K-WANG

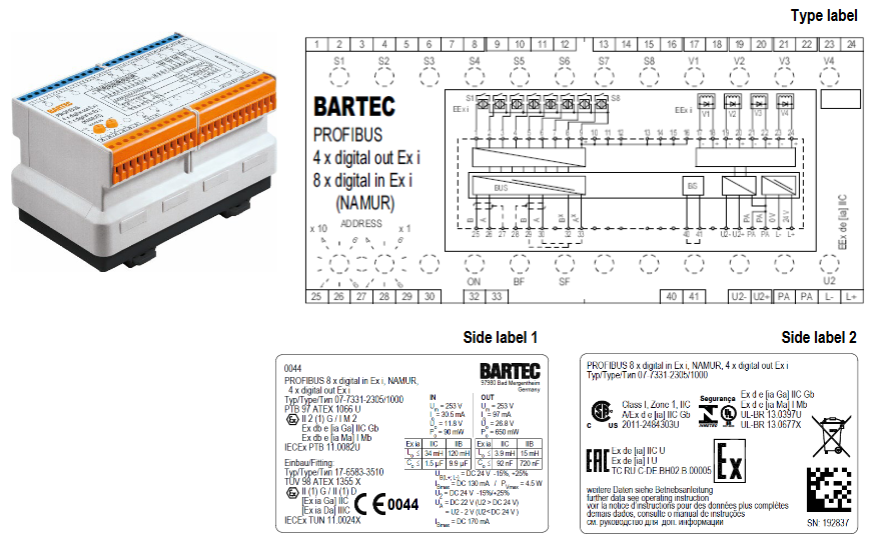

BARTEC MODEX PROFIBUS 07-7331-2305 Series Interface Module

Comparison item model 07-7331-2305/000 model 07-7331-2305/1000

Output explosion-proof level Ex e (increased safety type) Ex i (intrinsic safety type)

Output voltage U2-0.2V (approximately 23.8V when U2 is 24V) DC 22V (when U2 ≥ 24V)

Single channel maximum output current 500mA-

Single channel internal resistance -301 Ω

Module loss power maximum 3.5W maximum 4.5W

Control object: 4-channel Ex e valve, 4-channel Ex i valve

BARTEC MODEX PROFIBUS 07-7331-2305 Series Interface Module

Module core information and functional differences

Both modules are PROFIBUS-DP interface devices with "4-channel digital output+8-channel digital input". The core difference lies in the explosion-proof level of the output terminal. The specific comparison is as follows:

Comparison item model 07-7331-2305/000 model 07-7331-2305/1000

Output explosion-proof level Ex e (increased safety type) Ex i (intrinsic safety type)

Output voltage U2-0.2V (approximately 23.8V when U2 is 24V) DC 22V (when U2 ≥ 24V)

Single channel maximum output current 500mA-

Single channel internal resistance -301 Ω

Module loss power maximum 3.5W maximum 4.5W

Control object: 4-channel Ex e valve, 4-channel Ex i valve

Common core functions:

Input function: 8-channel Ex i intrinsic safety input, supporting NAMUR limit switches, mechanical contacts (compliant with EN/IEC 60947-5-6 standard), with wire breakage/short circuit detection;

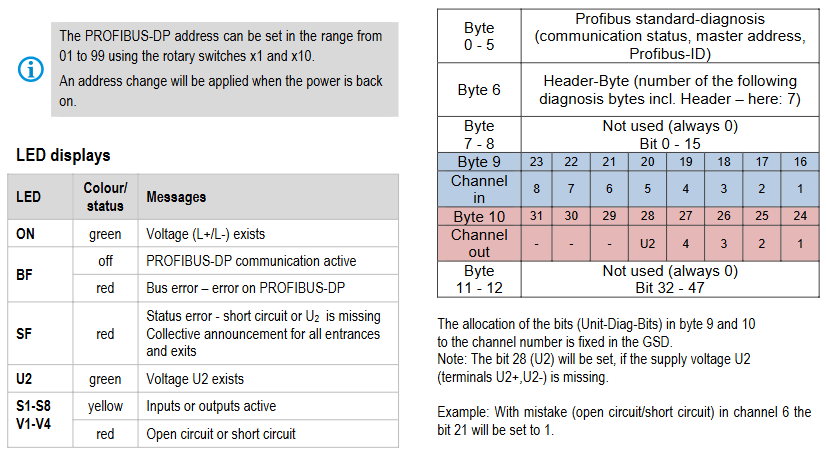

Display function: Real time display of power supply (ON light), bus communication (BF light), status fault (SF light), output power supply (U2 light), and activation/fault status of each channel through LED;

