K-WANG

Comprehensive analysis of NextMove ST motion controller

Comprehensive analysis of NextMove ST motion controller

NextMove ST is a high-performance, multi axis intelligent stepper motor motion controller launched by Baldor Corporation. This controller integrates power supply, drive, logic control, and communication interfaces, and is suitable for various motion control scenarios such as industrial automation, mechanical equipment, positioning systems, etc. This article will systematically elaborate on product features, hardware structure, software configuration, installation and debugging.

Product Overview and Core Features

NextMove ST has built-in MintMT motion control language, which is a specialized language based on BASIC architecture that supports rapid development of stepper and servo motion control programs. Its main characteristics include:

Three axis stepper drive output: maximum output of 37VDC, 2A per axis, supports half step mode, frequency range 10Hz-200kHz.

Fourth axis logic output: The fourth axis can be extended through an external driver.

Integrated power supply: Supports 24VDC/24VAC input, can choose independent or shared driver and logic power supply.

Rich I/O interfaces:

24 channels of 5V digital input, configurable for edge or level triggering;

16 digital outputs (open collector electrode Darlington type);

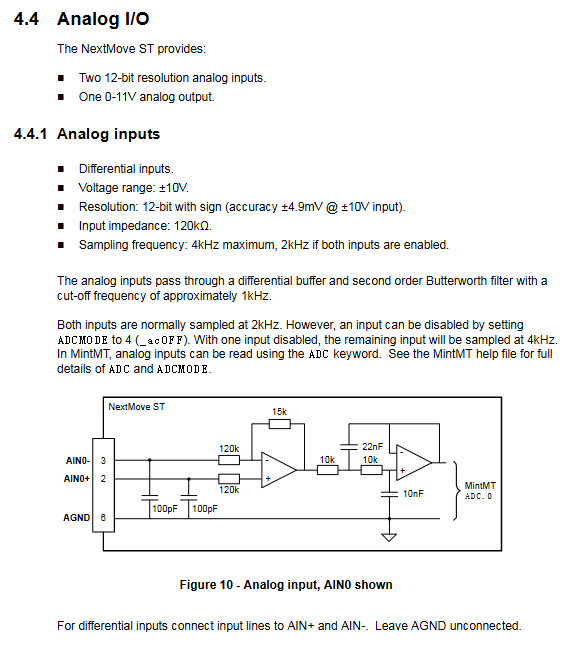

2-channel ± 10V differential analog input (12 bit resolution);

1-channel 0-11V analog output (8-bit resolution), can be used for fifth axis or external device control.

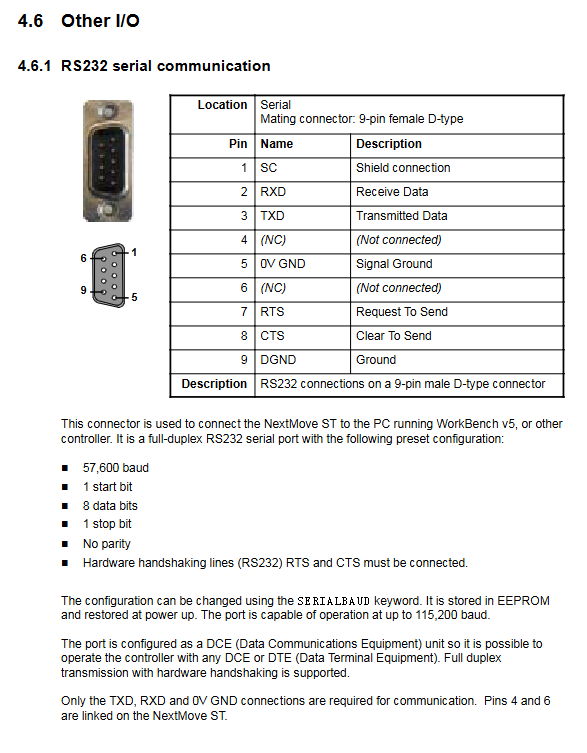

Communication interfaces: RS232, CAN (supporting CANopen and Baldor CAN protocols), facilitating system integration and network communication.

Hardware installation and electrical connection

Installation environment requirements

The controller should be installed indoors, with an ambient temperature of 0 ° C to 40 ° C and humidity below 80% (non condensing). Avoid environments close to heat sources, corrosive gases, or dust.

Power connection

NextMove ST supports three power configurations:

Shared power supply for drive and logic: connected to 24VDC/24VAC, with a maximum current of 8.5A.

Drive and logic independent power supply: Connect the drive power supply (maximum 6A) and logic power supply (12-35VDC) separately to enhance anti-interference ability.

Motor connection

Supports the connection of 4-wire, 6-wire, and 8-wire stepper motors, and the wiring method needs to be selected according to the motor type and winding configuration (parallel/series). When the direction is incorrect, the phase line sequence can be switched.

Software Configuration and Programming

WorkBench v5 development environment

NextMove ST is configured and programmed using WorkBench v5 software provided by Baldor. This software supports:

System parameter settings (such as axis scale, input/output configuration);

Online debugging and sports testing;

MintMT program editing and downloading;

Fault diagnosis and log viewing.

MintMT Language Fundamentals

MintMT supports motion commands (such as MOVE, JOG, HOME), logic control, analog and digital I/O operations. Users can convert steps to engineering units (such as millimeters, angles) through the SCALE parameter, simplifying programming.

I/O configuration and motion debugging

Digital Input/Output

Digital input can be configured as limit, origin, stop, or universal input; Digital output can be used to drive relays, indicator lights, or as enable signals. All I/O can be graphically configured in WorkBench v5.

Axis testing and calibration

The JOG command allows for manual testing of motor steering and motion response. The system supports soft limit, origin regression, and multi axis synchronous motion (such as electronic gears and cam curves).

Fault diagnosis and technical support

The controller has status indicator lights (LEDs) and error code display functions. Common issues include:

Abnormal power supply (red light constantly on);

Communication failure (check serial port cable and power supply);

The motor does not rotate (check the driver enable and wiring);

Position deviation (check load and motion parameters).

Users can generate diagnostic reports through the SupportMe feature of WorkBench v5 and contact Baldor technical support for assistance.

Summary of Technical Specifications

Power input: Logic power supply 60W, driver power supply 150W, shared power supply 210W.

Analog input: ± 10V, 12 bits, maximum sampling rate 4kHz.

Analog output: 0-11V, 8-bit, maximum 30mA.

Communication: RS232 (up to 115.2kbps), CAN (up to 500kbps).

Environment: Working temperature 0-40 ° C, humidity ≤ 80%, altitude ≤ 2000m.

Size and weight: 263 × 140 × 53mm, approximately 880g.

7. Summary

NextMove ST is a comprehensive and easy to integrate stepper motion controller suitable for multi axis coordinated motion, positioning control, and automation equipment. Its flexible I/O configuration, powerful MintMT programming capability, and reliable industrial communication interface make it an ideal choice for small and medium-sized motion control systems.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923