K-WANG

Allen Bradley 1326AB high-performance AC servo motor

Allen Bradley 1326AB high-performance AC servo motor

Product Overview and Core Positioning

1. Product type and applicable scenarios

The 1326AB series is a three-phase brushless permanent magnet synchronous servo motor designed for high-precision motion control, compatible with Allen Bradley 1391 AC servo controller. It is widely used in machine tools, automated production lines, material handling and other scenarios that require precise positioning and high-speed response. It supports various mechanical structures such as screw drive, gear rack drive, conveyor belt drive, etc.

2. Core standard features

Performance Design:

Permanent magnet rotor structure improves servo response speed; Sine wave winding stator achieves low-speed smooth operation and efficient heat dissipation.

100% continuous rated locked rotor torque at zero speed, meeting the requirements for maintaining static load.

Feedback system:

Standard brushless rotary transformer, providing position, commutation, and speed feedback, without built-in electronic components, suitable for harsh environments.

Supports 1391 A Quad B encoder output (up to 2048 PPR), achieving high-precision position detection through rotary transformer signal conversion.

Protection and reliability:

TENV (fully enclosed non ventilated) structure, optional shaft seal kit (1326AB-MOD-SSV-xx) can achieve IP65 protection level (dustproof, anti pulsating water flow), but IP65 fails when external encoder/rotary transformer or fan is connected.

The winding is equipped with a normally closed thermal switch (115V AC/1A, 24V DC/1A) to achieve overheating protection, with a trigger temperature of about 150 ° C and a reset temperature of 90-100 ° C.

Installation and compatibility:

Supporting vertical/horizontal axis installation, the rotor dynamic balance accuracy reaches 0.0005 inches (0.0127mm) peak to peak displacement, reducing operational vibration.

Equipped with MIL standard connectors, the power and feedback cables support standard flexibility, high flexibility of drag chains (- T suffix), and ultra long (ES suffix, up to 300 feet/91.4m) versions, adapting to different installation distance requirements.

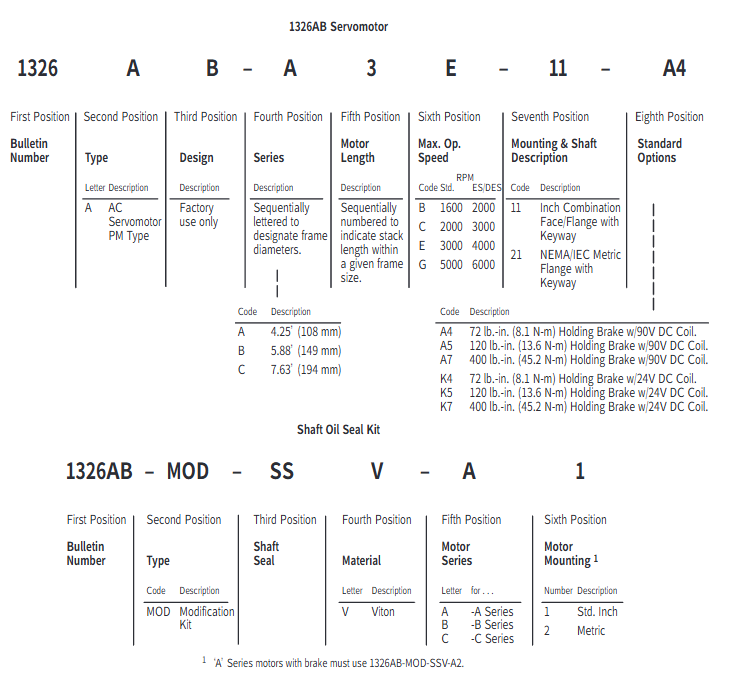

Model interpretation and optional configurations

1. Model coding rules (taking 1326AB-A1G-11-A4 as an example)

Explanation of the meaning of digit codes

1-4 Position 1326 Product Series AC Servo Motor

5th motor type A AC permanent magnet synchronous

6th B frame diameter A=4.25 inches (108mm), B=5.88 inches (149mm), C=7.63 inches (194mm)

The 7th position A is distinguished in alphabetical order based on the stacking length within the same framework (A<B<C<D, with increasing length and greater torque)