Safety design: Short circuit protection (automatically cuts off output in case of short circuit), reverse polarity protection, supports cutting off actuator power through U2 terminal external emergency stop switch;

Communication and diagnosis: Connected to the control system through PROFIBUS-DP, it can transmit user data and diagnostic data (output disconnection/short circuit status), supporting SYNC (output status freeze) and FREEZE (input status freeze) functions.

Explosion proof certification and compliance

The module is designed for explosive hazardous environments and has passed multiple international certifications to meet compliance requirements in different regions

Certification System Certification Number/Directive Explosion proof Identification/Key Requirements

ATEX PTB 97 ATEX 1066 U, T Ü V 98 ATEX 1355 X II 2 (1) G Ex db e [ia Ga] IIC Gb; I M2 Ex db e [ia Ma] I Mb

IECEx PTB 11.0082U、TUN 11.0024X Ex db e [ia Ga] IIC Gb; Ex db e [ia Ma] I Mb

Regional Compliance CSA(2011-2484303U)、INMETRO(UL-BR 13.0397U)、EAC(RU C-DE.BH02.B.00005) CSA Identification: A/Ex d e [ia] IIC Gb

EU directives ATEX 2014/34/EU, RoHS 2011/65/EU, EMC 2014/30/EU comply with EN 60079 series explosion-proof standards and EN 60529 protection standards

Special explosion-proof requirements:

The module is marked with a "U" symbol and needs to be installed in an enclosure that complies with EN/IEC 60079-0 standard and has a protection level of not less than IP54;

If the shell is of Ex e increased safety type, it must meet the electrical clearance and creepage distance specified in Table 1+2 of IEC/EN 60079-7.

Key technical parameters

1. Electrical parameters (general)

Power supply voltage: Electronic part (L+/L -) DC 24V (20-30V); Output section (U2+/U2-) DC 24V (20-30V, supports emergency stop);

Input parameters (Ex i): U ₀=11.8V, I ₀=31mA, P ₀=90mW, linear characteristics, external inductance/capacitance limits vary with explosion-proof level (e.g. Ex ia IIC, L ₀ maximum 47mH, C ₀ maximum 1.5 μ F);

Bus interface: RS485 (screw terminal), PROFIBUS-DP address set through rotary switch (01-99, effective after power failure);

Isolation design: Galvanic isolation is used between power supply, bus, circuit, output, and input.

