K-WANG

REXRTOH CDH1/CGH1/CSH1 series milling machine type hydraulic cylinder

REXRTOH CDH1/CGH1/CSH1 series milling machine type hydraulic cylinder

Introduction

In the field of modern industrial automation, hydraulic cylinders serve as the core power source, and their performance directly determines the machining accuracy and dynamic response speed of machine tools, packaging, and printing equipment. Bosch Rexroth's CDH1, CGH1, and CSH1 series hydraulic cylinders are heavy-duty actuators designed specifically for heavy industrial applications. This series has a rated pressure of 250 bar and piston diameters ranging from 40 mm to 320 mm, designed to maintain structural integrity and motion stability under extreme loads. These hydraulic cylinders can provide reliable solutions for eccentric forces, high-frequency cycles, and lateral loads.

Design principles and structural characteristics

The core design concept of the CDH1, CGH1, and CSH1 series lies in their "head and bottom flanges" (principle A). This structural design ensures mechanical integrity under extreme working conditions such as high-pressure impact or high moment of inertia. This series offers multiple installation methods to accommodate different mechanical settings, mainly including the following six standard configurations:

Earring Installation (MP3): Designed specifically for dynamic applications, allowing for slight deviations between the cylinder block and frame, reducing stress and bearing wear.

Self centering Earrings (MP5): Most suitable for heavy radial loads, its self-aligning ball bearings can compensate for misalignment, thereby reducing wear and extending lifespan.

Head flange (MF3): Provides a compact axial thrust connection point.

Bottom flange (MF4): provides a safe installation surface for the cylinder block, optimizing force transmission.

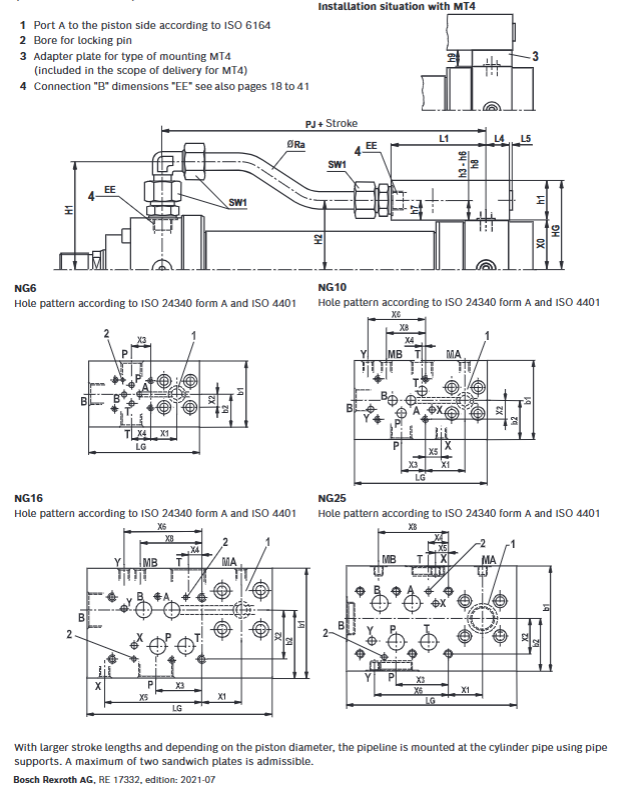

Ear Shaft Installation (MT4): allows the cylinder body to rotate around a pivot, suitable for complex mechanical linkages.

