K-WANG

Tektronix MSO4000/DPO4000 series digital fluorescence oscilloscope

Tektronix MSO4000/DPO4000 series digital fluorescence oscilloscope

Document Overview

This manual is the official guidance document for the Tektronix MSO4000 (mixed signal) and DPO4000 (digital fluorescence) series oscilloscopes, covering 2-channel (such as MSO4032/DPO4032) and 4-channel (such as MSO4054/DPO4104) models, with a core focus on high-end electronic design and debugging (such as embedded systems, automotive electronics, communication equipment). The document structure includes 11 core chapters and 1 appendix, catering to the complex analysis needs of novice operators and professional engineers, highlighting the ability to synchronously collect and decode "analog+digital" mixed signals, as well as professional measurement functions extended through application modules.

Core parameters and characteristics of the product

1. Model classification and key parameters

Series models, analog channels, digital channels, bandwidth, maximum sampling rate, record length, typical applications

MSO4000 MSO4032 2 2 16 350MHz 2GS/s 10M point mixed signal debugging (such as I2C/SPI)

MSO4000 MSO4054 4 4 16 500MHz 2GS/s 10M point multi-channel timing analysis

MSO4000 MSO4104 4 4 16 1GHz 5GS/s 10M high-speed signal capture (such as USB 2.0)

DPO4000 DPO4034 4-350MHz 2GS/s 10M point analog signal waveform analysis

DPO4000 DPO4104 4-1GHz 5GS/s 10M point high bandwidth signal (such as RF) testing

2. Core Features

Mixed signal analysis (MSO series exclusive): 16 digital channels and analog channels are synchronously collected, supporting MagniVu mode (60.6ps timing resolution), which can capture narrow pulses and edge jitter of digital signals;

High speed signal processing: The highest sampling rate for all channels is 5GS/s, with a recording length of 10M points. It supports a refresh rate of 50000 waveforms per second and can quickly capture transient anomalies;

Flexible triggering and decoding: 8 types of triggering types cover edge, pulse width, logic mode, and bus (such as I2C/CAN/RS-232), supporting sequence triggering (A event+delayed B event);

Professional Expansion Module: Extend functionality through modules such as DPO4PWR (Power Quality/Switching Loss Measurement) and DPO4USB (USB 2.0 Decoding) to meet vertical domain requirements;

Convenient data management: Supports CompactFlash, USB storage, Ethernet remote control (e * Scope), USBTMC protocol for direct connection to PC.

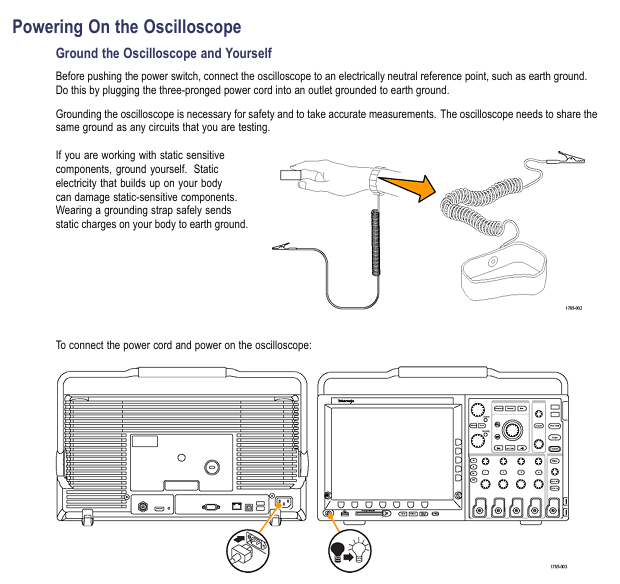

Safety operation standards

1. Electrical safety

Input voltage limit:

1M Ω input: maximum 400Vpk (DF ≤ 39.2%), 250V RMS (below 130kHz), 20dB/decade attenuation above 130kHz;

50 Ω input: maximum 5V (peak to peak value ≤± 20V), automatically switches to 1M Ω protection when overvoltage occurs;

Probe safety:

P6139A passive probe: CAT II 300V RMS, CAT III 150V RMS, with 20dB/decade attenuation for frequencies above 2.5MHz;

Logic probe P6516: maximum input ± 15V, threshold accuracy ± (100mV+3% threshold);

Grounding requirements: A 3-pin power cord must be used, and the equipment chassis must be reliably grounded. Floating operation is prohibited; During measurement, the reference end of the probe should only be connected to the signal ground and should not be connected to the mains ground.

2. Operation taboos

Do not use in damp (>90% RH) or explosive environments, and avoid liquid contact with equipment;

Before connecting/disconnecting the probe, the signal source must be disconnected first, and live plugging and unplugging are prohibited;

Before disassembling the application module or CF card, it is necessary to shut down and avoid short circuiting the battery or probe contacts.

Basic operation process

1. Probe operation and calibration

Key requirements for operation type steps

Passive probe compensation (P6139A) 1. Probe connected to CH1, set to 10X; 2. Connected to PROBE COMP( 2.5V@1kHz ); 3. Autoset; 4. Adjust the compensation hole to a flat square wave without overshoot/depression, and re compensate every time the channel is changed

Signal Path Compensation (SPC): 1. Disconnect all probes and preheat for 20 minutes; 2. Press 【 Utility 】 → 【 Calibration 】 → 【 Signal Path 】; 3. Wait for 10 minutes and display "Pass". If the environmental temperature difference exceeds 10 ℃ or once a week, ensure low range (≤ 5mV/div) measurement accuracy

Firmware Upgrade 1. Download firmware. img from the official website to the USB root directory; 2. Turn off the oscilloscope and plug it into a USB port, and it will automatically upgrade when turned on; 3. After upgrading, verify the version (Utility ->Config ->About). During the upgrade, it is forbidden to power off or unplug the USB. It is recommended to use a blank USB to avoid file conflicts

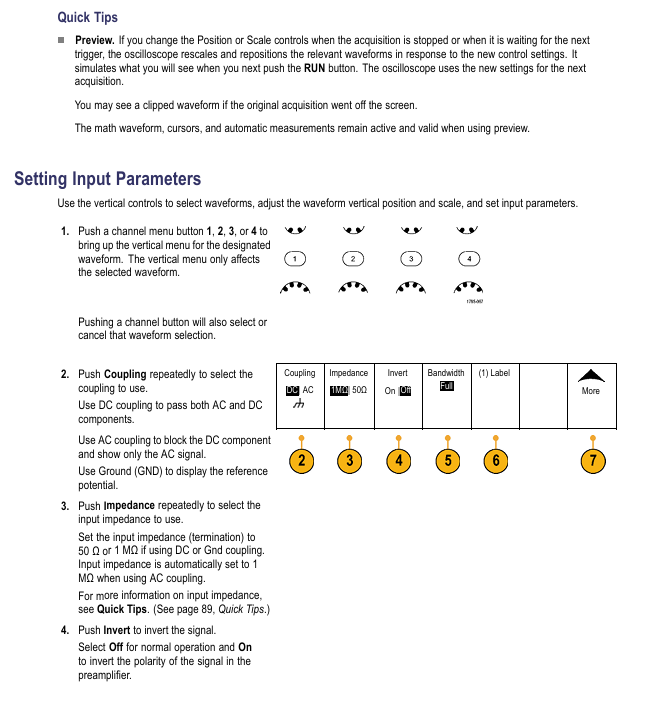

2. Channel settings

Simulation channel:

Press the CH1-CH4 button to activate the channel, press 【 Coupling 】 to select DC/AC/GND (AC coupling blocks DC, GND displays reference ground);

Select 1M Ω/50 Ω (50 Ω only DC/GND coupling, maximum 1V/div) according to the 'Impedance' button;

Select Full/250MHz/20MHz (20MHz is used to filter out high-frequency noise) according to [Bandwidth];

Digital Channel (MSO Series):

Press 【 D15-D0 】 to activate the digital channel, and press 【 On/Off 】 to select D7-D0/D15-D8;

Set the threshold according to [Thresholds] (such as TTL 1.4V, 3.3V CMOS 1.65V);

Press MagniVu → On to enable 60.6ps timing resolution (for precise measurement of digital edges).

