K-WANG

Watlow ANAFAZE 12LS type 1/8 DIN multi loop PID controller

Watlow ANAFAZE 12LS type 1/8 DIN multi loop PID controller

1. Product Overview

Core positioning: ANAFAZE 12LS is a high-performance multi loop PID controller with 1/8 DIN specifications. It supports 12 independent control loops and can be directly connected to various industrial sensors. It is suitable for process control such as temperature, pressure, and flow, and supports single machine operation or computer monitoring mode.

Core Features:

Control function: 12 channel dual output PID control (heating/cooling independent parameters), supporting three output types: ON/OFF, time proportional (TP), and distributed zero crossing (DZC).

Input interface: compatible with J/K/T/B/S/R thermocouples, RTDs, 4-20mA current signals, 0-11V voltage signals, 12 bit resolution, sampling rate of 1 time/second.

I/O configuration: 9 digital inputs (triggers), 11 digital outputs (alarms/events), supporting global alarm output.

Communication and Storage: RS-232 (single device, up to 50ft)/RS-485 (32 devices, up to 6000ft), 8 job file storage, 12 Ramp/Soak configuration files.

Power supply specifications: 10-30VDC input, typical power consumption of 3W, comes with a 110VAC adapter.

2. Installation process

2.1 Installation Preparation

Environmental requirements:

Environmental parameter specification requirements

Working temperature 0-40 ℃ (32-104 ° F)

Relative humidity ≤ 80% (below 31 ℃), drops to 50% at 40 ℃ (non condensing)

Altitude ≤ 2000m (6560ft)

Installation location: Indoor vertical installation, away from high temperature/corrosion/strong electromagnetic interference

Hardware and Tools:

Wire: 18-20AWG multi strand shielded wire, thermocouple requires dedicated extension wire.

Recommended cables: Belden 9154 (analog input), Belden 9729 (communication), Belden 8451 (analog output).

Tools: M5 bolt, crimping tool, 0.1% metal film resistor (for input calibration).

2.2 Key installation steps

Mechanical installation: The panel opening is 46mm × 92mm, and the controller is fixed with upper and lower fixtures after embedding. The distance between adjacent devices is ≥ 20mm to ensure natural heat dissipation.

Electrical connection:

Power supply: 10-30VDC connected, with positive and negative terminals corresponding to each other, to avoid reverse connection.

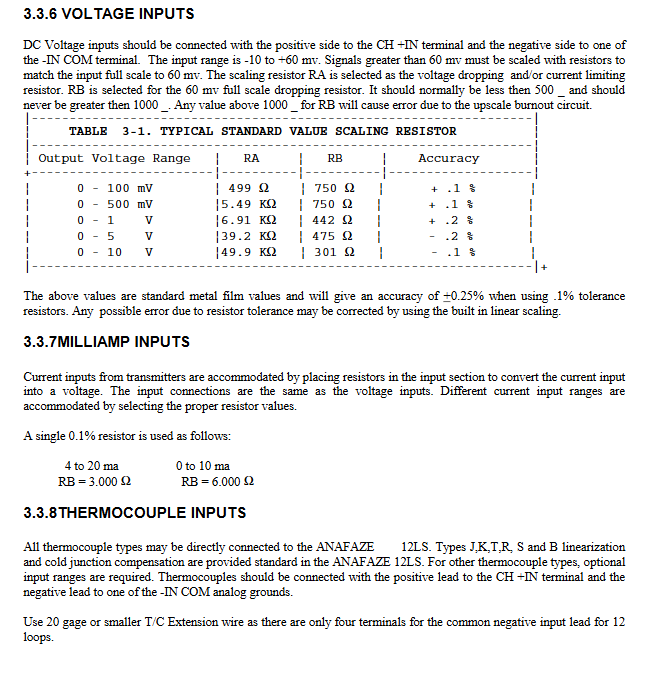

Sensor: Thermocouple connected to CH+IN/- IN COM, 4-20mA signal needs to be connected in series with a 3k Ω resistor to convert to 12-60mV, RTD needs external signal conditioning.

Communication: RS-232 is connected to a PC through a 9-pin D-type interface, RS-485 requires shielded twisted pair, and the end node is connected to a 200 Ω terminal resistor.

Noise suppression: When driving relays with digital outputs, parallel RC buffers (0.01 μ F+47 Ω) are required, and the power and signal lines are routed in separate slots.

3. Operation and Configuration

3.1 Front panel operation

Display mode:

Bar chart display: Overview of 12 circuit status, including deviation alarm indication.

Single loop display: single loop process value, set value, output percentage, status.

Scan display: Automatically display all circuits in a loop (1 second per circuit).

Alarm display: flashing to indicate the alarm circuit and type (high/low process value, deviation).

