K-WANG

YOKOGAWA AQ7420 High-Resolution Reflectometer

YOKOGAWA AQ7420 High-Resolution Reflectometer

Instrument positioning and core applications

AQ7420 is a high-resolution reflectometer based on the principle of Time Domain Optical Coherence Tomography (TD-OCT) with built-in Michelson interferometer. Its core function is to measure three key parameters of optical devices through USB connection with the control PC

Optical Return Loss (RL): measures the return loss of fiber optic connectors, internal scratches, and device connection points, locates the position (with a maximum accuracy of 1 μ m) and intensity of reflection points.

Burnout Detection: Scan the distribution of return loss throughout the entire measurement range to identify abnormal reflection peaks such as fiber breakage and component defects.

Optical Insertion Loss (IL): measures the power attenuation of an optical signal passing through a Device Under Test (DUT) to evaluate the transmission performance of the device.

The instrument needs to be used in conjunction with a dedicated PC application, supporting local operation and TCP/IP remote control. The measurement results can be automatically graded, saved, and printed to meet the requirements of automated testing.

PC application installation and environmental requirements

1. Hardware and system requirements

Before installation, it is necessary to confirm that the control PC meets the following conditions, otherwise it may cause abnormal software operation or communication failure:

Project Requirements Explanation

The operating systems Windows 10 (32/64 bit) and Windows 11 do not support Windows XP/Vista/7/8 and tablet mode

Hardware configuration with at least 10MB of free hard disk space, USB interface free space for software installation and data storage, USB for instrument communication

Display resolution of 1024 × 768 pixels and above, 256 colors and above to ensure complete display of the operation interface, clear waveform diagram

The driver relies on NI-VISA 16.0 and above versions for communication between instruments and PCs, requiring VISA drivers. If not installed, it needs to be installed from the product CD first

2. Installation and uninstallation process

(1) Software installation steps

Preparation: Close the installed AQ7420 series software (if any) and log in to Windows with administrator privileges.

Start installation: Insert the product CD and run the path in English Application ARB-EDIT Setup. EXE (or enter the path through "Start Menu ->Run").

Driver installation: After completing the PC application installation as prompted, the FTDI CDM driver installation window will automatically pop up. Click "Extract → Next → I agree → Finish" in sequence to complete the driver deployment.

Start verification: After installation is complete, add the "AQ7420Series-OLCR" program under "Start Menu → YOKOGAWA", generate a shortcut icon on the desktop, double-click to start and enter the main interface.

(2) Uninstalling process (taking Windows 11 as an example)

Open "Control Panel ->Apps ->Installed Apps" and find "AQ7420Series'OLCR".

Click on the icon on the right side of the program, select "Uninstall", confirm and complete the uninstallation; If there are any remaining installation folders, they can be manually deleted (self built data needs to be backed up in advance).

(3) Connection exception handling

If the software prompts "Device Error" when starting, check:

Is the USB cable securely connected to the AQ7420 and PC.

Whether the VISA driver is installed properly (can be verified through NI MAX tool).

Whether the instrument power is turned on and whether the warm up is completed (it is recommended to perform reference measurements after preheating for 1 hour).

If you only want to view data without connecting the instrument, you can click "Viewer Mode" to enter the view mode.

Core functions and operating procedures

1. Preparation before measurement

(1) Instrument preheating and reference measurement

Preheating requirement: After starting up, the "Repeat Mode" should be turned on to run for 1 hour for preheating, to avoid temperature drift affecting measurement accuracy; After preheating, the reference measurement calibration system needs to be executed.

