K-WANG

TOSHIBA VF-AS3 inverter RS485 communication function

TOSHIBA VF-AS3 inverter RS485 communication function

Document Overview and Security Standards

Document positioning: Special description of the RS485 communication function of VF-AS3 frequency converter, which needs to be used in conjunction with the main manual (E6582062). The core goal is to achieve remote data exchange between the frequency converter and the controller (PLC/computer) or frequency converter.

Core safety requirements:

Specific safety requirements and risk warnings

Cable operation prohibits live plugging and unplugging of RS485 cables, which may cause equipment failure

Interface restrictions prohibit Ethernet from being connected to RS485 interface for abnormal communication or hardware damage

Storage life: EEPROM write times ≤ 100000 times, RAM unlimited EEPROM overload failure

Communication timeout parameters (F803/F823) must be set for timeout settings. The device cannot stop in case of communication failure

Hardware wiring and transmission specifications

1. RS485 interface definition

VF-AS3 provides 2 RS485 interfaces, and the pin functions are shown in the table below (key pins are bolded):

Interface Type Pin Signal Name Function Description Wiring Requirements

Connector1 (default 2-wire) 4 RXA+/TXA+non-polar transmission and reception data must be connected, shared by 2-wire/4-wire

5 RXB -/TXB - polarity transmission and reception data must be connected, shared by 2/4 wires

8 (3) SG signal ground must be connected to prevent interference

1/2/6- Prohibit connection to avoid short circuit

7 Power prohibits connection to prevent power conflicts

Connector2 (supports 2-wire/4-wire) 4 RXA+/TXA+2-wire transceiver/4-wire receiver [F829]=0 (2-wire) takes effect

5 RXB -/TXB -2-wire transceiver/4-wire receiver [F829] takes effect when=0 (2-wire)

Effective when TXA 4-wire system sends [F829]=1 (4-wire)

Effective when TXB 4-wire system sends [F829]=1 (4-wire)

8 SG signal ground must be connected

2. Wiring specifications

Cable selection: shielded twisted pair, conductor cross-sectional area ≥ AWG24 (0.22mm ²), characteristic impedance 100-120 Ω.

Required resistance:

Terminal resistance: 120 Ω/1/2W, only connected to devices at both ends of the bus.

Up and down resistance: 510 Ω/1/2W, each node needs to be connected to enhance signal stability.

Distance requirement: The distance between communication cables and main circuit cables should be ≥ 20cm to avoid interference; In the 4-wire system, the transmission (TXA/TXB) and reception (RXA/RXB) need to be twisted separately.

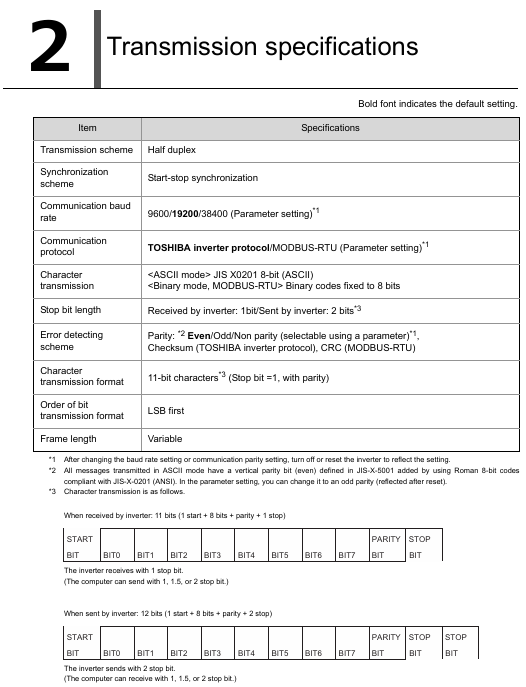

3. Transmission specifications

Project Specification Default Values Remarks

Transmission method half duplex - only receive/send at the same time

Synchronization start and end synchronization - identify the beginning and end of the frame by 3.5 bytes of blank time

