K-WANG

YOKOGAWA AQ6360 Optical Spectrum Analyzer

YOKOGAWA AQ6360 Optical Spectrum Analyzer

Overview

The Introduction Guide to YOKOGAWA AQ6360 Optical Spectrum Analyzer (7th Edition, document number IM AQ6360-02EN) introduces the core functions of the instrument (high-speed measurement of optical characteristics of LD, LED light source, optical amplifier and other equipment), preparation before use (packaging content inspection, instrument installation, power connection and power on/off process), basic operations (touch screen/mouse/keyboard operation, menu and parameter settings), maintenance points (firmware update, wavelength/level accuracy calibration, daily cleaning and component replacement), and key specifications (wavelength range 1200-1650nm, maximum input power+20dBm) At the same time, it emphasizes safety precautions (such as avoiding direct exposure to infrared light, correctly grounding to prevent electric shock), and provides user registration, technical support contact information, and access to relevant manuals.

Preparation before use

1. Packaging content inspection

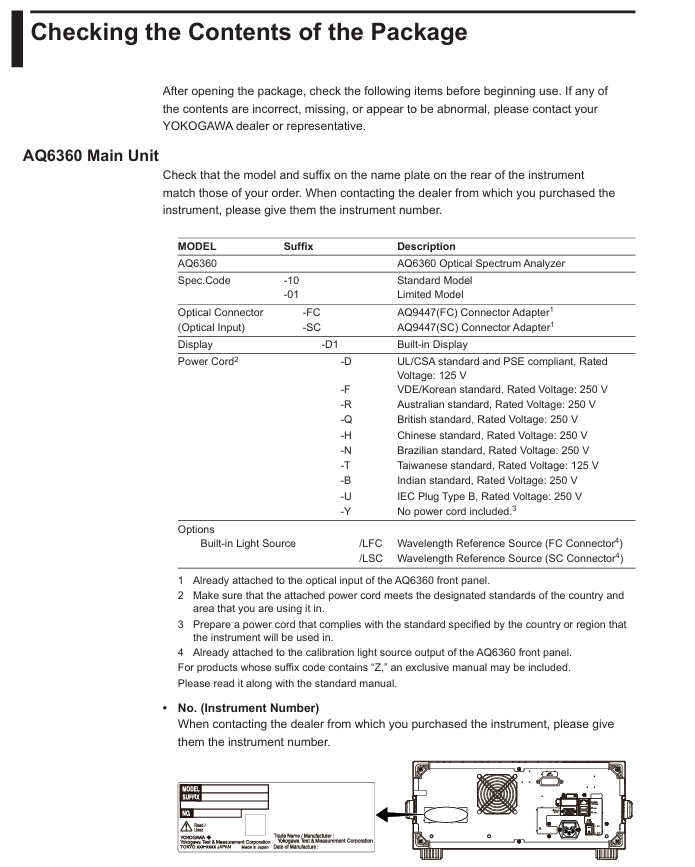

After unboxing, it is necessary to confirm that the host, standard accessories, and optional accessories are complete. The standard accessories are listed in the table below (optional accessories need to be purchased separately):

Category, Part Name, Model/Part Number, Quantity, Key Explanation

Host AQ6360 Host -1 Confirm that the back nameplate model is consistent with the order, and record the instrument number (to be provided when contacting the dealer)

Standard Attachment - Power Supply Cord A1006WD (UL/CSA) 1 needs to be matched with regional standards, such as A1064WD for China and A1009WD for Europe; Suffix - Y without power cord

Standard attachment - Other rubber foot pads A9088ZM 2 sheets A9088ZM includes 2 foot pads for fixing instruments to prevent sliding

Standard Attachment - Handbook Beginner's Guide IM AQ6360-02EN 1 Must Read Basic Document

Optional accessories - connector AQ9447 connector adapter (FC) AQ9447-FC - for optical input interface, also available in SC model (AQ9447-SC)

Optional accessories - connector AQ9441 connector adapter (FC) AQ9441-FC - for calibrating light source output interface, also available in SC model (AQ9441-SC)

2. Instrument installation requirements

Installation environment: For indoor use only, avoid direct sunlight, flammable and explosive environments, high vibration/high dust areas

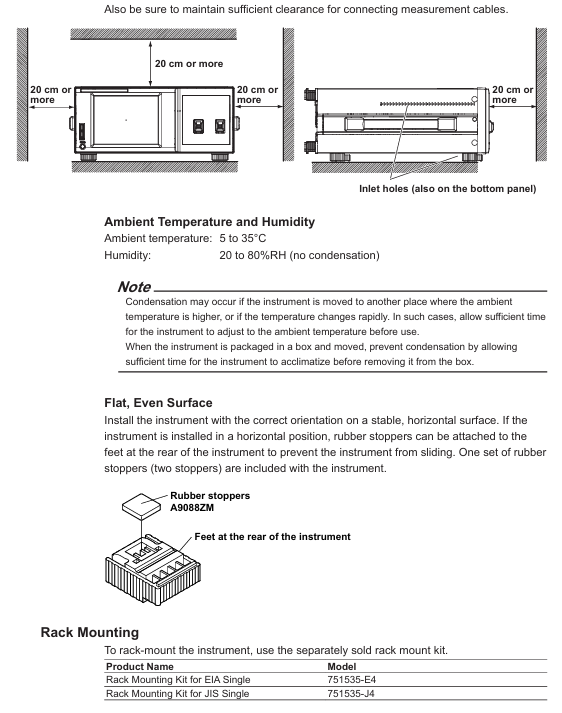

Placement requirements: Horizontal and stable tabletop, anti tilt; Ventilation gap ≥ 200mm (side/back ventilation holes) to prevent internal overheating

Anti impact: Avoid falling (dropping ≥ 2cm may damage the internal monochromator), use original factory grade cushioning packaging during transportation

Rack installation: A separate rack kit (such as EIA standard 751535-E4, JIS standard 751535-J4) needs to be purchased, and the bottom should be supported and not obstruct the ventilation holes during installation

3. Power connection and power on/off

Power specifications: Rated voltage 100-240V AC, frequency 50/60Hz, maximum power consumption ≈ 100VA; allowable voltage range 90-264V AC, frequency 48-63Hz

Power on/off process:

Connect the power cord in the shutdown state (grounded, using a three pin socket);

Turn on the back MAIN POWER switch, and the front POWER light will turn orange;

After waiting for a few seconds, press the front POWER switch, the light turns green, and the instrument starts initialization (displaying STEP 1/9 to STEP 9/9);

To shut down, first press the front POWER switch, confirm the pop-up window, and then click "Yes". After the POWER light turns orange, turn off the MAIN POWER switch.

Basic Operations

1. Control method

Touch screen operation:

Click (select menu/input parameters), drag (move waveform/marker), pinch and zoom (enlarge/shrink waveform);

During waveform operation, a "Operation Tool Window" will pop up, supporting functions such as restoring the initial state and peak alignment.

Mouse/keyboard operation:

Mouse: Left click=Touch screen click, right-click on waveform area to pop up menu, drag to zoom in and out of waveform;

External keyboard: Supports shortcut key operations (such as [SHIFT]+[F1] to start scanning, [ALT]+[F6] to enter system settings). Please refer to the table on page 3-15 of the document for specific mappings.

2. Core operating procedures

Menu operation: Click on the "Three Menu" in the upper right corner of the screen to open the Main Menu window, select a function (such as SWEEP/SETUP/MARKER), switch submenus through "More", and click on the corresponding item to perform the operation.

Parameter input:

Numerical input: Click on the parameter value to pop up the "Parameter Input Window", and adjust it through the numeric keypad or arrow keys (COARSE/FINE switch step size);

String input: When entering a label/file name, a on-screen keyboard pops up, supporting cursor movement and character insertion/deletion.

DUT connection:

Clean the end face of the optical connector (using NTT-AT specialized cleaning agent, press and rotate to wipe);

Connect the optical fiber to the "Optical INPUT" interface of the instrument, and set "NORM" (regular PC) or "ANGLED" (APC) through Main Menu → SETUP → Fiber Connector.

Maintenance and Calibration

1. Firmware update

Update purpose: To enhance the functionality and usability of the instrument, the latest firmware needs to be downloaded from the Yokogawa official website;

Update method:

USB update: Create an "Update" folder in the USB root directory, place the. upd firmware file, and execute it through System → Version → Update (USB);

Network update: Connect to the PC via Ethernet, copy the firmware to the internal Update directory of the instrument, and execute it through Update (NETWORK);

Attention: Do not turn off the power during the update. The instrument will automatically restart after the update, and the settings data will be initialized (backup is required in advance).

2. Accuracy calibration

Wavelength calibration:

Applicable scenario: After 1 hour of preheating and before measurement, ensure wavelength accuracy (±) 0.02nm@1520-1580nm );

Tools: Use built-in reference light sources (/LFC/LSC options) or gas lasers with known wavelength accuracy;

Exception handling: If the error is greater than ± 5nm, contact the dealer for adjustment.

Level calibration:

Tools: 1310/1550nm light source, optical power meter;

Process: Connect the light source to the instrument, measure the peak level, and then connect the light source to the optical power meter to confirm that the difference between the two is within ± 0.5dB (meeting the level accuracy requirements).

3. Daily maintenance and component replacement

Daily cleaning:

External: Wipe with a dry cloth after power failure, and prohibit volatile chemicals;

Optical interface: Clean the connector end face with an alcohol swab and disable compressed air blowing (to prevent dust from entering the monochromator).

Component replacement cycle:

Key Explanation of Component Name Replacement Cycle

LCD backlight ≈ 70000 hours lifespan reference value under normal usage conditions

It is recommended to replace the cooling fan regularly for 3 years to prevent overheating

Backup battery (lithium battery) for 5 years to store settings data, needs to be replaced if expired

Safety and Compliance

1. Safety Warning

Warning (risk of fatal/serious injury):

Cannot directly view the optical output interface (built-in reference light source continuously outputs infrared light, which may cause blindness);

Grounding must be used, and ungrounded extension cords are prohibited;

Do not use in flammable and explosive environments, and do not disassemble the instrument by yourself (there is high pressure inside).

CAUTION (Minor Injury/Equipment Damage Risk):

The instrument is a Class A industrial equipment, which may cause radio interference when used in residential areas and needs to be resolved by the user themselves;

To avoid strong light input (which may damage optical components), initialization must be completed before connecting the DUT.

2. Compliance requirements

Environmental compliance: compliant with the EU WEEE Directive (must not be mixed with household waste for disposal) and the Battery Directive (lithium batteries must be separately recycled);

Laser compliance: The built-in laser light source is Class 1 (compliant with IEC 60825-1:2014, 21 CFR 1040.10/11), with a wavelength of 1.53 μ m and a maximum output power of 0.04mW;

Regional compliance: Taiwan region needs to inquire about restricted substance information for power cord (A1100WD) (official website) https://tmi.yokogawa.com/support/... ).

Key specification parameters

The core specifications of AQ6360 are shown in the following table (limited models should refer to IM AQ6360-51EN):

Specification category specific parameters

Suitable for fiber optic SM (9.5/125 μ m), GI (50/125 μ m, 62.5/125 μ m)

Wavelength range 1200-1650nm

Wavelength accuracy ± 0.02nm (1520-1580nm), ± 0.04nm (1580-1620nm), ± 0.10nm (1200-1650nm)

Wavelength resolution of 0.1/0.2/0.5/1/2nm (setting options), accuracy of ± 5%

Level sensitivity -80dBm (1300-1620nm, resolution 0.1nm, HIGH2 level)

Maximum input power+20dBm (single wavelength resolution input power), maximum safe input power+25dBm (total input power)

Level accuracy ± 0.5dB (1310/1550nm, input -20dBm, MID/HIGH1/HIGH2 levels)

Dynamic range 55dB (peak ± 0.4nm), 40dB (peak ± 0.2nm), resolution 0.1nm

Interface GP-IB, Ethernet, USB (2 each), SVGA output

Display 8.4-inch color LCD (touch screen, resolution 800 × 600 pixels)

Physical dimensions 426 (W) × 177 (H) × 459 (D) mm (excluding protective cover/handle)

Weight ≈ 15.5kg

The working environment temperature is 5-35 ℃, and the humidity is 20-80% RH (without condensation); Performance guarantee temperature 18-28 ℃

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923