K-WANG

Westinghouse WPX2700H/WPX3100H High Pressure Cleaning Machine

Working pressure 2700PSI (186BAR) 3100PSI (213BAR) The higher the pressure, the stronger the cleaning power, suitable for stubborn stains

Flow rate 2.3GPM (8.71LPM) 2.5GPM (9.46LPM) The larger the flow rate, the higher the cleaning efficiency

The 212cc OHV four stroke engine, with a speed of 3600RPM, is designed with the same left OHV to improve combustion efficiency and extend lifespan

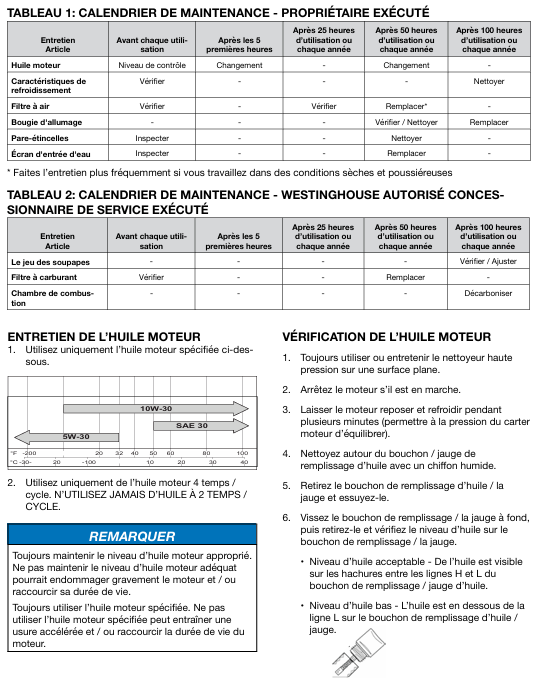

The fuel and oil tank capacity is 3.3L, suitable for unleaded gasoline of grade 87 and above (ethanol ≤ 10%); The oil capacity is 0.5L, and SAE 10W-30 is recommended. E15/E85 ethanol gasoline is prohibited on the left to avoid damage to the fuel system

Spark plug model F7TC, with a gap of 0.030 inches (0.76mm), regularly cleaned or replaced on the left to ensure ignition efficiency

High pressure hose 25 feet (approximately 7.6 meters) with left wear-resistant and pressure resistant, suitable for equipment pressure rating

The soap tank has a capacity of 1.6L and supports low-pressure soap spray on the left side to enhance the cleaning effect

Westinghouse WPX2700H/WPX3100H High Pressure Cleaning Machine

Core parameters and product configuration

1. Key specifications (comparison of two models)

Specification item WPX2700H WPX3100H Remarks

Working pressure 2700PSI (186BAR) 3100PSI (213BAR) The higher the pressure, the stronger the cleaning power, suitable for stubborn stains

Flow rate 2.3GPM (8.71LPM) 2.5GPM (9.46LPM) The larger the flow rate, the higher the cleaning efficiency

The 212cc OHV four stroke engine, with a speed of 3600RPM, is designed with the same left OHV to improve combustion efficiency and extend lifespan

The fuel and oil tank capacity is 3.3L, suitable for unleaded gasoline of grade 87 and above (ethanol ≤ 10%); The oil capacity is 0.5L, and SAE 10W-30 is recommended. E15/E85 ethanol gasoline is prohibited on the left to avoid damage to the fuel system

Spark plug model F7TC, with a gap of 0.030 inches (0.76mm), regularly cleaned or replaced on the left to ensure ignition efficiency

High pressure hose 25 feet (approximately 7.6 meters) with left wear-resistant and pressure resistant, suitable for equipment pressure rating

The soap tank has a capacity of 1.6L and supports low-pressure soap spray on the left side to enhance the cleaning effect

2. Core configuration

Nozzle set: WPX2700H includes 0 ° (red), 25 ° (green), 40 ° (white), soap nozzle (black); WPX3100H adds an additional 15 ° (yellow) nozzle to adapt to more cleaning scenarios.

Safety configuration: Hot release valve (140 ° F automatic pressure relief, protecting pump body), spray gun trigger lock (preventing accidental triggering), engine low oil protection (avoiding dry grinding).

Convenient configuration: Foldable handle+swivel wheel (easy to move), nozzle storage rack (easy to organize), soap siphon hose (automatic suction of soap).

Core functions and usage scenarios

1. Core functions

Multi pressure adaptation: By replacing the nozzle, different pressures and spray angles can be achieved, covering everything from low-pressure fine cleaning to high-pressure descaling.