Baud rate 9600/19200/38400bps. After changing 19200bps, power off reset is required to take effect

No/even/odd parity check. After the parity check is changed, it needs to be powered off and reset to take effect

Data bit ASCII: 8-bit (JIS X0201); Binary/MODBUS: 8-bit --

Stop bit reception: 1 bit; Send: 2 bits - compatible with devices with 1/1.5/2 stop bits

Error detection Toshiba protocol: checksum; MODBUS:CRC16 - -

Detailed Explanation of Communication Protocol

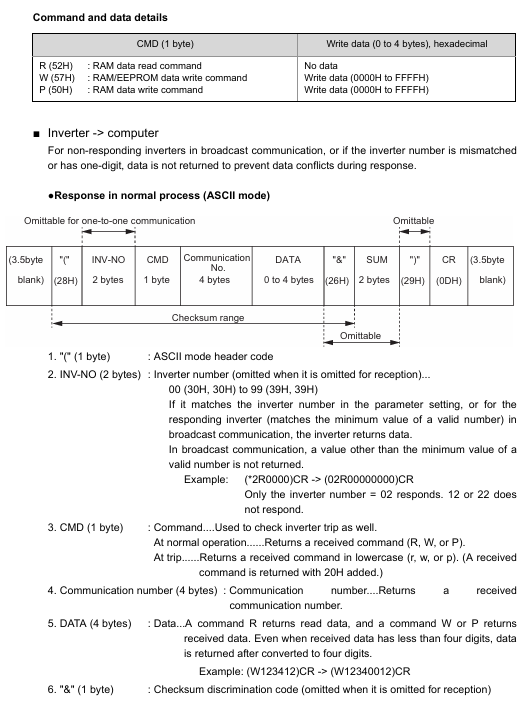

1. Toshiba inverter protocol (default, [F807]/[F827]=0)

Supports ASCII, Binary, and block communication modes. The core is to access parameters through the "communication number", and commands include R (read), W (write RAM+EEPROM), P (write RAM), S (inter inverter), etc.

ASCII mode:

Format: (INV-NO CMD communication number DATA&SUM) CR (INV-NO: 2 bits, 00-99; SUM optional).

Example: Assuming a frequency of 60Hz (communication number FA01, 60Hz=1770H), the command is (00PFA011770) CR, and the response is (00PFA011770) CR.

Binary mode:

Format: INV-NO CMD communication number DATA SUM (header code "/", INV-NO: 1 bit, 00H-3FH; SUM must be selected.

Example: Read output frequency (communication signal FD00), command is 2F 52 FD 00 82, response is 2F 52 FD 00 17 70 05 (60Hz).

Block communication:

Function: Read and write multiple preset parameters in a single communication ([F870]/[F871] set write parameters, [F875] - [F879] set read parameters).

Format: The computer sends the X command, and the frequency converter sends the Y command back. It supports up to 2 write parameters and 5 read parameters.