Core operation:

Basic operations: setting value modification (CHNG SP key), manual/automatic switching (MAN AUTO key), alarm confirmation (ALARM ACK key).

Advanced configuration: Enter the password (ENTER → ALARM ACK → CHNG SP) to enter the settings menu, configure PID parameters, input calibration, and Ramp/Soak programming.

3.2 Core Function Configuration

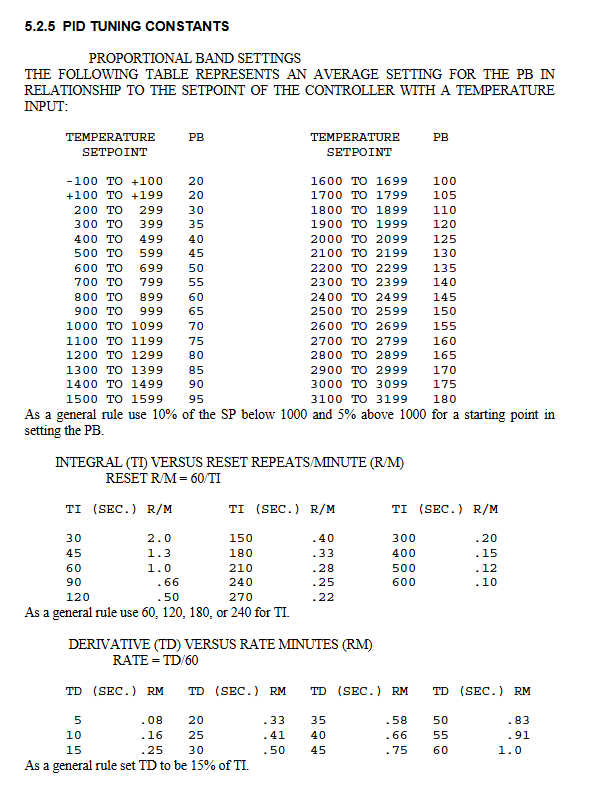

PID parameter tuning:

Control mode: Supports three modes: P (proportional), PI (proportional integral), and PID (proportional integral derivative).

Typical parameter range: proportional band (PB) 3% -200%, integration time (TI) 30-600 seconds, differentiation time (TD) 3-60 seconds.

Adjustment method: First adjust PB to the critical oscillation, and then set TI (PB × 1.2) and TD (TI × 0.15) according to the empirical formula.

Input calibration: Use the "two-point calibration method" to input the process values and readings corresponding to the high and low ranges of the sensor, and automatically scale linearly.

Alarm settings: Each circuit supports high/low process value alarms and deviation band alarms, which can be allocated to 9 digital outputs. It also supports dead zone settings to avoid false alarms.

3.3 Advanced Features: Ramp/Soak Batch Control

Function positioning: Suitable for temperature/pressure curve control in mass production, with 12 independent configuration files (A-L) and a maximum of 20 segments per file.

Key parameters: Each segment can be set with a target value, duration, trigger (digital input), event output (digital output), and over tolerance protection time.

Loop setting: Supports 1-99 loops or continuous loops, and supports external reset triggering.

4. Troubleshooting and Safety Standards

4.1 Common fault handling

Troubleshooting direction

Display 'BATTERY DEAD' internal memory battery failure, needs to be replaced and parameters input again

Control output unresponsive check output type configuration, manual/automatic mode, wiring for short circuit

Measurement drift sensor grounding failure, environmental temperature fluctuation, input calibration failure (recalibration)

Communication failure baud rate mismatch (2400/9600 optional), RS-485 terminal resistance not connected, address conflict

4.2 Safety Regulations

Mandatory requirement: It must be equipped with an external independent safety device to prevent danger caused by controller failure resulting in full on/off output.

Operation taboos: Disconnect the load power supply before cutting off the power, and avoid plugging and unplugging sensors while they are live; Thermocouples need to be non grounded to prevent interference from grounding loops.

Anti static: Wear an anti-static wristband during installation to avoid touching circuit board components.

5. Summary of Technical Specifications

Category key parameters

Input characteristics: 12 analog inputs, resolution of 12 bits, accuracy of 0.1% (25 ℃), support for thermocouples (J/K/T, etc.), 4-20mA, 0-11V

Output characteristics: 11 digital outputs (5VDC/10mA), supporting ON/OFF, TP, DZC three types, dual outputs (heating/cooling)

Communication interfaces RS-232 (57600 baud rate), RS-485 (500Kbit/s, 32 devices)

Environmental parameters: Operating temperature 0-40 ℃, humidity ≤ 80%, altitude ≤ 2000m

Physical parameters 1/8 DIN specification (48 × 96mm panel), depth 155mm, power supply 10-30VDC (3W)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923