Core functional system

1. Collection system (5 modes)

The working principle of the collection mode is applicable to different scenarios

Sample: equidistant sampling, 1 point/interval regular stable signal (sine wave/square wave), strong real-time performance

Peak Detect records the maximum/minimum value of each interval to capture narrow spikes (≥ 1ns), effective at low-speed time base (≥ 5 μ s/div)

Hi Res (High Resolution) calculates the average value of each interval sample to reduce noise and improve the resolution of low-frequency signals

Envelope records the maximum/minimum waveform collected multiple times, observing the range of signal amplitude changes (such as power ripple fluctuations)

Average: After multiple acquisitions, the average (4/16/64/128 optional) suppresses random noise, and averaging 128 times can significantly improve the signal-to-noise ratio

2. Trigger system (8 types)

Trigger type key parameters applicable scenarios

Edge slope (rising/falling), coupling (DC/LF Reject/HF Reject), stable display of conventional signals (such as clock, square wave)

Pulse Width condition (>/</=/≠), width (33ns-10s), polarity capture of abnormal pulses (such as narrow pulse interference in communication links)

Logic channel status (High/Low/Don't Care), clock edge multi-channel logic combination triggering (such as I2C SDA=1 and SCL=0)

Setup&Hold: Clock channel, data channel, violation time detection bus timing violation (such as insufficient setup time between FPGA and memory)

Bus type (I2C/CAN/RS-32, etc.), trigger conditions (address/data/error), decode and trigger bus specific events (such as Write operation for I2C address 0x7F)

3. Measurement and analysis functions

Automatic measurement: Supports 11 types of parameters, with a maximum of 8 displayed simultaneously. The key measurements are as follows:

Measurement type definition accuracy conditions

The amplitude of the reciprocal signal of the first cycle of frequency (Freq) is ≥ 1div, without any truncation

Rise Time: The time signal with an amplitude of 10% -90% has no noise on the rising edge and is horizontally scale adapted (such as 10ns/div)

Peak to peak value (Pk Pk) full waveform maximum minimum value waveform without truncation, vertical scale adaptation (such as 100mV/div)

FFT spectrum analysis:

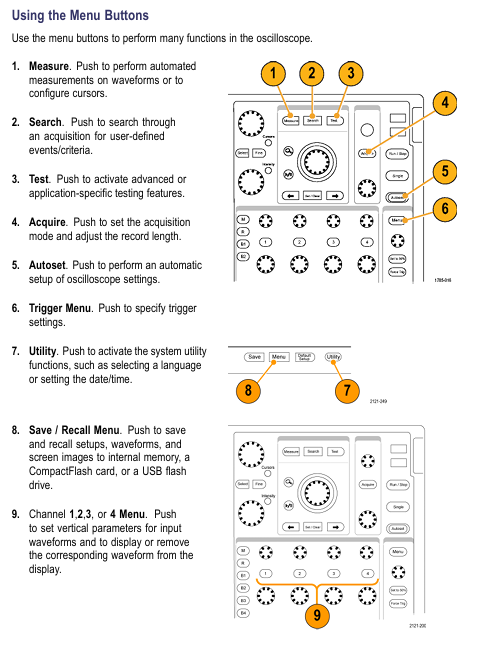

Press 【 Math 】 → 【 FFT 】, select the source channel (such as CH1);

Press [Window] to select the window function (Rectangular: optimal frequency resolution; Blackman Harris: excellent amplitude accuracy);

Select dBV RMS/Linear RMS according to 'Vertical Units' (dBV RMS is suitable for multi frequency comparison);

Histogram analysis:

Press 【 Measure 】 → 【 Waveform Histograms 】, select Vertical (voltage)/Horizontal (time);

Set the boundary of the rectangular frame (Horizon. Limits/Vert. Limits) and add statistical measurements (such as σ 1/σ 2/σ 3);

Vertical histograms are used to measure noise (the smaller the σ value, the lower the noise), while horizontal histograms are used to measure jitter.