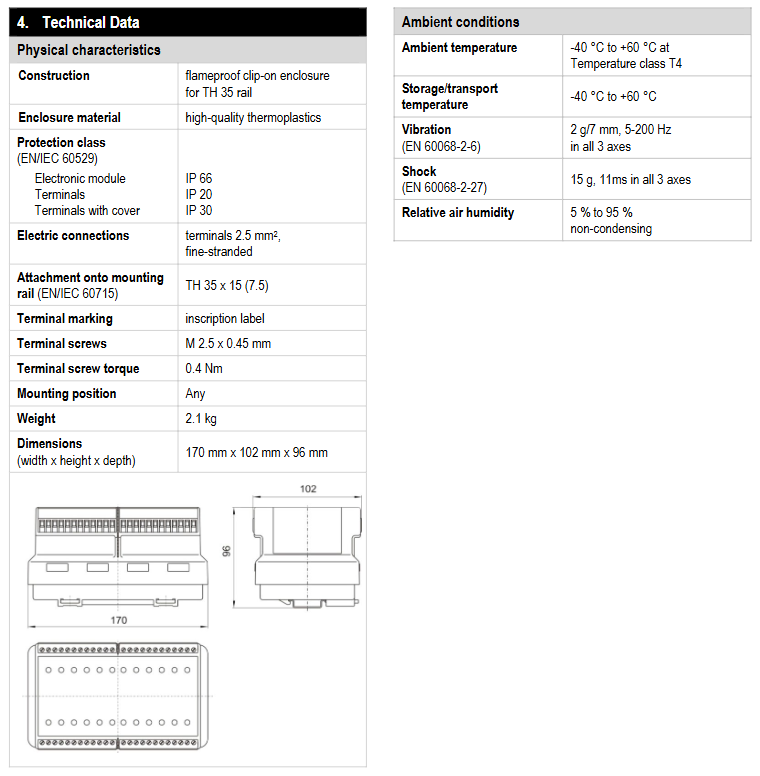

2. Physical and environmental parameters

Protection level: Electronic module IP66, terminal IP20 (uncovered)/IP30 (covered);

Installation: Suitable for TH35 × 15 (7.5) standard guide rail (EN/IEC 60715), with any installation direction;

Size and weight: 170mm x 96mm x 102mm (width x height x depth), weight 2.1kg;

Environmental conditions: working/storage temperature -40 ℃~+60 ℃ (T4 temperature level), relative humidity 5% -95% (no condensation); Anti vibration (2g/7mm, 5-200Hz, 3-axis), anti impact (15g, 11ms, 3-axis).

3. Terminals and Connections

Terminal specification: 2.5mm ² multi strand wire, terminal screw M2.5 × 0.45mm, tightening torque 0.4Nm;

Grounding requirements: 1-2 grounding terminals should be installed on the right side of the module, and the PA terminal should be connected to the grounding terminal with a 2.5mm ² wire.

Installation and operation specifications

1. Installation requirements

Installation personnel: must have the qualification to install electrical equipment in explosive hazardous areas and have read and understood the instructions;

Preprocessing: Before installation, check that the module is clean and undamaged, there is a power outage, and adjacent live parts are protected;

Operation steps: Insert the module into the guide rail until the buckle makes a sound, and tighten the terminal screws with a torque wrench at 0.4-0.7Nm.

2. Debugging and troubleshooting

Pre debugging inspection: installation correctness, shell integrity, wiring compliance, address and baud rate settings;

Priority for troubleshooting: LED status (such as BF red light indicating bus fault, SF red light indicating short circuit or U2 power failure) → Wiring/terminal fastening → Address/baud rate → Bus terminal and jumper → System restart (required after address change).

3. Maintenance and disposal

Maintenance: No maintenance is required under normal use, and regular inspections by electricians are required according to EN/IEC 60079-17/19;

Repair: Self repair is prohibited, please contact BARTEC GmbH;

Disposal: Belonging to B2B equipment under the WEEE directive, it needs to be disposed of in accordance with local regulations and can be returned to BARTEC (with shipping costs borne by the sender), WEEE number DE 95940350.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

-

HIMA F60AI801 PLC Module | Analog Input Module

-

HIMA F60MI2401 PLC Module | Modular Safety Automation

-

HIMA F8603 PLC Module | Safety Automation Control Module

-

HIMA K1412A PLC Module | Industrial Safety Module

-

HIMA K9203 PLC Module | Safety Automation Module

-

X-DO1201 HIMA Control Pulse Card | Digital Output Module

-

F6705 HIMA Analog Output Module | Safety Control Output Module

-

HIMA B9361 PLC Module | Safety Automation System Module

-

HIMA H41Q-HRS / H41QX PLC Module | Safety Automation Module

-

HIMA F3003 Controller Unit | HIMAtrix Compact Safety Controller

-

HIMA HIMatrix F1DI1601 PLC Module | Digital Input Module for Safety Systems

-

HIMA X-DI 64 51 PLC Module | Digital Input Module for Safety Automation

-

HIMA F30 Controller Unit HIMAtrix 01 OPEN | Safety PLC Controller

-

HIMA K9202B PLC Module | Safety-Oriented Control Module

-

HIMA F3DIO20802 Controller PLC Module | Digital I/O Control for Safety Automation

