K-WANG

TOSHIBA TOSBERT VF-A3 frequency converter

Equipment specifications:

Voltage level, power range, core application scenarios

200V level 0.4-55kW small and medium-sized motor drive (such as conveyor, fan)

400V level 0.75-75kW medium and large motor drive (such as pumps and compressors)

TOSHIBA TOSBERT VF-A3 frequency converter

Overview and Basic Equipment Information

Positioning: The official user manual for Toshiba TOSBERT VF-A3 series high-performance frequency converters, used to guide users in installation, operation, maintenance, and troubleshooting.

Equipment specifications:

Voltage level, power range, core application scenarios

200V level 0.4-55kW small and medium-sized motor drive (such as conveyor, fan)

400V level 0.75-75kW medium and large motor drive (such as pumps and compressors)

Equipment features:

High reliability: Built in current limiting, retry, soft stop, and instantaneous power-off protection functions to reduce the probability of tripping.

Easy to operate: keyboard style operation panel, supports memory commands, basic settings do not require stopping the machine to consult the manual.

Compact design: The research body integrates multiple protection functions, saving installation space.

Model coding rules: Taking "VFA3-2150P" as an example, the meanings of each part are as follows:

VFA3: Series Code (VF-A3 Series)

2: Voltage level (2=200V level, 4=400V level)

15: Capacity (15kW)

0: Special configuration (0=Standard)

P: Panel configuration (P=equipped with operation panel)

Installation and wiring specifications

1. Installation requirements

Installation method: Only supports vertical wall mounted installation. For non vertical installation, please consult a Toshiba representative.

Ventilation gap (Figure 1.1):

Top/bottom: minimum 10cm

Left and right sides: minimum 5cm

Environmental restrictions:

Temperature: -10 ℃~40 ℃ (up to 50 ℃ without casing)

Humidity: ≤ 90%, no condensation

Altitude: ≤ 1000m (3300ft)

Vibration: Acceleration ≤ 0.5G (20-50Hz), amplitude ≤ 0.1mm (50-100Hz)

Special note: Models with 3.7kW and below have a built-in regenerative discharge resistor on the back. Frequent start stop cycles can cause the exhaust temperature to reach 150 ℃. It is recommended to install it on a metal surface for heat dissipation.

2. Wiring process and specifications

Preparation before wiring:

Disconnect the main switch of the distribution panel and confirm that the "CHARGE" light of the frequency converter is off (to avoid electric shock).

Open the front cover: Pull forward and lift up (Figure 1.2).

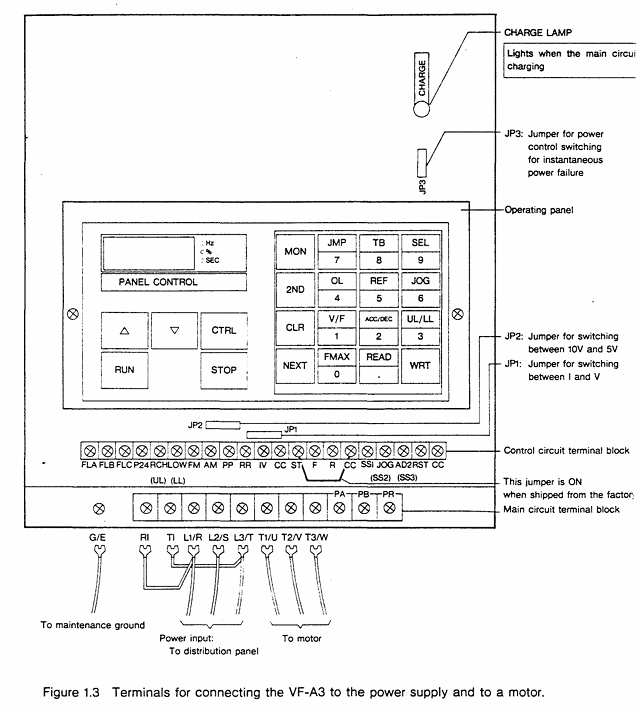

Main circuit wiring (Figure 1.3):

Terminal Name Connection Object Precautions

L1/R, L2/S, L3/T 3-phase power input cannot be reversed to the motor end (T1/U, etc.), otherwise the equipment will be damaged

T1/U, T2/V, T3/W 3-phase motors require corresponding motor U, V, and W terminals

The grounding wire of the G/E system complies with Class 3 grounding specifications

R1/T1 (200V level), R38/R41 (400V level) control circuit power supply single-phase signal, ensuring independent power supply for the control circuit

Control circuit wiring:

Frequency setting signal: PP (10Vdc reference) RR(0-10Vdc/0-5Vdc)、IV(0-5Vdc/4-20mAdc), The type needs to be switched through JP1/JP2 jumper (Table 6.1).