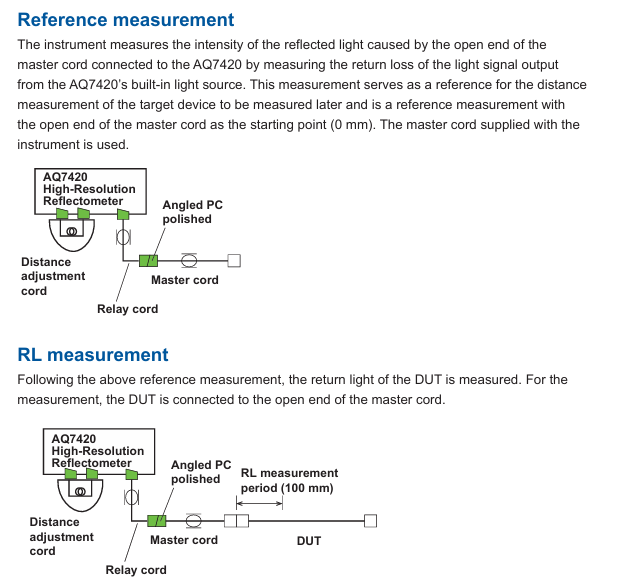

Reference measurement type:

Detection REF: The reference measurement for RL and burn detection requires the use of a dedicated main cable (Master Cord), with the open end of the main cable as the measurement starting point (0mm), to record the reference reflection intensity.

IL REF: Reference measurement of insertion loss, connect the main cable directly to the optical input port of AQ740023 sensor head, and record the reference optical power.

All REF: Simultaneously execute Detection REF and IL REF, suitable for scenarios where RL/burn detection and IL need to be measured simultaneously.

(2) Key hardware connections

When measuring different parameters, cables need to be connected according to specifications. The core components include the main cable (standard accessories, can be purchased separately), distance adjustment cable, relay cable, FC/APC adapter, and AQ740023 sensor head. The example connections are as follows:

RL/burn detection: AQ7420 test port → relay cable → FC/APC adapter → main cable → device under test (DUT), the open end of the main cable should be kept away from reflective objects (at least 100mm).

IL measurement: AQ7420 test port → relay cable → FC/APC adapter → main cable → DUT → AQ740023 sensor head, ensure that the connector end face is clean (dirt can cause excessive splicing loss, prompt "Under Range").

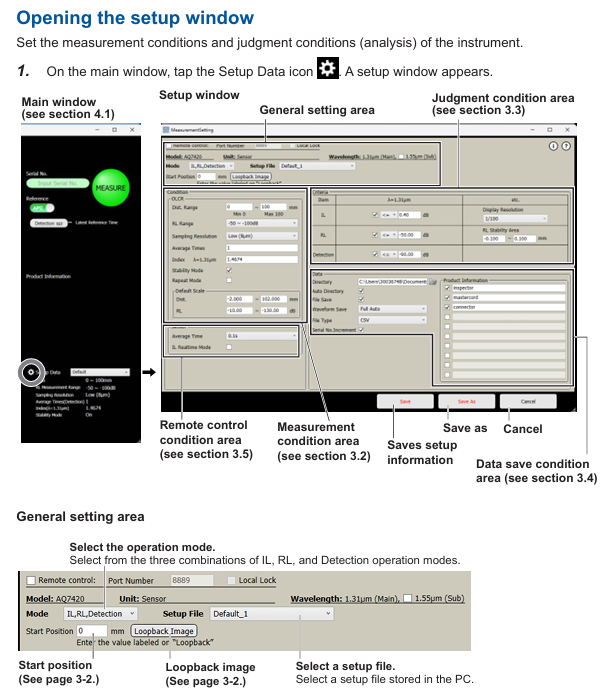

2. Measurement setup (Setup window)

Open the settings window through the "Setup" button on the main interface, configure measurement conditions, grading standards, data saving, and remote control parameters. The core settings are as follows:

(1) General settings

Operation mode: Supports three combination modes - "IL, RL, Detection" (single measurement of three types of parameters), "Detection" (only RL and burn detection), and "IL" (only IL).

Wavelength selection: main wavelength of 1.31 μ m, sub wavelength of 1.55 μ m (dual wavelength data can be measured simultaneously when sub wavelength needs to be enabled).

Start Position: Used for long-distance cable adjustment (optional accessory), input the distance compensation value displayed in the "Loopback Image" window to correct the measurement starting point offset.

(2) Measurement conditions

Scope of Settings/Option Description

Measurement distance (Span) from 0 to 100mm. The measurement time increases with distance and defaults to 100mm

RL measurement range -14.7~-85dB/-50~-100dB. The former is suitable for strong reflection scenarios, while the latter is suitable for weak reflection (such as deep loss)

The higher the sampling resolution of High (1 μ m)/Middle (4 μ m)/Low (8 μ m), the higher the measurement accuracy but the longer the time consumption

The average number of detections (Detection) is 1-16 times, and the more detections, the lower the noise

The refractive index (Index) of 1.0000~2.0000 is set according to the refractive index of the measured fiber (such as SM fiber 1.4674), which affects the accuracy of distance measurement

After turning on/off the Stability Mode, it automatically corrects the length drift of the main cable caused by changes in ambient temperature (0mm correction)

(3) Grading criteria (Analysis)

Set the qualified threshold for each parameter, and automatically compare and grade after measurement (blue "Pass", red "Fail"):

IL threshold: 0~40dB, supports setting display resolution (1/10~1/10000).

RL threshold: -120~-10dB, can limit the grading range (-10~110mm).

Burn detection threshold: -120~-10dB. Reflection peaks exceeding the threshold will be marked and counted on the waveform.

(4) Data saving settings

Storage path: Specify the data storage directory, enable "Auto Directory" to automatically create subfolders by "year/month/day".

File type: Waveform data supports CSV (numerical), JPG/BMP (image), measurement data (PS format) includes grading results, peak positions, and RL values, and dual wavelength data is merged and saved.

Auto Save: After enabling "File Save", save numerical data on a daily basis; The 'Waveform Save' supports modes such as' NG only auto save 'and' fully auto save 'to meet different testing needs.

3. Measurement operation process

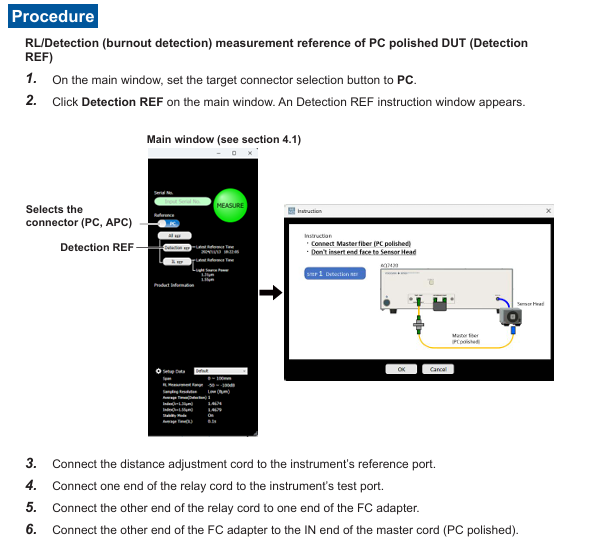

(1) Reference measurement (taking PC polished DUT as an example)

RL/Burn Detection Reference (Detection REF):

Set the "Target Connector Selection" on the main interface to "PC", click on "Detection REF", and follow the prompts to connect the distance adjustment cable, relay cable, FC adapter, and PC polishing main cable (open end).

Click "OK" to perform the reference measurement. After completion, the command window will automatically close and record the reference reflection value at the 0mm starting point.

IL Reference (IL REF):

Click on "IL REF" on the main interface and connect the open end of the main cable to the optical input port of the AQ740023 sensor head.

Click "OK" to perform reference measurement, record the reference optical power, and use it for subsequent IL calculation (power difference after DUT insertion).

(2) DUT measurement

RL/Burn Detection Measurement:

Disconnect the main cable from the open end, connect the DUT (ensure the connector is clean and scratch free), and enter the DUT serial number (optional, supports automatic increment).

Click the "MEASURE" button on the main interface, and the instrument will scan the distribution of return loss within the measurement range. After completion, the RL value will be output in the "Measurement Result Display Area", and the waveform will display the burn detection peak.

IL measurement:

Connect the DUT in series between the main cable and AQ740023, click "Measure", and the instrument calculates the insertion loss of the DUT (the difference between the reference power and the measured power), and the result is displayed in real time (enabling "IL Realtime Mode" for continuous measurement).