Data Management and Communication

1. Storage medium operation

Storage content operation steps, file name format, 1MB capacity, approximate storage quantity

Waveform file 1. Press 【 Save/Recall 】 → 【 Save Waveform 】; 2. Select [To File] → [Internal File Format (. ISF)]; 3. Edit file name tekXXXX_Cx.ISF (x=1-4) 18 (10M point waveform)

Set file 1. Press 【 Save/Recall 】 → 【 Save Setup 】; 2. Select [To File] or [To Setup 1-10]; 3. Confirm to save 250 units of tekXXXXX.SET

Screen Image 1. Press 【 Save/Recall 】 → 【 Save Screen Image 】; 2. Select format (. BMP/. TIF/. PNG); 3. Press [OK Save] tekXXXXX.BMP 16

2. Remote communication settings

Ethernet(e*Scope):

Connect the Ethernet cable to the rear panel LAN port, press 【 Utility 】 → 【 I/O 】 → 【 Ethernet Network Settings 】;

Set DHCP to On (automatically obtain IP) or Off (manually set IP);

Input the oscilloscope IP into the PC browser and access the e * Scope interface to control the oscilloscope;

USBTMC (PC Control):

Connect the Rear panel USB Device port of the oscilloscope to the PC using a USB cable;

Install VISA driver (official website download), and send SCPI command through LabVIEW/Excel on the PC end;

Application modules and case studies

1. Optional application modules

Module model, function, applicable scenarios

DPO4PWR power analysis: power quality, switching losses, harmonics, safe working area (SOA) power supply design (such as AC-DC converter efficiency testing)

DPO4USB 2.0 decoding: low-speed/full speed bus triggering and decoding, supporting PID error detection and USB device debugging (such as troubleshooting USB disk enumeration failures)

DPO4AUTO Automotive Bus: CAN/LIN triggering and decoding, supporting frame type/ID filtering for automotive electronics (such as CAN bus communication faults)

DPO4VID video trigger: HDTV (such as 1080i), custom video (3-4000 lines), video equipment (such as monitoring camera signal testing)

2. Typical troubleshooting cases

Case 1: Abnormal RS-232 bus

Connection: CH1 is connected to the TX line, CH2 is connected to the RX line, press 【 B1 】 → 【 Bus 】 → 【 RS-232 】;

Set parameters: baud rate 9600, data bit 8, parity None, stop bit 1;

Trigger: Press 【 Trigger Menu 】→【 Type 】→【 Bus 】→【 Trigger On 】→【 Tx Data 】, set the trigger data to 0x55;

Analysis: Press 【 Search 】 → 【 Bus 】 → 【 Tx Data 】, mark all 0x55 frames, and use Wave Inspector to view the timing of abnormal frames;

Case 2: Relay arc capture

Parameter setting: CH1 is connected to both ends of the relay, Vertical scale 100V/div,Horizontal scale 10μs/div;

Trigger: Press 【 Trigger Menu 】→【 Type 】→【 Edge 】→【 Slope 】→【 Rising 】, set the trigger level to 50V;

Capture: Press [Single] to trigger when the relay is disconnected, observe the peak generated by the arc (amplitude>200V);

Optimization: Zoom in on the peak area (Zoom x 10) and measure the peak width with the cursor (approximately 50ns).

Appendix and Support

1. Key performance parameters

System parameter description

Analog channel DC gain accuracy ± 1.5% (1M Ω path), ± 3% (50 Ω path), with a 0.1% decrease per ℃ above 30 ℃

The timing resolution of the digital channel (MSO) is typically 121ps, while in MagniVu mode it is 60.6ps

Trigger system edge trigger sensitivity DC coupling: 1div (DC-10MHz), 2div (100-1GHz)

Display system screen resolution 1024 × 768 pixels (10.4-inch XGA)

2. Probe compatibility

Probe model, type, bandwidth, maximum voltage, applicable scenarios

P6139A (standard) passive voltage 500MHz CAT II 300V RMS conventional analog signal measurement

P6516 (MSO standard) logic probe DC-100MHz ± 15V digital channel signal acquisition

TCP303 (optional) current probe DC-15MHz 150A RMS high current AC/DC measurement

P5200 (optional) differential probe DC-200MHz 1000V RMS high-voltage differential signal (such as motor drive)

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923