8th highest speed G=5000rpm, E=3000rpm, C=2000rpm, B=1600rpm

Installation of positions 9-10 and shaft type 11=NEMA British flange+keyway shaft; 21=IEC metric flange+metric shaft

The 11th to 12th positions of A4 can be selected with attachment A series=90V DC brake (A4=72 lb in/8.1N · m, A5=120 lb in/13.6N · m, A7=400 lb in/45.2N · m); K series=24V DC holding brake (K4/K5/K7 correspond to the same torque)

2. Key optional configurations

Configuration Type Model/Option Code Function Description

The 1326-MOD-BPS brake power supply converts 115V AC to 90V DC and is compatible with A-series brakes. A single unit can drive 4 brakes

Shaft seal kit 1326AB-MOD-SSV-xx on-site installation of Viton material shaft seal, no need to disassemble the motor, compatible with A/B/C series

Feedback component 1326AB-MOD-Vxxxx 4.25-inch (108mm) rotary transformer, supports absolute/fine adjustment format, compatible with 8600GP, IMC and other controllers

Junction box 1326AB-MOD-RJxx axial lead out connector (replacing radial default), maintaining IP65 protection, compatible with A/B/C series

Fan cooling 1326AB-MOD-G3/G4 G3=C2E/C4B motor rear fan; G4=C4B motor "saddle shaped" fan, increasing torque output by 35%

Cable 1326 CPxx (power supply), 1326 CFx (commutation) standard length 15-100 feet, ES version up to 300 feet, only compatible with 1391B-ES/DES driver

Performance parameters and characteristic curves

1. Core performance parameters (typical model examples)

Motor model: Continuous locked rotor torque (lb in/N · m), peak locked rotor torque (lb in/N · m), rated speed (rpm), rotor moment of inertia (lb in s ²/kg-m ²), rated power (kW), continuous current (A)

1326AB-A1G 16/1.8 48/5.4 5000(1391B)/6000(ES/DES) 0.004/0.0005 0.9 4.5

1326AB-B2E 102/11.5 204/23.0(1391B)/279/31.5(ES/DES) 3000(1391B)/4000(ES/DES) 0.05/0.006 2.5 16.4

1326AB-C3E 310/35.0 568/64.1 3000(1391B)/4000(ES/DES) 0.22/0.024 7.5 49.1

1326AB-C4B 420/47.5 840/94.8(1391B)/989/111.8(ES/DES) 1600(1391B)/2000(ES/DES) 0.29/0.032 5.6 38.2

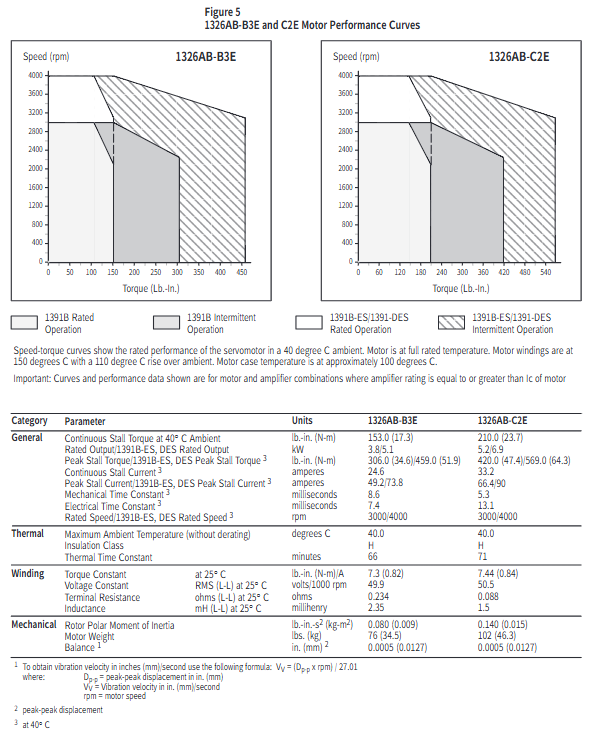

2. Interpretation of speed torque curve

Curve type: divided into two curves: 1391B controller (regular mode) and 1391B-ES/DES (enhanced mode). The peak torque of the former is twice the continuous torque, while the latter can reach three times, and the highest speed is increased (such as A1G from 5000rpm to 6000rpm).