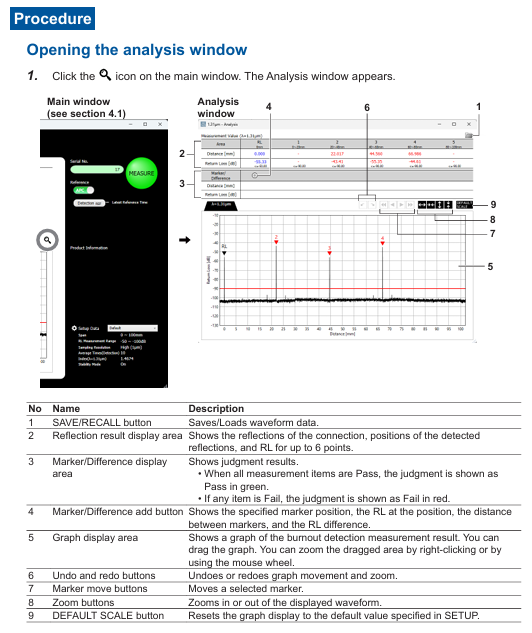

4. Data analysis (Analysis window)

After the measurement is completed, click the "Analysis Mode" button on the main interface to enter the analysis window, which supports waveform detail viewing and marking analysis:

Waveform interaction: Drag and drop the mouse to pan the waveform, right-click or scroll to zoom in and out of a specific area, and use "DEFILT SCALE" to restore the default display scale.

Marking operation:

Click the "Marker Add" button to add markers on the waveform, and check the distance (mm) and RL value (dB) of the marker position.

Support calculating the distance difference and RL difference between two markers (such as A-B distance difference and RL difference) to assist in locating defect spacing.

Peak recognition: Reflection peaks that exceed the classification threshold are automatically marked, and the table displays the peak position, RL value, and classification result, making it easy to quickly locate outliers.

5. Data storage and printing

(1) Data saving

Manual Save: Click "SAVE" in the analysis window, and save the waveform data (CSV/JPG/BMP) according to the set path. The file name should include the date, time, and serial number (such as "PW20241115_103040-AA1. csv").

Auto Save: After enabling "Waveform Save", the measurement is automatically saved upon completion (only data classified as Fail is saved in NG mode to save storage space).

(2) Report printing

Click the "Report" button on the main interface to open the Windows print settings window, select the printer or "PDF" (generate PDF file).

The printed content includes instrument model, measurement time, set parameters, IL/RL/Detection results, waveform diagrams, and peak data, which are automatically summarized into a single page report for easy testing and archiving.

Remote control

1. Preparation for remote control

Hardware connection: The control PC is connected to the remote server via LAN, and the instrument is connected to the control PC via USB, ensuring that the network port (default 8889) is not blocked by a firewall.

Software settings: Enable "Remote Setting" in the PC application "Setup window → Remote Conditions", set the port number (consistent with the remote terminal), and enable "Local Key Display" to display the "Local Release Button" when connecting remotely.

2. Login and permission management

Login command: Remote terminal sends LOGIN<wsp>ID, Password. The default administrator ID/password is "reflectometer/reflectometer". After successful login, control the PC to display the "Remote" icon.

Permission classification:

Administrator: Can modify ID/password (IDWrite: ADMin<wsp>new ID, new password), create users (up to 5).

User: Only performs basic operations such as measurement and query results, and does not have permission to modify system settings.

Logout command: Send: LOGOut to disconnect the remote connection, or click on the control PC "Local Key" to force a switch to local control.

3. Core control commands

Remote control is based on TCP/IP protocol, with commands divided into "program messages" (control) and "query messages" (read). Examples of key commands are as follows:

Command group command example function

MAIN group: MAIN: EASure start/stop measurement

: MAIN: REF: ILREf Perform IL reference measurement

:MAIN:RESUlt:JUDGe? Query the overall judgment level result (0=Fail, 1=Pass)

SETUp group: SETUp: MODE<wsp>0 Set the operation mode to "IL, RL, Detection"

SETUP: EASure: STARt<wsp>20 Set measurement starting position 20mm

General command * IDN? Query instrument information (manufacturer, model, serial number, firmware version)

*RST resets instrument settings and stops all processes

The command supports abbreviations (such as SETUp, which can be abbreviated as SETU), is not case sensitive, the response message is in ASCII format, and the error command returns "Invalid Command".

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923