K-WANG

YOKOGAWA ADMAG TI Series AXW Electromagnetic Flow Meter (25-450mm) Installation and Operation

YOKOGAWA ADMAG TI Series AXW Electromagnetic Flow Meter (25-450mm) Installation and Operation

Basic Information and Security Standards

1. Document scope and supporting materials

Applicable equipment: AXW series electromagnetic flowmeter (integrated+remote sensor), paired with AXW4A/AXG1A/AXFA11G remote transmitters, supporting multiple communication protocols such as BRAN, HART, Modbus, FOUNDATION Fieldbus, PROFIBUS PA, EtherNet/IP, etc.

2. Core security principles

The document clearly identifies risks through four levels of Warning, Caution, Important Notice, and NOTE, and the key safety requirements are as follows:

Personnel qualifications: Installation, wiring, and maintenance must be carried out by professional engineers or skilled personnel, and ordinary operators are prohibited from participating.

Electrical safety: Power off and wait for at least 20 minutes before wiring; The power supply voltage needs to match the rated value of the equipment (AC 100-240V/24V, DC 100-120V/24V); Unused cable entrances need to be sealed with dedicated plugs to avoid failure of protection level.

Explosion proof requirements: Explosion proof equipment requires additional reading of the corresponding explosion-proof manual (such as ATEX/IECEx/NEPSI certified version), and grounding must comply with the requirements of the explosion-proof system to avoid the generation of mechanical sparks.

Static electricity protection: Equipment components are susceptible to static electricity damage, and anti-static wristbands should be used during operation. Direct contact with circuit components is prohibited.

Environmental restrictions: ambient temperature -10~60 ℃ (refer to special manual for explosion-proof type), humidity 0~100% (avoid long-term high humidity of 95% or more); Avoid corrosive gases (such as H ₂ S, SO ₓ), strong vibrations, and direct sunlight.

Reception and Storage

1. Arrival inspection

Appearance and accessory verification: Upon arrival, visual inspection of transportation damage is required to confirm the standard accessories according to the model (as shown in the table below). If missing, please contact Yokogawa in a timely manner.

|Equipment type | Standard accessories (example) | Quantity|

|Integrated flowmeter | centering device, plug, cable sealing sleeve | 1 set/0-2 pieces/0-3 pieces|

|Remote Sensor | Centering Device, Cable Sealing Sleeve, Special Double Headed Bolt (Specific Model) | 1 set/0-2 pieces/2 pieces|

|Remote transmitter (such as AXW4A) | Installation bracket, plug, cable sealing sleeve | 1 set/0-2 pieces/0-5 pieces|

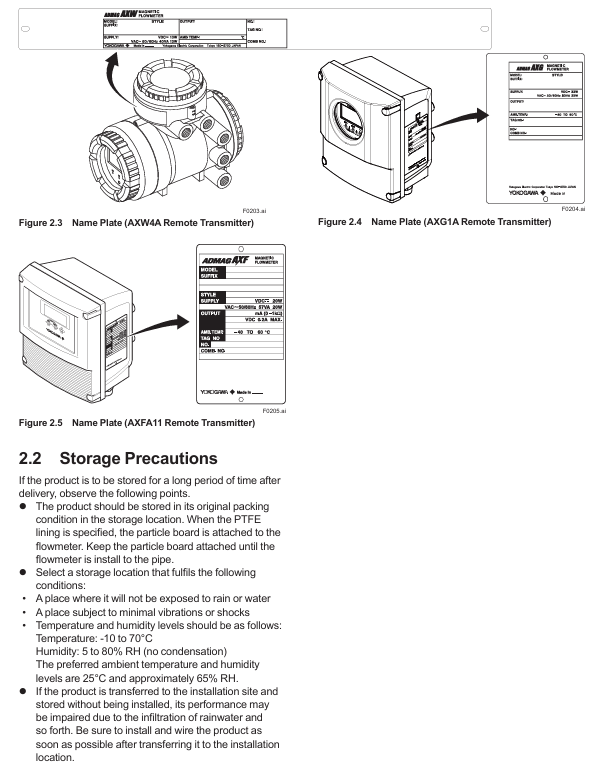

Model and specification confirmation: Verify the model, serial number, instrument coefficient, fluid specifications, etc. through the equipment nameplate (as shown in Figure 2.1-2.5) to ensure consistency with the order; The nameplate information can also be viewed through the parameter menu (refer to the corresponding communication type manual).

2. Storage requirements

Packaging: The original packaging should be retained for long-term storage, and the PTFE lining model should retain the accompanying particle board until it is removed before installation.

Environment: Storage temperature -10~70 ℃, humidity 5~80% RH (non condensing), preferably 25 ℃, 65% RH environment; Avoid exposure to rain, vibration, and impact, and install as soon as possible after transportation to the installation site to prevent rainwater infiltration.

Installation process and requirements

1. Preparation before installation: pipeline design principles

Requirements for straight pipe section: It must meet JIS B 7554 standard. The length of the upstream straight pipe section should be 5D~10D (D is the sensor diameter) depending on the upstream pipe fittings, and 2D~3D (as shown in Figure 3.1.1) downstream to avoid uneven flow distribution affecting measurement.

Fluid conditions: The pipeline should always be filled with liquid (when installed vertically, the fluid flows from bottom to top) to avoid bubbles (valves should be installed downstream first to prevent negative pressure from generating bubbles); The injection point of chemical agents should be downstream of the flow meter. If it is necessary to reserve a straight pipe section of more than 50D upstream to ensure uniform mixing.

Anti interference: Keep away from power equipment such as motors and transformers; The distance between multiple electromagnetic flow meters should be ≥ 5D (taking the larger diameter D); To avoid pipeline misalignment and tilting (as shown in Figure 3.2.2), new pipelines need to be flushed to remove foreign objects such as welding slag and sawdust.

2. Installation of sensors and transmitters

(1) Integrated/remote sensor installation

Classification installation:

**Wafer type (25-200mm) * *: It is necessary to use a centering device to ensure concentricity, and the bolt torque should be based on the flange grade (such as JIS 10K, ASME Class 150) according to Table 3.3.2; 50mm/2-inch submersible JIS 20K wafer requires special double headed bolts.

Flange type (25-450mm): The gasket needs to be provided by the user (except in special circumstances), and the use of wrapped gaskets is prohibited; Attention should be paid to avoiding negative pressure for PTFE lining models, and uneven force on the lining should be prevented during installation (refer to Table 3.3.6-3.3.7 for torque values).

Grounding requirements: The protective grounding resistance should be ≤ 100 Ω (Class D), and the lightning protection requirement should be ≤ 10 Ω (Class C); Metal pipelines should be connected to sensor flanges through grounding rings or grounding wires first, while plastic pipelines must use grounding rings.

(2) Remote transmitter installation

Installation location: Avoid direct sunlight and ensure that the environment meets temperature/humidity requirements; AXW4A can be installed vertically/horizontally on 2-inch pipes, while AXG1A/AXFA11G supports surface mounting, 2-inch pipe mounting, and panel mounting (must meet load-bearing requirements: AXG1A 3.5kg, AXFA11G 3.4kg, and the bracket needs to withstand 4 times the weight).

Direction adjustment: The cable entry direction (non submersible/DHC type) can be rotated by -90 °/+90 °/+180 °, and the display screen direction can be rotated clockwise by 90 ° (the cover plate needs to be removed, pay attention to protecting the threads and O-ring).

3. Gasket selection and size

Core requirement: The inner and outer diameters of the gasket must not extend into the pipeline to avoid fluid leakage or affect measurement; Different linings (such as natural hard rubber, PTFE, polyurethane rubber) need to be matched with corresponding hardness gaskets (such as non asbestos gaskets, PTFE coated gaskets), with thickness reference to Tables 3.3.1/3.3.4.

Size inquiry: The user's pipeline gasket size should refer to Table 3.3.8, specifying the effective sealing inner diameter (ø A) and recommended gasket inner diameter (ø C/ø D) corresponding to different linings and connection types (wafer/flange).

Wiring specifications

1. Preparation before wiring

Cable requirements:

Excitation/power/IO cables: JIS C 3401 control cables and JIS C 3312 power cables are recommended, with a wire diameter of 0.5~2.5mm ² (single strand)/0.5~1.5mm ² (multiple strands), and the outer diameter needs to match the cable sealing sleeve (such as waterproof sealing sleeve compatible with 7.5~12mm).

Special signal cable (AX01C): Double shielded structure, with a maximum length of 200m when paired with AXG1A/AXFA11 and 100m when paired with AXW4A. Cutting or splicing is prohibited, and excess length must be cut off.

Protective measures: When the ambient temperature is above 50 ℃, cables with a temperature resistance of 70 ℃ or above are required; Power and signal cables need to be separately threaded through steel conduits (excluding 24V power supply and 4-core cables); Explosion proof wiring must comply with the corresponding explosion-proof standards.

2. Wiring operation

Power wiring: DC power supply should pay attention to the positive and negative poles (L/+connected to the positive pole, N/- connected to the negative pole), and 24V models should not be connected to 100-240V power supply; 15A external switch/circuit breaker needs to be installed and labeled as "power-off equipment".

Grounding Wiring: The protective grounding wire requires a 600V ethylene insulated cable, and the terminals require circular crimping terminals (M4 screws) with insulation covers to ensure reliable connection; Remote type requires separate grounding sensors and transmitters.

Cable entrance sealing: Unused entrances need to be sealed with dedicated plugs, waterproof sealing sleeves need to be evenly tightened (to avoid damaging the cable due to over tightening), and vertical conduits need to be equipped with drainage valves at the low end and regularly drained.

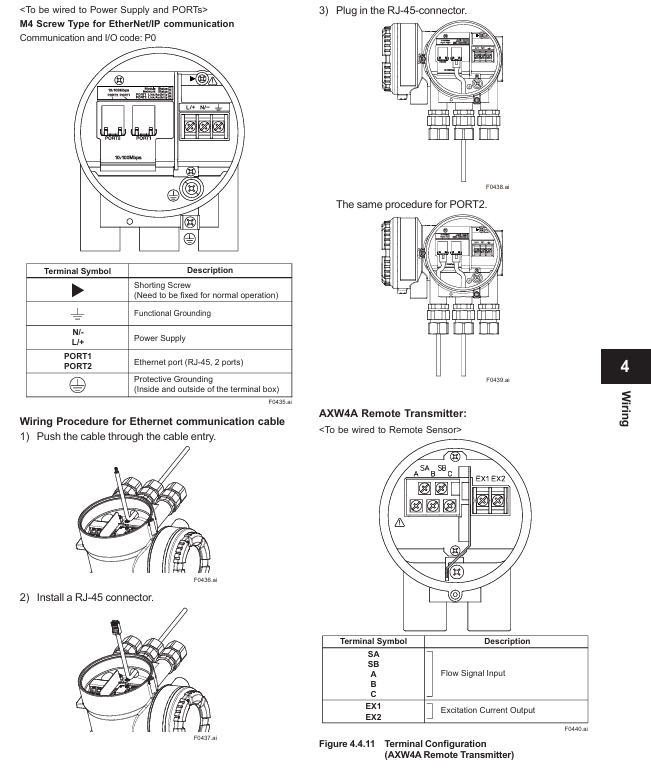

3. Communication and IO wiring

Communication protocol wiring: Modbus requires 3-core shielded wire (AWG24 or above), FOUNDATION Fieldbus/PROFIBUS PA requires Type A cable, EtherNet/IP requires CAT5e or above shielded twisted pair (without protective cover).

IO signal wiring: current output (4-20mA), pulse output (maximum 10000 pulses/second), status input (no voltage contacts), etc. need to be wired according to the terminal configuration table (such as 4.4.4/4.5.2) to ensure galvanic isolation (input/output/power circuits are isolated from each other).

Basic operations and parameter settings

1. Operation method

Display screen operation: Operated through three infrared (IR) buttons ([SET], [SHIFT], [▼]), supporting parameter viewing/modification, zero point adjustment, etc; The default display language is English, which can be switched through "Device setup ► Language" (supports multiple languages such as Chinese, French, German, etc., depending on the display code).

Operation level: divided into three levels: Operator (no password required, only basic display settings), Maintenance (maintenance personnel, password required, including zero adjustment), Specialist (expert, password required, full parameter settings), default password "0000".

2. Key operational procedures

(1) Mode switching: Display mode → Set mode

Long press [SET] for a few seconds, touch [FFT]+[INC];

Select "Yes" with [INC], double-click [SET] to confirm;

Select the operation level, enter the corresponding password (Maintenance/Specialist requires password), and enter the "Device setup" menu.

(2) Example of Parameter Setting

Flow unit setting (optional parameter): Path "Device setup ► Detailed setup ► Pro var ► Volume ► Unit/Time Unit". If setting "l/min", select "l (lite)" (physical unit) and "/min" (time unit) respectively.

Flow range setting (numerical parameter): Path "Device setup ► Detailed setup ► Pro var ► Volume ► Span", the unit needs to be set first, and the range value will be automatically converted with the unit.

Tag number setting (alphanumeric parameter): Path "Device setup ► Detailed setup ► Device info ► Order info ► Tag No.", maximum input of 8 ASCII characters.

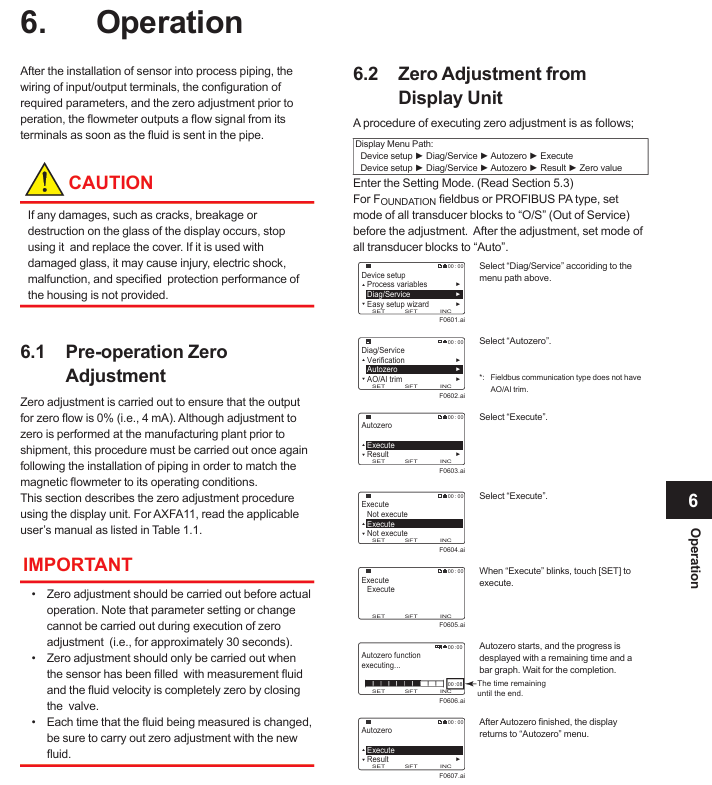

(3) Pre operation Zero Adjustment

Prerequisite: The sensor is filled with fluid and the flow rate is 0 (with the valve closed). For the FILDVUE/PROFIBUS PA type, all sensor blocks must first be set to "O/S" mode.

Operation path: "Device setup ► Diag/Service ► Autozero ► Execute". Double click [SET] to start, taking about 30 seconds. After completion, check the "Result ► Zero value" to confirm the result (exceeding 10cm/s will trigger a warning "092: AZ warning").

3. Use of configuration tools

BRAN/HART: Connected through BT200 or FieldMate, it needs to be parallel in a 4-20mA circuit, with load resistance ≥ 250 Ω/230 Ω respectively.

Modbus/FOUNDATION Fieldbus/PROFIBUS PA: Corresponding DTM (such as AXW4A Modbus DTM 1.1.4.0 or above) is required, and FieldMate needs to be upgraded to the corresponding version.

EtherNet/IP: Supports web configuration (requires IE8+/Chrome/Edge browser), requires installation of corresponding EDS file (supplier ID 250, product code 206).

Operation and maintenance

1. Hardware switch settings

Burnout switch: When the CPU fails, the current output direction defaults to a high value (>21.6mA), and when C1/C2 is installed, a low value (<2.4mA) is set.

Write Protect: To prevent parameter tampering, rewriting is prohibited when the hardware switch is set to "ON" (in conjunction with software write protection).

Address switch: Modbus (1-127), PROFIBUS PA (0-126), EtherNet/IP (set IP segment 4) need to be set through 8-bit dialing, and priority is controlled by the SW3-1 switch.

Terminal resistor switch (SW2): A 150 Ω terminal resistor (SW2-1/SW2-2 both "ON") is required at both ends of the Modbus bus.

2. Correction factor setting (for specific flanges)

Applicable scenarios: When using 40-125mm wafer type and specific linings (such as polyurethane rubber U, natural hard rubber H) with carbon steel flanges, a correction factor (CFL/CFH: double-sided carbon steel) needs to be set; CF1L/CF1H: single-sided carbon steel), the coefficient is marked on the nameplate or on the Yokogawa official website for reference.

Set path: such as the display screen "Device setup ► Detailed setup ► Sensors ► Low MF/High MF", Modbus address 40321 (Low MF)/40323 (High MF).

3. Fault handling

Chapter 7 of the document provides a detailed list of four types of faults: system alarms (equipment failures, such as "010: Main CPU FAIL" requiring contact with the service center), process alarms (process issues, such as "051: Empty detect" requiring fluid filling), set alarms (parameter errors, such as "060: Span cfg ERR" requiring range adjustment), and warnings (such as "087: Adhesion lv 3" requiring electrode cleaning). Each fault includes NE107 status (F/C/S/M/N), description, and countermeasures. Examples are as follows:

NE107 status error code/information reason countermeasures

F 010: Main CPU FAIL Mainboard CPU failure Contact Yokogawa Service Center

S 051: Empty detect sensor fills the pipeline with liquid through the empty tube

C 060: Span cfg ERR flow range setting error (requires 0.05<Span<16m/s) Check and correct range parameters

M 087: Adhesion lv 3 electrode adhesion insulation (resistance exceeding level 3). It is recommended to clean the electrode

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB PDD200A101 Power Drive Module Industrial Automation Component

-

ABB SPIET800 Ethernet Communication Module Industrial Network Interface

-

ABB SPAD346C3 Protection Relay Module Industrial Power System

-

ABB 15.04.20.05 Industrial Control Module Automation Component

-

ABB FPX86-9329--C Control Processor Module Industrial Automation System

-

ABB ARCOL 0339 Industrial Power Resistor Component

-

ABB 5SDD1060F0001 Thyristor Module High Power Semiconductor Device

-

ABB KUC720AE Control Unit Industrial Automation Processor

-

ABB UFC718AE01 Control Board Industrial Automation Module

-

ABB FI820F Fieldbus Interface Module Industrial Communication System

-

ABB CB801 Communication Base Unit Control System Module

-

ABB DSAI130D Analog Input Module Industrial Control System

-

ABB 086345-504 Control Board Module Industrial Automation Component

-

ABB PFCL201C 10KN Load Cell Tension Measurement Module

-

ABB 3HAC17484-8108 Robot Drive Unit Industrial Motion Control Module

-

ABB 5SHY3545L0009 IGCT Module High Power Semiconductor Device

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923