-

HIMA F8627-1 F8627X Communication Module | Safety System Communication Interface

-

HIMA B4237-2 PLC Module | Safety Control and Logic Processing Module

-

HIMA X-DO2401 PLC Module | Digital Output Module for Safety Automation

-

HIMA 22100 PLC Module | Industrial Safety Control and Logic Processing

-

HIMA 90100 PLC Module | Safety-Oriented Industrial Control Module

-

HIMA 895210001 PLC Module | Industrial Safety Control and Processing Module

-

HIMA 157528-0 PLC Module | Industrial Safety Control and Processing Module

-

HIMA B5322 PLC Module | Industrial Safety Control and Processing Module

-

HIMA BV7032 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F3300 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7105A PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7150 PLC Module | Industrial Safety Control and Processing Module

-

HIMA F7508 PLC Module | Industrial Safety Control Processing Module

-

HIMA F8627 984862765 PLC Module | Industrial Safety Control Module

-

HIMA M3410 PLC Module | Industrial Safety Control Processing Module

-

HIMA Z7308 PLC Module | Safety Control System Processing Module

-

F8640 HIMA Central Module | Safety System Core Controller

-

HIMA F8630 Module | Safety System Functional Module

-

F8651X HIMA Central Module | Safety System Core Controller

-

F3236 Digital Input Module | HIMA Safety System Input Interface

-

F7131 HIMA Power Monitoring Module | Safety System Power Supervision

-

F8627X HIMA Communication Module | Safety System Network Interface

-

HIMA F8560X PLC Module | Safety-Related Control System Component

-

HIMA P8403 PLC Module – Industrial Safety Control Processor

-

HIMA F8628X Communication Module – Industrial Safety System Interface

-

HIMA F8621A Communication Module – Safety System Communication Interface

-

HIMA 984865066 PLC Module – Safety Control Processing Unit

-

HIMA F60CPU01 PLC Module – Safety Control Processing Unit

-

HIMA F8650E PLC Module – Safety Control Processing Unit

-

HIMA F8652E Central Module – Safety Control Processing Unit

-

HIMA F8650X Card – Safety Central Processing Module

-

F8652X HIMA Central Module – Safety Control Central Processing Unit

-

HIMA 99-7105233 B5233-1 Safety Module – Industrial Safety Control Component

-

KEBA KeTop T70-rqa-AK0-LK Teaching Device – Industrial Robot Teach Pendant

-

KEBA KETOP T50-T41-CPU 2495D-0 – Industrial CPU Module

-

KEBA E-CON-CC100/A/ 22178 – Industrial Controller Module

-

KEBA Kemro K2-200 CP 250/X 71580 CPU-MODULE – Industrial Control CPU Module

-

KEBA D3‑DA 330/A‑1211‑00 Drive – KeDrive D3 Axis Controller Industrial Servo Drive

