K-WANG

Allen Bradley 1753 Series GuardPLC 1800 Controller

Allen Bradley 1753 Series GuardPLC 1800 Controller

Core framework and scope of application of the document

The document follows the logical mainline of "security standards → hardware awareness → installation and practical operation → functional verification", covering the entire process of controller preparation to later testing. The applicable product is GuardPLC 1800 safety controller, which is a programmable electronic system (PES) with safety certification. It integrates 24 digital inputs, 8 digital outputs, 2 high-speed counters, 8 analog inputs, and 4 GuardPLC Ethernet communication interfaces. It complies with SIL 3 (IEC 61508) and PLe (ISO 13849-1 Cat.4) safety levels and is suitable for scenarios with extremely high requirements for fault tolerance and risk control, such as mechanical safety control and process safety monitoring.

Core content sorting

(1) Controller Overview and Safety Standards

Core functions and hardware composition

Function integration: Supports the separation of secure and non secure communication. Secure communication is connected to distributed I/O, other GuardPLC controllers, or OPC servers through 4-channel 10/100BaseT RJ45 interfaces (GuardPLC Ethernet protocol); Non secure communication is achieved through 3-channel 9-pin D-shell interfaces (RS-485, etc.) to realize functions such as Modbus slave and Profibus DP slave (only 1753-L32BBBP-8A).

Hardware structure: including DIN rail installation buckle, 24V DC power interface, I/O plug-in terminal, high-speed counter interface, Ethernet interface (top 2+bottom 2), reset button (received design, anti misoperation), status indicator lights (24V DC, RUN, ERROR, PROMess, etc.). The controller is of open design and needs to be installed in a closed enclosure (protection level ≥ IP20).

Safety and Environmental Regulations

Operation qualification: It must be operated by trained professionals who are familiar with the application requirements of safety related PES (such as EN ISO 13849-1, IEC 61508).

Static electricity protection: The controller is sensitive to static electricity. When operating, it is necessary to touch a grounded object to discharge and wear a grounding wristband. It is forbidden to touch the pins or components of the circuit board. When idle, it should be stored in anti-static packaging.

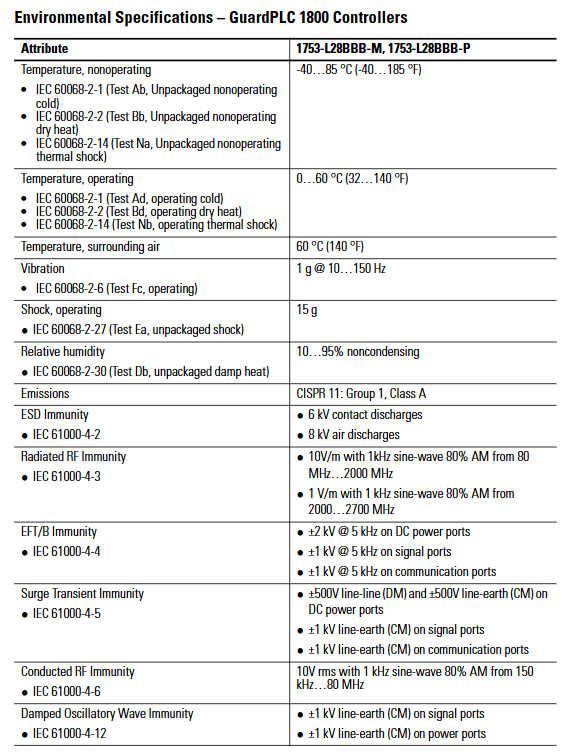

Environmental requirements:

Working temperature: 0 ° C~60 ° C (32 ° F~140 ° F), storage temperature: -40 ° C~85 ° C (-40 ° F~185 ° F);

Relative humidity of 10%~95% (no condensation), pollution level 2 industrial environment, altitude ≤ 2000 meters (no need to downgrade);

It needs to be installed inside a metal casing with flame retardant properties (flame propagation level 5VA/V0, etc.), and the interior can only be accessed through tools to avoid the risk of electric shock.

