K-WANG

CENTUM CS 3000 Integrated Production Control System

Developer Yokogawa Electric Corporation

Applicable to over 10 industries including petroleum refining, petrochemicals, chemicals, pharmaceuticals, food and beverage

Core positioning for large-scale process control applications, achieving monitoring, control, and optimization of production processes

Related safety system ProSafe RS (Safety Instrumented System, compliant with IEC 61508 SIL3 standard)

CENTUM CS 3000 Integrated Production Control System

System basic information

Key content of the project

Product Name: CENTUM CS 3000 Integrated Production Control System

Developer Yokogawa Electric Corporation

Applicable to over 10 industries including petroleum refining, petrochemicals, chemicals, pharmaceuticals, food and beverage

Core positioning for large-scale process control applications, achieving monitoring, control, and optimization of production processes

Related safety system ProSafe RS (Safety Instrumented System, compliant with IEC 61508 SIL3 standard)

Core advantages of the system

Open and compatible enterprise level environment

Support linkage with ERP, MES and other systems, and achieve data sharing through OPC interface

Compatible with Windows 2000/XP system, can run general office software (such as Excel)

Flexible and scalable hardware configuration

Support 100000 monitoring tags (expandable to 1000000)

Connect up to 256 sites (16 domains, with a maximum of 64 sites per domain)

Control station type: FIO/RIO standard type, compact type, suitable for different factory sizes

High reliability design

Dual redundancy configuration: FCS processor, power supply, bus, I/O module and other key components are redundant

Fault switching: active/standby mode with no interruption, I/O module crashes within 4 seconds in case of CPU failure

Whole life cycle cost optimization

Compatible with existing Yokogawa systems (CENTUM CS, CENTUM-XL, etc.), supporting hardware reuse

Remote I/O deployment reduces wiring costs, PRM tool optimizes equipment maintenance efficiency

System hardware composition

(1) Core equipment

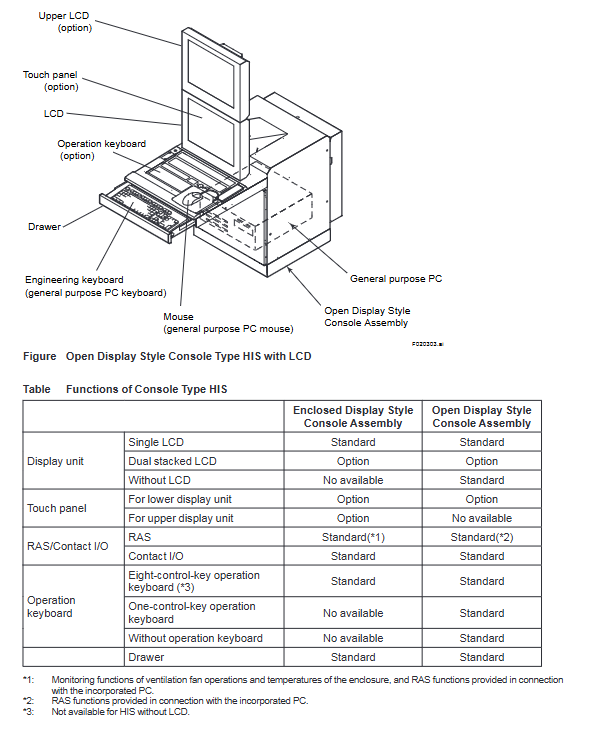

Human Machine Interface Station (HIS): divided into console type (closed/open display style) and desktop type, supporting multi display function

On site Control Station (FCS):

FCS for FIO (KFCS, KFCS2, etc.): paired with Fieldnetwork I/O modules

FCS for RIO (LFCS, LFCS2, etc.): paired with Remote I/O modules

Compact FCS (PFC - H/- S/- E, etc.): close range deployment, adapted to subsystem communication

Other key equipment:

Engineering PC (ENG): System Generation and Maintenance Management

Bus Converter (BCV): Connecting different domains or old systems

Communication Gateway (CGW): Interconnection between V net and Ethernet bus

(2) Network Architecture

V net: 10Mbps real-time control bus, supporting dual redundancy, with a maximum transmission distance of up to 20km (including repeaters)

Ethernet: connects HIS, ENG, and monitoring systems for data file transfer and HIS data synchronization

Fieldbus: Supports Foundation Fieldbus, replacing traditional 4-20mA analog interfaces

Core functional modules

(1) Operation and monitoring functions

Display modes: full screen mode, multi window mode (up to 5 operation monitoring windows can be displayed simultaneously)

Core functions: Window hierarchy management, navigation windows, dynamic window groups, alarm processing (priority level 5), trend analysis (supporting 8 data overlay displays)

Support functions: multi monitor, ITV camera access, voice message notification, web monitoring

(2) Control function

Adjustment control: Standard functional blocks such as PID and proportional control, supporting continuous/batch process control

Sequential control: sequence table, logic diagram, SFC, SEBOL language programming

Advanced Control: APCS (Advanced Process Control Station), supporting long cycle complex calculations (scan cycle 4/8/16 seconds)

Batch management: CS Batch 3000 package, compliant with ISA S88.01 standard, supports multi product formula management

(3) Engineering Function

Core features: concurrent engineering (multi person collaboration), virtual testing (hardware free), engineering data reuse

Tool support: system view (tree database), module builders, self document generation function

Maintenance functions: online maintenance (uninterrupted control), remote maintenance (via public network)

(4) Safety feature (ProSafe RS)

Safety protection: emergency parking, fire and gas protection, interlocking control

Compliance certification: T Ü V Rheinland certification, compliant with IEC 61508 SIL3 standard

Integration feature: Shared operating environment with CENTUM CS 3000, supporting unified monitoring

Key software packages and extended features

Software Package Name Core Features

Exapilot standardized operating procedures (SOP) to improve efficiency in non steady state operations

Exaopc OPC interface service, realizing data exchange between DCS and MES/ERP

PRM (Plant Resource Manager) equipment maintenance management, supporting preventive maintenance and remote parameter reading

FDA 21 CFR Part 11 compatibility package for data security and audit tracking, meeting electronic record/signature compliance requirements

SEM (Sequence of Events Manager) 1ms level event recording and analysis, supporting traceability of trip causes

LTTH (Long term Trend Historian) stores 1-year trend data and event messages, supporting trend comparison analysis

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923