K-WANG

TEKTRONIX 5A22N Differential Amplifier

Core features:

Bandwidth: Maximum DC to 1MHz, bandwidth can be limited by HF-3dB (high frequency) and LF-3dB (low frequency) switches to improve signal-to-noise ratio;

Deflection coefficient: The knob skirt edge emits light and displays, supporting automatic scaling of 10X encoding probes;

Other: High common mode rejection ratio (CMRR), variable DC offset, suitable for displaying small signals at large DC levels.

TEKTRONIX 5A22N Differential Amplifier

Operation Instructions (Section 1)

1. Instrument description

Positioning: High gain differential amplifier plug-in unit, used for 5100 series oscilloscopes, can directly couple input to achieve high sensitivity.

Core features:

Bandwidth: Maximum DC to 1MHz, bandwidth can be limited by HF-3dB (high frequency) and LF-3dB (low frequency) switches to improve signal-to-noise ratio;

Deflection coefficient: The knob skirt edge emits light and displays, supporting automatic scaling of 10X encoding probes;

Other: High common mode rejection ratio (CMRR), variable DC offset, suitable for displaying small signals at large DC levels.

2. Panel controls and interfaces (key functions)

Control/Interface Function Description

Display switch plugin working status (only valid for vertical cabin), when turned on, the knob skirt light is on

POSITION adjusts the trajectory position on the screen

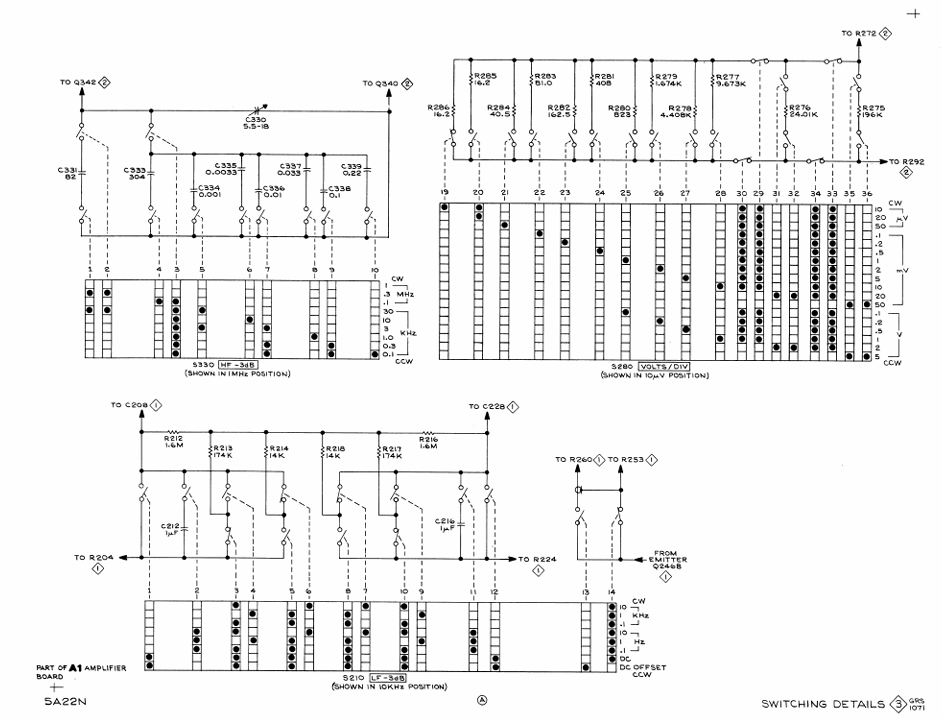

HF -3dB/LF -3dB - HF -3dB: 1-3-10 sequence with 7 levels (0.1kHz-1MHz), reducing the upper bandwidth limit and improving signal-to-noise ratio

-LF-3dB: 1-10-100 sequence with 7 levels (DC-10kHz), limited to 2Hz during AC coupling; adjustable DC offset in DC OFFSET level

VOLTS/DIV - Calibration mode: 18 levels 1-2-5 sequence, 10 μ V/Div to 5V/Div (accuracy 2%)

-Variable gear: Non calibrated continuous adjustment, range extended to 12.5V/Div

