K-WANG

Tektronix 2440 digital oscilloscope

Tektronix 2440 digital oscilloscope

Document Overview

This document is a quick reference guide for the Tektronix 2440 digital oscilloscope, first printed in 1987. Its core positioning is a "practical operation manual" - it does not replace the complete "2440 Operation Manual" (070-6695-00), but focuses on step-by-step operation and menu logic analysis of the instrument's core functions. The document structure is centered around the "front control panel buttons" and follows the process of "basic power on → functional modules → data output". It covers 19 key functional chapters, including 19 hardware schematics and menu screenshots, clarifying the hierarchical menu relationship, parameter adjustment range, and typical application scenarios of each button. It is suitable for engineers who have already understood the basic principles of oscilloscopes and need to quickly get started, especially focusing on practical guidance for characteristic functions such as dual trigger systems, multi-mode acquisition, GPIB communication, etc.

Core parameters and hardware layout of the instrument

2.1 Core Technical Parameters

Detailed Explanation of Key System Parameters

Vertical system channel configuration with 2 analog channels (CH1/CH2), supporting ADD/MULT/XY combination mode

Sensitivity range 2mV/div -5V/div (equivalent to 20mV/div -50V/div after 10X probe adaptation)

Coupling method AC/DC/GND, AC coupling and 50 Ω terminal mutually exclusive

The bandwidth limit is adjustable in three levels: 20MHz/100MHz/FULL, and can be extended to 300MHz in Repet mode (only repeating waveforms)

Horizontal system time base range A/B dual time base, 5ns/div -100ms/div, ≤ 100ms/div automatically switches to ROLL mode

Trigger positions 1/8, 1/4, 1/2, 3/4, 7/8, a total of 5 preset positions, supporting GPIB custom positions

Trigger system trigger type A/B dual trigger, supporting Edge/Video/Word/Pulse trigger (Video/Word requires optional)

Coupling method DC/AC/Noise Reject/LF Reject/HF Reject, adapted to different signal noise environments

There are a total of 5 collection modes for the collection system: Normal/Average/Explore/Repet/Save On Delta

Average frequency 2/4/8/16/32/64/128/256 times optional

The storage system has four independent reference memories (REF1-REF4), which support waveform freezing and calling

The GPIB communication interface supports Talk/Lite mode and is compatible with printer/plotter data output

2.2 Core Layout of Front Control Panel (Divided by Function)

(1) Display control area

INTENSITY knob: continuously adjusts the brightness of 4 types of screen elements (reading readout, waveform display, A INTEN area, scale texture), and defaults to controlling the last selected element;

SELECT button: Switch brightness adjustment object (read out) ↔ display);

STATUS/HELP button: Press once to display the "Instrument Status Menu" (including trigger status, acquisition mode, parameter configuration), press again to enter HELP mode (operate any button to display the corresponding function description).

(2) Quick operation area

AUTO SETUP button: One click optimization of vertical/horizontal/trigger parameters to ensure stable signal display (default activation of CH1, no switching for selected channels);

PRGM button: Enter the "AutoStep Sequencer" menu, support storing/calling 50-200 panel settings, and can name 40 test processes;

MEASURE button: activates waveform parameter extraction function, supports continuous measurement or single snapshot;

OUTPUT button: Configure GPIB communication parameters, control data transmission/printing/drawing.

(3) Vertical control zone

CH1/CH2 independent control:

POSITION knob: adjust the vertical position of the channel waveform;

VARIABLE button: Unlock non calibration adjustment (CH1 affects ADD mode reading, CH2 does not affect);

VOLTS/DIV knob: adjusts sensitivity (2mV-5V/div), automatically adapts to 1X/10X/100X/1000X Tek encoding probes;

COUPLING/INVERT button: switch coupling mode, reverse waveform polarity;

BANDWIDTH button: Select the bandwidth limit gear.

MODE button: Switch vertical mode (CH1/CH2/ADD/MULT/YT: XY), ADD and MULT are mutually exclusive. In XY mode, CH1 is the X-axis and CH2 is the Y-axis.

(4) Horizontal control zone

A/B button: Switch between A/B time base mode (A is the regular time base, B is the delayed scan);

A INTEN button: Activate A enhancement mode, SEC/DIV knob switches to control B time base;

A AND B SEC/DIV knob: adjust the time base (5ns-100ms/div);

POSITION knob: Adjust the horizontal position of the waveform and control the CH1 (X-axis) position in XY mode.

