K-WANG

TEKTRONIX 4K/UHD Monitoring and Measurement Guidelines

TEKTRONIX 4K/UHD Monitoring and Measurement Guidelines

Background and 4K/UHD basic specifications

Tektronix's "4K/UHD Content Creation Guide" aims to address the technical pain points throughout the entire process of 4K/UHD content acquisition, storage, post production, and transmission. The core focus is on "how to ensure signal compliance and content quality through professional monitoring tools", and it is recommended to use Tektronix 8000 series waveform monitors/rasterizers as the core equipment.

4K/UHD core specifications

Category Details Key Parameters

Resolution movie level 4096 × 2160 pixels

Home grade (UHDTV1) 3840 × 2160 pixels

Enhanced technology with dynamic range support for HDR (high dynamic range) to enhance light and dark details

Color gamut supports ITU-R BT.2020 wide color gamut (wider coverage than BT.709)

Signal transmission high frame rate (50p/59.94p/60p) four link 3G-SDI

Low frame rate (23.98p-30p) HD-SDI

6 Core Challenges in 4K/UHD Content Creation

Challenge 1: Inter channel timing synchronization of Quad Link signals

The four link 4K/UHD signal consists of four independent SDI physical links. Due to differences in transmission paths (cable length, equipment delay), timing deviations are prone to occur, resulting in signal splicing errors.

Standard requirements:

According to SMPTE ST 425-5 standard, the inter channel delay at the output end of the device should be ≤ 400ns (approximately 29 clock cycles);

There is no unified standard for the receiving end, and users need to control the delay difference themselves. Tek 8000 series devices can tolerate a maximum of 1024 clock differences.

Monitoring and investigation:

Using Tek 8000 series patented Timing Display, compare the horizontal/vertical offset of Link B/C/D with Link A as a reference;

If a "Video Format Mismatch" error occurs, switch to "Single Link" mode and check if the formats (resolution, frame rate) of each link are consistent;

Check the specific delay value through "MEAS>Timing Display" and adjust the transmission path (such as replacing equal length cables).

Challenge 2: Video Payload Identifier (VPID) Monitoring

VPID (based on SMPTE ST 352 standard) is stored in the auxiliary data area for devices to quickly identify video formats (resolution, sampling rate, number of links, etc.), and is key to 4K/UHD format compatibility.

VPID structure and key fields:

VPID data consists of 5 core components: Ancillary Data Flag(ADF)、Data Identifier(DID=41h)、Secondary Data Identifier(SDID=01h)、 4 user data words (UDW1-4), checksum (CS), where:

Example of UDW Byte Core Function Key Values

UDW1 identification standard and link type 89h=SMPTE ST 425-5 (four link 3G-SDI), C0h=ST 2081-10 (single link 6G-SDI)

UDW2 image frame rate 2h=24/1.001fps, 5h=25fps, Ah=60/1.001fps

UDW3 sampling rate and color gamut 0h=4:2:2 (YCbCr), 2h=4:4:4 (RGB); 0h=BT.709、2h=BT.2020

UDW4 link number 01h=Link A, 41h=Link B, 81h=Link C, C1h=Link D

Monitoring tools and troubleshooting:

Video Session Display: Directly view the UDW1-4 bytes of each link's VPID. Normal four links require UDW1-3 to be consistent, and UDW4 should be 01h/41h/81h/C1h in the order of A → D;

ANC Data Inspector: locates the field/line position of VPID packets (such as Field1/Line9), verifies the checksum (Exp/ACT Chksum must be consistent);

Common problem: Link sequence error (such as Link B/C switching), physical connection needs to be adjusted to make UDW4 conform to the order.

Challenge 3: Choosing the right color gamut

4K/UHD supports ITU-R BT.709 (traditional HD color gamut) and ITU-R BT.2020 (wide color gamut). Choosing the wrong color gamut can result in color distortion, which needs to be matched with content requirements and display devices.

