K-WANG

Yokogawa AQ1210 Series OTDR Multi Field Tester

Yokogawa AQ1210 Series OTDR Multi Field Tester

Applicable Devices

The AQ1210A, AQ1215A, AQ1210D, AQ1210E, AQ1215E, AQ1215F, and AQ1216F OTDR (Optical Time Domain Reflectometer) models are mainly used for the installation and maintenance of fiber optic lines in access networks and user networks. They can detect fiber optic fault locations, monitor transmission losses, fusion losses, and other parameters.

Core functions and operations

(1) OTDR core functions

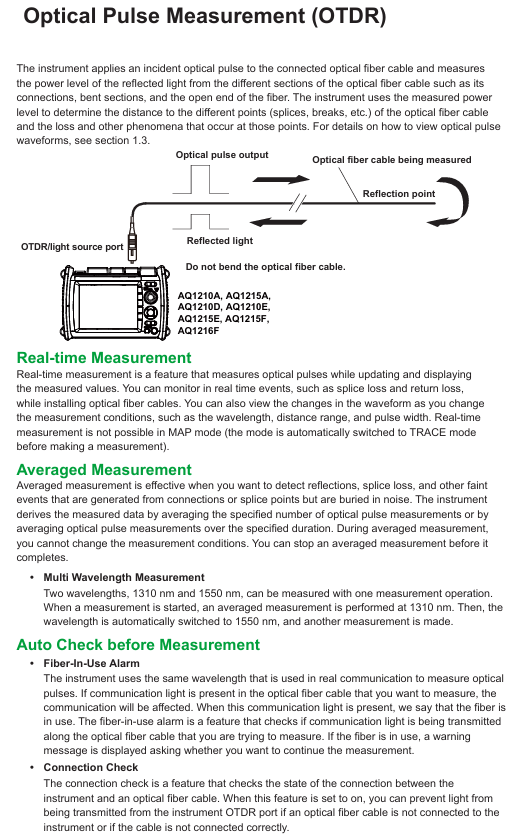

Optical pulse measurement

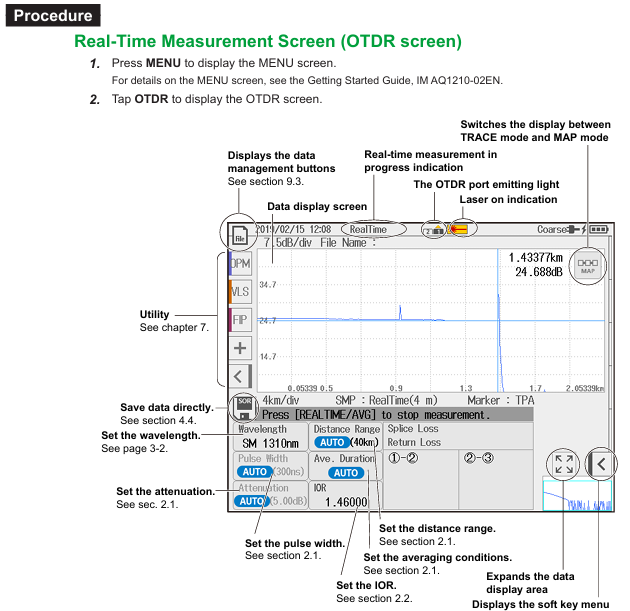

Real time measurement (TRACE mode): The waveform is updated and displayed in real time during measurement, and events such as fusion loss and return loss can be monitored in real time. It supports adjusting parameters such as wavelength and distance range. In MAP mode, it will automatically switch to TRACE mode.

Average measurement:

TRACE mode: Take the average of multiple measurements to display the waveform, suitable for detecting weak events masked by noise.

MAP mode: Automatically analyze OTDR waveform after average measurement, display various event types with icons, support preset qualified/unqualified judgment conditions, and identify results with colors.