(5) Trigger and Delay Control Zone

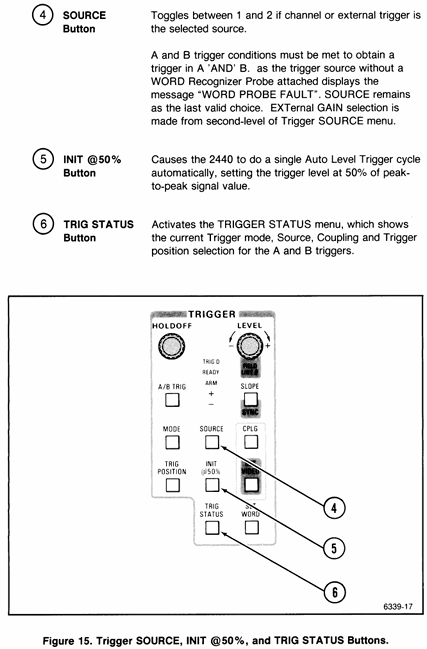

A/B TRIG button: Switch A/B trigger menu, share trigger slope, mode, source selection and other controls;

TRIGGER LEVEL knob: adjust trigger level;

Initiat @ 50% button: automatically sets the trigger level to 50% of the signal peak to peak value;

DELAY area: EVENT and TIME buttons, CURSOR/DELAY knobs (adjust delay parameters or cursor position).

(6) Collection and Storage Control Area

ACQUIRE button: start/restart acquisition, switch acquisition mode;

SAVE button: Freeze waveform, enter storage menu;

Display REF button: Call the reference waveform (REF1-REF4) to switch the horizontal position adjustment mode.

Basic operation process (from startup to signal display)

3.1 Startup and self-test process

Power on preparation: Connect the 3-pin power supply (ensure grounding), press the POWER button below the front panel;

Self check process: The instrument automatically performs a power on self-test, and the screen displays "RUNNING SELF TEST". After completion, the prompt disappears;

Self check passed: directly enter oscilloscope mode, CAL/DIAG menu displays "PASS";

Self check failure: Enter extended diagnostic mode, the screen displays the fault area, press MENU OFF to exit and enter oscilloscope mode (temporary use when the fault does not affect measurement);

Preheating waiting: Within 10 minutes after starting up, the CAL/DIAG menu displays "NOT WARMED UP", during which it is not recommended to perform calibration or high-precision measurements;

Parameter initialization:

Connect probe: 10X probe connected to CH1 BNC, probe tip connected to instrument CALIBRATION circuit( 2.5V@1kHz Square wave), ground wire connected to oscilloscope ground;

Call initial settings: Press PRGM SETUP → press the bezel key (no label button at the bottom of the screen) to select "Initiat PANEL", load default parameters (CH1 activation, 1V/div, 1ms/div, AUTO LEVEL trigger, 1M Ω DC coupling);

Verification channel: Confirm that the CH1 VOLT/DIV reading is displayed in the upper left corner of the CRT. If it is not displayed, press Vertical MODE → Select CH1.

3.2 Signal Capture and Optimization

Signal connection: Connect the probe tip to the measured signal and the ground wire to the signal reference ground (shorten the length of the ground wire as much as possible to reduce noise);

Automatic optimization: Press the AUTO SETUP button, and the instrument will automatically adjust the vertical sensitivity, horizontal time base, and trigger level, displaying 2-5 signal cycles;

Manual fine-tuning:

Vertical adjustment: If the waveform is truncated, turn the VOLTS/DIV knob clockwise (to reduce sensitivity); If the waveform is too small, adjust counterclockwise;

Horizontal adjustment: If the signal period is displayed too much/too little, adjust the SEC/DIV knob (fast time base displays less period, slow time base displays more period);

Trigger optimization: If the trigger is unstable, press Initiat @ 50% or manually turn the TRIGGER LEVEL knob to ensure that the trigger point is on the edge of signal stability.