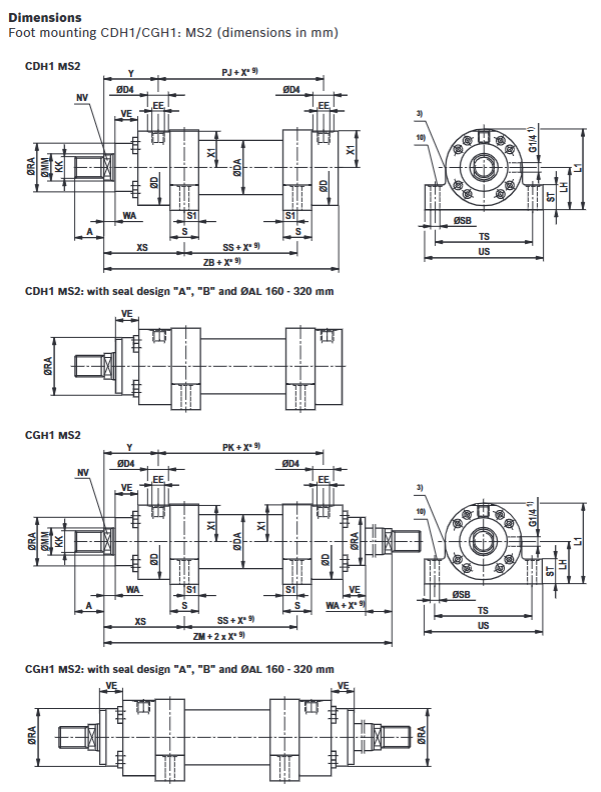

Base Installation (MS2): A standard solution for long-distance applications, providing a stable support base.

Technical specifications and performance parameters

The performance parameters of this series of hydraulic cylinders vary with the change of cylinder diameter size. The following is an overview of key technical indicators:

Piston diameter (Ø AL): ranging from 40 mm to 320 mm. The larger the diameter, the greater the output thrust is usually (for example, a 40 mm piston force is about 31.4 kN, while a 320 mm piston force can reach 2010 kN).

Stroke: Optional length up to 6 meters.

Wire connection: Supports multiple standard interfaces, such as ISO 1179-1 (pipe thread), ISO 9974-1 (flange), and ISO 6164.

Sealing system and reliability

Industrial environments are often accompanied by oil mist, high humidity, and chemical corrosion. Bosch Rexroth offers a variety of sealing options to ensure long-term operational stability:

Standard Seal (M): Suitable for mineral oil HL, HLP, and HFA hydraulic systems.

Servo Quality (T): Low friction option, suitable for heavy industry.

HFC (Water Ethylene Glycol): Suitable for water containing ethylene glycol HFC media, with corrosion resistance protection (code "G").

HFDR/HFDU (phosphate ester/polyol ester): suitable for phosphate ester and polyol ester media (code "S").

V (herringbone seal): Suitable for specific dynamic load applications.

Terminal buffering technology

The impact caused by high-speed movement may cause damage to the equipment. Bosch Rexroth's CDH1, CGH1, and CSH1 series solve this problem through self-adjusting and adjustable end position buffering. This function can effectively absorb end impact energy, protect the hydraulic cylinder body and connecting equipment.

Self regulating buffer: automatically compensates damping for different loads to reduce vibration.

Adjustable buffer (E): allows for optimization of cycle time based on specific operating conditions.

Selection guide and ordering code

Proper selection is crucial to meet specific engineering requirements. The ordering code structure of this series is rigorous, divided into 16 fields. Engineers need to configure according to the following steps:

Series selection: Distinguish between CDH1 (differential cylinder), CGH1 (dual rod cylinder), or CSH1 (with position measurement).

Installation method: Choose from MP3, MF3, MF4, MT4, or MS2.

Size definition: Specify the piston diameter (e.g. 100 mm) and piston rod diameter (e.g. 56 mm).

Travel specification: Define the extension length in millimeters.

Port selection: Determine the interface position (1 to 4) and interface type (such as ISO pipe thread "M" or flange connection).

Piston rod and seal:

Material: Choose standard hard chrome plating, quenched hard or nickel plating (codes C, H, N).

Sealing design: According to the medium selection criteria (M, T, G, L, R, S or V).

