+086-15305925923

K-WANG

Service expert in industrial control field!

Product

Article

NameDescriptionContent

Adequate Inventory, Timely Service

pursuit of excellence

Ship control system

Equipment control system

Power monitoring system

Current position:

新闻动态

newS

Brand

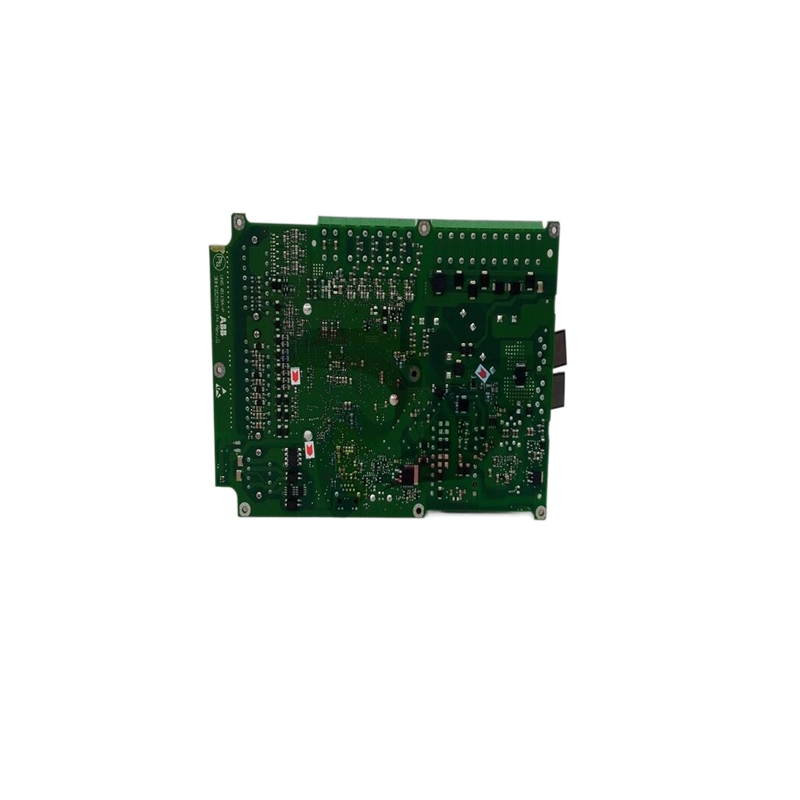

ABB 3HNA024871-001 ACU-01B Robot Controller

ABB 3HNA024871-001 ACU-01B Robot Controller

ABB 3HNA024871-001 ACU-01B Robot Controller

Continuous motor cable shield or enclosure for equipment on the motor cableTo minimize the emission level when safety switches, contactors, connection boxes or similar equipment are

installed on the motor cable between the drive and the motor:

– European Union: Install the equipment in a metal enclosure with 360 degree grounding for the shields of

both the incoming and outgoing cable, or connect the shields of the cables otherwise together.

– US: Install the equipment in a metal enclosure in a way that the conduit or motor cable shielding runs

consistently without breaks from the drive to the motor.

DCSLink wiring

The DCSLink is a 500 kBaud serial communication between drives and from drives to field exciters.

It is based on CAN hardware and using twisted cables.

The topology is a bus system.

Switched OFF nodes can remain in the bus and do not disturb the serial communication.

The function of the interface is predefined:

Communication to field exciter types DCF803, DCF804 and large field exciters using standard DCS880 modules.

Communication for 12-pulse operation, DCS880 to DCS880.

Cabling

Every bus device requires its own individual node number.

Only two physical ends are allowed for the bus system.

The termination resistance of 120 Ohm is selected for typical twisted pair cables. The cables must be

terminated at both ends. This is done using jumpers or switches inside the drives or field exciter.

Maximum total cable length is 100 m.

Preferred cable type: DEVICENET

Supplier: Helu Kabel, Germany; type 81910PUR

Belden, USA; type 3084A

Connecting a control unit at H7 and H8 power units

During installation the control unit needs to be connected with the power unit using fiber optic cables.