Two major color gamut core differences (CIE 1931 coordinates):

|Color gamut standard | Red (x, y) | Green (x, y) | Blue (x, y) | Applicable scenarios|

|ITU-R BT.709 | (0.640, 0.330) | (0.300, 0.600) | (0.150, 0.060) | Traditional HD, 4K compatible HD content|

|ITU-R BT.2020 | (0.708, 0.292) | (0.170, 0.797) | (0.131, 0.046) | 4K wide color gamut content (such as HDR videos)|

Color gamut conversion and verification:

The difference between brightness (Y) and color difference (Pb/Pr) calculation: The Y formula for BT.2020 is Y=0.2627R '+0.6780G'+0.0593B ', and BT.709 is Y=0.2126R'+0.7152G '+0.0722B';

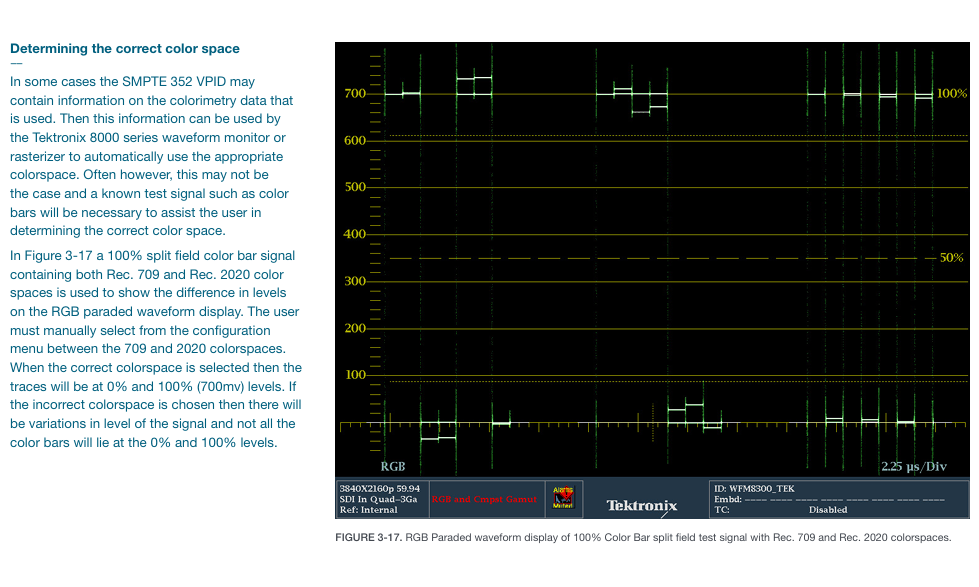

Verification method: Using 100% split field color bar signals (including BT.709 and BT.2020 dual color gamut), in RGB waveform display, the signal level should be stable at 0% (0mV) and 100% (700mV) under the correct color gamut, without significant fluctuations.

Challenge 4: Determine the aspect ratio of input 4K/UHD content

The aspect ratio of 4K/UHD content varies depending on the application scenario (movies, TV), and it is necessary to verify whether the image is scanned and cropped correctly to avoid stretching or cropping.

Common aspect ratios and corresponding resolutions:

|Aspect ratio | Application scenarios | Image size (pixels) | Effective pixels/line|

|16:9 (1.778:1) | UHDTV1 (Home) | 3840 × 2160 | 3840 pixels/2160 rows|

|1.896:1 | 4K Movie (Standard) | 4096 × 2160 | 4096 pixels/2160 lines|

|1.85:1 | widescreen movie | 3996 × 2160 | 3996 pixels/2160 lines (first line 83, last line 2242)|

|2.39:1 | Ultra widescreen movie | 4096 × 1716 | 4096 pixels/1716 lines|

Verification steps:

Vertical direction: Use the "Line Select" mode to check the effective signals of the first row (such as row 83 corresponding to 1.85:1) and the last row (row 2242);

Horizontal direction: Display with "Datalist", check the first pixel (such as sample 50 corresponding to 1.85:1) and the last pixel (sample 4045) to ensure that the image is not cropped.

Challenge 5: Meet the high-quality requirements of 4K/UHD content

4K/UHD viewers have higher expectations for image quality and need to monitor brightness, color gamut, audio volume, etc. through strict quality control (QC) to ensure compliance and not disrupt artistic intent.

