K-WANG

YOKOGAWA FCN/FCJ Autonomous Controller

YOKOGAWA FCN/FCJ Autonomous Controller

Product Overview

(1) Product positioning and core applications

FCN/FCJ are two core autonomous controllers under Yokogawa Electric Corporation's STARDOM series, designed specifically for industrial automation scenarios. They are suitable for various industrial processes from sequence control to analog control, and can achieve core functions such as equipment linkage, parameter adjustment, data acquisition, and monitoring. The two products are designed with modularity (FCN) and integration (FCJ) respectively, adapting to different installation environments and system complexity requirements. They are widely used in distributed control systems in factories, built-in control of mechanical equipment, industrial process monitoring and other scenarios, providing highly reliable and efficient control solutions for industrial production.

(2) Product Classification and Definition

Product type, English abbreviation, meaning, structural characteristics, subdivision models, and core configurations

FCN Field Control Node has a modular structure that can be flexibly matched with CPU, I/O, and other expansion modules according to needs, with strong scalability - FCN-100: equipped with NFCP100 CPU module

-FCN-500: Equipped with NFCP501/NFCP502 CPU modules

-FCN-RTU: equipped with NFCP050 CPU module, low-power design

FCJ Field Control Junction integrated structure, built-in I/O interface, no need for additional module assembly, compact structure without subdivision models, unified as FCJ series, integrated control and I/O functions

Core product features

(1) High performance: adaptable to diverse control requirements

Multi process compatibility: It can seamlessly integrate various industrial processes such as sequence control and analog control, and can meet the control needs of different processes without the need to replace controllers, reducing system upgrade and maintenance costs.

Flexible operation mode: supports independent operation (single controller completes local control) and interconnected control (communicates and links with other autonomous controllers or external devices), adapting to system architectures ranging from simple to complex.

Software linkage extension:

Paired with Versatile Data Server (VDS) or Supervisory Systems (FAST/TOOLS), a feature rich operation and monitoring system can be built to achieve advanced functions such as centralized data management, visual monitoring, and report generation.

Supports FCN/FCJ OPC servers, and PC OPC clients (following the OLE for Process Control standard) can directly access controller data, achieving cross platform data interaction.

Java Scalability: Built in Java Virtual Machine, supporting various Java application development and deployment, including:

Web browser image display: Visualize device status, control parameters, and other information through web pages.

Data management: Save data files locally and transfer files through FTP protocol.

Communication extension: Sending/receiving emails (supporting SMTP/POP3 protocol and SMTP server authentication), connecting to the public network through PPP protocol (such as GPRS network).

Programming free application: Paired with InfoWell software, web browsing, email communication, and other functions can be achieved without writing code, reducing the threshold for application deployment.

(2) High reliability: ensuring continuous operation of industry

Comprehensive diagnosis and protection: Equipped with complete RAS features (CPU self diagnosis, temperature monitoring, I/O diagnosis, etc.), it can monitor the equipment's operating status in real time, detect faults in a timely manner, and issue alarms; Equipped with ECC (Error Correcting Code) error correction memory, effectively avoiding control exceptions caused by memory data errors.

Low power fanless design: High heat dissipation efficiency, stable operation without the need for a cooling fan, reducing mechanical failure points, suitable for harsh environments with high dust and vibration in industrial sites.

Dual redundant configuration:

FCN-100: The Ethernet control network, CPU module, power module, and SB bus (local bus) can all be configured with dual redundancy, allowing seamless switching in case of any component failure without downtime.

FCJ: The control network supports dual redundancy to ensure the continuity of communication links and meet the high reliability communication requirements of distributed systems.

(3) Engineering Efficiency: Simplify Development and Configuration

Multi programming language support: compatible with 5 IEC 61131-3 standard programming languages (such as ladder diagrams, functional block diagrams, instruction lists, etc.), users can flexibly choose according to process requirements and development habits, reducing programming barriers.