For a standard drive connect the fiber optic cables from the SDCS-DSL-H1x (control unit) to the

SDCS-OPL-H01(power unit).

The mains contactor is controlled via XSMC (X96) on the SDCS-OPL-H01 located in the power unit.

The current measurement using a scope is possible via X4.

Connecting according to the drawing below:

Technical data

Chapter overview

The technical data contain the technical specifications of the converter, e.g. the ratings, sizes and technical

requirements, provisions for fulfilling the requirements for CE and other markings and warranty policy.

Environmental Conditions

Note: If an FSPS-21 or FSO-21 module is used, the atmospheric pressure of the module is limited to 70 ... 106 kPa.

See manual FSPS-21 PROFIsafe safety functions module (3AXD50000158638) or FSO-21 Safety functions module

(3AXD50000015614).

System connections Environmental limit values

Voltage, 3-phase: 100 ... 1000 V acc. to IEC 60038 Permissible cooling air temp.

100 ... 690 V acc. to UL508c - at converter module air inlet: 0 ... +55°C

Voltage deviation: IEC: -10% +15% continuous; with rated DC current: 0 ... +40°C

±20% short-time (0.5 to 30 cycles) with different DC current: +30 ... +55°C

UL: ±10 % continuous; - Options: 0 ... +40°C

±15 % short-time (0.5 to 30 cycles) Relative humidity (at 5...+40°C): 5 ... 95 %, no condensation

Rated frequency: 50 Hz or 60 Hz Relative humidity (at 0...+5°C): 5 ... 50 %, no condensation

Static frequency deviation: 50 Hz ± 2 %; 60 Hz ± 2 % Change of the ambient temp.: < 0.5°C / minute

Dynamic: frequency range: 50 Hz ± 5 Hz; 60 Hz ± 5 Hz Storage temperature: -40 ... +55°C

df/dt: 17 % / s Transport temperature: -40 ... +70°C

Please note: Special consideration must be taken for voltage

deviation in regenerative mode.

Pollution degree (IEC/EN 61800-5-1)

The drive must be installed in clean

air according to enclosure classification. Cooling air must be clean, free

from corrosive materials and electrically conductive dust.2

Degree of protection Site elevation

Converter module and options IEC: IP 00; acc. to IEC/EN 60529 < 1000 m above M.S.L.: 100 %, without current reduction

(line chokes, fuses, field UL: open type acc. to UL 508c > 1000 m above M.S.L.: with current reduction

exciters, etc.):

Overvoltage category

(all inputs):

Protective class:

III acc. to IEC 60664-1

I acc. to IEC 61800-5-1

Permissible supply systems: IT, TN, TT (neutral earthed)

IT (corner earthed)

TT (corner earthed)

Paint finish

Converter module: Body RAL 7012

Cover RAL 9017 & RAL 9002

Sound pressure level and vibration North American Standards

In North America the system components fulfil the requirements of

the table below. Size Sound pressure level LP (1 m distance) Vibration

as module enclosed conv. as module

H1 55 dBA 68 dBA

3 mm, 2 - 9 Hz

1 g, 9 ... 200 Hz

H2 55 dBA 72 dBA

H3 60 dBA 78 dBA

H4 66 ... 70 dBA,

depending on

fan

77 dBA

H5 75 dBA 77 dBA

0,3 mm, 2 - 9 Hz

0,1 g, 9 ... 200 Hz

H6 70 dBA 78 dBA

H7 69 dBA 67 dBA

H8 82 dBA 80 dBA

Rated supply

voltage

Standards

Converter module Enclosed

converter

to 990 V UL 61800-5-1

Power Conversion Equipment

CSA C 22.2 No. 274-13

Industrial Control Equipment, Industrial Products

Available for converter modules

including field exciter units. Types

with UL mark:

• see DCS880-DCS800-DCS550 Certificate, UL, TÜV-SÜD NRTL

DCF505-DCF506-DCF80x Certificate, UL, TÜV-SÜD NRTL

TÜV SÜD is NRTL listed.

• or on request

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

51

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector