K-WANG

YOKOGAWA VP6F1900/1905 Control Function (A2FV70 Dedicated)

YOKOGAWA VP6F1900/1905 Control Function (A2FV70 Dedicated)

Classification and specifications of core functional blocks

1. Basic functional blocks (7 categories)

Functional block type, core usage, representative model and key characteristics

Continuous process control PID (standard PID), PID-STC (self-tuning PID), ONOFF (two position switch control), FF-PID (fieldbus PID), etc

Compute block signal operations and logical processing ADD (addition), SQRT (square root), AND (logical AND), Calcu (general computing), etc

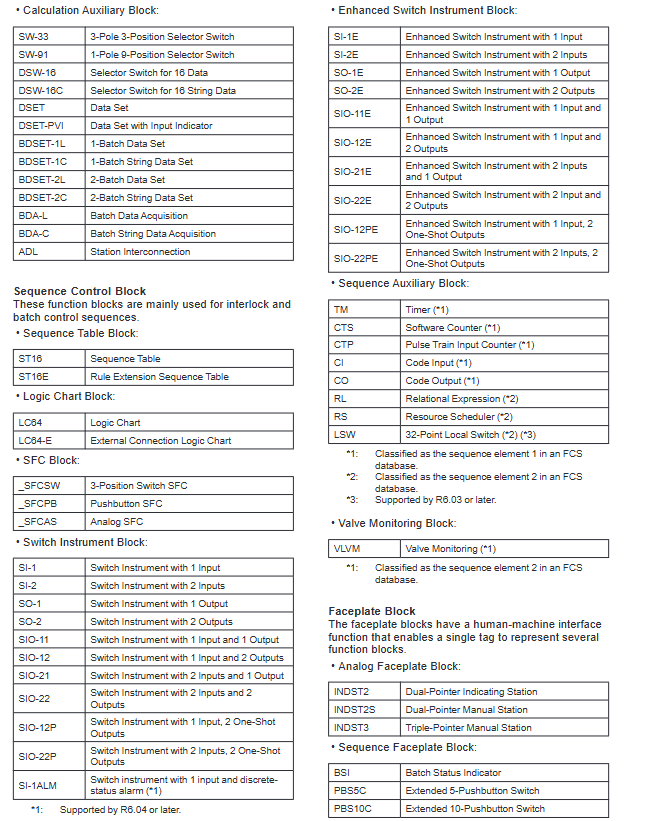

Sequence control block interlocking and batch control ST (sequence table), LC (logic diagram), SIO-11E (enhanced switch instrument), TMF (timer), etc

Panel block multifunctional block unified label display INDST3 (three pointer manual station), BSI (batch status indication), HAS3C (mixed manual station), etc

Unit instrument block, whole unit equipment control, UTAS (analog unit instrument), UTPB-N (non resident 5-key unit instrument), etc

Valve mode monitoring block (optional) Valve switch status monitoring VPM64 (64 points) - VPM512A (512 points with alarm)

Off site Block (optional) Refinery Off site Mixing/Shipping Control FSBSET (batch setting), BLEND (mixing master control)

2. Featured functional blocks (3 types of core extensions)

Functional block type, core characteristics, applicable scenarios

ZWOPID (Wireless PID Compensation) is compatible with wireless field devices and provides PID control for stable process response in wireless communication scenarios when data packets are lost

YS instrument block compatible with YS series controllers/manual stations/total meters YS series instrument integrated control

Enhanced switch instrument block supports 1-2 input/output channels, including single trigger output type complex interlocking logic control

I/O function and communication support

1. Classification of I/O functions

I/O Type Core Function Signal Identification/Support Range

Process I/O on-site device signal interaction simulation I/O ≤ 1760 points, contact I/O ≤ 4096 points

Software I/O FCS internal virtual signal internal switches (% SW: 9999,% GS: 256), message output (6 types of messages including% AN/% PR)

Communication I/O subsystem data exchange% W/% X identification, supports PLC and other subsystem data access, 16 bit data volume ≤ 8000 words

Fieldbus I/O fieldbus device access% Z identification, compatible with FOUNDATION fieldbus devices

2. Subsystem Communication Protocol

Supports 5 types of core communication modules and protocols, requiring corresponding hardware modules:

Serial communication: ALR111/ALR121 modules (N-IO/FIO specific)

Ethernet communication: ALE111 module (N-IO/FIO specific)

FOUNDATION fieldbus communication: ALF111 module (N-IO/FIO specific)

PROFIBUS-DP communication: ALP121 module (N-IO/FIO specific)

PROFINET communication: A2LP131 module (N-IO/FIO specific)

Application capacity and operating parameters

1. Core indicators for three types of capacity configuration

Configuration type: Standard type (C01) Extended type (C02) Large type (C03)

Number of tags (maximum) 18000 18000 18000 18000

Number of functional blocks (maximum) 5500 7000 9000

Simulate I/O points (maximum) 1760 points 1760 points 1760 points

Contact I/O points (maximum) 4096 points 4096 points 4096 points 4096 points

Control the number of drawings 200 (optional 300/400/500) 200 (optional 300/400/500)

1 second trend collection points 1024 points 1024 points 1024 points

2. Scanning cycle and database requirements

Scanning cycle:

Standard scan: 1 second (fixed)

Medium speed scanning: 200ms/500ms (can directly input 50/100/250ms), suitable for analog quantity calculation

High speed scanning: 200ms/500ms (can directly input 50/100/250ms), suitable for sequence control