Detailed analysis of core functions

4.1 Vertical system (signal amplitude control)

4.1. Key functional operations

Coupling mode selection: Press the COUPLING button on CH1/CH2 to cycle through AC/DC/GND:

DC coupling: retaining the AC+DC components of the signal (such as measuring ripple with DC offset);

AC coupling: Block the DC component and only display the AC signal (such as measuring the amplitude of the AC signal);

GND coupling: Disconnect signal input and display ground reference line (used for calibrating vertical position);

ADD/MULT mode usage:

ADD mode: CH1 and CH2 signals are superimposed, and the CH1 VARIABLE knob can adjust the amplitude of CH2 signal to cancel interference (such as eliminating power noise);

MULT mode: The CH1 and CH2 signals are multiplied, and the result is automatically reduced by 5.12 times to adapt to the screen range (such as measuring power signals);

Bandwidth restriction application: When high-frequency noise interference occurs, press the BANDWIDTH button to select 20MHz/100MHz restriction to filter out high-frequency noise (such as selecting 20MHz bandwidth when measuring 50Hz power signals).

4.1.2 Common problem troubleshooting

No waveform display: Check if the coupling mode is GND → switch to AC/DC; Check if the probe is securely connected → Re plug and unplug the probe;

Waveform truncation: VOLTS/DIV sensitivity is too high → adjust clockwise to increase the gear;

High waveform noise: switch to AC coupling → enable bandwidth limitation → shorten the length of the probe ground wire.

4.2 Horizontal System (Signal Timing Control)

4.2.1 A/B dual time base operation

A time base (regular mode): Press the A button to activate, adjust the time base with SEC/DIV knob, and when ≤ 100ms/div, the AUTO trigger mode will automatically switch to ROLL mode (waveform scrolling display from left to right, suitable for slow signals);

B time base (delayed scan):

Press the B button to activate, and switch the SEC/DIV knob to control the B time base;

Adjust the A time base to display the complete signal, and adjust the B time base to amplify the signal locally (such as amplifying the rising edge of the pulse);

Press the A INTEN button, and the screen will display the A enhanced area (the local signal amplified by the B time base) for easy observation of details.

4.2.2 Trigger position adjustment

Press the TRIG POSITION button to cycle through the trigger positions (1/8, 1/4, 1/2, 3/4, 7/8):

Trigger position is 1/8: More display signals after triggering (such as observing the attenuation process after pulse triggering);

Trigger position is 7/8: more display of pre trigger signals (such as capturing interference pulses before triggering);

GPIB customization: Set non preset positions without screen underline identification through GPIB commands.

4.3 Trigger System (Stable Signal Display Core)

4.3.1 A/B Dual Trigger System Logic

A trigger is the "main trigger" (the initial condition for initiating data collection), and B trigger is the "delayed trigger" (further filtering of signals after the main trigger). It supports a combination of "main trigger+delayed event/time" trigger and is suitable for capturing signals with specific temporal relationships.

4.3.2 Detailed Explanation of Trigger Modes

Trigger Mode Function Description Applicable Scenarios

AUTO LEVEL automatically adjusts the trigger level to ensure stable display. Even when the signal disappears, regular signals (sine wave/square wave) can still be scanned for quick debugging

Stable triggering when the AUTO signal is present, and stopping scanning when the signal disappears requires clarification of the scene where the signal is present or absent

NORMAL is only triggered when the triggering conditions are met, and when there is no signal, the screen blank captures rare events (such as occasional pulses)

SINGLE SEQ single acquisition, automatically enters SAVE mode after completion to capture single transient signals (such as relay action)

4.3.3 Special triggering function (requires optional support)

Video trigger:

Press the SET Video button to enter the A Video COUPLING menu;

Select synchronization mode (Field 1/Field 2/ALT/TVLINE), only valid for interlaced signals;

Adjust TVLINE to select the trigger wire number, and CLAMP ON/OFF controls whether to clamp the synchronization signal;

Word trigger:

Press the SET WORD button to enter the Word Recognizer configuration menu;

Select encoding (OCT/HEX), clock signal (CLK), trigger word (such as 0x1234);

Only supports Word recognition probes, displaying "WORD PROBE FAULT" when there is no probe.

4.4 Delay function (capturing specific signals after triggering)

4.4.1 Delay by Events

Function: After A triggers, wait for a specified number of B triggering events before completing the collection;

Operation steps:

Press the DELAY → EVENT button to activate the event delay;

Rotate the CURSOR/DELAY knob to set the event count (such as 10, which is the 10th B event triggered for collection after A is triggered);

Press the TRIG STATION button and confirm that the trigger status is "ARMED";

Applicable scenario: Capture the Nth data bit after the master clock in bus communication.