DC OFFSET (COARSE/FINE) requires LF-3dB to be placed in the DC OFFSET mode to achieve display adjustment of small signals at large DC levels

STEP ATTEN DC BAL balanced input amplifier to reduce trajectory offset during VOLTS/DIV switching

Input coupling button (AC/DC/GND/PRE CHG) - AC: capacitive coupling (blocking DC); DC: direct coupling

-GND: Input ground (disconnect signal); PRE CHG: Press AC+GND to pre charge the coupling capacitor to the signal DC level

+/-Input interface BNC interface,+positive signal deflects upwards, - positive signal deflects downwards; Equipped with a 10X encoded probe ring

3. Basic operation steps

Installation and startup:

Insertion: Align the plug-in guide rail with the 5100 series module compartment (priority vertical compartment: center/left; X-Y operation can be inserted into the horizontal compartment), and the panel should be level with the oscilloscope;

Power on: Adjust the oscilloscope brightness to the lowest level → Power on → Preset time base (2ms/Div) and trigger (automatic trigger).

Initial setup:

Set PLAY to ON,+/- input coupling to DC+GND, POSITION and STEP ATTEN BAL to median, HF/LF-3dB to full bandwidth, VOLTS/DIV to 50mV/Div, and variable gear to CAL (clockwise to bottom).

Preheating and trajectory adjustment:

Preheating: Short term DC measurement for 5 minutes, long-term DC measurement for 15 minutes;

Adjust the brightness to normal, and the trajectory should be near the center of the scale. Use POSITION to move the trajectory to 2 grids below the centerline.

Example of signal measurement:

Single ended DC coupling:+input connected to 400mV peak to peak calibration signal → release+GND → display 4 grid square waves (bottom alignment step 3 reference line);

Single ended AC coupling: POSITION moves the trajectory from bottom to center → presses AC → the trajectory shifts downward by about 2 grids (to the average value);

Differential AC coupling:+/- input connected to dual input cable → - input set to AC → display straight line (common mode signal suppressed).

4. Key precautions

Input protection: The maximum voltage of the input FET gate is ± 12V (diode clamp), and the input fuse will melt when the signal source current exceeds 1/16A;

Pre charge (PRE CHG): When measuring AC signals containing DC components, first connect the AC+GND signal → wait for 1 second for charging → release GND to avoid damaging the signal source due to coupling capacitor charging current;

High impedance input: When VOLTS/DIV is in the 50mV-10 μ V range, removing the circuit board jumper can disconnect the 1M Ω ground resistor, achieving high impedance input (requiring the signal source to provide a DC path for FET gate current).

5. Electrical characteristics (core parameters)

Specific parameters of characteristics

Bandwidth (-3dB) - DC coupling: DC to ≥ 1MHz (independent of deflection coefficient)

-AC coupling: 2Hz to ≥ 1MHz

Common mode rejection ratio (CMRR) - DC coupling: 10 μ V/Div-0.1mV/Div range ≥ 100dB (DC-30kHz, 20Vp-p sine wave); 0.1V/Div-5V/Div mode ≥ 50dB (100Vp-p sine wave)

-AC coupling: ≥ 80dB at 5kHz and above, reduced to 50dB at 10Hz

DC offset range -10 μ V/Div-50mV/Div range: ± 0.5V

-100mV/Div-5V/Div mode: ± 50V

Input RC 1M Ω (± 0.1%) in parallel at approximately 47pF

Maximum input voltage DC coupling: 10V (DC+peak AC) (10 μ V-50mV range); 350V (DC+peak AC) (100mV-5V range)

-AC coupling: 350VDC+10V peak AC (10 μ V-50mV range, pre charged); 350V (DC+peak AC) (100mV-5V range)

Noise at full bandwidth (DC-1MHz) ≤ 20 μ V (25 Ω source resistance, tangent measurement)

Working principle (Section 2)

1. Overall block diagram path

Signal → Input coupling (AC/DC/GND) → Input attenuator (1X/100X, frequency compensation) → Pre amplifier (differential structure, floating ground power supply) → Low frequency limiting circuit (LF-3dB switching) → Gain switching stage (VOLTS/DIV control) → Offset generator (DC OFFSET) → Isolation stage (emitter follower) → Output amplifier (push-pull structure, POSITION adjustment) → Trigger signal amplifier (output to time base plugin, 0.25V/display panel).

2. Analysis of core circuit modules

Input attenuator:

Attenuation ratio: VOLTS/DIV 0.1V-5V range with 100X attenuation, 10 μ V-50mV range with 1X attenuation;

Features: Frequency compensation, maintaining 1M Ω//47pF input characteristics, balancing common mode signals through R132 (Atten DC CMR).

Pre amplifier:

Structure: Two identical operational amplifiers form a differential circuit (Q150A/B, Q190A/B, Q200A/B);

Floating power supply: composed of Q170/Q176 (constant current source) and VR173/175/176 (Zener transistor), it maintains the stability of the amplification device operating point and improves CMRR as the common mode signal changes;

Gate current compensation: Regulate R121/R127 to offset FET gate leakage current (≤ 100pA) and avoid high-sensitivity offset (such as 100pA × 1M Ω=100 μ V offset in 10 μ V/Div mode, which may cause trajectory offset screen).

DC offset generator:

Structure: Q240/Q244/Q246A/B form a voltage comparator, with VR251 (transistor) providing a reference voltage;

Function: By adjusting COARSE (R260) and FINE (R268), offset current is generated to cancel the DC component of the input signal, with a maximum cancellation of 0.5V.

Output amplifier:

Structure: Push pull amplifiers Q348/Q352, R351 (GAIN) adjust the total gain to match the requirements of the host;

Position adjustment: Q360/Q362 (positioning current drive), R360 (POSITION) changes the current to adjust the static position of the CRT beam.

Calibration (Section 3)

1. Calibration prerequisites and preparations

Applicable scenarios: After instrument maintenance, long-term use (component aging) leads to accuracy deviation;

Environmental requirements: Temperature of 20-30 ℃, preheating for 20 minutes;

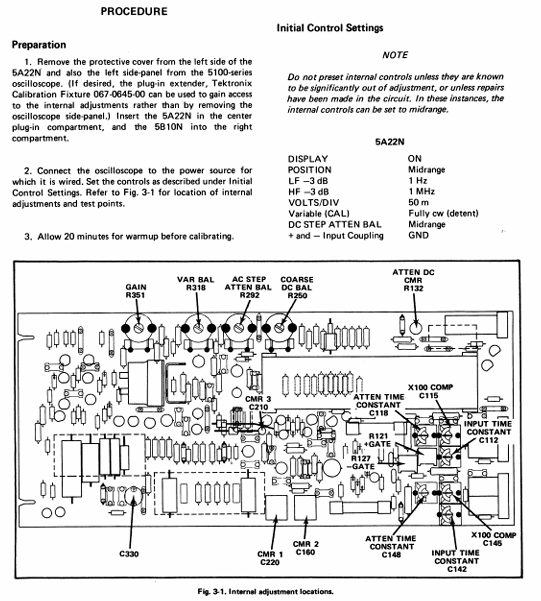

Equipment disassembly: Remove the left protective cover of 5A22N and the left panel of 5100 series oscilloscope (or use plug-in extender 067-0645-00);

Initial settings: Set the 5A22N control to POSITION median LF-3dB=1Hz、HF-3dB=1MHz、VOLTS/DIV=50mV、 Variable gear=CAL,+/- input=DC+GND, STEP ATTEN BAL median; The 5B10N time base is set to automatic triggering,+slope, and AC coupling.

2. Required testing equipment (including accessories)

Specific requirements/model examples for equipment types

Oscilloscope System 5100 Series (including 5B10N Time Base Plugin)

Constant amplitude sine wave generator frequency 2Hz-1MHz, output 0.5V-40Vp-p (such as General Radio 1310-B)

Standard amplitude calibrator 1kHz square wave, output 5mV-50V, accuracy ± 0.25% (recommended 067-0502-01)

Accessories - Coaxial Line: 50 Ω, 42 inches, BNC(012-0057-01)

-Dual input cable: matching signal path, BNC(067-0525-00)

-1000:1 voltage divider: accuracy ± 0.2% (067-0529-00)

-Input RC Normalizer: 1M Ω× 47pF (067-0541-00)

-Serial terminal: 50 Ω, accuracy ± 2% (011-0049-01)

3. Key Calibration Steps (Core 8 Steps)

Step attenuator balance:

R292 (AC STEP ATTEN BAL): Switch between VOLTS/DIV 50mV-0.1V to minimize trajectory offset;

Adjust R318 (VAR BAL): Shift the variable gear from CLOCKWISE to COUNTERCLOCKWISE to minimize trajectory deviation;

Adjust R250 (COARSE DC BAL): Set LF-3dB to DC, switch VOLTS/DIV 50mV-0.1V, and minimize trajectory offset.

Gate current regulation:

+Input to 50 Ω terminal → LF-3dB=DC → Release+GND → Switch+AC, adjust R121 (+GATE CURRENT), minimize trajectory offset;

-Input to 50 Ω terminal → press+GND → release - GND → switch - AC, adjust R127 (- GATE CURRENT), minimize trajectory deviation.

Attenuator DC common mode rejection:

Release+/- GND → VOLTS/DIV=0.1V →+/- Input through dual cables connected to a 50V square wave (calibrator) → Adjust R132 (ATT DC CMR) to display the minimum amplitude.

Input compensation:

-GND pressed ->VOLTS/DIV=50mV ->+input connected to 0.5V square wave (normalized by RC) ->C118 adjusted (Atten Time Constant), with the best square wave front;

Similarly, input C148, C145, C142.

Amplifier gain calibration:

VOLTS/DIV=10mV →+input connected to 50mV square wave → adjust R351 (GAIN), display amplitude exactly 5 grids;

Turn the variable gear to COUNTERCLOCKWISE, with a display amplitude of<2 grids, and then turn it back to CAL.

VOLTS/DIV accuracy check:

VOLTS/DIV=5V →+input connected to 20V square wave (through 1000:1 voltage divider X1 gear) → gradually decrease VOLTS/DIV, synchronously adjust the calibrator output, ensure display of 4-5 grids, accuracy ± 2%;

VOLTS/DIV=5mV gear → voltage divider set X1000 → calibrator output 20V → HF-3dB=10kHz → repeat the above checks.

Common mode rejection ratio (CMRR) calibration:

Release - GND → VOLTS/DIV=10mV →+/- input connected to 20Vp-p, 50kHz sine wave → adjust C160 (CMR 2), display minimum;

VOLTS/DIV=50 μ V → Time base=10 μ s/Div → Adjust C220 (CMR 1), display minimum;

LF-3dB=0.1kHz → switch to C210 (CMR 3), display minimum, repeat until there is no interaction effect.

Bandwidth calibration:

-GND pressed → VOLTS/DIV=1mV → LF-3dB=DC → Time base=1ms/Div →+input connected to 1kHz, 8-grid sine wave → Generator output 1MHz → C330 adjusted, display amplitude reduced to 5.6 grid (-3dB point).

Drawings and Parts List (Section 4)

1. Symbols and reference identification rules

Component symbol: Following ANSI Y32.2-1970 standard, logical symbol follows MIL-STD-806B (positive logic);

Reference identification prefixes: C=capacitor, R=resistor, Q=transistor, CR=diode, F=fuse, J=fixed connector, S=switch, VR=voltage regulator (transistor), etc.

2. Core Parts List (Example)

Part Type Reference Identification Tektronix Part Number Specification Description

Capacitor C103 283-0002-00 0.01pF, ceramic, 500V

Capacitor C133 283-0626-00 1800pF, mica, 5%

Resistance R120 322-0481-07 1M Ω, 1/4W, 1/10%

Resistance R121 311-1223-00 250 Ω, variable

Transistors Q150A/B 151-1027-00 silicon FET, replaceable with D/2N4394 or FD1392

Transistors Q103/Q105 151-0347-00 silicon NPN, replaceable with 2N5551

Diode VR138 152-0520-00 Zener diode, 1W, 12V, replaceable with UZ8712 or HW12B

Switch A10 (LF-3dB) 105-0310-00 cam switch

Switch S280 (VOLTS/DIV) 105-0309-00 cam switch

Circuit board A1 670-1894-00 main circuit board component

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923