+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

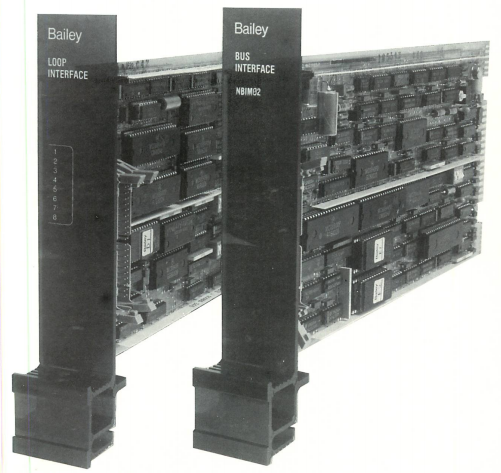

ABB Bailey* network90 Loop Interface/Bus Interface(LIM/BIM)

ABB Bailey* network90 Loop Interface/Bus Interface(LIM/BIM)

ABB Bailey* network90 Loop Interface/Bus Interface(LIM/BIM)

WARNING notices as used in this manual apply to hazards or unsafe practices which could result in severe personal injury

CAUTION notices apply to hazards or unsafe practices which could result in minor personal injury or property damage.

or death.

NOTES highlight procedures and contain information which assists the operator in understanding the information con.

tained in this manual.

WARNING

INSTRUCTION MANUALS

DO NOT INSTALL, MAINTAIN OR OPERATE THIS EQUIPMENT WITHOUT READING, UNDERSTANDING AND FOLLOW.

ING THE PROPER Babcock & Wilcox, Bailey Controls INSTRUCTIONS AND MANUALS, OTHERWISE INJURY OR

DAMAGE MAY RESULT.

RADIO FREQUENCY INTERFERENCE

BE EXERCISED WITH REGARD TO THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT IN'THE AREA AROUND

MOST ELECTRONIC EQUIPMENT IS INFLUENCED BY RADIO FREQUENCY INTERFERENCE (RFI). CAUTION SHOULD

EQUIPMENT CAUTIONING AGAINST THE USE OF PORTABLE COMMUNICATIONS EQUIPMENT.

SUCH EQUIPMENT. PRUDENT PRACTICE DICTATES THAT SIGNS SHOULD BE POSTED IN THE VICINITY OF THE

POSSIBLE PROCESS UPSETS

MAY UPSET THE PROCESS BEING CONTROLLED. SOME PROCESS UPSETS MAY CAUSE INJURY OR DAMAGE.

MENT CONTROLLED BY THIS PRODUCT.ADJUSTING OR REMOVING THIS PRODUCT WHILE IT IS IN THE SYSTEM

MAINTENANCE MUST BE PERFORMED ONLY BY QUALIFIED PERSONNEL AND ONLY AFTER SECURING EQUIP.

AVERTISSEMENT

MANUELS D'OPERATION

NE PAS METTRE EN PLACE, REPARER OU FAIRE FONTIONNER CE MATERIEL SANS AVIOR LU, COMPRIS ET SUIVI

LES INSTRUCTIONS REGLIMENTAIRES DE Babcock & Wilcox, Bailey Controls TOUTE NEGLIGENCE A CET EGARD

PURRAIT ETRE UNE CAUSE D'ACCIDENT OU DE DEFAILLANCE DU MATERIEL

PERTURBATIONS DE LA FREQUENCE RADIOPHONIQUE

LA PLUPART DES EQUIPEMENTS ELECTRONIQUES SONT SINSIBLES AUX PERTURBATIONS DE LA FREQUENCE

PORTATIF, LA PRUDENCE EXIGE QUE LES PRECAUTIONS A PREDRE DANS CE CAS SOIENT SIGNALEES AUX

RADIO. DES PRECAUTIONS DEVRONT ETRE PRISES LORS DE L'UTILISATION DE MATERIEL DE COMMUNICATION

ENDROITS VOULOUS DANS VOTRE USINE.