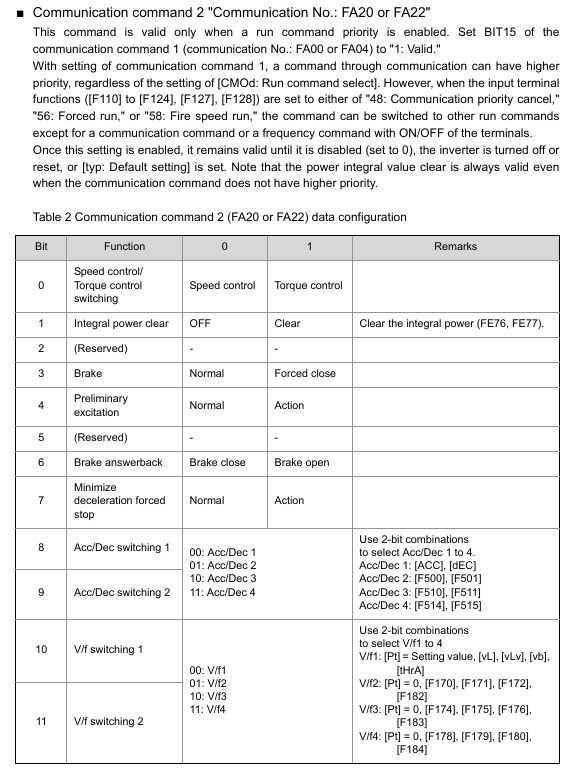

2. MODBUS-RTU protocol ([F807]/[F827]=1)

Only partial instructions are supported, with binary data and frame synchronization relying on 3.5 bytes of blank time. The core instructions are shown in the table below:

Example of Applicable Scenarios for Instruction (Hex) Function (Read Output Frequency FD00)

03H reads 1/multiple parameters (indirect reading ≤ 5, direct reading ≤ 8). Computer sends: 01 03 FD 00 00 01 B5 A6; Inverter Return: 01 03 02 17 70 B6 50

06H single write data write 1 parameter write FA01=1770H (60Hz): 01 06 FA 01 17 70 E6 C6

10H block write data write multiple parameters (such as [F870]/[F871]) write FA00+C400 (forward rotation)+ FA01=1770H:01 10 18 70 00 02 04 C4 00 17 70 6D AF

Write and read data simultaneously at 17H+read and write FA00+read FD01/FD00:01 17 18 75 00 02 18 70 00 02 04 C4 00 17 70 XX XX

2BH reads model information, manufacturer/model/version, VFAS3-2037P: 01 2B 0E 01 00 70 77; Return to "TOSHIBA" "VFAS3-2037P" "0100"

CRC calculation: 16 bits, initial value FFFFH, polynomial A001H, with the lower bits first (e.g. the CRC for command 01 03 FD 00 00 01 is B5 A6).

Core function: Communication between frequency converters

Implementing master-slave control of multiple frequency converters through RS485 (without PLC), only supporting Toshiba protocol, core parameters [F806]/[F826] (master-slave mode).

1. Master slave setting

Role parameter setting (F806/F826) function

Main station 3 (sends frequency command)/4 (sends output frequency)/5 (sends torque command)/6 (sends output torque) continuously sends S command (normal)/s command (fault), no response

Receive master station commands from station 0 (0Hz in case of failure)/1 (continue operation in case of failure)/2 (emergency stop in case of failure), but do not respond

2. Speed proportional control

The sub station frequency is proportionally converted by the main station command and supports two-point correction ([F810] - [F814]):

No correction: Slave frequency (Hz)=(Master command (%) x Slave maximum frequency)/10000 (1%=100).

Two point correction: Slave station frequency=[(Point 2 frequency - Point 1 frequency)/(Point 2 command - Point 1 command)] × (Master station command - Point 1 command)+Point 1 frequency.

Example: The master station sends 50% (5000), the maximum frequency of the slave station is 90Hz, and without calibration, the slave station frequency=(5000 × 9000)/10000=45Hz.

Communication related parameters

The core parameters need to be set through the panel or communication, and some require power-off reset to take effect. The key parameters are shown in the table below:

Parameter number, parameter name, function adjustment range, default value, effective method

F800/F820 RS485 baud rate set communication rate 0=9600bps, 1=19200bps, 2=38400bps 1 power-off reset

F801/F821 RS485 verification setting verification method 0=none, 1=even, 2=odd 1 power-off reset

F802 frequency converter number set unique address 0-247 0 immediately

F803/F823 communication timeout setting timeout detection duration 0.0 (disabled), 0.1-100.0s 0.0 immediately

F804/F824 timeout operation timeout action 1=continue running, 4=trip immediately, 6=trip immediately after deceleration, 1=trip immediately

F807/F827 protocol selection: Toshiba/MODBUS 0=Toshiba, 1=MODBUS 0 power off reset