-

KEBA KETOP O70‑bra‑A0a‑F Demonstrator – Industrial Automation Control Module

-

KEBA KETOP O70-BRA-A0A-F Demonstrator | Industrial HMI Operating Terminal

-

KEBA SO84.012.0083.0101.2 Servo Drive | Industrial Motion Control Solution

-

HIMA X-AO1601 Termination Boards

-

HIMA X-AI3251 Digital Output Module

-

HIMA X-DO3251 Digital Output Module

-

HIMA X-DI3202 Termination Board

-

HIMA X-DI6451 Digital Input Module

-

XYCOM 96574-001 - Circuit Board Card Rev A

-

XYCOM 99212A-001 - Control Board Card CPX-7

-

XYCOM 99222-001 - Circuit Board Card Rev A

-

XYCOM 97780-002 - Circuit Board for Operator Panel Screen

-

XYCOM XVME-164/1 - Circuit Board 61116

-

XYCOM CMX-7D - Power Supply Circuit Board PN99865-001

-

XYCOM 10330-00800 - Digital I/O Board Circuit Card

-

XYCOM 8450-HU - Husky Monitor 98916-001

-

XYCOM XVME-428/2 - IASCM Communication Board

-

XYCOM 3512KPT - Industrial PC Operator Interface

-

XYCOM Checkpoint Cognex - Inspection Machine Vision Camera

-

XYCOM XVME-080 - IPROTO Intelligent Prototyping Module

-

XYCOM IV-1653 - Ironics VMEbus CRT Circuit Board

-

XYCOM M032000220 - Control Board

-

XYCOM 4850A - Operator Interface Panel 91855-001

-

XYCOM 9462 - HMI Operator Interface Panel 9462-016214001

-

XYCOM 9465 KPM - Monitor Industrial PC 9465-219114103

-

XYCOM 9486 - Monitor-Miniflex Portrait 9486-0343

-

XYCOM MVME-490/1 - Circuit Board Tegal 6550 Etcher

-

XYCOM 1300 - Node Module 1300-000100000

-

XYCOM 3510 T - Operator Interface

-

XYCOM 3512 KPM - Operator Interface Part No 3512-A1F114103

-

XYCOM 4615KPM - Operator Interface

-

XYCOM 8320 - Operator Interface Display Panel 94321-002

-

XYCOM 4105 - Operator Interface P/N 91904-001

-

XYCOM PM101683E - Operator Interface PM101683 E

-

XYCOM 301993 - Operator Panel 89086-501 Raycon

-

XYCOM 2000 - Operator Panel 97957-001

-

XYCOM 9410KP - Operator Touchscreen HMI 51338-STN

-

XYCOM 9987 - Operator Workstation CPU Board

-

XYCOM 94144-002 - CPU Board Rev V

-

XYCOM 9487 - Programmable Interface HMI Panel PC

-

XYCOM 70956-411 - PLC Module Card Ethernet Card MESA 4I29X

-

XYCOM PM101587 - Operator Panel

-

XYCOM XT1502-BB-RB - Display Panel XT 1502

-

XYCOM PM3510 - Operator Interface Terminal

-

XYCOM PM8450 - Operator Interface Repair Evaluation

-

XYCOM PM8480 - Operator Interface PM101269

-

XYCOM 8000-SKM - Power Supply Board Module

-

XYCOM 510084 - Power Supply Board

-

XYCOM 1546 - Proface Industrial Workstation 1546-102031013

-

XYCOM 86864-002-E - Processor Board Module

-

XYCOM 3112T - Pro-face Operator Interface

-

XYCOM 3712 KPM - Pro-face Operator Panel

-

XYCOM 4615KPMT - Proface Industrial PC Display Panel PM-070007

-

XYCOM 5015T - Pro-Face Touch Monitor 100-240 VAC

-

XYCOM 5015T/R2 - Industrial Flat Panel Touch Monitor 5015R2-0100000

-

XYCOM 1341 - Proface Embedded Computer TF-AEC-6920-C2

-

XYCOM GLC150-BG41-DN - Graphic Logic Controller M-24V

-

XYCOM GP2301H-SC41-24V - Pro-face Operator Interface 5.7" w/ Cable

-

XYCOM 1547 - Pro-face Industrial PC Model 1547-00113101

-

XYCOM ST401-AG41-24V - Graphic Touchscreen Operator Interface

-

XYCOM 3310T - Pro-face Operator Panel 3310-001101001

-

XYCOM 5015 KPMT - Proface Operator Panel Display

-

XYCOM XVME-684 - PC Module VME Bus Processor 70684-201

-

XYCOM 3300 MT - Screen Monitor Display

-

XYCOM SXT1811T - Touch Panel Monitor 100/240VAC

-

XYCOM XT-1502 - Touch Screen Monitor Flat Panel Display Interface

-

XYCOM SXT1811 - Viewtronix SXGA Flat Panel Monitor 18.1" Display

-

XYCOM VT1040T - ViewTronix Touch Screen Monitor

-

XYCOM WS2786291 - Industrial Workstation PC

-

XYCOM XCME-540 - Analog I/O Module VMEbus 70540-001

-

XYCOM XVME-682 - CPU PCB Processor Module 70682-101

-

XYCOM CU040103500 - VME Rack System Module 4200401

-

XYCOM XVME-085 - Proto VMEbus Non-Intelligent Prototyping Module

-

XYCOM XVME-100 - PCB Controller Card ROM Board 70100-001

-

XYCOM XVME-103 - VMEbus Board 10103-001

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923