Operation control signals: ST (preparation for operation), F (forward rotation), R (reverse rotation), JOG (jog), short circuit the corresponding terminal to CC to achieve the function.

Taboo:

Do not connect power factor compensation capacitors on the power side or motor end.

The control circuit (excluding FLA/FLB/FLC) needs to be insulated from the main circuit to avoid interference.

Operation process and core function settings

1. Operation panel and basic operations

Panel layout (Figure 2.1): including "PANEL CON" LED, MON (monitoring/setting switch), RUN/STOP (run/stop), frequency ± key, parameter setting key (WRT/READ/NEXT, etc.).

Simplify the operation process (trial run, recommended low-frequency startup):

Power ON: When the MCCB is closed, the monitor flashes "OFF" first and then displays "0.0".

Switch panel control: Press the "CTRL" key, and the "PANEL Control" LED will light up.

Set frequency:

Numerical keys: If set to 10Hz, press "1", "0", and "WRT" to display "10" and "FC" alternately.

± key: Long press "△" (increase)/"▽" (decrease), if set to 5.5Hz, press "WRT" to save.

Start/Stop: Press "RUN" to accelerate to the set frequency; Press' STOP 'to slow down and stop.

2. Core Function Settings

(1) Frequency and voltage characteristic settings

Maximum frequency (FH): 30-400Hz (1Hz step size), default 50Hz for 50Hz models and 60Hz for 60Hz models, cannot be modified during operation (requires shutdown).

Torque boost (ub): 0-30% (1% step size), default 3%, used to boost starting torque, excessive can cause overcurrent during startup.

Automatic torque boost (Rub): 0=off, 1=on, automatically adjusts voltage based on load current (Figure 3.4).

Fundamental frequency (uL): 25-400Hz (1Hz step size), set 50Hz for 50Hz motors and 60Hz for 60Hz motors (Table 3.1).

V/f mode (Pt.): 0=constant torque (conveyor), 1=variable torque (fan/pump, energy-saving) (Figure 3.6).

(2) Acceleration, deceleration, and braking control

Acceleration and deceleration time (ACC/DEC):

Range: 0.1-6000 seconds, supports 2 sets of time (ACC1/ACC2, DEC1/DEC2).

Mode: 0=linear, 1=non-linear 1 (slow acceleration at low torque), 2=non-linear 2 (slow acceleration at high speed) (Figure 3.8).

DC injection braking (dbF/dbu/dbt):

Starting frequency (dbF): 0-10Hz, braking voltage (dbu): 0-20%, braking time (dbt): 0-5 seconds, used for precise positioning (Figure 3.27).

Regenerative braking (Pb):

Applicable scenarios for Pb setting function

0 normal load without regenerative braking (or using regenerative discharge unit)

1. There is regenerative braking, no resistance overload detection, and moderate inertia load

2. There is regenerative braking and resistance overload detection for large inertia loads (such as centrifuges)

(3) Multi speed and special operation

Multi speed operation (S1-S7): 7 speeds are achieved through the combination of SS1/SS2/SS3 terminals, with a frequency range from the lower limit frequency (LL) to the upper limit frequency (UL), and can be controlled by panel or external signals (Table 3.7).

Jog operation (JOG): frequency 0-20Hz (0.1Hz step size), only starts when stopped, press the "RUN" button to run, release to stop (Figure 3.21).

Frequency jump (FJ1-FJ3): 3 jump points, set the jump frequency and width to avoid load resonance (Figure 3.24).