Software component reuse: Control logic can be encapsulated as standardized software components, supporting reuse, avoiding duplicate development, improving system configuration efficiency and consistency, and ensuring control quality.

Application Portfolios: Built in Yokogawa Electric's years of industrial application experience, providing rich pre made software packages that can quickly implement advanced functions, including:

Control class: Control circuit instrument blocks (such as PID controllers, indicators, etc.).

Communication class: Communication adaptation module for non Yokogawa PLCs (such as Mitsubishi MELSEC, Omron SYSMAC, etc.).

(4) Maintainability: Reduce operation and maintenance costs

Online download function: During system operation, control applications can be directly modified, supporting the addition, deletion, and modification of I/O interfaces, variables, data types, program code, and library files. Modifying a single control circuit does not affect the operation of other circuits, and does not require shutdown maintenance, ensuring production continuity.

Hot swappable support: All modules of FCN-100 support hot swappable, so there is no need to cut off the system power when replacing faulty modules, further reducing downtime.

Convenient maintenance tool: supports remote access to the controller through a web browser for network configuration, database backup/recovery, parameter adjustment, and other maintenance operations; Paired with the Resource Configurator tool, hardware parameter configuration can be quickly completed, improving operational efficiency.

System configuration and development maintenance

(1) System configuration type

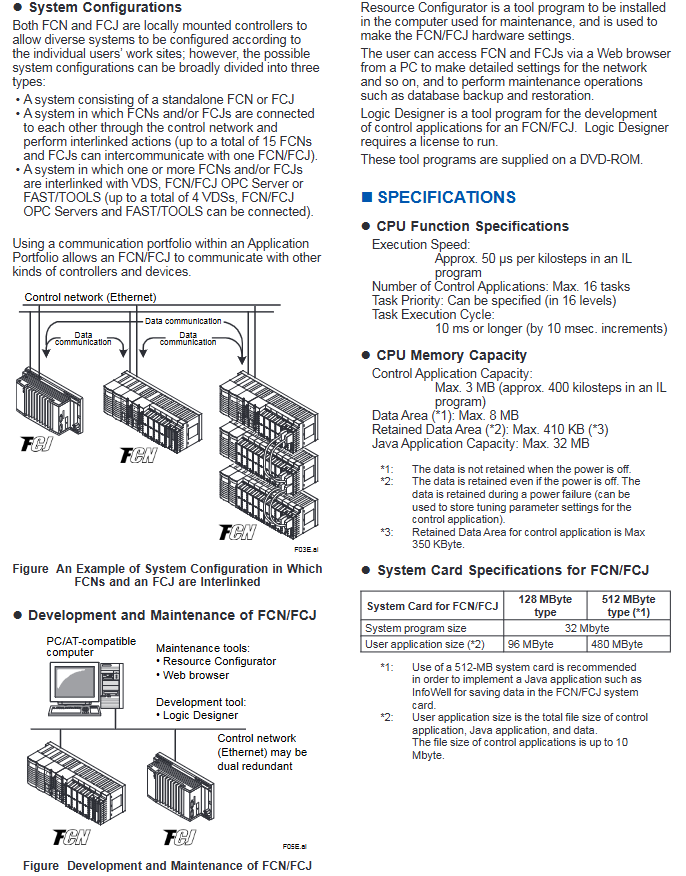

FCN/FCJ are both locally installed controllers that can be flexibly configured with three system architectures according to user on-site needs:

Independent system: A single FCN or FCJ operates independently, suitable for local area control (such as a single device or production unit), with a simple structure and low deployment cost.

Interconnected system: Multiple FCNs/FCJs are interconnected through a control network to achieve cross device linkage control. It supports communication between up to 15 FCNs/FCJs and one controller, adapting to distributed production scenarios such as multi workshop and multi production line collaboration.

Linkage system: One or more FCN/FCJ are linked with upper level software such as VDS, FCN/FCJ OPC Server, FAST/TOOLS, etc., supporting up to four such software to connect simultaneously, achieving centralized monitoring and advanced data management.

Cross device communication: Through the communication module in the application package, it can be interconnected with third-party controllers, display units, temperature controllers, power monitoring devices, and other devices to expand system compatibility.

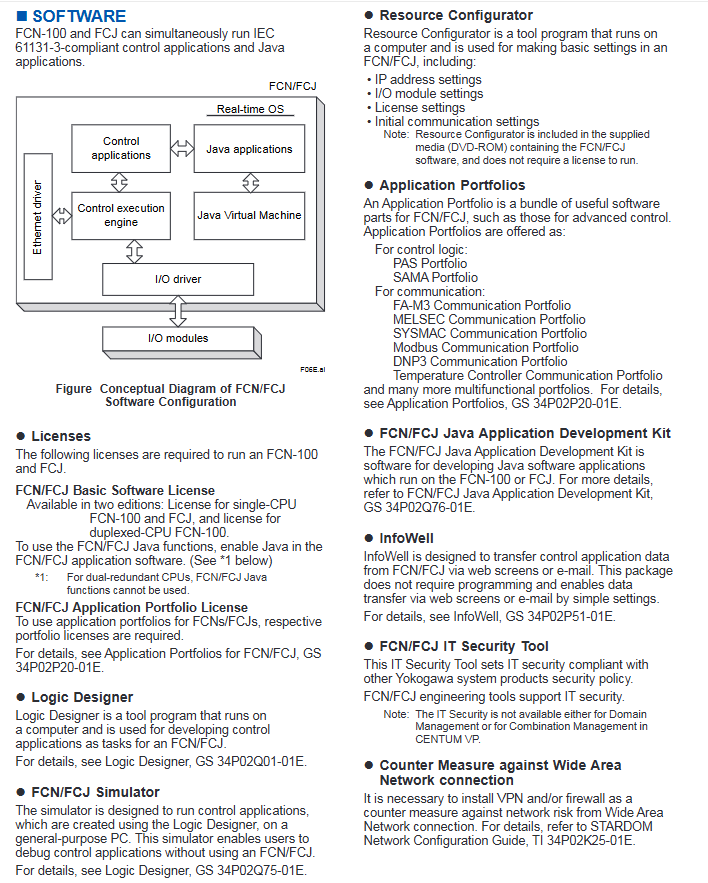

(2) Development and maintenance tools

Tool Name Core Function Operation Requirements

Logic Designer develops FCN/FCJ control applications (organized in task form), supports IEC 61131-3 standard programming language, requires separate license purchase, runs on PC/AT compatible machines

The Resource Configurator is used to configure the hardware parameters of the controller, including IP address, I/O module model, license activation, initial communication protocol settings, etc. No license is required, and it is provided free of charge with the software DVD-ROM

Web browser remote access controller for network configuration, database backup/recovery, device status monitoring and other maintenance operations. Supports mainstream browsers and connects to the controller via Ethernet

FCN/FCJ Simulator simulates the controller operating environment on a general-purpose PC and debugs control applications developed by Logic Designer without the need for actual controller hardware. A separate license needs to be purchased and is provided with the software DVD-ROM

(3) Development and maintenance process

Hardware configuration: Set basic parameters such as controller IP address, I/O module model, communication protocol, etc. through the Resource Configurator tool.

Application development: Use Logic Designer to write control programs (tasks), support multi task parallel design, and specify task priorities and execution cycles.

Debugging and testing: Use FCN/FCJ Simulator to debug the program on the PC side and verify the correctness of the control logic; After debugging, download it to the controller via Ethernet.

Operation and maintenance: During the operation of the system, the device status is monitored through a web browser or local tools. If program modifications are needed, they can be updated through the online download function. In case of faults, modules can be hot plugged and replaced.

Key technical specifications

(1) CPU function and memory specifications

CPU core parameters:

Execution speed: The instruction list (IL) program has a processing speed of about 50 µ s/thousand steps, with high computational efficiency, which can meet the real-time control requirements of industry.

Control application capacity: Supports up to 16 tasks, with task priorities divided into 16 levels and execution cycles ≥ 10 ms (adjusted in increments of 10 ms), suitable for multi task parallel control scenarios.

Memory capacity allocation:

Control application capacity: up to 3 MB, capable of storing approximately 400 thousand steps of IL program.

Data area: Maximum 8 MB, used to store temporary data during runtime, not retained after power failure.

Reserved data area: up to 410 KB (including 350 KB dedicated to control applications), data will not be lost after power failure, and key information such as control parameters and tuning settings can be stored.

Java application capacity: up to 32 MB, used for deploying Java applications.

(2) System card specifications

The system card is used to store system programs, user applications (control programs+Java programs), and data, and offers two specifications to choose from:

System card type, system program occupying space, user application total capacity, recommended usage scenarios

128 MB type 32 MB 96 MB (control application ≤ 10 MB) No complex Java applications, only running basic control programs

512 MB type 32 MB 480 MB (control application ≤ 10 MB) requires running Java applications such as InfoWell, or storing a large amount of historical data

(3) Network communication specifications

1. Ethernet (Control Network)

Standard compatibility: Following the IEEE802.3 standard, supporting dual redundancy configuration to ensure communication reliability.

Core purpose: To connect FCN/FCJ, PLC, display unit, VDS and other devices, and also for the development and maintenance of controllers (program download, parameter configuration).

Connection ability:

Remarks on the maximum number of connections for the connection target

VDS/FCN/FCJ OPC Server/FAST/TOOLS 4 units, total number of Class III devices not exceeding 4 units

FCN/FCJ controllers can link up to 15 devices of the same type with a single controller

32 third-party PLCs (such as FA-M3, MELSEC), each occupying 1 communication channel

2. Serial communication

Purpose: To connect display units, temperature controllers, power monitors, and other devices, supporting multiple serial communication protocols.

Hardware configuration:

Controller type serial port configuration remarks

FCJ 2 RS-232-C ports fixed configuration, non expandable

The FCN-100 CPU module comes with one RS-232-C port; Expandable serial communication module (2 ports per module, supporting RS-232-C or RS-422/RS-485) can install up to 8 expansion modules, and the CPU's built-in serial port is not available when using dual redundant CPUs

(4) Control the upper limit of application capacity

Function Blocks (POUs): Supports up to 512, including:

Regulator control blocks (such as indicators, controllers, manual loaders): ≤ 128.

Other functional blocks (such as calculation block, switch instrument block, communication POU): ≤ 384.

Sequential program:

Ladder diagram: ≤ 180 kilosteps.

Sequence table: ≤ 128 (each table contains 32 condition rows+32 action rows).

Maximum configuration example:

I/O interface: 96 AI (analog input), 32 AO (analog output), 256 DI (digital input), 256 DO (digital output).

Control circuit: 32 PID circuits.

Sequence program: 128 sequence tables.

Control cycle: 1 second.

(5) Dual redundant CPU specifications (only supported by FCN-100)

Fault switching: After the main CPU fails, the backup CPU instantly takes over control permissions, and the switching process is undisturbed and does not affect system operation.

Balance operation: When adding or replacing CPU modules, the All program copy (APC) command needs to be executed to achieve data synchronization between two CPUs, and automatic execution is supported (only applicable to dual Style-3 NFCP100 CPU configurations); When the APC command runs, the first control cycle is extended by 1-2 seconds, and it returns to normal thereafter.

Operational restrictions:

Multi tasking cannot access the same global variable.

The CPU module's built-in serial port is not available.

Unable to run Java application.

When configuring a non dual Style-3 NFCP100 CPU, the APC command needs to be manually executed. During execution, the control pauses, and the I/O module runs according to the Fallback option (such as maintaining output or outputting specified values).

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923