K-WANG

YASKAWA Z1000 series HVAC dedicated frequency converter

YASKAWA Z1000 series HVAC dedicated frequency converter

Applicable models:

200V level: 2.2~110kW (3~150HP);

400V level: 2.2~370kW (3~500HP);

Model identification: CIMR-ZU A series.

Core positioning: A practical guide for engineering and technical personnel, covering the entire process from parameter initialization, motor debugging to troubleshooting, supporting multiple modes such as V/f control and PM motor open-loop vector control, and adapting to the dynamic adjustment needs of HVAC systems.

Core functional framework

The document revolves around three core modules: parameter configuration, function implementation, debugging and maintenance. The core modules include parameter details, regular inspection and maintenance, and communication protocol configuration (BACnet/APOGEE FLN/Metasys N2/EMOBU/Modbus), forming a complete closed loop of "setup run monitoring maintenance".

Core parameter configuration (classified by functional modules)

1. Initialize parameters (Group A)

The core is used for initial driver settings, including basic configurations such as language, control mode, parameter reset, etc.

A1-00 (Language Selection): Supports English, Japanese, French, Spanish, Portuguese, and does not reset this parameter during initialization.

A1-02 (Control mode selection): 0 (Induction motor V/f control, speed range 1:40), 5 (PM motor open-loop vector control, speed range 1:20).

A1-03 (Parameter Initialization): Supports multiple initialization modes such as user-defined, 2-wire/3-wire control, HVAC dedicated, OEM bypass, etc., and automatically returns to 0 after reset.

A1-04/A1-05 (password setting): A1-05 hides the parameter setting password, A1-04 unlocks by entering the password, and restricts the modification permission of core parameters (such as A1-01~A1-03).

2. Application Function Parameters (Group B)

Focus on core application functions such as operating mode, braking, speed search, PI control, etc., and adapt to HVAC load characteristics.

(1) Operation mode selection (b1 group)

B1-01 (AUTO mode frequency source): Supports four input methods: HOA keyboard, analog terminal, communication, and tab.

B1-02 (AUTO mode operation command): Optional control terminals, communication, and tab triggers. Selecting 3 when no tab is installed will trigger the oPE05 error.

B1-03 (stop mode): 0 (slope stop), 1 (free stop), 2 (DC injection brake stop), 3 (free stop with delay).

(2) PI control (b5 group)

Specially designed for closed-loop control of pressure, flow, and temperature in HVAC systems, with core parameters:

B5-01 (PI function enabled): 0 (disabled), 1 (PI output directly as frequency command), 3 (PI output combined with frequency command).

B5-02/B5-03 (Proportional/Integral Parameters): Proportional gain of 0.00~25.00, integration time of 0.0~3600s, can suppress overshoot or accelerate response speed.

B5-12 (PI feedback loss detection): Supports low/high feedback detection, can set alarms, faults, or only output signals to avoid sensor failures causing system loss of control.

(3) Energy saving function (b8 group)

B8-01 (Energy saving control enable): When enabled, automatically optimize the motor operating voltage to improve light load efficiency. PM motors should be used with caution.

3. Motor parameters (Group E)

The core parameter configuration covering induction motors and PM motors directly affects control accuracy.

E1 group (V/f mode setting): E1-03 selects V/f curve (15 presets+1 customization), suitable for constant torque, variable torque (fan/pump), high starting torque and other scenarios.

E2 group (induction motor parameters): requires input of motor rated current (E2-01), rated slip (E2-02), no-load current (E2-03), etc., supporting automatic tuning and automatic acquisition.

E5 group (PM motor parameters): Only visible when A1-02=5, stator resistance (E5-05), d/q-axis inductance (E5-06/E5-07), induced voltage constant (E5-09/E5-24), etc. need to be set.

4. Protection function parameters (L group)

Comprehensively ensuring the safety of drivers, motors, and systems, with core components including:

Motor protection (L1 group): L1-01 selects overload protection type (general motor/PM motor), supports PTC thermistor connection (L1-03~L1-05) to detect motor temperature.

Power protection (L2 group): L2-01 is configured with instantaneous power failure response strategy, and L2-05 is set with undervoltage detection level (default 190V for 200V level, default 380V for 400V level).

Lock rotor protection (L3 group): Install lock rotor protection during acceleration, deceleration, and operation to avoid motor overload or overvoltage faults.

