K-WANG

YOKOGAWA AQ23011A/AQ23012A Modular Framework Equipment

YOKOGAWA AQ23011A/AQ23012A Modular Framework Equipment

Product positioning and core applications

AQ23011A/AQ23012A is a modular framework device that requires the use of AQ23811A and other source measurement modules (SMUs). Its core function is to achieve high-precision output (source function) and measurement (measurement function) of voltage/current, supporting multi-channel synchronous control and complex scanning analysis. The main application scenarios include:

Semiconductor testing: testing of chip pin voltage/current characteristics, measurement of MOSFET threshold voltage.

Electronic component verification: impedance characteristic analysis of resistors/capacitors/inductors, and forward voltage drop testing of diodes.

Calibration of new energy devices: collection of lithium battery charge and discharge curves, scanning of photovoltaic module IV characteristics.

Core technical parameters and hardware structure

1. Key technical parameters

Taking the core module AQ23811A (2-channel SMU) as an example, the core parameters are as follows:

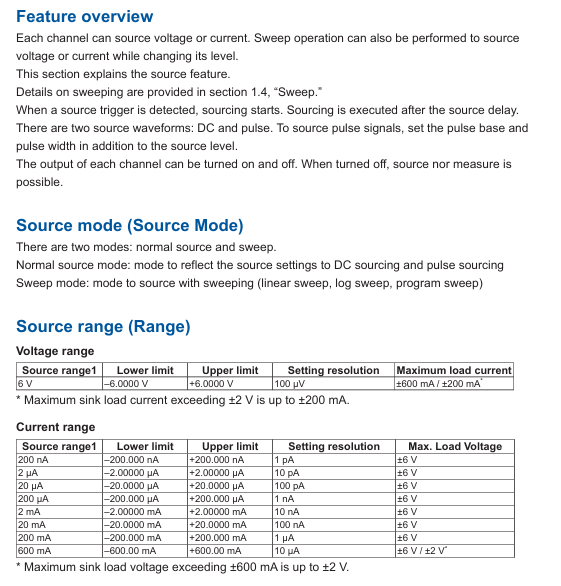

Parameter category specific specifications

Source output range voltage: ± 6.0000 V (resolution 100 μ V, maximum load current ± 600 mA/± 200 mA, drops to ± 200 mA when exceeding ± 2 V)

Current: 200 nA~600 mA, with a total of 8 ranges (such as a resolution of 1 pA for the 200 nA range, a resolution of 10 μ A for the 600 mA range, a maximum load voltage of ± 6 V/± 2 V, and a decrease to ± 2 V when exceeding ± 600 mA)

Measurement accuracy voltage measurement: ± 0.01% reading ± 0.01% range (23 ℃± 5 ℃, 6 V range)

Current measurement: ± 0.02% reading ± 0.02% range (23 ℃± 5 ℃, 200 mA range)

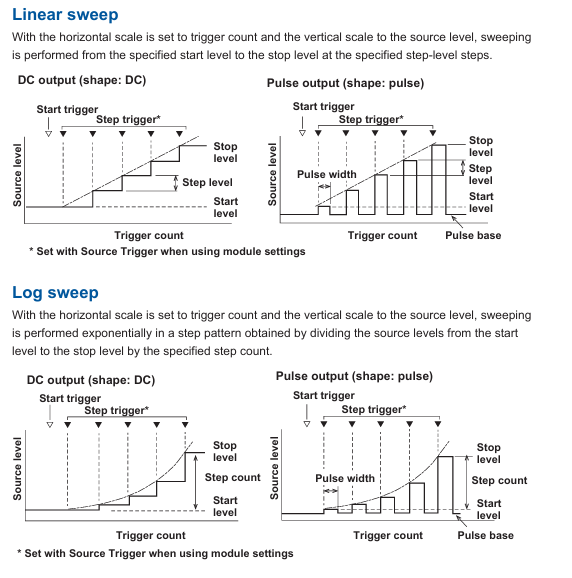

Scanning Function Scanning Types: Linear Scan, Logarithmic Scan, Program Scan (CSV Format Custom, Maximum 100001 Steps)

Repetition frequency: 1-1000 times or infinite loop

Trigger system trigger source: Bus trigger (BUS Trigger1-9), front panel trigger, internal timer (1 μ s~1s adjustable), source signal change (Src Change)

Trigger delay: 1 μ s~1 s (resolution 1 μ s)