F829 RS485 (2) wiring 2-wire/4-wire switch 0=2 wire, 1=4 wire 0 immediately

Troubleshooting and Appendix

1. Common faults and solutions

Possible causes and solutions for the fault phenomenon

Communication unresponsive 1. Baud rate/checksum/protocol mismatch; 2. Wiring error; 3. Mismatch of frequency converter numbers. 1. Unified parameters (such as 19200bps+even parity+Toshiba protocol); 2. Check the A+/B -/SG wiring and connect the resistor; 3. Confirm that INV-NO is consistent with [F802]

Err5 tripped (communication timeout) 1. Cable disconnected; 2. The timeout period is too short; 3. The main station has no data transmission. 1. Check the cable; 2. Increase [F803]/[F823] (if set to 1.0s); 3. Confirm that the main station is sending commands normally

Write parameter error (N0000): 1. During operation, write prohibited parameters (such as maximum frequency); 2. Parameter locking ([F700]=2/4) 1. Write after shutdown; 2. Set [F700]=0 (unlock)

2. Appendix Information

Appendix 1 (Data Code Table): Provide JIS ASCII codes such as "41H=A" and "30H=0" for ASCII mode data parsing.

Appendix 2 (Response Time): The calculation method is "Data communication time (bytes x bits/baud rate)+frequency converter processing time (maximum 10ms)", for example: 19200bps, 8 bytes, 11 bits, communication time=(8 x 11)/19200 ≈ 4.6ms, total response time ≈ 14.6ms.

Appendix 3 (Model Table): Corresponding to the [FB05] parameter, for example, the FB05 value of VFAS3-2037P (200V/3.7kW) is 9 (decimal).

Key issues

Question 1: What hardware specifications must be followed when wiring RS485 communication for VF-AS3 frequency converter? What are the consequences of ignoring these regulations?

Answer: The hardware specifications that must be followed are as follows:

Cable selection: Use shielded twisted pair cables with a conductor cross-sectional area of ≥ AWG24 (0.22mm ²) and a characteristic impedance of 100-120 Ω. Avoid parallel connection with the main circuit cable (spacing ≥ 20cm) to prevent interference.

Resistance connection:

The devices at both ends of the bus must be connected to a 120 Ω/1/2W terminal resistor (to suppress signal reflection);

All nodes must be connected to 510 Ω/1/2W pull-up and pull-down resistors (to enhance signal driving capability).

Pin and wiring mode:

Connector1 only supports 2-wire system and must be connected to 4-pin (A+), 5-pin (B -), and 8-pin (SG). Connections to pins 1/2/6/7 are prohibited;

Connector2 supports 2-wire/4-wire (F829) switching): The 2-wire system is the same as Connector1, and the 4-wire system requires an additional 3-pin (TXA) and 6-pin (TXB) connection, with separate twisted transmission/reception wires.

Interface restrictions: Ethernet connection to RS485 interface is prohibited, and live plugging and unplugging of communication lines is also prohibited.

The consequences of ignoring norms:

No terminal resistance can cause signal reflection, resulting in communication packet loss or data errors;

No pull-down resistor can cause communication interruption in weak signal environments;

Cables that do not meet the requirements or are parallel to the main circuit can introduce electromagnetic interference, resulting in frequency/current monitoring deviations;

Live plugging or misconnection of Ethernet can damage the RS485 interface circuit and cause equipment failure.

Question 2: How to read the output frequency (communication signal FD00) of VF-AS3 frequency converter through the 03H instruction under the MODBUS-RTU protocol? It is necessary to clarify the instruction format, CRC calculation process, and response parsing.