Soap spray: A dedicated black nozzle is used in conjunction with a soap tank to spray and clean soap at low pressure. After soaking, it is rinsed at high pressure to improve the cleaning effect of oil stains and dust.

Safety protection: Heat release valve to prevent pump body from overheating and damage; Trigger lock to prevent accidental spraying; The engine automatically shuts down at low fuel levels to protect core components.

Flexible Mobility: Designed with swivel wheels and folding handles, it can be easily moved by a single person and is suitable for multiple scenarios such as courtyards and construction sites.

2. Applicable and taboo scenarios

Applicable: vehicle cleaning, courtyard flooring (cement/brick), fences, building exterior walls, outdoor furniture, agricultural machinery and equipment, etc.

Taboo: It is forbidden to spray human bodies, animals, and fragile items (such as glass); Prohibit the use of acidic/corrosive cleaning agents (which can damage equipment and surfaces); Do not operate in confined spaces (engine exhaust containing carbon monoxide); Prohibit starting without water (burning the pump body).

Safety operation standards

1. Environment and placement safety

Placement requirements: Use only in outdoor ventilated areas, at least 5 feet (about 1.5 meters) away from doors, windows, and ventilation openings; Place on a hard horizontal surface to avoid tilting and causing fuel/oil leakage.

Environmental restrictions: Do not use on rainy days or damp ground (to prevent electric shock); Prohibited from use in environments with excessive dust and corrosive gases (blocking heat vents, corroding components); The water temperature should not exceed 104 ° F (40 ℃) to avoid damaging the pump body seals.

2. Fuel and Electricity Safety

Fuel operation:

Before refueling, turn off the engine and cool it down to room temperature. Do not smoke or approach open flames.

The fuel tank cannot be filled to the brim, leaving space for fuel expansion. Any spilled fuel must be wiped dry and allowed to evaporate before starting.

Fuel needs to be stored in compliant containers, away from heat sources, and long-term storage requires the addition of fuel stabilizers.

High voltage operation:

Do not aim the spray gun at yourself or others. When spraying, maintain a distance of 8-24 inches (20-61cm) to avoid injury caused by high-pressure water jets.

Before replacing the nozzle and connecting/disassembling the hose, the system pressure must be released (by pressing the spray gun trigger).

If the high-pressure hose is damaged, it should be replaced immediately. It is prohibited to continue using it after repair (it is prone to bursting).

3. Personnel safety

During operation, goggles (to prevent splashes from entering the eyes) and gloves (to prevent oil stains and high-pressure water impact) must be worn, and long hair should be curled up.

Do not operate after fatigue, drinking alcohol, or taking medication. Children and pets should stay away from running cleaning machines.

If high-pressure water spray causes injury (especially puncture injury), seek medical attention immediately and do not handle it simply.

Operation process (assembly+start+stop)

1. Assembly and preparation

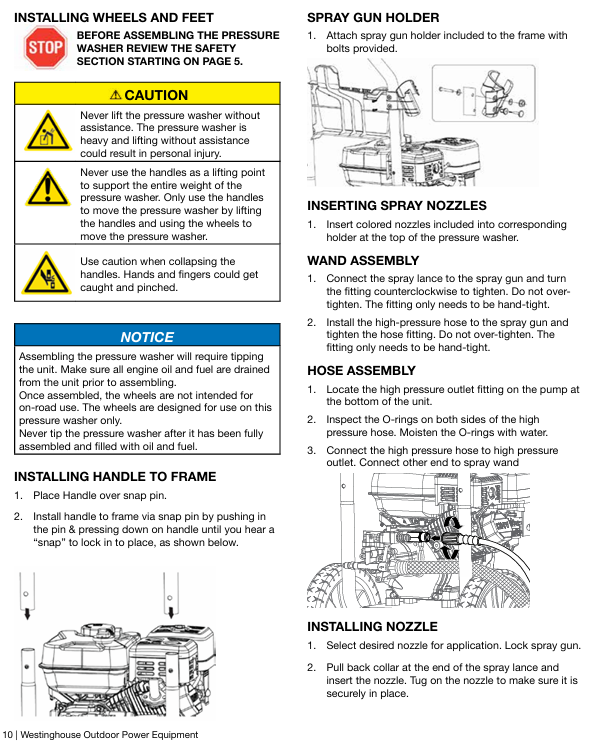

Installation of wheels and handles: Use axle pins and split pins to secure the wheels to the body bracket, and install the handles with buckles to ensure they are locked in place.

