K-WANG

YOKOGAWA YS100 series instrument

YOKOGAWA YS100 series instrument

The YS100 series instruments (including YS150/YS170/YS131/YS135/YS136 models) support RS-485 (option code/A31) and DCS-LCS (option code/A32) communication functions. The former can be interconnected with multiple monitoring computers (up to 16 units, communication distance ≤ 1200m), while the latter can be connected to the Yokogawa CENTUM-XL/μ XL DCS system (up to 24 units/EFCS); The core communication parameters include baud rate of 1200-9600bps, half duplex mode, ASCII 8-bit encoding, support for data read and write (DG/DP commands), watchdog timer settings, and other functions. The parameters need to be configured through the front-end panel to adapt to the monitoring and operation requirements in industrial process control, while providing a comprehensive error handling mechanism and programming examples.

Core communication specifications

(1) RS-485 communication specifications

Category specific parameters

Communication interface RS-485 five signals: SD (A), SD (B), RD (A), RD (B), SG (signal ground)

Communication protocol without protocol (command response format), asynchronous operation

Transmission parameter baud rate: 1200/2400/4800/9600bps; Stop position: 1/2 position; Parity check: None/Odd/Even

Data format ASCII 8-bit encoding, single block structure, maximum block length of 220 bytes (including CR/LF)

Up to 16 instruments can be connected (multi station connection), with a communication distance of ≤ 1200m

Wiring requirements recommend shielded twisted pair cables (0.5-1.25mm ²), supporting 2-wire/4-wire wiring, with 120 Ω± 1% terminal resistors at both ends

(2) DCS-LCS Communication Specification

Category specific parameters

Adaptation System Yokogawa Distributed Control System (CENTUM-XL, μ XL)

The connection method is to connect the LCS circuit communication card to the DCS on-site control unit

The maximum connection capacity is 8 instruments/LCS cards, 3 LCS cards/MFCU, 24 instruments/MFCU, and 120 instruments/EFCS

Wiring requirements: KS4 cable (maximum length 100m), SCCD shielded twisted pair cable

The core function of YS100 is registered as an internal instrument of DCS, which can be monitored, operated, and parameter set through the DCS operator station

Installation and parameter configuration

(1) Terminal allocation

Terminal number RS-485 communication function DCS-LCS communication function

14 Signal Ground (SG) LCS+, LCS-

Send Data A (SD (A))-

16 Send Data B (SD (B))-

17 Receive Data A (RD (A))-

18 Receive Data B (RD (B))-

FG (GND) shielding layer shielding layer

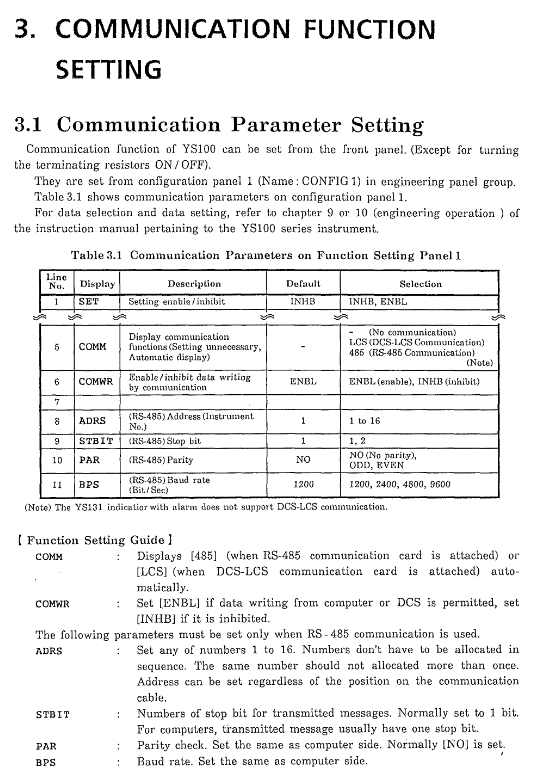

(2) Parameter configuration (front-end panel CONFIG1 menu)

Configuration item function description default value optional range

SET configuration enable/disable INHB INHB (disable), ENBL (enable)

COMM communication function display -485 (RS-485), LCS (DCS-LCS)

COMWR communication write enable ENBL ENBL (allowed), INHB (prohibited)

ADRS RS-485 instrument address 1-16

STBIT RS-485 stop bits 1, 2

PAR RS-485 parity check NO NO, ODD odd, EVENT even

BPS RS-485 baud rates 1200, 2400, 4800, 9600bps

(3) Computer mode settings

Mode Type Applicable Model Function Description

SPC mode YS150/YS170 monitoring system sends set values

DDC mode YS150/YS170 monitoring system sends operation signals

Switch between backup mode YS150/YS170 in case of monitoring system failure (BUA automatic/BUM manual)

Communication functions and commands

(1) RS-485 core command

Example of Command Function Format

DG (Data Reading) reads instrument parameters (PV/SV/MV, etc.) and sends: DG 02 03 PV1 SV1 MV1 [CR] [LF]; Response: DG 02 03 50.0 30.0 65.5 [CR] [LF]

DP (Data Write) sets instrument parameters (alarm values/set values, etc.) and sends: DP 02 03 PH1 98.0 PL1 5.0 [CR] [LF]; Response: DP 02 03 98.0 5.0 [CR] [LF]

Set timeout time in WDT (watchdog setting) DDC/SPC mode and send: WDT 01 0060 [CR] [LF]; Response: WDT 01 0060 [CR] [LF]

(2) Communication data type (core commonly used)

Data Type Name Applicable Model Range Read/Write Permissions

PV1/PV2 process variable series -6.3~106.3% read-only

SV1/SV2 set values YS150/YS170/YS135-6.3~106.3% can be written (specific mode)

MV1/MV2 operation variables YS150/YS170/YS136-6.3~106.3% writable (specific mode)

PH1/PL1 high and low limit alarm set values for the entire series -6.3~106.3% can be written

PRCA process alarm status series 8-bit binary (0=normal/1=fault) read-only

LS1/LS2 operating modes YS150/YS170 MAN/OUT/CAS/SPC/DDC can be written

(3) DCS-LCS communication correspondence

YS100 DCS Instrument Model Core Monitored Parameters

YS150 SLPC PV, SV, MV, P (proportional band), I (integral time), D (derivative time)

YS170 SLPC PV、SV、MV、 Program control parameters, alarm status

YS135 SMST-111 PV、SV、 High and low limit alarm setting values

YS136 SMST-121 PV、MV、 Upper and lower limits of manipulated variables

Error Handling and Programming Examples

(1) Common types of errors and their handling

Measures for handling error type phenomena

Communication parameters do not match, instrument does not respond, unified computer and instrument baud rate, parity check and other parameters

Address error: The instrument is unresponsive. Please confirm the instrument address (1-16) to avoid duplicate allocation

The response message is too long and returns an error code @ 100. Reduce the amount of data read in a single attempt and ensure that the message is ≤ 220 bytes

Return the corresponding error code for syntax errors (such as @ 011=invalid command). Check the command format, parameter names, and data format

(2) Programming Example

Provide an IBM-PC BASIC program example for reading data from YS100 instrument PV1, SV1, and MV1 at address 01. The core steps include port configuration, command sending, response receiving, and display.

User Program Example (YS170 Proportional Controller)

Proportional control is achieved through DCS-LCS communication, using BS (corresponding to P1 parameter) to set the proportional coefficient, X2 as the cascaded input value, Y4/Y5 as the communication register feedback intermediate calculation result, and finally outputting CSV1 as the set value to drive the control loop.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923