Interface and storage interface: Ethernet (1000BASE-T), USB 3.0 (2 host ports+1 device port), GP-IB (optional)

Storage: Internal storage (219 GB for each dual zone), USB external storage, supporting BIN/CSV/PNG formats

2. Hardware structure and component functions

(1) Core components of the front panel

Component name, location, and function

There are 9 slots on the left side of the module slot (AQ23011A/AQ23012A universal), used for installing modules such as AQ23811A, slot numbers 1-9

10.1-inch color LCD (1280 × 800 pixels) in the center of the touch screen display, supporting touch operation (menu navigation, parameter settings)

The F1~F6 keys at the bottom of the function soft key screen correspond to menu options and dynamically change with the interface

Each module on the front panel corresponds to one trigger input/output terminal (TTL level, negative logic) for external trigger signal interaction

There are two USB 3.0 ports on the right side of the USB host interface, which can be inserted into a USB flash drive/portable hard drive to save data, or connected to a mouse/keyboard

Power button on the right side of the power and status light (with LED indicator light, green constant light for normal), error indicator light (red flashing for fault)

(2) Core components of the rear panel

Component Name Function

AC power interface connected to dedicated power cord (input 100~240 VAC, 50/60 Hz, maximum power consumption 120 VA)

Ethernet interface RJ45 interface, supporting TCP/IP protocol, used for remote control (HiSLIP/RawSocket) or network file sharing

External trigger interfaces Trig IN1/Trig IN2 (BNC interface, TTL level), Trig OUT1/Trig OUT2 (BNC interface), used for external trigger synchronization

The Remote Interlock terminal of the interlocking interface requires a dedicated plug (A1288JA) to enable module output and ensure safety

GP-IB interface optional interface (requires module configuration), used for remote control of traditional instruments

USB device interface USB Type-B interface, connected to PC for high-speed data transfer or remote control

Basic operation process

1. Startup and initialization settings

(1) Power on preparation

Hardware connection: Confirm that the framework is powered off, install the AQ23811A module (insert it into the slot rail and lock it), connect the AC power cord, and turn on the power switch on the rear panel.

Self check and startup: automatic framework detection module after startup DRAM、 File system, after passing self-test, enters the main interface (summary view); If the self-test fails (such as module not recognized), the screen will display an error code (such as E021: Slot 1 module abnormal), and the module needs to be reinstalled or repaired.

Restore default settings: Press the "Function icon" → "System" → "Reset Frame to factory default" in the upper left corner of the screen, confirm and restore the factory settings (source output turned off, measurement mode default voltage, trigger source set to None).

(2) Module calibration (key steps)

When the AQ23811A module is used for the first time or when the ambient temperature changes by more than ± 10 ℃, zero calibration needs to be performed:

Disconnect the external wiring of the module output terminal to ensure no load connection.

In the summary view, long press the module name (such as "AQ23811A SMU") → a pop-up menu → select "CH1 ZeroSet" or "CH2 ZeroSet".

Wait for calibration to complete (about 3-5 seconds), the screen displays "ZeroSet OK", and after calibration, the source output offset error is ≤± 10 μ V (voltage)/± 1 pA (current).

2. Source output and measurement settings (taking AQ23811A CH1 as an example)

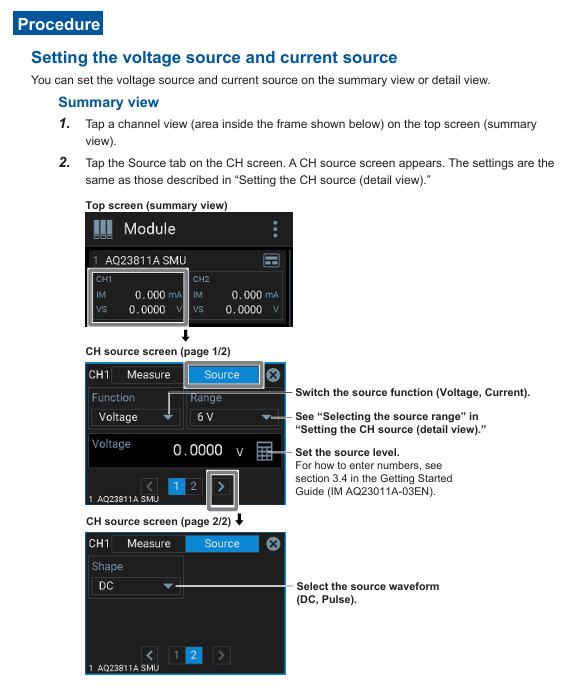

(1) Voltage source output setting

In the summary view, click on the CH1 channel area → switch to the "Source" tab.