Add engine oil: Open the oil filling port on a level surface, add the recommended model of engine oil to between the "L" and "H" marks on the dipstick, and tighten the dipstick.

Add fuel: Open the fuel cap, slowly add qualified gasoline, tighten the fuel cap and clean any spilled fuel.

Connect the waterway: Connect the garden hose to the water inlet (ensure that the inlet filter is intact), open the water source, and press the trigger of the spray gun to discharge the air in the pipeline.

Install nozzle: Select the nozzle according to the cleaning requirements, pull the lance collar of the spray gun into the nozzle, release and lock it.

2. Start the process

Preprocessing: Confirm that the fuel valve is open, the engine switch is set to "ON", the throttle is set to "CHOKE" (cold start), and the spray gun trigger lock is locked.

Startup operation: Hold the startup rope and slowly pull until there is resistance, then quickly pull to start; After starting the engine, gradually adjust the throttle to the "RUN" position and run it without load for 1-2 minutes to preheat.

Cleaning operation: Unlock the spray gun trigger, aim at the cleaning target, maintain a safe distance and start spraying; When soap solution is needed, replace the black nozzle, insert the siphon hose into the soap solution tank, spray soap solution to soak for 3-5 minutes, and then replace the high-pressure nozzle for flushing.

3. Shutdown process

Normal shutdown: Turn off the water source, press the trigger of the spray gun to release system pressure, turn the engine switch to "OFF", and close the fuel valve.

Emergency shutdown: In case of leakage, abnormal noise, overheating, etc., directly turn the engine switch to "OFF" to forcibly shut down.

Cleaning and organization: Disconnect all pipelines, drain the hoses and residual water in the pump body, clean the nozzle (use special tools to remove blockages), and store the spray gun and hoses.

Maintenance and Storage

1. Routine maintenance

Maintenance project cycle operation content

Check the oil level before each use, and if it is below the "L" mark, replenish it

Oil change for the first 5 hours/every 50 hours thereafter. After heating up, drain the oil, replace with new oil, and drain the bolt seal gasket

Check the air filter maintenance every 25 hours/replace the foam filter element every 50 hours, clean it with detergent, dry it in the air, and then apply a small amount of engine oil; The additional paper filter element of WPX3100H needs to be blown with compressed air

Spark plug maintenance: Check every 100 hours/replace annually to clean carbon deposits, check gaps, and replace damaged ones

Clean the nozzle with a specialized tool after each use to remove any blockages and ensure even spraying

Clean the spark suppressor every 50 hours by removing the muffler cover, cleaning the carbon buildup on the filter screen, and replacing it if it is damaged

Clean the inlet filter before each use, remove the inlet filter and flush impurities to avoid clogging the pump body

2. Storage requirements

Short term storage (≤ 3 months): Clean the equipment, drain the pipeline water, fill with fresh gasoline and add stabilizer, and store in a dry and ventilated place.

Long term storage (>3 months): Drain the fuel tank and carburetor, replace with new engine oil; Inject 1 tablespoon of engine oil into the cylinder and pull the starting rope several times (to prevent rust); Disconnect the spark plug wire and cover it with a dust cover.

Winter storage: After following the long-term storage process, inject RV specific antifreeze (6 ounces/177mL) into the pump body to prevent freezing and cracking.

Common troubleshooting

Possible causes and solutions for the fault phenomenon

Unable to start battery depletion (some models), insufficient/deteriorated fuel, incorrect throttle position, spark plug failure, low fuel protection triggering refueling or replacement with fresh fuel; Adjust the position of the air door; Clean or replace spark plugs; Add engine oil

Insufficient pressure/no pressure inlet flow, nozzle blockage, inlet filter blockage, high-pressure hose leakage, pump body failure increase water source flow; Clean the nozzle and inlet filter screen; Replace damaged hoses; Check the sealing components of the pump body

Unstable engine operation, clogged air filter, poor fuel supply, and air damper not adjusted to the "RUN" position. Clean or replace the air filter; Check if the fuel pipeline is blocked; Adjust the air damper to a stable operating state

The soap cannot be suctioned out, the siphon hose is blocked, the black nozzle is not used, and the soap tank level is too low. Clean the siphon hose; Replace the black nozzle; Supplement soap solution

Avoid running the pump without load for more than 5 minutes due to overheating, insufficient water intake, and malfunction of the heat release valve; Check if the water inlet is unobstructed; Contact after-sales service for maintenance of the heat release valve

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923