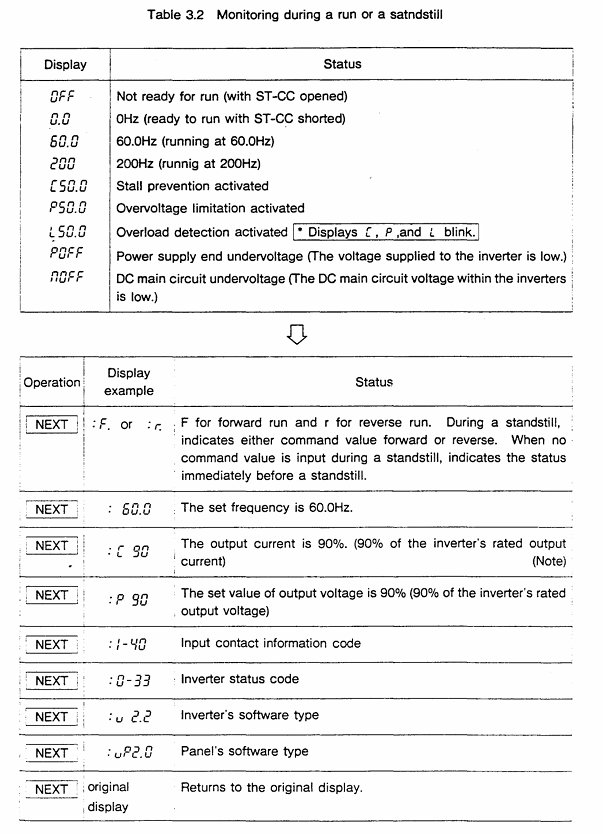

3. Status monitoring and fault reset

Operation/shutdown monitoring: Press the "NEXT" button to cycle through the status (Table 3.2), such as "60.0"=operating frequency 60Hz, "PSO. 0"=overvoltage limit activation, "OC"=overcurrent detection.

Fault monitoring: When tripping, press "NEXT" to check the fault status (such as frequency, current, voltage), and support tracing the last 4 faults (Table 3.4).

Fault reset:

Panel reset: Press "CLR"+"WRT".

External reset: Short circuit the RST-CC terminal (Figure 4.9).

Troubleshooting and Maintenance

1. Fault codes and solutions (Table 9.1)

Meaning of fault code and solution measures

OC1 acceleration overcurrent 1. Increase ACC time; 2. Reduce UB settings; 3. Check if there is a sudden change in the load

OH frequency converter overheating 1. Check the cooling fan; 2. Confirm that the ambient temperature is ≤ 40 ℃; 3. Clean the heat dissipation channel

EF load terminal grounding fault 1. Check the insulation of the motor and output circuit; 2. Check the grounding short circuit point

EEP EEPROM abnormality 1. Restart the power supply; 2. If ineffective, repair/replace EEPROM

2. Regular maintenance and storage

Regular inspection (every 3-6 months):

Terminal screws: Tighten loose screws to prevent poor contact.

Line inspection: Check if the wire crimping point is overheated (discolored) and if the insulation is damaged.

Dust removal: Use a vacuum cleaner to clean the ventilation openings and printed circuit board dust to avoid overheating.

Insulation test: Use a 500V megohmmeter to test the insulation of the main circuit. The motor needs to be tested after disconnecting the frequency converter.

Storage requirements:

Environment: Dry, dust-free, non corrosive gas, temperature -10-40 ℃.

Activation: Long term storage (>2 years) requires power on every 2 years; After removing the storage, the motor needs to be powered on for at least 5 hours before running.

Optional accessories and warranty terms

1. Optional accessories (Table 7.1/7.2)

Type Accessory Name Model Example Function

External installation of input reactor PFL2012-2100 improves power factor and suppresses harmonics

External installation of regenerative discharge resistor PBR3-2055 enhances braking effect, suitable for large inertia loads

Built in multi option printed circuit board VF3X-0888B supports RS-232C communication, BCD code input, etc

External installation of PANEL-KIT (1M/3M/5M) remote control panel, including 1/3/5 meter cable

2. Warranty terms

Warranty period: 12 months after delivery.

Warranty expiration situation:

Unauthorized maintenance/modification of equipment.

Damage caused by vibration/impact during transportation/installation.

Force majeure events such as fires, floods, lightning strikes, and abnormal power grid voltage.

Used for designated purposes of non industrial frequency converters.

Acceptance requirements: After opening the box, check that the equipment is undamaged and the model is consistent with the order. If there are any problems, immediately contact a Toshiba representative.

Key issues

Question 1: What are the space and environmental restrictions that must be followed when installing the TOSBERT VF-A3 frequency converter? What are the consequences of ignoring these restrictions?

Answer:

Restrictions that must be followed:

Installation method: Only supports vertical wall mounting, non vertical installation requires prior consultation with Toshiba representatives.