Additional options: Proximity switches, position sensors, IO Link interfaces, or special coatings can be added.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

-

ABB UAC326AE Industrial Process Control Module

-

ABB NU8976A Industrial Automation Control Module

-

ABB LT8978bV1 High-Performance Industrial Automation Module

-

ABB ARC093AV1 Industrial Control and Monitoring Module

-

ABB UAC318AE Advanced Automation Control Module

-

ABB UFC092BE01 Universal Field Controller Module

-

ABB UNS2980c-ZV4 Advanced Industrial Control Module

-

ABB UNS0874A Industrial Energy Management Module

-

ABB 5SHY3545L0003 Advanced Industrial Power Protection Module

-

ABB 5SHY35L4510 High-Speed Circuit Breaker Module

-

ABB DSDP140B Distributed Control System Module

-

ABB DAPC100 High-Performance Automation Control Module

-

ABB DSQC545A Servo Drive Module

-

ABB PM861AK01 Programmable Logic Controller Module

-

ABB 57160001-KX Communication Interface Module

-

ABB EI813F Intelligent Energy Interface Module

-

ABB IEPAS01 Power and Signal Interface Module

-

ABB AI845 Analog Input Module

-

ABB PM803F Safety CPU Module

-

ABB 3HAC4776-1/1 Industrial Control Module

-

ABB IMASI23 Analog Signal Interface Module

-

ABB YB560100-EA S3 Power Interface Module

-

ABB XO16N1 Digital Output Module

-

ABB XM06B5 Analog Input Module

-

ABB XI16E1 Digital Input Module

-

ABB V4550220-0100 Industrial Automation Module

-

ABB TU804-1 Terminal Unit Module

-

ABB TK516 Industrial Control Module

-

ABB TC625 Communication Interface Module

-

WATLOW LLS200212 E257034 Accessory Line - CLS208 Compatible

-

WATLOW ANAFAZE 997D-11CC-JURG Controller - Industrial Temperature Regulation

-

WATLOW CLS2163C1 Temperature Controller - High-Precision Industrial Control

-

WATLOW PPC-TB50 30280-00 Temperature Controller - Industrial Process Control

-

WATLOW NLS300-CIM316 Temperature Controller - Industrial Precision Control

-

WATLOW MLS300 Temperature Controller - High-Performance Thermal Management

-

WATLOW CAS16CLS/CAS Temperature Controller - Advanced Industrial Control

-

WATLOW CAS200 CLS216 Temperature Controller - Industrial PID Solution

-

WATLOW CLS208 Temperature Controller - Precision Industrial Control

-

HIMA K9212 Fan Assembly

-

ABB 500TRM02 Termination Module | 1MRB150011R1

-

ABB 500AIM02 Analog Input Module | 1MRB150022 R0002Y | 1HDF 930412 X010

-

ABB 500MTM02 Interface Module | 1MRK001967-AA | 1HDF 930512 X010

-

ABB 500CSP04 Power Supply Module | HE401314/0002 | 1MRB150051R2

-

ABB 500CIM05 Communication Interface Module | 1MRB150077R1/B

-

ABB 500PSM03 Power Supply Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500AIM02 Analog Input Module

-

ABB 500CPU05 Central Processing Unit Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB 500BIM01 Binary Input Module (1MRB150024R0002)

-

ABB 500MBA01 Memory Backup Module (1MRB150003R0002)