(2) Installation process: from fixing to grounding

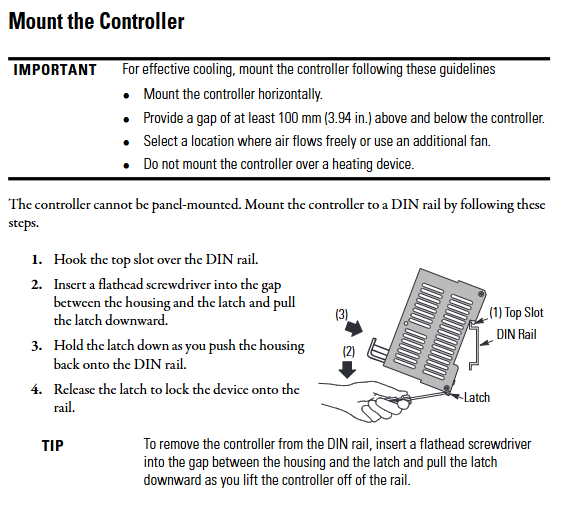

DIN rail installation (only supports DIN rail, not panel installation)

Align the guide rail: Hang the top slot of the controller on the IEC standard DIN rail (such as 199-DR1), and it is recommended to use galvanized yellow chromium steel material for the guide rail (to ensure good grounding). Fix it every 200mm (7.8 inches) and install end anchors.

Locking device: Insert a flathead screwdriver into the gap between the housing and the buckle, pull the buckle downwards, push the controller towards the guide rail, and release the buckle to complete the locking process; Reverse the operation during disassembly.

Heat dissipation requirements: Install horizontally with a minimum gap of 100mm (3.94 inches) above and below, avoiding installation above heating equipment to ensure air circulation. Install a fan if necessary.

Grounding configuration

Double grounding: The controller is functionally grounded through DIN rail, and protective grounding must be connected through a dedicated grounding screw (with grounding symbol) in the upper left corner of the housing. The grounding wire must comply with local electrical regulations (refer to Industrial Automation Wiring and Grounding Guidelines 1770-4.1).

Guide rail requirements: It is prohibited to use guide rails made of aluminum, plastic, or other materials that are prone to corrosion or have poor conductivity, in order to avoid equipment failure or safety risks caused by poor grounding.

(3) Wiring Specification: Power Supply and I/O Circuit

Power wiring (24V DC)

Power requirements: An isolated power supply that complies with EN 60950/UL 1950 must be used, and it must be of the SELV (Safety Extra Low Voltage) or PELV (Protection Extra Low Voltage) level. The SELV voltage should be ≤ 30V rms/42.4V peak/60V DC, and the PELV must be connected to a protective grounding.

Wiring details: Connect the power supply through a 4-pin terminal, and ensure that L+(positive pole) and L - (negative pole) are correctly connected (without reverse polarity protection, as reversing the connection may damage the controller); The terminal supports a maximum of 2.5mm ² (14 AWG) wire and requires external 10A delay fuse protection; The L+and L - terminals are internally connected, and 24V DC Daisy chain power can be supplied to other devices through the remaining terminals.

Current characteristics: The maximum current consumption of the controller is 9A (including I/O load), and it requires 1A for its own operation. The remaining 8A can be used to power input/output devices.

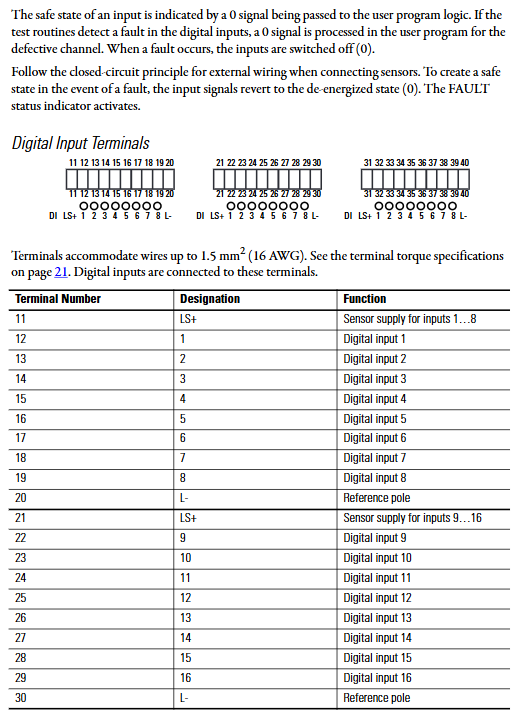

Digital input wiring (24 channels, divided into 3 groups, with 8 channels per group)

Power supply and circuit: Each set of inputs is powered by an independent LS+(24V DC sensor power supply with short-circuit protection), and the input signal is referenced to L - (common terminal); Supports dry contact input or sensors with independent power supply (such as safety light curtains), and the negative pole of the external power supply needs to be connected to the controller L.

Safety design: Following the "closed circuit principle", the input signal is reset to "0" by default in case of a fault (power-off safety state); If an input fault (such as a short circuit) is detected, the input signal of the fault channel is forced to be "0", and the FAILT indicator light is activated.