PERTES PROCEDE RENVERSEMENTS

L'ENTRETIEN DOIT ETRE ASSURE PAR UN PERSONNEL QUALIFIE ET EN CONSIDERATION DE L'ASPECT

SECURITAIRE DES EQUIPEMENTS CONTROLES PAR CE PRODUIT. L'ADJUSTEMENT ET/OU L'EXTRACTION DE CE

PRODUIT LORSQUI'IL EST INSERE A UN SYSTEME ACTIF PEUT OCCASIOINNER DES A-COUPS AU PROCEDE CON-

BLESSURES,

TROLE. SUR CERTAINS PROCEDES, CES A-COUPS PEUVENT EGALEMENT OCCASIONNER DES DOMMAGES OU

NOTICE

The information contained in this document is subject to change without notice.

Bailey Controls Company, its affiliates, employees, and agents, and the authors of and contributors to this publica-

and fitness for a particular purpose), for the accuracy, currency, completeness, andior reliability of the information

tion specifically disclaim all liabilities and warranties, express and implied (including warranties of merchantability

ment selected in whole or part with the user of/or in reliance upon information contained herein. Selection of materials

contained herein and/or for the fitness for any particular use and/or for the performance of any material and/or equip-

and/or equipment is at the sole risk of the user of this publication.

This document contains proprietary information which is protected by copyright. All rights are reserved. No part of

this document may be photocopied or reproduced without the prior written consent of Bailey Controls Company.

General

Installation - gives step-by.step procedures for

preparing the LIM/BIM'pair for installation in

The Loop and Bus Interface Modules(LIM/BIM) pro-

the PCU.

vide the principal communication interface between

NETWORK 90 Process Control Units and the Plant

Operation - provides the user with normal,

Communication Loop (PCL). Information is passed

everyday operating instructions.

over the Loop to other nodes. A node can be a Pro-

cess Control Unit (PCU),Management Command

Troubleshooting - explains possible error

System (MCS), Operator Interface Unit (OIU),Plant

situations and correctivemeasures; also

Loop Gateway(PPG) or Computer Interface Unit (CIU).

includes service/replacement information.

A maximum of 63 nodes, in any combination, can be

on the Loop.

How to Use this Manual

The basic function of the BIM is to gather data

from modules and transfer it to the LIM. The basic

Read the introductory material first. Then, proceed to

function of the LIM is to examine the data and

the Theory of Operation section to get a fundamen-

transmit it to the assigned destination on the Loop.

tal understanding of how the modules work. Next,

Detailed theory of LIM/BIM operation is covered in the

read the Installation section. This should be read

Theory of Operation section of this document.

thoroughly, and all preparatory steps performed,

before putting the modules into operation. After

This document is divided into the following

installing the modules, read the Operation section to

sections:

find out what to look for in the normal and abnormal

operating modes. Refer to the Troubleshooting sec.

tion if any abnormal situations occur after putting the

Theory of Operation - provides an in-depth view

modules into operation.

of how the LIM/BIM pair work.

Glossary

Common Database

Data shared by LIM/BIM pairs on the Plant Loop.

Exception Report

Information update generated when a point change is greater than a speci-

fied significant amount.

Frame

Valid string of bytes on the Plant Loop.

Node

Any drop on the Loop; can be a Management Command System, Operator

Interface Unit, Computer Interface Unit, Plant Loop Gateway or Process

Control Unit.

Packing

The process of grouping multiple Exception Reports into one message.

Plant Communication Loop

The unidirectional highway for serial data shared by all nodes on the Loop.

Polling Rate

The time interval that the BIM checks the modules for Exception Reports.

Receive Data

Data received by destination PCU.

Synchronization Time

The time it takes for internal circuitry to readjust when a module goes into or

comes out of bypass.

Transmit Data

Data sent by one PCU to another.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

51

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923