-

ABB 500BIO01 Binary Input/Output Module 1MRB150005R1

-

ABB 500BOM01 Binary Output Module 1MRB150023R0002

-

ABB 500CIM05 Communication Interface Module 1MRB150077R1/B

-

ABB 500CMP04 Control Module HE401314/0001 1MRB150051R1

-

ABB 500CSP04 Control System Processor Module

-

ABB 500MBA02 Memory Backup Module

-

ABB 500MTM02 Measurement Module

-

ABB 500PB101 Processor Bus Module

-

ABB 500PSM03 Power Supply Module

-

ABB 500SCM01 System Communication Module

-

ABB 500TTM02 Temperature Transmitter Module

-

ABB TA524 Temperature Monitoring Module – Industrial Thermal Safety

-

ABB SR511 Signal Relay – Industrial Signal Control

-

ABB SPCJ4D34-AA Programmable Controller – Advanced Industrial Control

-

ABB SPAD346C Digital Automation Controller – Industrial Process Control

-

ABB SE96920414 YPK112A Motor Protection Relay – Reliable Motor Control

-

ABB SC513 Control Relay – Industrial Automation Control

-

ABB SB512 Safety Relay – Industrial Safety Control

-

ABB SAFT103 Battery Monitoring Module – Reliable Power Management

-

ABB SA801F Safety Automation Module – Industrial Machine Protection

-

ABB RF615 Feeder Protection Relay – Reliable Industrial Power Safety

-

ABB REF542PLUS Protection Relay – Advanced Power System Protection

-

ABB RB520 Remote I/O Module – Reliable Industrial Connectivity

-

ABB R1.CAIR Air Circuit Breaker – Industrial Power Protection

-

ABB PU515A Processor Unit – Advanced Automation Control

-

ABB PS130/6-75-P Power Supply – Reliable Industrial Power

-

ABB PM630 Protection Relay – Advanced Industrial Protection

-

ABB NAIO-03 Analog I/O Module – Industrial Signal Control

-

ABB MSR04XI Safety Relay Module – Industrial Safety Control

-

ABB M2004HW Motor Module – Precision Industrial Motion

-

ABB L110-24-1 DC Power Supply – Reliable Industrial Power

-

ABB IMMPI01 Motor Interface Module – Robust Industrial Control

-

ABB IMMFP12 Motion Feedback Processor – Accurate Motion Control

-

ABB IMFEC12 Fieldbus Encoder Module – Precision Industrial Feedback

-

ABB IMDSI14 Digital Signal Interface – Robust Industrial Connectivity

-

ABB EI803F Encoder Interface – Accurate Position Feedback

-

ABB EHDB280 Digital Output Module – Industrial Control Interface

-

ABB EHDB130 Digital Input Module – Reliable Industrial Sensing

-

ABB DSQC627 Robot Controller – Advanced Automation Control

-

ABB DSQC608 Robot Controller Interface – High-Reliability Control

-

ABB DSQC346U Servo Drive Module – Advanced Robot Control

-

ABB DSQC327A Robot Servo Drive – High-Performance Motion Control

-

ABB DSPC406 Robot Interface & Power Module – Industrial Automation

-

ABB 07KT97B Control Logic Module – Efficient Industrial Automation

-

ABB PU516 Processor Board – High-Performance Industrial Control

-

ABB DSIH72VP ENOK Interface Unit – Reliable Industrial Connectivity

-

ABB DSBB175 System Board Module – Central Control Backbone

-

ABB DSAO110 Analog Output Module – Precision Industrial Control

-

ABB DRA02 Card Rack Module – Modular Automation Framework

-

ABB DPW01 Power Supply Module for ABB Control Systems

-

ABB DLM01 Load Management and Distribution Module

-

ABB DAO01 Analog Output Module

-

ABB D-20-0-1102 Digital Input Module

-

ABB CP450-T-ETH Touch Panel Operator Interface

-

ABB CI520V1 Communication Interface Module

-

ABB BRC300 Controller

-

ABB BB510 (DC5256) Control System Module

-

ABB AX411/50001 Communication Interface Module

-

ABB AO610 Analog Output Module

-

ABB AI835 Analog Input Module

-

ABB AI625 Analog Input Module

-

ABB AI610 Analog Input Module

-

ABB 3HNA000512-001 Robot Automation System Component

-

ABB 3HAC17326-1/02 Robot Controller Component

-

ABB 3HAC14550-2/09A Industrial Robot Control Component

-

ABB 3HAC031683-001 Robot Control System Component

-

ABB 3HAC025466-001 Robot Automation Component

-

ABB 3HAB8101-8/08Y and Related Robot Control Components

-

ABB 3HAB3700-1 Automation Module

-

ABB 3BHB003689 Control Board

-

ABB 3ASC25H204 Control Board

-

ABB 3ASC25H203 Control Board

-

ABB 35AE92 Control Module

-

ABB CP800 Control Panel

-

KEBA JB241 22336 - HT Junction Box

-

KEBA EC100A03/C0L/C AN/4MB/53890 - PLC Chassis 16-Slot Rack Motherboard

-

KEBA GVME-610-I/O - VME I/O Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923