Terminal specifications: The terminal supports 0.13-1.3mm ² (26-16 AWG) wires, with a tightening torque of 0.51N · m (4.5 lb · in). Terminals 11-20, 21-30, and 31-40 correspond to three sets of input LS+, input channel, and L-。

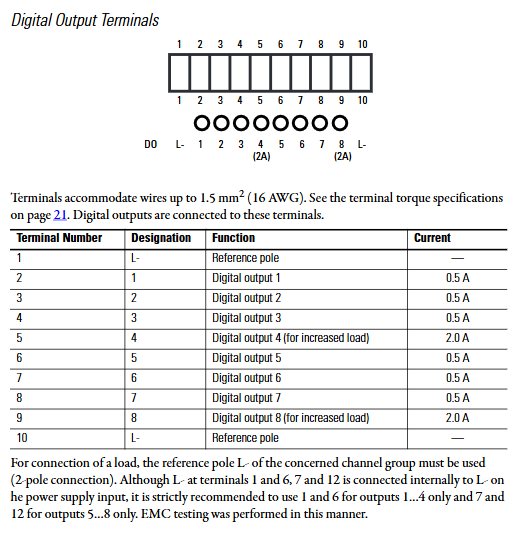

Digital output wiring (8 channels)

Load capacity:

At channels 1-3 and 5-7, the maximum current per channel is 0.5A at 60 ° C;

Channels 4 and 8 (heavy-duty channels): 1A/channel at 60 ° C, 2A/channel at 50 ° C;

The total output current is ≤ 7A, with a minimum load of 2mA per channel. When overcurrent occurs, the output is turned off and automatically restored after troubleshooting.

Wiring requirements: The output circuit should use L - (terminal 1/10) of the corresponding group as the common terminal. Even if L - is internally connected, it is still recommended to use it according to the group (EMC test verification configuration); It is recommended to parallel 1N4004 diodes to suppress interference voltage for inductive loads.

Safety feature: In the event of a fault, all outputs are forced to shut down (in a power-off safety state), and there is no monitoring of the external circuit. However, a short circuit will trigger a fault indication.

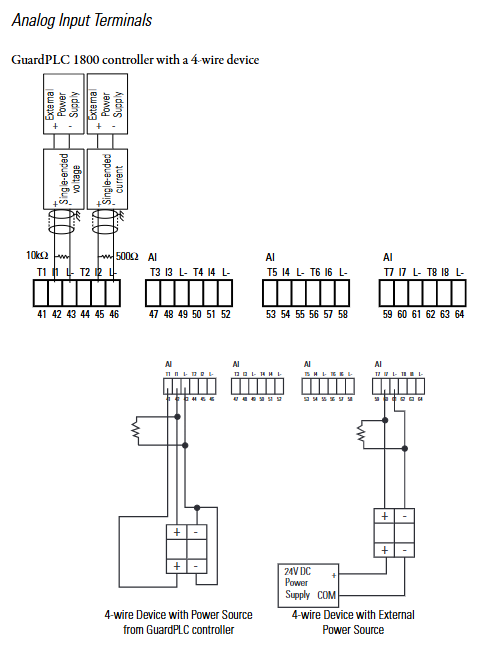

Analog input wiring (8 channels, single polarity)

Signal type:

Voltage signal: 0~10V DC (requires an external 10k Ω shunt resistor);

Current signal: 0~20mA (requires an external 500 Ω shunt resistor);

Unused analog inputs need to be short circuited (connected to I and L -) to avoid interference.

Wiring specifications: Use shielded twisted pair cables, with both ends of the shielding layer grounded, and a maximum wiring length of 300m (984 feet); Terminals 41-64 correspond to transmitter power supply (T1-T8), signal input (I1-I8), and reference terminal (L -) with 8 inputs, supporting 0.13-1.3mm ² (26-16 AWG) wires.

High speed counter wiring (2 channels, 24 bits)

Function configuration: Each counter includes three terminals: A (counting input), B (direction input), and Z (reset input). It supports 5V/24V DC signals and has a maximum input frequency of 100kHz. It can be used as a counter or a 3-digit Gray code decoder.

Wiring requirements: Use shielded twisted pair cables, with both ends of the shielding layer grounded, and a maximum wiring length of 500m (1640 feet); Terminals 65-72 correspond to A1/B1/Z1/L - and A2/B2/Z2/L - of the 2-channel counter, and unused inputs do not need to be terminated.

