K-WANG

Bently Nevada 3300 XL 8mm Proximity Sensor System

Bently Nevada 3300 XL 8mm Proximity Sensor System

Core positioning and composition of the product

1. Core functions

Based on the principle of eddy current induction, a voltage signal proportional to the distance between the probe tip and the conductive surface is output, which can simultaneously measure static position (such as radial/axial position of the shaft) and dynamic vibration (such as vibration of rotating equipment). It also supports Keyphasor signal reference and speed measurement, mainly used for state monitoring of fluid film bearing equipment.

2. System composition

The entire system consists of three parts, and each component supports complete interchangeability without the need for separate matching or bench calibration:

3300 XL 8mm probe: core sensing component responsible for collecting distance signals;

3300 XL extension cable: connects probe and preamplifier, 1-meter system does not require extension cable;

3300 XL Proximitor Sensor: processes probe signals and outputs standard voltage, supporting multiple installation and communication scenarios.

Core advantages of the product

1. High compatibility and interchangeability

Backward compatibility: 3300 XL 8mm components (electrical+physical) can be interchanged with non XL series 3300 5mm/8mm components to adapt to old system upgrades; However, when used in combination, system performance may be limited by the specifications of non XL components.

Flexible adaptation: When the installation space is limited and an 8mm probe cannot be used, it can be replaced with a 3300 series 5mm probe (refer to document 141605); If a narrow side view probe is required, the 3300 NSv system can be used (refer to document 147385).

2. Strong environmental adaptability

Structural durability: The probe adopts patented TipLoc molding technology (the probe tip is more firmly combined with the body), CableLoc design (75lbf/330N tensile strength), 8mm probe coil packaging is thicker, and the resistance to physical damage is stronger;

Protection and anti pollution: FluidLoc cable is optional to prevent oil and other liquids from leaking through the interior of the cable; The preamplifier has high immunity to radio frequency interference (RFI/EMI) and can meet EU CE certification without the need for special shielded conduits;

Wide temperature range and resistance to extreme conditions: Standard probe operating temperature -52~+177 ℃ (-62~+350 ℉), extended temperature range (ETR) probe tip can reach 218 ℃ (425 ℉), ETR cable can reach 260 ℃ (500 ℉), while resisting 50g impact and 30g vibration (10Hz~2kHz).

3. Convenient installation and maintenance

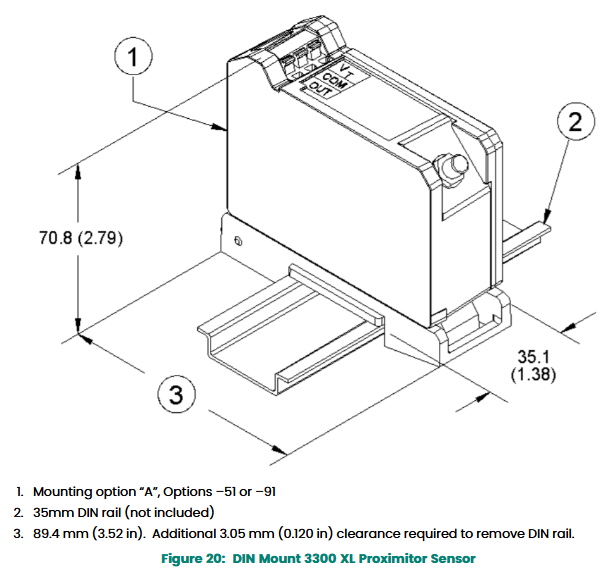

Flexible installation: The preamplifier supports high-density DIN rail installation or traditional panel installation (4-hole installation position compatible with the old model), without the need for additional isolation plates;

Simplified connection: The components use gold-plated ClickLoc connectors, which only require finger tightening (indicated by a "click" when in place), without the need for specialized tools; It is recommended to install a connector protective cover (or use accompanying silicone tape, but not recommended for use in turbine oil environments).

Key technical parameters

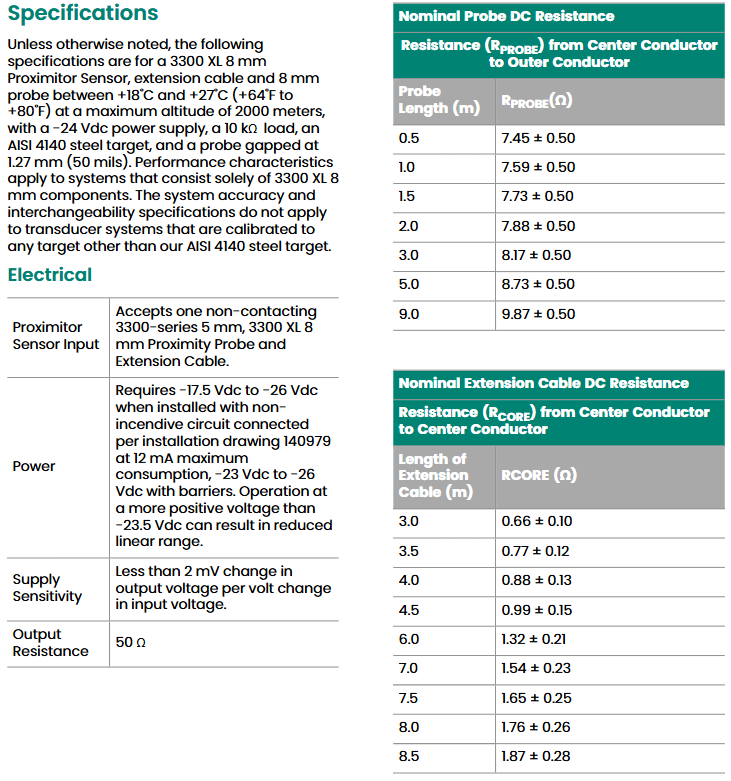

1. Electrical performance (standard conditions:+18~+27 ℃, altitude of 2000 meters, -24Vdc power supply, AISI 4140 steel target)