Set parameters:

Function: Select "Voltage".

Range: default "6 V" (only 1st gear), no need to manually switch (automatic range is consistent with fixed range).

Source level: Input target voltage (e.g. 3.3000 V, resolution 100 μ V).

Shape: Select "DC" or "Pulse" (pulse, additional pulse width and base level need to be set).

Limit: Set the maximum output current (such as 100.000 mA to prevent load overload).

Enable output: In the detail view, click the "OUTPUT" button (long press for 2 seconds). The button turns green to indicate that the output is turned on, and the CH1 terminal outputs the set voltage.

(2) Current measurement settings

Keep the CH1 output connected to the tested load, click on the CH1 channel area in the summary view → switch to the "Measure" tab.

Set parameters:

Measurement type: default "Current" (current measurement, voltage measurement automatically turned on to calculate power).

Wiring method (Wire): Select "2wire" (two-wire system, ordinary measurement) or "4wire" (four wire system, high-precision low resistance measurement).

Integral Time: Set 1 PLC (20 ms for 50 Hz grid and 16.67 ms for 60 Hz grid) to reduce power supply noise interference.

Measure Delay: Set to 10 μ s and ensure stable load before collecting data.

View results: The summary view displays the real-time measured current of CH1 (such as 50.123 mA), and pressing the "Math" key can display the calculated power (voltage x current) or resistance (voltage/current).

3. Scanning function operation (linear scanning example)

Taking "CH1 voltage linearly scanned from 0 V to 5 V, step size 0.1 V, synchronous measurement of load current" as an example:

Enter scanning settings: Press "Function icon" → "Application" → "Sweep" → select "Linear Sweep".

Configure scanning parameters:

Scan channel (Sweep CH): Select "AQ23811A CH1".

Measure CH: Check "AQ23811A CH1" for measuring current.

Scanning range: Start Level 0 V, Stop Level 5 V, Step Level 0.1 V.

Trigger settings: Set the Start Trigger to "None" (immediate start) and the Step Trigger to "Cyclic" (triggered by an internal timer with an interval of 100 ms).

Start scanning: Click the "Start" button (long press for 2 seconds), the screen displays the scanning progress (steps, expired time), and the measurement data is automatically saved to internal storage (default CSV format).

View results: After scanning is complete, press "File" ->"Internal memory" ->view the "sweet_xxx. csv" file, which contains the voltage, current, and power values for each step.

Core functions and advanced operations

1. Trigger function (precise synchronization signal)

The AQ2300 series supports multiple types of triggering, ensuring that source output or measurement is initiated under specific conditions. The core triggering modes are as follows:

Trigger type functional characteristics and applicable scenario operation examples

Bus triggering utilizes the framework bus (BUS Trigger1-9) to synchronize multiple modules, supporting external trigger signals (Trig IN1/Trig IN2) or internal timers. Set BUS Trigger1 to "Trig IN1" and CH1 source trigger to "BUS Trigger1", and start voltage output when external signals trigger

Source change triggers measurement when the source level changes (Src Change), suitable for capturing the dynamic response of the load CH1. When the source level jumps from 1 V to 2 V, it automatically triggers current measurement and records the current changes before and after the jump

Periodic triggering: Repeat the triggering measurement at a fixed cycle (minimum 1 ms), suitable for long-term stability monitoring. Set the "Cyclic" triggering cycle to 1 s, measure continuously for 1 hour, and analyze the load current drift situation

Scan start trigger: Wait for an external trigger (such as Trig IN2) before starting the scan, suitable for multi device synchronous testing. Set the scan start trigger to "Trig IN2", and only start voltage scanning after the external signal is triggered, synchronously collecting oscilloscope waveforms

2. File operation (data management)

(1) Data saving types and formats

Data Type Format and Usage Save Operation

Measure data BIN (binary, high-precision, small space occupation), CSV (text, can be imported into Excel for analysis) in the detail view, press "Store" ->set the number of collection points (such as 100 points) ->"Save Store Data" ->select the storage path

Configuration files. 811 (module configuration) and. FRM (framework configuration) are used to save the current parameters. Next time, long press the module name ->"Save Setup" ->name the file (such as "SMUFHIR 1_3V. set") ->save to a USB drive

Screenshot PNG (image format, resolution 1280 × 800), used for report recording. Press "Function icon" → "Take a Screenshot" and automatically name it "AQ2300_SC_000. PNG" to save to internal storage

Error log (text), automatically records hardware failures and operational errors, used for troubleshooting framework to automatically save, export to USB drive by pressing "System" → "System Log" → "Save System Log File"

(2) File management operations

Folder creation: Press "File" ->"Location" ->select "USB Storage" ->"Create new folder" ->Name (e.g. "Test_202410").