Fault restart (L5 group): L5-01 sets the number of automatic restarts (0-10 times), supports automatic recovery after overcurrent, overload, overvoltage and other faults, and the lifting application is disabled.

5. Terminal functional parameters (H group)

Configure digital/analog input/output terminals to achieve external signal interaction.

H1 group (digital input): 7-channel programmable terminals (S1~S7), supporting functions such as forward and reverse rotation, multi-stage speed, fault reset, emergency stop, etc., and can be configured with 2-wire/3-wire control logic.

H2 group (digital output): 3 relay outputs (M1-M2/M3-M4/M5-M6), which can map signals such as operating status, zero speed, fault, and consistent speed.

H3 group (analog input): 2 analog terminals (A1/A2), supporting 0~10V/4~20mA signals, configurable frequency command, PI feedback, torque detection level and other functions.

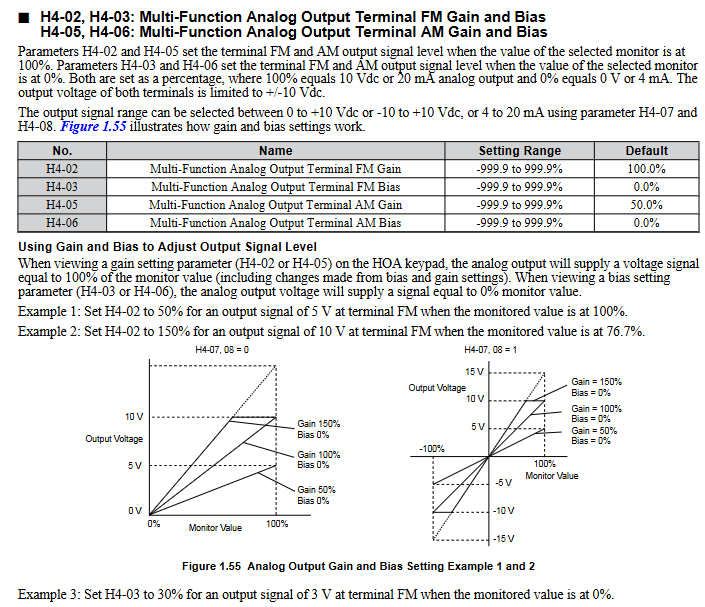

H4 group (analog output): 2 analog terminals (FM/AM), capable of outputting monitoring data such as frequency, current, power, etc., supporting gain/bias adjustment.

6. Communication parameters (H5/F6/F7 group)

Supports multiple industrial communication protocols and is compatible with building automation system integration.

Core protocols: BACnet, APOGEE FLN, Metasys N2, MEMOBU/Modbus;

Basic configuration: H5-01 (slave address), H5-02 (baud rate), H5-03 (checksum), which need to be unified with the upper computer;

Fault handling: F6-01 configuration communication fault driver behavior (shutdown/continue running/alarm).

Motor debugging (T group)

Obtain precise motor parameters through automatic tuning to ensure control performance.

1. Induction motor debugging (T1 group)

T1-01 selects tuning mode: 2 (static resistance detection), 3 (V/f energy-saving mode rotation tuning);

Pre input of motor rated power (T1-02), voltage (T1-03), current (T1-04) and other nameplate parameters is required, and after tuning, the E2 group parameters will be automatically updated.

2. PM motor debugging (T2 group)

T2-03 Select motor type (0=IPM motor, 1=SPM motor);

T2-18 starts tuning and automatically calibrates key parameters such as stator resistance, inductance, and induced voltage constant, ensuring that the motor is unloaded.

Monitoring parameters (U group)

Real time viewing of drive operation status, fault records, and maintenance information, core categories:

U1 group (operating status): output frequency (U1-02), output current (U1-03), DC bus voltage (U1-04), etc;

U2/U3 group (fault tracing): record parameter snapshots (such as current, frequency) and historical fault lists (up to multiple records can be stored) when faults occur;

U4 group (maintenance monitoring): cooling fan running time (U4-03), percentage of capacitor life (U4-05), pre charge relay life (U4-07), etc. If it is less than 20%, it needs to be replaced in advance;

U5 group (PI monitoring): PI set values, feedback values, output values, etc., facilitate closed-loop control optimization.