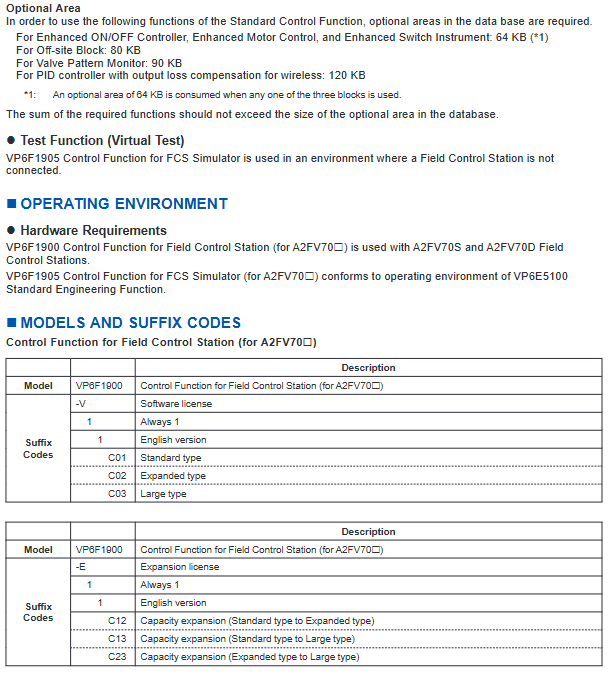

Database optional area occupation:

Enhanced switch instrument/motor control/ONOFF controller: 64KB (occupied by using any function block)

Off site block: 80KB

Valve mode monitoring: 90KB

Wireless PID compensation: 120KB

Featured features and model specifications

1. Core characteristic functions

RIO system upgrade support: Adapt to RIO system upgrade hardware, optimize application capacity and database size

N-IO module compatibility: supports integration of multiple signal types (AI/AO/DI/DO), channel level adapter expansion (such as thermocouples)

Late Binding Technology: First create control logic, determine the I/O list, and then allocate I/O through software to avoid construction delays

HART feature enhancement: Supports HART7 protocol, receives device status change notifications, shortens variable updates and device inspection cycles

2. Model and ordering specifications

Product Type Basic Model Suffix Code Description Extended License Model

On site control station control functions VP6F1900-V11C01 (standard)/- V11C02 (extended)/- V11C03 (large) VP6F1900-E11C12 (standard → extended), etc

FCS simulator control functions VP6F1905-V11C01 (standard)/- V11C02 (extended)/- V11C03 (large) VP6F1905-E11C13 (standard → large), etc

Note: The suffix "11" represents the English version, and the extended license only supports upward upgrades (not downgrades)

4. Key issues

Question 1: What are the core differences between the three capacity configurations (C01/C02/C03) of VP6F1900/1905? How to select based on project requirements?

answer

Core difference: The number of labels (all 18000) and I/O points (all analog 1760 points/contact 4096 points) for the three types of configurations are completely the same, only the number of functional blocks and the number of control drawing options are different:

Standard type (C01): 5500 functional blocks, 200 control graphics (non expandable);

Expansion type (C02): 7000 functional blocks, 200 control graphics (optional 300/400/500);

Large type (C03): 9000 functional blocks, 200 control graphics (optional 300/400/500).

Selection principle:

Small projects (≤ 5500 functional blocks, ≤ 200 control graphics): Choose C01 standard type;

Medium sized project (function blocks 5501-7000, control drawing needs to be expanded): choose C02 expansion type;

Large scale projects (7001-9000 functional blocks, complex control logic): Choose C03 large type;

Possible future expansion: prioritize CO2/C03, or upgrade from C01 through an extended license.

Question 2: Features of VP6F1900 (N-IO compatibility Late Binding、 What engineering pain points does wireless PID compensation solve? What are the applicable scenarios?

answer

N-IO compatibility function:

Pain point: Traditional I/O modules have fixed signal types and poor adaptability;

Solution: Single module supports AI/AO/DI/DO multi signal types, and channel level adapters can be used to extend special signals (such as thermocouples);

Applicable scenarios: New projects with complex signal types that require flexible expansion.

Late Binding Technology:

Pain point: Change in I/O list leads to rework of control logic and delays in construction;

Solution: First complete the control logic design, determine the I/O list, and then allocate I/O through software;

Applicable scenario: Engineering projects with frequent changes in I/O requirements.

Wireless PID compensation (ZWOPID):

Pain point: Wireless communication is prone to packet loss, leading to unstable PID control;

Solution: Built in packet loss compensation mechanism, stable process response when restoring communication;

Applicable scenario: PID control loop using wireless field devices (such as remote tank pressure/liquid level control).

Question 3: What are the I/O types and communication protocols supported by VP6F1900? How to integrate with third-party subsystems such as PLC and fieldbus devices?

answer

Supported I/O types:

Process I/O: Analog quantity (≤ 1760 points), contact quantity (≤ 4096 points);

Software I/O: Internal switches (% SW/% GS), Category 6 message outputs (% AN/% PR, etc.);

Communication I/O: Subsystem data access (% W/% X, 8000 words of 16 bit data);

Fieldbus I/O: FOUNDATION fieldbus device (marked with% Z).

Third party integration implementation method:

PLC integration: Supports protocols such as Modbus through ALR111/ALR121 (serial port), ALE111 (Ethernet), ALP121 (PROFIBUS-DP) modules;

Fieldbus device integration: Connect to FOUNDATION fieldbus devices through ALF111 module, and achieve data exchange through FF series functional blocks (FF-AI/FF-PID, etc.);

PROFINET device integration: Connect to the PROFINET subsystem through the A2LP131 module to achieve data reading, writing, and control.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923