Operating area:

Rated operating zone: Both the motor and controller shall not exceed the RMS rated value, meeting the continuous operation requirements. The calculation formula is:

Torque (T pa=peak acceleration torque, T ss=steady-state torque, T pd=peak deceleration torque, T r=static torque)

Intermittent operation zone: suitable for acceleration and deceleration scenarios, with a duty cycle RMS torque ≤ rated torque to avoid overheating.

Installation and Dimensional Specifications

1. Mechanical installation requirements

Rail adaptation: The A/B/C series both support 35 × 7.5mm DIN rails (models 199-DR1, etc.). The top hook of the module is locked by rotation after being hooked in, and the grounding resistance should be ≤ 2 Ω (detected through the metal shell of the RS-232 port).

Axial load limit: Radial and axial loads must meet the bearing life requirements (B10 life of 15000 hours). Taking the C series as an example, the maximum radial load at 500rpm is 900lbs, and the axial load is 600lbs (refer to the load curve in Figure 8 for details).

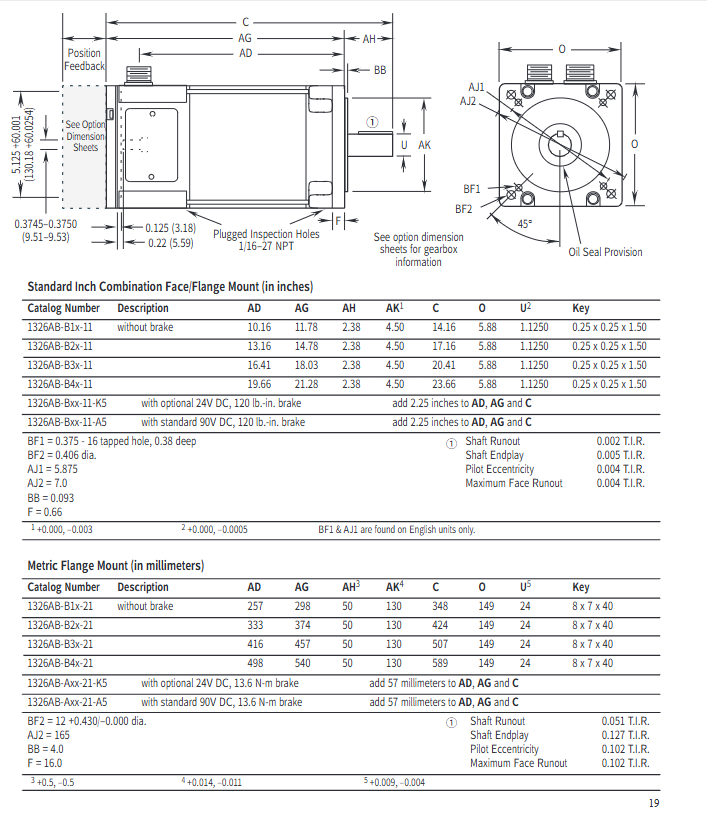

2. Key dimensions (taking imperial flanges as an example)

Series length AD (inches) flange diameter O (inches) shaft diameter U (inches) keyway size (inches) with brake length increase (inches)

A1x-11 8.69 4.38 0.625 0.19×0.19×1.38 2.25

B2x-11 13.16 5.88 1.125 0.25×0.25×1.50 2.25

C3x-11 17.38 7.63 1.375 0.31×0.31×2.00 2.5

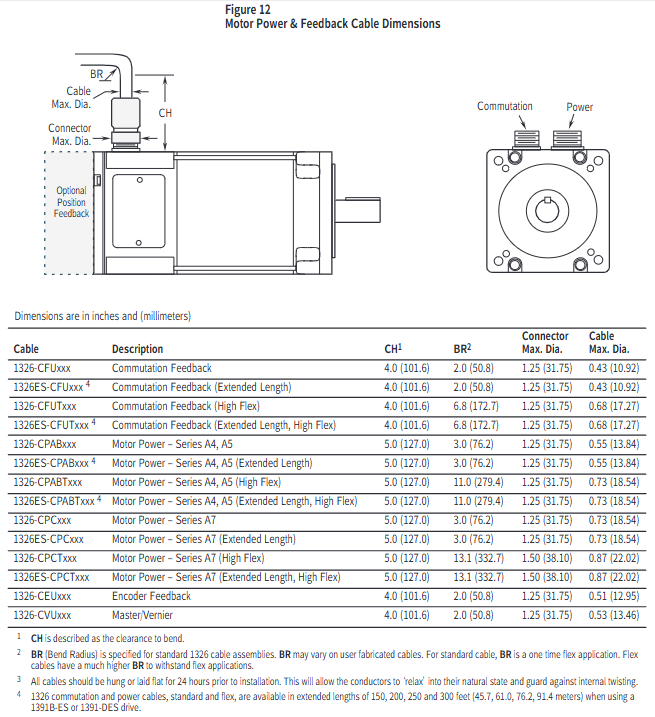

3. Cable installation

Wiring specifications: Power cables (1326-CPABxx) are wired by color (red=PWR, white=CAN_S, blue=CAN_L, black=COM, bare wire=shielded); The feedback cable (1326 CFUxx) needs to distinguish between the switching signal and the encoder signal, and the shielding layer should be grounded separately.

Bending radius: The standard cable has a single bending radius of ≥ 2 inches (50.8mm), and the high flexibility drag chain cable has a bending radius of ≥ 6.8 inches (172.7mm). Before installation, it needs to be laid flat for 24 hours to release internal stress.

Application Selection and Calculation Guide

1. Selection steps

Determine the speed requirement: Calculate the peak speed of the motor based on the mechanical transmission ratio (for example, if the lead screw is 2 inches and the slide table speed is 400ipm, then the motor speed=400/2=200rpm, with a 20% margin to be reserved).

Calculate continuous torque: Taking screw drive as an example based on load type (friction, cutting force, etc.):

T m=6.28 × e 1 × e 2 × G.R. (W 1 × u+Trust) × Lead × 1.1 (W 1=slide weight, u=friction coefficient, Lead=lead screw, e 1/e 2=lead screw/gearbox efficiency, G.R.=transmission ratio, 1.1 is safety factor)

Verify peak torque: Considering acceleration and deceleration requirements, the calculation formula is:

Peak torque (J total=total moment of inertia, Δ rpm=speed change, t accel=acceleration time, T l=load torque)

Match motor parameters: Ensure that the peak speed of the motor is ≥ the calculated value, the continuous torque is ≥ the required value, and the total inertia is ≤ 5 times the motor inertia (to avoid response lag).

2. Typical application calculation example (screw drive)

Known conditions: slide weight of 500lbs, friction coefficient of 0.05, lead screw of 1 inch, transmission ratio of 1:1, efficiency of 0.9, acceleration time of 0.5 seconds, and speed from 0 to 1000rpm.

Continuous torque calculation: T m=6.28 × 0.9 × 1 (500 × 0.05) × 1 × 1.1 ≈ 5.0 lb in, select A1G (16 lb in) to meet the demand.

Peak torque calculation: Total inertia=sliding table inertia (386500 × (6.281) 2 ≈ 0.0033 lb in ²)+motor inertia (0.004)=0.0073, peak torque=9.6 × 0.5 0.0073 × 1000+0 ≈ 1.52 lb in, which is less than the A1G peak value of 48 lb in and meets the requirements.

Maintenance and safety precautions

Thermal protection: The maximum temperature of the motor winding is 150 ° C (H-class insulation). When the ambient temperature exceeds 40 ° C, it needs to be de rated for use (for every 10 ° C increase, the torque is de rated by 10%).

Brake usage: The brake is only used for static load holding (switching ≤ 90 times per hour) and cannot be used for positioning or frequent braking. The 24V DC brake requires the user to provide their own power supply (0.88-1.2A).

Protection level: IP65 is only applicable to situations with shaft seals and no external feedback/fan. Additional protection is required in humid or corrosive environments.

Troubleshooting: When triggering the thermal switch, it is necessary to first investigate issues such as excessive load and poor heat dissipation. Resetting requires waiting for the winding temperature to drop to 90-100 ° C.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923