4.4.2 DELAY by TIME

Function: After triggering A, delay the specified time before completing the collection, supporting switching between "main delay" and "Δ delay";

Operation steps:

Press the DELAY → TIME button to activate the time delay;

Rotate the CURSOR/DELAY knob to set the delay time (e.g. 100 μ s);

Press the Δ TIME button to switch to Δ delay mode and adjust the delay time increment;

Applicable scenario: Capture fault signals that occur after a delay in triggering (such as voltage attenuation after power is turned off).

4.5 Acquisition System (Signal Sampling and Processing)

4.5.1 Comparison of 5 acquisition modes

Working principle of collection mode, key parameters, applicable scenarios

Normal sampling, taking 1 sample point every interval - stable signal (sine wave/square wave), pursuing real-time performance

Average: After multiple acquisitions, take the average value to reduce random noise. The average number of times to reduce random noise is 2-256 for signals containing noise (power ripple, sensor output)

Envelope records the maximum/minimum sample points collected multiple times, generating envelope numbers: 1-256 times/CONT Observe the range of signal amplitude fluctuations (such as RF signal amplitude modulation)

Repet is only effective for repetitive waveforms, extending bandwidth to 300MHz - high-speed repetitive signals (clock signals, high-frequency pulses)

Save On Delta real-time comparison between live waveform and reference envelope, automatically stores reference memory when exceeding the limit: REF1-REF4 long-term monitoring occasional anomalies (such as ripple mutation, pulse distortion)

4.5.2 Acquisition mode switching and restart conditions

Switching method: Press the ACQUIRE button and select the mode and related parameters (such as average frequency and envelope frequency) from the menu;

Restart condition: The following actions will restart Average/Envelope collection:

Vertical/horizontal mode change;

Channel VOLTS/DIV or vertical position adjustment;

Change in input coupling method;

Trigger mode or slope change;

Press MENU OFF to close the menu;

Delay parameter change (only in Average mode).

4.6 Storage System (waveform saving and calling)

4.6.1 Waveform Storage (SAVE Button)

Storage objects: CH1/CH2/ADD/MULT waveforms, delayed waveforms;

Operation steps:

Press the SAVE button to enter the SAVEREF SOURCE menu;

Select storage source (such as CH1);

Enter the SAVEREF DESTIATION menu and select the storage target (REF1-REF4);

Confirm storage, the screen displays the prompt "STORED";

Special function: Press the STACK REF button, and the waveform will be automatically stored in the preset order to REF1-REF4 (such as CH1 → REF1, CH2 → REF2).

4.6.2 Waveform Call (Display REF Button)

Calling steps:

Press the PLAY REF button to enter the PLAY REF menu;

Select the reference memory to be called (REF1-REF4), and display "EMPTY" when there is no waveform;

After calling, the horizontal position of the reference waveform can be adjusted according to HORIZ POS REF;

XY mode call: Select XYREF and call the XY combination waveform from REF1-REF4.

4.7 Measurement system (waveform parameter extraction)

4.7.1 Overview of Measurement Functions

Measurement type: 17 parameters, covering amplitude, time, and special categories:

Amplitude parameters: Peak to peak value (Pk Pk), maximum value (Max), minimum value (Min), mean (Mean), RMS, overshoot (Ovrsht), undershoot (Undrsht), area (Area);

Time parameters: Period, Freq, Rise, Fall, Width, Duty, Delay;

Special parameters: Events, Slope, 1/TIME (reciprocal frequency);

Measurement methods: continuous measurement (MEAS TYPE), single snapshot (SNAPSHOT).

4.7.2 Typical Measurement Operations (Taking "Rise Time" as an Example)

Preparation work: Ensure stable signal triggering, no obvious noise on the rising edge, and horizontal time base adaptation (such as measuring ns level rise time using 5ns/div);

Enter the measurement menu: press the Measure button;

Select measurement type: Press MEAS TYPE → check "RISE" in the parameter matrix;

Set measurement standards (default 10% -90%, customization requires SETUP → LEVEL):

Rotate the knob to adjust the levels of DISTAL (corresponding to 10%) and PROXIMAL (corresponding to 90%);

Press the MARK ON button, and the screen will display measurement markers (X-shaped) indicating the 10% and 90% level positions;

Reading result: The screen measurement reading area displays the rise time value (such as 28.4ns);

Single snapshot: Press SNAPSHOT → select the target channel (such as CH1), and the instrument captures all parameters of the current waveform and freezes the display.

