capacity)

Core specifications and performance parameters

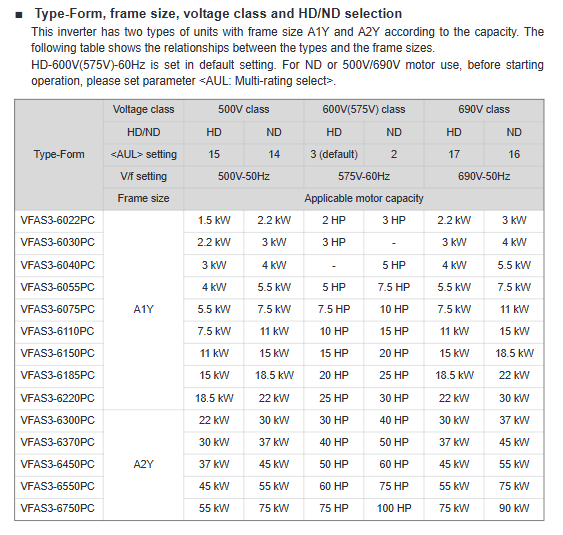

(1) Voltage and power range

Voltage level, power range (HD rated), power range (ND rated), applicable motor capacity labeling

500V class 1.5kW-55kW 2.2kW-75kW in kW

600V (575V) class 2HP-75HP 3HP-100HP in HP units

690V class 2.2kW-75kW 3kW-90kW in kW

(2) Key performance indicators

Control method: sine wave PWM control

Output frequency: set range 0.01-590Hz, default 0.01-60Hz, frequency accuracy ± 0.01% ± 0.022Hz (digital input)

Carrier frequency: A1Y frame 1.0-6.0kHz (default 2.5kHz), A2Y frame 1.0-4.9kHz (default 2.5kHz)

Overload capacity: HD rated 150% -60s, ND rated 120% -60s

Frequency resolution: Input 0.1Hz on the operation panel, communication command 0.01Hz

Core protection functions: overcurrent, overvoltage, undervoltage, overload, short circuit, ground fault, overheating, etc

(3) Environmental and physical parameters

Working environment: Temperature -15 ° C~+60 ° C (capacity reduction required for temperatures above 50 ° C), relative humidity 5% -95% (no condensation), working altitude ≤ 2000m (capacity reduction of 1% for every 100m exceeding 1000m)

Physical specifications: There are two types of machine bases, A1Y (VFAS3-6022PC~6220PC) and A2Y (VFAS3-6300PC~6750PC), with a weight of 21.6kg~57kg

Cooling method: forced air cooling, cooling fan design life of 8 years

Protection level: IP00 (IEC60529), shell color RAL7016

Core functions and configurations

(1) Control and operation functions

Core control mode: supports multiple V/f characteristics such as constant V/f, variable torque, automatic torque boosting, vector control, etc

Operation functions: forward and reverse operation, jog operation, preset speed operation (up to 31 speeds), PID control, torque control, automatic acceleration and deceleration, etc

Display and Monitoring: Equipped with LCD/LED display screens, it can monitor output frequency, current, voltage, fault records, etc., and support fault trip record retention

Parameter settings: Support user default parameter saving, automatic search for parameters different from default values, multi regional parameter adaptation (Japan/North America/Asia/Europe/China)

(2) Interface and Communication Capability

Digital interface: 14 programmable digital inputs (6 optional), 3 programmable digital outputs (2 optional)

Analog interface: 5 frequency command inputs (2 optional), 2 programmable analog outputs

Communication interface: Built in Ethernet (dual port with switch, supporting EtherNet/IP, Modbus TCP, Webserver), 2-channel RS485 (supporting Modbus RTU); Optional protocols include PROFINET, DeviceNet, PROFIBUS DP, etc

Safe Interface: Supports Safe Torque Off (STO) function and complies with IEC61800-5-2 standard

Installation and wiring specifications

(1) Installation requirements

Installation foundation: It must be installed on a metal plate, and the rear panel should not be installed on flammable materials due to high temperature

Installation space: For single unit installation, a space of 10cm up and down, and 5cm left and right should be reserved; Multiple units installed side by side need to reserve a gap of ≥ 11mm, and capacity reduction is required in environments above 50 ° C or when installed side by side

Handling specifications: Models weighing over 20kg require 2 people to handle, VFAS3-6300PC~6750PC require a crane to handle, and it is forbidden to grip the front cover for handling

Peripheral equipment: Short circuit protection devices (such as MCCB, ELCB) and emergency stop devices must be installed, and thermal relays are required (when multiple motors are shared, each motor is separately configured)

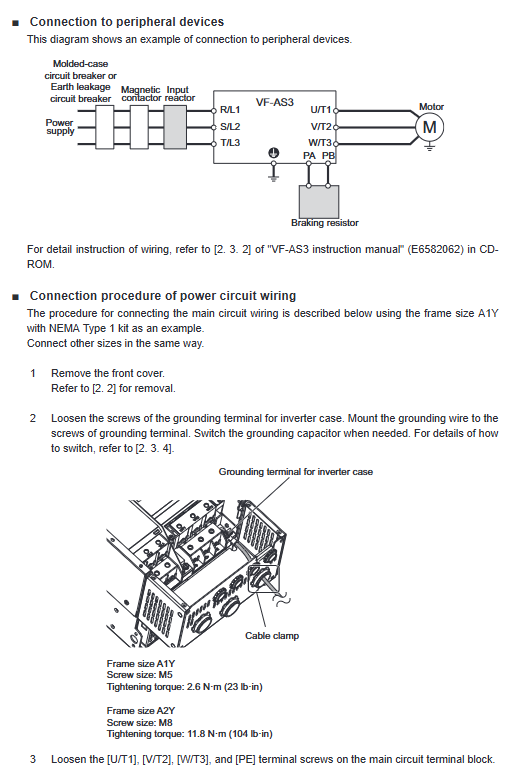

(2) Wiring specifications

Core principle: Power must be disconnected before wiring, wait for at least 15 minutes, confirm that the charging light is off and the DC main circuit voltage is ≤ 45V before operation

Wiring requirements:

Power wiring: Connect a 3-phase power supply to the [R/L1], [S/L2], and [T/L3] terminals, with voltage fluctuations within ± 10% (± 10% during continuous operation at full load)

Motor wiring: Connect to [U/T1], [V/T2], [W/T3] terminals, and it is strictly prohibited to connect the power supply to the output terminal

Grounding requirements: The grounding wire should be firmly connected, with specifications not lower than the input/output wire, and should be grounded separately and not shared with the chassis screws

Braking resistor: can only be connected to [PA/+] and [PB] terminals, and it is strictly prohibited to connect between [PA/+] and [PC/-]

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923