(4) Communication connection: Separation of secure and non secure

Secure Communication (GuardPLC Ethernet)

Interface configuration: 4 RJ45 interfaces (top 2+bottom 2), connected internally through an Ethernet switch, supporting automatic negotiation (full/half duplex, 10/100Mbps), can use direct or crossover Ethernet cables, supporting star/line topology (network loops are prohibited).

Application scenario: Connect distributed security I/O, other GuardPLC controllers, OPC servers (requiring 1753-OPC modules) and programming software, with MAC address attached to the bottom RJ45 interface.

Non secure communication (3-channel 9-pin D-shell interface)

Interface function:

COMM1:RS-485, Supports Modbus slave (1753-L32BBBM-8A) or Profibus DP slave (1753-L32BBBP-8A);

COMM2: Reserved (TBD);

COMM3:RS-485, Support GuardPLC ASCII protocol;

Pin definitions: Pin 3 (RxD/TxD-A) and Pin 8 (RxD/TxD-B) are for data transmission and reception, Pin 5 (DGND) is for data ground, Pin 6 (VP) is for 5V power supply, and Pin 4/9 are for control signals.

Default parameters: IP address defaults to 192.168.0.99, system ID (SRS) defaults to 60000, and custom parameters can be recorded through transparent labels (note not to obstruct ventilation holes).

(5) Fault diagnosis and status indication

Reset button operation

Trigger scenario: When forgetting the online password for programming software and unable to obtain IP address/SRS, use an insulated needle to press the reset button (top received hole, 4-5cm from the left edge).

Reset process: Press and hold the button for 20 seconds, while restarting the controller (power off and then on). After resetting, only the default account is retained, and the IP address/SRS is restored to its default value; Restore the parameters modified before or after resetting during the next power on (depending on whether they have been modified).

Controller self-test

Power monitoring: Alarm 1 is triggered when the 24V DC voltage is below 19.3V (recording internal variables), alarm 2 is triggered when the voltage is below 15.4V (preparing to shut down), and automatic shutdown is triggered when the voltage is below 13.0V.

Temperature monitoring: A warning is triggered when the temperature is between 60 ° C and 70 ° C, a main alarm is triggered when the temperature is above 70 ° C, and the main alarm is released when the temperature drops to 64 ° C and 54 ° C (the warning is retained). When the temperature drops below 54 ° C, it returns to normal.

Interpretation of status indicator lights

|Indicator light | Status | Meaning|

|24V DC | Always on | 24V DC power supply is normal|

|| Off | No power supply or power failure|

|RUN | Always on | Running normally (executing programs, processing I/O, communication, self-test)|

|| Blinking | STOP mode (no program executed, output reset, triggered by emergency stop)|

|| OFF | VNet STOP mode (see ERROR light)|

|ERROR | Always on | Hardware failure (controller, I/O, counter), system software error, watchdog timeout (out of cycle), software restart required|

|| Off | No errors|

|PROGress | Always on | Uploading new controller configuration|

|| Blinking | Upload new operating system to non-volatile ROM|

|FAULT | Always on | Program logic error, configuration failure, operating system damage|

|| Flashing | ROM write error, I/O failure|

|OSL | Blinking | Emergency Operating System Loader Activation|

|BL | Blinking | Boot loader unable to load operating system|

|Ethernet (green/yellow) | Green constant light | Full duplex; Huang Changliang: Connection establishment|

|| Green flashing | Conflict; Yellow flashing: Interface activity|

(6) Technical specifications and certification

Core parameters

Memory: Maximum 250KB user program memory, 250KB application data memory;

Safety performance: minimum watchdog time of 10ms, minimum safety time of 20ms;

Insulation voltage: 50V DC (basic insulation) between I/O and Ethernet, Ethernet and DC power supply;

Protection level: IP20 (controller body), size 257 × 114 × 66mm (width × height × depth), weight 1.2kg.

Safety certifications: UL Listed (USA&Canada), CE (EMC Directive 2004/108/EC), C-Tick (Australia), T Ü V certification (SIL 3/IEC 61508, PLe/ISO 13849-1).

Key considerations and supplementary resources

Compliance verification: Wiring must comply with local electrical regulations (such as NEC, IEC), and safety circuit design must meet corresponding safety level requirements to avoid reducing safety performance due to improper configuration.

EMC protection: Shielded wires are required for analog inputs, high-speed counters, and Ethernet, with both ends of the shielding layer grounded; Install a filter in the power circuit to reduce the impact of electromagnetic interference on safety functions.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923