Parameter category specific specifications

Linear range of 0.25~2.3mm (10~90mil), corresponding to output voltage of -1~-17Vdc

Incremental scaling factor (ISF) standard 5/1-meter system: 7.87V/mm (200mV/mil) ± 5%; 9-meter system/ETR system: ± 6.5% (0~45 ℃)

Linear Deviation (DSL) standard 5/1-meter system: ± 0.025mm (± 1mil); 9-meter system/ETR system: ± 0.038mm (± 1.5mil)

Supply voltage -17.5~-26Vdc (with safety barrier -23~-26Vdc), maximum power consumption 12mA

Frequency response 0~10kHz,+0/-3dB (supports up to 305 meters/1000 feet of on-site wiring)

2. Mechanical and physical parameters

Key specifications of components

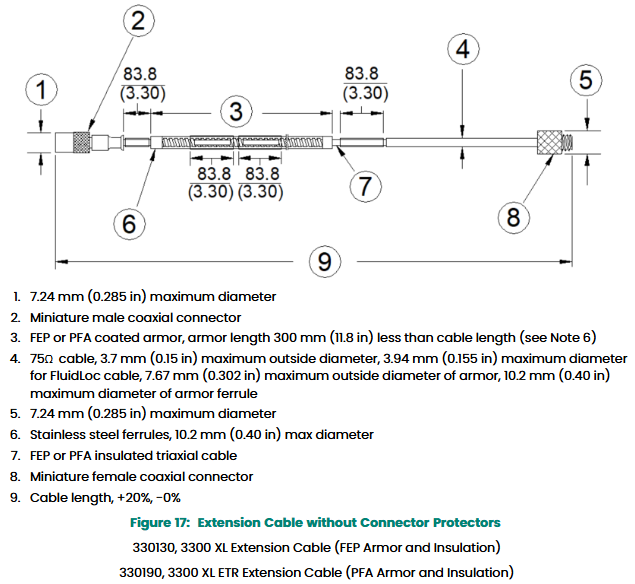

Probe material: PPS plastic at the tip of the probe, AISI 303/304 stainless steel casing; Cable: 75 Ω three-axis FEP/PFA insulation

Extended cable capacitance 69.9pF/m; 3-meter cable resistance: core wire 0.66 Ω± 0.10 Ω, outer conductor 0.20 Ω± 0.04 Ω

The material of the preamplifier is A308 aluminum; Weight 246g (8.67oz); Installation torque: maximum probe housing 11.2~33.9N · m

The typical total weight of the system is 0.7kg (1.5lb); Probe 323g/m, extension cable 34g/m (with armor 103g/m)

Applicable scenarios and compliance certification

1. Target application areas

Mainly used in industrial scenarios that require monitoring the status of rotating equipment, including:

Energy: Wind turbines;

Heavy industry: steel, aluminum equipment;

Manufacturing: Pressure machines, metal forming equipment;

Special scenarios: testing and simulation systems, chemical equipment, robots.

2. Compliance and Security Certification

Specific standards and levels for certification types

Electromagnetic compatibility (EMC) complies with EN 61000-6-2 (industrial immunity) and EN 61000-6-4 (industrial emissions)

Functional safety SIL 2 (HFT=0), SIL 3 (HFT=1)

ATEX/IECEx hazardous area certification: II 1 G Ex ia IIC T4/T5 Ga (Zone 0), II 3 G Ex nA IIC T4/T5 Gc (Zone 2); cNRTLus:Class I Zone 0/2、Div 2

Environmental compliance complies with RoHS directive (2011/65/EU) and maritime certification (2019 classification society regulations)

Ordering Information (Core Model and Configuration)

The system components need to be ordered in combination with "probe+extension cable+preamplifier", and the core models and configuration rules are as follows:

1. Probe (divided into standard type/ETR type, armored/unarmored)

Probe Type Model Example Key Configuration Options (Part Number Encoding)

Standard British thread (3/8-24) 330101 (unarmored), 330102 (armored) A: length without thread (0.0~8.8 in, 0.1 in increments); B: Total length of the shell (0.8~9.6 inches, increments of 0.1 inches); C: Total length (0.5-9m); D: Cable type (01=standard with protective cover, 11=FluidLoc with protective cover)

Standard metric thread (M10 × 1) 330103 (unarmored), 330104 (armored) A: length without thread (0~230mm, 10mm increment); B: Total length of the shell (20-250mm, 10mm increments); C: Total length (0.5-9m); D: Cable type

ETR type (high temperature) 330191 (imperial), 330193 (metric) configuration rules are the same as the standard type, with temperature level raised to 218 ℃ (probe)/260 ℃ (cable)

2. Extension cable

Standard cable: model 330130-AAA-BB-CC, AAA=length (030=3m to 085=8.5m), BB=cable type (00=standard, 10=FluidLoc), CC=certified (05=CSA/ATEX/IECEx);

ETR cable: model 330190-AAA-BB-CC, with the same length options as the standard cable, and upgraded insulation material to PFA.

3. Pre processor

Model 330180-AA-BB, AA=total length and installation method (e.g. -50=5-meter panel installation, -91=9-meter DIN rail installation), BB=certification (05=CSA/ATEX/IECEx).

4. Common accessories

Installation bracket: 137491 (aluminum without threads), 137492 (aluminum with threads), 27474 (phenolic resin with threads, used for electrical isolation);

Testing tools: 148722-01 (test plug), 163356 (connector crimping tool kit);

Protective parts: 40113-02 (connector protective cover kit), 03200006 (silicone self-adhesive tape).

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923