4.8 GPIB Communication and Data Output (OUTPUT Button)

4.8.1 GPIB parameter configuration

Enter the configuration menu: press OUTPUT → SETUP;

Core parameter settings:

Mode: T/ONLY (only sends data), L/ONLY (only receives commands), T/L (sends and receives), DEVICES (connects to printer/plotter), OFF BUS (turns off GPIB);

Address (ADDR): Set GPIB address (such as 3) to match the controller address;

Terminator (TERM): EOI (default) LF/EOI, Ensure consistency with the receiving device;

Encoding (ENCDG): ASCII, RP (positive integer), RI (default), positive integer data should be set to RP;

Device adaptation: Press DEVICES → select device type (HPGL plotter, THINKJET printer) → set paper size (US: A4), whether to display scale (GRAT ON/OFF).

4.8.2 Data Transmission and Status Monitoring

Sending data: Press the TRANSMIT/RINT button to send the current waveform (CURVE), panel settings (PRGM), or measurement results to an external device;

Status monitoring: Press OUTPUT → STATUS to check the GPIB status (such as address, mode, error messages), with the undersigned item indicating the current effective setting;

Troubleshooting: If data transmission fails, check:

Is the GPIB cable connection secure;

Whether the address, terminator, and code are consistent with the receiving device;

Does the device support the selected data format (such as WHOLE WFMS/ARTIAL WFMS).

Safe operation and precautions

5.1 Safety prerequisites

It is necessary to refer to the "Operator Safety Summary" in the 2440 Operation Manual, with a focus on:

Input voltage limit: maximum 400Vpk for 1M Ω coupling, maximum 5Vrms for 50 Ω coupling;

Probe usage: Only use Tek recommended probes (such as 10X passive probes), and the probe ground wire must not be connected to mains power;

Grounding requirements: The instrument must be grounded through a 3-pin power supply and disconnection of the grounding pin is prohibited;

Do not use in damp or explosive environments, and do not plug or unplug probes or signal cables with power on.

5.2 Maintenance and Calibration

Signal Path Compensation (SPC): If the environmental temperature difference exceeds 10 ℃ or once a week, follow Utility → Calibration → Signal Path, which takes about 10 minutes to ensure low range (≤ 5mV/div) measurement accuracy;

Probe compensation: Every time the probe or channel is replaced, a CALIBRATOR circuit needs to be connected( 2.5V@1kHz )Adjust the compensation hole of the probe to a straight square wave;

Calibration prompt: If the extended diagnosis displays "UNCALD", perform a SELF CAL after the instrument is preheated. If it still fails, contact a professional for calibration. At this time, the instrument may use the previous calibration parameters, and the measurement accuracy may decrease.

5.3 Common troubleshooting

Troubleshooting steps for possible causes of fault phenomena

No waveform display 1. Channel not activated; 2. The coupling method is GND; 3. Unstable triggering; 4. The brightness setting is too low. 1. Press MODE to activate the corresponding channel; 2. Switch the coupling to AC/DC; 3. Press AUTO SETUP or Initiat @ 50%; 4. Adjust the INTENSITY knob

Unstable triggering: 1. Improper triggering level; 2. The coupling method is not adapted; 3. Excessive signal noise. 1. Manually adjust TRIGGER LEVEL; 2. Enable Noise Reject coupling; 3. Switch to Average acquisition mode

Abnormal measurement result: 1. waveform truncation; 2. Inappropriate adaptation of time base/sensitivity; 3. Measurement standard error: 1. Adjust VOLTS/DIV to avoid waveform truncation; 2. Adapt to time base/sensitivity; 3. Adjust the measurement level by pressing MEASURE → SETUP

GPIB communication failure: 1. Address/code mismatch; 2. Cable malfunction; 3. Equipment not ready. 1. Check GPIB parameters; 2. Replace the cable; 3. Confirm that the external device is in a ready state

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923