Ventilation gap: minimum 10cm at the top/bottom, and minimum 5cm on both sides to ensure smooth heat dissipation.

Environmental parameters: temperature -10 ℃~40 ℃ (≤ 50 ℃ without casing), humidity ≤ 90% (no condensation), altitude ≤ 1000m, vibration acceleration ≤ 0.5G (20-50Hz)/amplitude ≤ 0.1mm (50-100Hz).

Special models: Models with 3.7kW and below have regenerative discharge resistors on the back, and the exhaust temperature can reach 150 ℃. It is recommended to avoid installing on flammable surfaces and choose metal surfaces for heat dissipation.

The consequences of ignoring restrictions:

Insufficient ventilation can cause the frequency converter to overheat (fault code OH), triggering a protective shutdown and potentially damaging the power module in the long run.

Excessive humidity/condensation can cause a short circuit and ground fault (EF code) in the main circuit.

Excessive vibration may cause loose terminals, poor contact leading to overcurrent (OC code) or equipment shutdown.

Question 2: In the daily operation of VF-A3 frequency converter, how to set the "DC injection braking" function through the panel to achieve precise motor stop? It is necessary to clarify the setting range and default values of key parameters.

Answer: The steps and key parameters for setting "DC injection braking" through the panel are as follows:

Enter the second functional mode:

Press the "MON" button, and the display will show "no.0 →: t: JP"; Press the "2ND" key to switch to the "2nd" mode.

Select DC injection braking related parameters (function number 0, Table 3.1):

Parameter Name Function Setting Range Default Value Operation Instructions

When the DBF (DC injection braking start frequency) motor drops to this frequency, it triggers the braking 0-10Hz (0.1Hz step size) 0Hz. Press "READ" to read the current value, press "△/▽" or the numerical key to adjust, and press "WRT" to save

DBU (DC injection braking voltage) injects a DC voltage that accounts for 0-20% (1% step size) during braking. If the voltage is too high, it will cause the motor to overheat. It is recommended to adjust according to the inertia of the load (such as 10% -15%)

DBT (DC injection braking time) braking duration 0-5 seconds (0.1 second step) 0 seconds. It is necessary to ensure that the time is sufficient to stop the motor and avoid incomplete braking caused by too short a time

Confirm settings: Press the "MON" key to return to the original display (frequency/OFF), and the settings will take effect.

Attention: DC injection braking is only activated during deceleration and stopping process, and should be accompanied by appropriate deceleration time (DEC) to avoid triggering overcurrent protection due to excessive current during braking.

Question 3: What are the possible reasons when the VF-A3 frequency converter displays "OC1" (acceleration overcurrent) fault? What are the corresponding solutions? What safety precautions should be taken during troubleshooting?

Answer:

Reason for "OC1" fault: During acceleration, the main circuit current exceeds the protection threshold. Common reasons include:

The acceleration time (ACC) is set too short, and the motor speed cannot keep up with the frequency increase, resulting in excessive stalling current.

The torque boost (ub) is set too high, causing overcurrent due to high voltage during startup.

Sudden load changes in the motor (such as sudden blockage of the conveyor), and the load current exceeds the rated output of the frequency converter.

Poor wiring of the main circuit (such as loose wiring at the motor end) can cause current fluctuations.

Solution:

Extend acceleration time: Enter the first function ("MON" → select function number 2), adjust "ACC1/ACC2" to a longer time (such as changing from 1 second to 3 seconds), and press "WRT" to save.

Reduce torque boost: Enter the first function (function number 1), reduce the "ub" value (such as from 10% to 5%), and avoid starting overvoltage.

Check the load: Check if the mechanical load is stuck, clean up foreign objects or reduce the load to ensure that the load is within the rated range of the motor.

Check wiring: Disconnect the power supply (MCCB), confirm that the "CHARGE" light is off, tighten the terminal screws of the main circuit (L1/R, T1/U, etc.), and check the insulation of the circuit.

Check safety precautions:

Before checking all wiring, the main switch of the distribution panel must be disconnected and wait for the "CHARGE" light to turn off (to avoid electric shock caused by residual voltage of the capacitor).

When adjusting parameters, it is necessary to ensure that the frequency converter is in a stopped state. Modifying acceleration time/torque increase during operation may cause equipment instability.

If the fault still exists after multiple troubleshooting, it is necessary to check the motor insulation (using a 500V megohmmeter) to avoid overcurrent caused by internal short circuit of the motor.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923