File copying/deleting: Select the file (such as "sweet_001. csv") ->click on the menu on the right side of the file ->select "Copy" ->select the destination folder ->"Paste"; The deletion operation is similar and requires confirmation of a second prompt.

File filtering: In the file list interface, enter filtering criteria (such as "*. csv") to display only CSV format files and quickly locate the target data.

3. System settings (remote control and security)

(1) Remote control configuration

Supports four remote control methods: RawSocket, HiSLIP, GP-IB, and USB. Taking Ethernet as an example:

Press "Function icon" → "System" → "Network" → "IPv4" → Set to "DHCP ON" (automatically obtain IP) or manually enter (e.g. IP: 192.168.1.100, subnet mask: 255.255.255.0).

Configure remote protocol: "Remote" → "Function" Select "HiSLIP" → Set port (default 4880), encryption (Encryption OFF/ON, select as needed).

PC control: Install the NI-VISA driver and use LabVIEW/Python to send SCPI commands (such as "SOURce1: CHANnel1: VOLTage: LEVel 3.3" to set CH1 output to 3.3 V).

(2) Safety interlock setting

To prevent damage to the load caused by misoperation, the interlocking function needs to be activated:

Connect the "Remote Interlock" terminal on the rear panel to the dedicated plug (A1288JA).

Press "System" → "Inter Lock" → Set to "Locked", and the module output will be disabled; You need to enter the default password "12345" → set it to "Unlocked" to enable output.

Password management: It can be modified through "Reset Password" (default) or "Change Password" (custom password, 6-12 digits) to enhance security.

Maintenance and troubleshooting

1. Daily maintenance

Cleaning: Wipe the display screen and housing with a dry soft cloth. If there is dust on the BNC terminal and USB interface, blow it off with compressed air (pressure ≤ 0.3 MPa); Prohibit the use of solvents such as alcohol and acetone to avoid damaging the coating.

Module maintenance: Regularly check whether the module is in close contact with the slot (once a month), and when not in use for a long time, turn on the power for 1 hour every month to prevent capacitor aging.

Calibration cycle: It is recommended to send it to the authorized service center of Yokogawa for calibration once a year, or use a standard source (such as Yokogawa 7520 calibrator) for self calibration to ensure that the accuracy meets the requirements.

2. Troubleshooting

Possible causes and solutions for the fault phenomenon

Unrecognized module not locked, poor slot contact, module failure. Re plug and lock the module, replace the slot for testing; If still not identified, contact maintenance

Source output voltage interlock not unlocked, output not enabled, current limit value set to 0, load short circuit unlock interlock, long press "OUTPUT" to enable output, check current limit value (set to ≥ 1 mA), check load wiring

The measurement value fluctuates greatly, the integration time is too short, the wiring is loose, and the power supply noise interference increases the integration time (such as 10 PLC). Check the wiring (ensure good contact of the sense line in the four wire system) and stay away from interference sources such as frequency converters

USB cannot read USB flash drive format not supported (FAT32/NTFS required), poor interface contact, damaged USB flash drive, formatted USB flash drive as FAT32, re plug and unplug USB flash drive, replace USB flash drive for testing

Remote control failed due to IP address mismatch, protocol not enabled, firewall interception confirmation framework on the same network segment as PC, HiSLIP/RawSocket protocol enabled, PC firewall disabled

3. System self-test and logging

Self check operation: Press "System" ->"Self Test" ->select "DRAM Test", "File System Test", "Battery Test" ->"Start". The self-test result shows "Pass/Tail". If it fails, please contact maintenance.

Log viewing: Press "System" → "System Log" to view system logs (such as module installation time, firmware update records) and user logs (such as operation error codes). The logs can be exported in ZIP format and saved to a USB drive for maintenance analysis.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923