Answer: Taking "inverter number 1 (01H), baud rate 19200bps, even parity" as an example, the steps are as follows:

1. Instruction format (computer → frequency converter)

The MODBUS-RTU read instruction (03H) is fixed at 8 bytes and follows the following format:

Example value of byte position content description (Hex)

Inverter number 0-247, 0 is broadcast (no response) 01

2 instruction code reading data fixed as 03H 03

The output frequency communication signal of the 3-4 channel signal (high bit → low bit) is FD00H FD 00

5-6 word count (high position → low position) Read 1 parameter fixed as 0001H 00 01

7-8 CRC16 (low bit → high bit) Calculate B5 A6 according to polynomial A001H

Final instruction: 01 03 FD 00 00 01 B5 A6.

2. CRC16 calculation process (taking the first 6 bytes of the instruction "01 03 FD 00 00 01" as an example)

Initial value: FFFFH;

XOR byte by byte:

FFFF XOR 01H = FFFEH;

FFFEH XOR 03H = FFFDH;

FFFDH XOR FD H = FF00H;

FF00H XOR 00H = FF00H;

FF00H XOR 00H = FF00H;

FF00H XOR 01H = FEFFH;

Left shift 8 times per byte, XOR A001H when encountering the lowest bit 1, and the final calculation result is B5A6H (low bit B5H comes first, high bit A6H comes back).

3. Response analysis (frequency converter → computer)

The normal response is 7 bytes, in the following format:

Byte position content description example value (Hex) parsing result

1. The frequency converter number is consistent with the instruction 01-

The instruction code is consistent with the instruction (03H) 03-

3 data bytes 1 parameter=2 bytes 02-

4-5 output frequency (high bit → low bit) unit 0.01Hz 17 70 1770H=6000 → 60.00Hz

CRC B6 50 for 6-7 CRC16 response data-

If the output frequency is 60Hz and the response is 01 03 02 17 70 B6 50, the actual frequency obtained by analysis is 6000 × 0.01=60.00Hz.

Question 3: What are the key requirements for parameter settings between the master and slave stations in VF-AS3 frequency converter communication (master-slave mode)? How to achieve a proportional change in the frequency of the slave station following the master station (for example: the master station sends a 50% command, and the slave station outputs 45Hz)?

Answer:

1. Key parameter settings for master and slave stations (both require Toshiba protocol, [F807]/[F827]=0)

Example of Key Parameter Setting Requirements for Roles (45Hz Output from the Slave Station)

The main station [F806]/[F826] is set to 3 (frequency command)/4 (output frequency), with only one main station [F826]=3 (frequency command)

The master station [F800]/[F820] is consistent with the slave station, with a default of 19200bps 1 (19200bps)

The master station [F801]/[F821] is consistent with the slave station, and defaults to even parity 1 (even parity)

Set station [F806]/[F826] to 0 (fault 0Hz)/1 (fault continues)/2 (fault emergency stop) [F826]=0

Set from station [F823] (timeout) to 0.1-100s (loss of control due to disconnection of defense cable) and 1.0s

Set 21 (Connector1)/22 (Connector2) 22 (using Connector2) from the FMOd (frequency command source)

Set the target maximum frequency from the slave station [FH] (maximum frequency), for example, 90Hz 90.0Hz (9000 × 0.01Hz)

2. Proportional control implementation (without two-point correction, [F810]=0)

Main station instruction calculation: The main station frequency instruction is in units of "%" (1%=100). If a slave station needs to output 45Hz, the main station instruction=(slave station target frequency x 10000)/slave station maximum frequency=(45 x 10000)/90=5000 (i.e. 50%).

Main station sends command: The main station sends S command (53H) through Binary mode, in the format of/INV-NO 53H signal DATA SUM, where:

INV-NO: FFH (broadcast, all received from slave stations);

Communication number: FA05 (Connector2 frequency command);

DATA:5000(50%,Hex=1388H);

Instruction example: 2F FF 53 FA 05 13 88 XX (XX is the SUM value).

Slave frequency conversion: After receiving instructions from the slave station, calculate the frequency according to the formula: Slave frequency (Hz)=(Master station instruction (%) x Slave station maximum frequency)/10000=(5000 × 9000)/10000=4500 → 45.00Hz, achieving proportional following.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923