Core monitoring dimensions of QC:

|Monitoring Type | Standard/Threshold | Tool Configuration|

|Video color gamut | RGB color gamut: Set diamond area threshold (such as 1% deviation alarm); Brightness: -230mV~120IRE | Tek 8000 series "Gamut Thresholds" menu, supports EBU-R103 preset|

|Audio loudness | Compliant with EBU R128 (target -23 LKFS), ITU-R BS.1770 | "Loudness Settings" menu, set alarm threshold (such as ± 2 LU deviation)|

|Signal error | Freeze frame, black field detection, SDI link error | "Alarms" menu, enable screen prompts, logging, and beep alarms|

Error recording and tracing:

Record error types (such as "RGB Gamut Error") in the associated timecode (e.g. 00:08:16:02);

The error log can be downloaded as a file and sent to the post production team along with the content to quickly locate the problem frame.

Challenge 6: Selection of Transmission Methods for 4K/UHD Signals

The four link signal needs to go through the "splitting transmission reassembly" process, with two mainstream splitting modes that match the transmission protocol supported by the device.

Comparison of two transmission modes:

|Transmission mode | Split logic | Advantages | Applicable scenarios|

|Square Division | Divide 4K images into 4 quadrants (Link A=upper left, B=upper right, C=lower left, D=lower right), each quadrant packaged as an independent SDI | Simple logic, easy to reorganize | Post production equipment (such as editing machines, color palettes)|

|Two Sample Interleave | Split by horizontal pixel groups: every 2 adjacent pixels are grouped and allocated to 4 links (such as pixel 0/4/8 → Link A, 1/5/9 → Link B) | Low memory usage, high transmission efficiency | Signal transmission links (such as broadcasting networks, satellite transmission)|

Mode configuration and validation:

Tek 8000 series: automatically recognizes VPID and standard recognition mode, or manually selects "Tile" or "Sample Interleaved" in "CONFIG MENU>Quad SDI Mode";

Verification: Confirm through image display (Rasterizer) that there is no misalignment after recombination (such as no black edges, no pixel offset).

Recommended monitoring tools and reference resources

1. Tektronix core equipment

Equipment series types, core functions, applicable scenarios

WFM8000 waveform monitor for high-precision measurement (timing, color gamut, VPID), supporting four link synchronous monitoring signal acquisition, engineering testing, and main control room

WVR8000 waveform grating instrument image display+waveform monitoring, supporting 4K/UHDTV1, including quality alarm content creation (post production, color grading), and content distribution

2. Reference standards and resources

Timing: SMPTE ST 425-5 (four link timing) SMPTE ST 352(VPID);

Color gamut: ITU-R BT.709, ITU-R BT.2020;

Loudness: EBU R128, ITU-R BS.1770;

Key issues

Question 1: How to troubleshoot channel timing deviation issues using Tektronix 8000 series devices in four link 4K/UHD signal transmission? Please refer to the standard requirements and operating procedure instructions.

Answer: Four link timing deviation needs to be checked according to SMPTE ST 425-5 standard (device output delay ≤ 400ns). The Tek 8000 series operation steps are as follows:

Preliminary check for link format consistency:

If the status bar displays "Video Format Mismatch", switch to "Single Link" mode, open the "Video Session" display, confirm that the resolution (such as 3840 × 2160), frame rate (such as 59.94p), and sampling rate (such as 4:2:2) of Link A/B/C/D are completely consistent, and eliminate timing misjudgments caused by format differences;

Enable Timing Display to monitor latency:

Go to "MEAS>Timing Display" and use Link A as a reference (default) to check the "Horizontal Offset" and "Vertical Offset" of Link B/C/D relative to Link A. The Tek 8000 series can tolerate a maximum clock difference of 1024, and if exceeded, it cannot be correctly spliced;

Adjust transmission path:

If the delay of a certain link exceeds the standard, priority should be given to checking the cable length (replacing equal length 3G-SDI cables), followed by investigating the delay differences of intermediate devices (such as switches and distributors), adjusting and re monitoring until the delay of all links is ≤ 400ns;

External reference calibration (optional):

If higher accuracy is required, a black field or three-level reference signal can be connected to the "External Reference" port of the instrument to compare the timing of Link A with the reference signal and further calibrate the link delay.