Multi wavelength measurement: A single operation can measure two wavelengths, 1310nm and 1550nm (or 850nm and 1300nm). First measure 1310nm (or 850nm), and then automatically switch to another wavelength.

Automatic check before measurement:

In use fiber optic alarm: detect whether there is communication light in the tested fiber optic cable to avoid affecting normal communication. If there is, a pop-up window will prompt whether to continue.

Connection check: Check the connection status between the device and the fiber optic cable, and prevent the OTDR port from emitting light if it is not connected correctly.

The data shows

TRACE mode (waveform display): The horizontal axis represents distance and the vertical axis represents loss level. The waveform can be scaled and moved, and the detected loss or reflection events (such as connectors, fusion points, bending points, etc.) are marked on the waveform.

MAP mode (icon display): Use different icons to display the loss and reflection of events such as connection points, curved sections, and open ends, arranged in order from the measurement starting point to the open end, clearly presenting the event location and distance.

data analysis

Trace mode: manually measure the distance between two points, fusion loss, return loss, etc. using the cursor and markers, supporting multiple measurement methods such as 4-point and 6-point markers.

Event analysis: Automatically detect all events in the waveform, display event types (such as positive/negative fusion loss, reflection, bending loss, etc.) and analysis results (distance, loss value, etc.), support manual editing of events (insertion, deletion, adjustment of marker position).

Qualified/unqualified judgment: preset thresholds for fusion loss, return loss, loss per kilometer, total loss, etc., automatically judge whether the measured value meets the standard. In TRACE mode, qualified items are marked in green and unqualified items are marked in red, and in MAP mode, color coded icons are used.

File function: Supports saving measurement data (. SOR format, including waveform, condition, event list), reports (. PDF format), system settings (. CFG format), screenshots (. BMP/. JPG format), can be stored in built-in memory (approximately 256MB) or USB devices, supports file copying, deletion, renaming, and report generation (can choose to include measurement conditions, waveform, event list, etc.).

(2) Practical tool functions

Light Source: Generate specific wavelength measurement light (such as AQ1210A supporting 1310nm, 1550nm) for fiber loss measurement or identification, and can output continuous light (CW) or modulated light (such as 270Hz, 1kHz).

Visible light source (/VLS option): 650nm wavelength visible light, used for visual detection of fiber breakage and inspection of multi-core fiber cores, supporting CW and 2Hz modulation modes.

Optical power meter (/SPM//HPM//PPM option)

Standard optical power meter (/SPM): measuring fiber loss or optical signal power of communication equipment in the wavelength range of 800-1700nm.

High power optical power meter (/HPM): Maximum measurement+27dBm high power, used for loss measurement in high-power scenarios.

PON optical power meter (/PPM): Simultaneously measure the optical power of passive optical networks (PON) at three wavelengths of 1310nm/1490nm/1550nm.

Support logging function, record short-term optical power stability, generate CSV format log files, calculate maximum, minimum, and average values.

Power checker (/PC option): detects the presence and power value of communication light in the tested fiber through the OTDR port, measuring wavelengths covering commonly used bands such as 1310nm and 1490nm.

Fiber end face inspection (/FST option): Connect the designated fiber end face inspection probe of Yokogawa, capture the status of the fiber end face and display it on the device screen. The image can be saved, and qualified/unqualified judgments can be made for the end face contact area, cladding area, and fiber core area respectively (in accordance with IEC 61300-3-35 standard).

Optical switch control: Connect a compatible optical switch box (such as AQ3550, 1 × 12 port configuration) to switch the measurement optical path in optical pulse measurement, and automatically switch the target channel during multi-core measurement.

(3) Application Function

OTDR Smart Mapper: Automatically repeat average measurements with different pulse widths in a single operation, analyze events automatically after completion, support MAP/TRACE mode display, MAP mode presents line events with icons, and TRACE mode combines multiple pulse width waveforms to improve measurement accuracy.