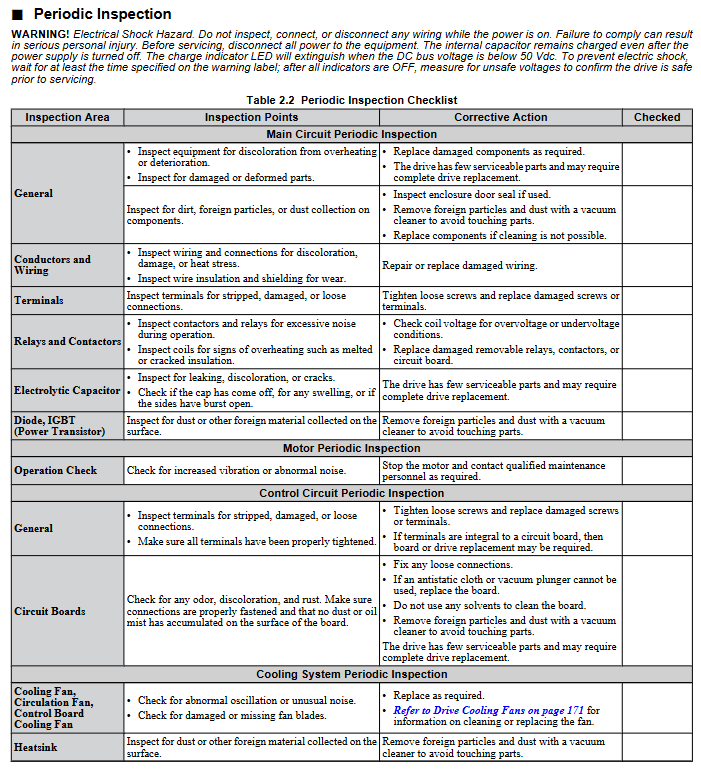

Regular inspection and maintenance

1. Safety regulations

After power failure, wait for the capacitor to discharge (DC bus voltage below 50V) before wiring or replacing components;

Do not remove the cover plate or touch the circuit board while it is powered on to avoid static electricity damaging the components.

2. Inspection cycle and content

(1) Daily inspection (daily)

Appearance: The driver/motor has no abnormal noise, odor, or vibration, and the cooling fan is running normally;

Display: No alarm code, stable parameters such as current and voltage;

Environment: Temperature (-10~+50 ℃), humidity (0~95% without condensation) meet the requirements, and there is no dust accumulation.

(2) Regular inspection (annually)

Electrical components: The wiring terminals are securely fastened, the insulation of the wires is not aged, the capacitors are not leaking or bulging;

Cooling system: The radiator is clean, the fan is not stuck, and the air duct is not blocked;

Function verification: No abnormal changes in parameters, protection functions (such as overload and overvoltage) triggered normally.

3. Replacement of vulnerable parts

Cooling fan: Replace it after running for 20000 hours or 5 years, and reset the o4-03 parameter after replacement;

HOA keyboard battery: The model is CR1220 lithium battery, with a lifespan of about 2 years. Replace it when "bAT" is displayed, and pay attention to the installation of the positive and negative poles;

Capacitors and relays: After 5-7 years of operation, the capacity/contact status needs to be checked, and if it is lower than 80% of the initial value, it should be replaced.

Communication Protocol Configuration (Core Protocol Summary)

1. MEMOBU/Modbus communication

Physical interface: RS-422/RS-485 (terminal R+/R -/S+/S -);

Core parameters: Slave address (H5-01:0~FFH), baud rate (H5-02:1200bps~115200bps), parity bit (H5-03: none/even/odd parity);

Function: Supports reading monitoring data, writing parameters, controlling start stop, and fault reset.

2. BACnet communication

Adapt to building automation systems and support BACnet MS/TP protocol;

Configuration parameters: F6-46 (baud rate), device object, analog input/output object mapping;

Function: Implement remote monitoring and control of the frequency converter by the upper computer, and support fault alarm uploading.

Compliance and Safety Tips

Safety level: Complies with UL 508C, CSA C22.2 No.14, CE LVD/EMC and other standards;

Prohibited scenarios: It is prohibited to use equipment that directly affects personal safety, such as medical, aviation, nuclear power, etc. The lifting application is disabled and automatically restarted due to malfunction;

Operation specifications: All wiring, parameter modification, and maintenance work must be carried out by authorized personnel, and the power-off discharge process must be strictly followed.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923