Question 2: What is the role of VPID (Video Payload Identifier) in 4K/UHD systems? How to verify the correctness of VPID through Tek 8000 series devices, and what are the common errors?

Answer: VPID is based on the SMPTE ST 352 standard and stored in the SDI auxiliary data area. Its core function is to enable devices to quickly recognize video formats (resolution, number of links, sampling rate, color gamut, etc.), avoiding manual configuration errors. It is a "format passport" compatible with multiple 4K/UHD devices.

1、 Steps to verify VPID for Tek 8000 series:

Quick verification of video sessions:

Open the "Video Session" display (Page 1) and view the "352M Payload" field (i.e. UDW1-4 bytes of VPID) for each link:

The four links must meet the following requirements: UDW1-3 (format information) is completely consistent (such as 89h CAh 00h), UDW4 (link number) is 01h → 41h → 81h → C1h according to A → D;

ANC Data Inspector deep validation:

Go to "ANC Data Inspector", filter for "DID/SDID=41/01" (VPID identification), and view:

Checksum (Exp/ACT Chksum): must be consistent, otherwise VPID data will be damaged;

Location information: Normal VPID is located at "Field1/Line9", abnormal location may cause the device to not recognize it;

Datalist locates sample level information:

Based on the "Line" and "Sample" displayed by the ANC Inspector, locate the VPID packet in the "Datalist" and confirm that UDW1-4 bytes have no bit errors (such as stuck bits).

2、 Common VPID errors and reasons:

Link number error: UDW4 is not in the order of A → D (01h/41h/81h/C1h), such as Link B/C exchange, resulting in device splicing image misalignment;

VPID duplication/missing: If there are multiple VPIDs on the same link or if a link does not have a VPID, the device cannot determine the format, resulting in an "unknown format" error message;

Checksum mismatch: Data is damaged during signal transmission, and cable shielding needs to be checked or intermediate equipment (such as SDI distributor) needs to be replaced.

Question 3: How to choose between BT.709 and BT.2020 color gamut in K/UHD content creation? How to verify the correctness of color gamut settings through testing signals with Tek 8000 series devices?

Answer: Color gamut selection needs to be combined with content usage and display device capabilities, and verification relies on standard test signals and professional monitoring tools, as follows:

1、 Color gamut selection principle:

Choose the scene for BT.709:

The content needs to be compatible with traditional HD devices (such as old TVs and HD players);

The production environment does not have BT.2020 display devices (such as the monitor only supporting BT.709) to avoid color deviation in the later stage;

Choose the scene for BT.2020:

4K HDR content (such as movies and high-end TV programs) needs to utilize a wide color gamut to enhance color richness;

The target display device supports BT.2020 (such as 4K HDR TV, professional cinema projection).

2、 Color gamut correctness verification steps (using Tek 8000 series):

Prepare test signal:

Generate a "100% split color bar signal" (left half BT.709, right half BT.2020), ensuring that the signal contains RGB three channel full range levels (0% -100%);

Switching instrument color gamut settings:

Go to "CONFIG MENU>Colorimetry", select "BT.709" and "BT.2020" respectively, and observe the RGB waveform display:

Correct setting: The RGB level of the corresponding half is stable at 0% (0mV) and 100% (700mV) without fluctuations;

Error setting: The RGB level of non corresponding half deviates by 0%/100% (for example, under BT.709 setting, the green level of BT.2020 half is only 80%);

Comparison brightness and color difference formula:

Go to "MEAS>Amplitude>Y" and measure the brightness value:

BT.709:Y=0.2126R'+0.7152G'+0.0722B', The Y value of the white color bar is approximately 700mV;

BT.2020:Y=0.2627R'+0.6780G'+0.0593B', The Y value of the white color bar is approximately 680mV;

If the values match, the color gamut setting is correct, and if the deviation exceeds 5%, it needs to be readjusted.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923