Multi Fiber Project: Manage the conditions and core information required for multi-core fiber measurement through "projects", support real-time measurement, average measurement, optical power measurement, fiber inspection probe operation, automatically save the measurement results of each fiber core to the corresponding folder, and avoid missing measurements.

Auto Loss Test: Two devices act as light sources and optical power meters respectively, automatically switching between 1310nm and 1550nm wavelengths to measure fiber loss; A single device can test fiber loss through loopback mode (OTDR port connected to OPM port).

Multicore Loss Test: Two devices are set as the master (optical power meter) and slave (light source), respectively. The master creates a project and transmits it to the slave. Through signal transmission of fiber optic synchronization information, the multi-core fiber loss is measured in batches, and testing can be resumed from the next core after interruption.

Advanced Analysis

Multi trajectory analysis: Load up to 4 waveforms and display comparisons simultaneously, with the ability to adjust the vertical position of each waveform.

Bidirectional trajectory analysis: Combining waveforms measured from both ends of the fiber, accurately measure the fusion loss of fibers with different levels of backscattering.

Differential trajectory analysis: Load two waveforms, display their difference waveforms, and measure the loss and distance of the difference waveforms with markers.

Segment analysis: Set starting point (S) and ending point (E) markers, measure the specified segment return loss and total loss, and support setting reference point (B) to calculate return loss.

(4) System setup and maintenance

System settings: configurable power-saving mode (screen brightness, automatic sleep), network (LAN/WLAN, supports remote control and data transmission), language, startup interface (TRACE/MAP/settings information), screen color (Color 1/Color 2/Black and White), operation lock (PIN code restricts laser output, mode switching, etc.), expiration date (expiration prompt for calibration or device lock).

Troubleshooting and Updating: Provides common troubleshooting solutions, error code explanations, supports firmware updates via USB, can restore factory settings (divided into "Reset Settings" and "Reset Settings and Delete User Files"), supports adding optional feature licenses.

Maintenance and storage: Regular mechanical and operational inspections should be conducted, and high temperature, humidity, and vibration environments should be avoided during storage. The battery pack should be operated according to the specifications in the dedicated manual.

Safety and usage regulations

Safety warning: When measuring, the light source port will light up. Do not disconnect the connected fiber optic cable to avoid direct light to the eyes, which may cause visual damage; When the fiber optic cable is not connected, the light source port cover needs to be closed.

Operating standards: Before use, read the manual thoroughly and strictly follow the steps to set measurement conditions and perform measurements; USB devices should not be unplugged or powered off during reading and writing to avoid data damage; Fiber optic connections need to be checked for correctness to prevent equipment or fiber optic damage.

Trademark statement: Microsoft, Google Chrome, Adobe, Bluetooth, etc. are registered trademarks of corresponding companies, omitted from the manual ® And TM symbol.

Summary of Key Tables

(1) Wavelength of various types of light sources (partial)

Model measurement of light wavelength

AQ1210A 1310nm、1550nm

AQ1215A 1310nm、1550nm

AQ1210D 1310nm、1550nm、850nm、1300nm

AQ1210E 1310nm、1550nm、1625nm

(2) File format description

Extension Description

. SOR optical pulse measurement results (including measurement/analysis conditions, waveforms, and event lists)

. PDF report format for current waveform or saved files

CFG device system settings (devices, connections, etc.)

Screenshot of. BMP/. JPG devices

Multiple waveforms measured simultaneously by SOZ

The waveform measured by the SMP Smart Mapper function

(3) Meaning of warning symbols

Symbol+Text Meaning

Warning: Operations/conditions and preventive measures that may cause serious or fatal injuries

CAUTION prompts operations/conditions and preventive measures that may cause minor injuries, equipment damage, or data loss

Note: Important information for correct device operation

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

-

BENTLY NEVADA 3500/15 133292-01 Power Supply Module

-

ABB PM877 3BDH000777R1 Central_Unit Controller

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor