K-WANG

YOKOGAWA FIO System (compatible with Vnet/IP) Hardware Specification Manual

YOKOGAWA FIO System (compatible with Vnet/IP) Hardware Specification Manual

Positioning and core use

The "FIO (Fieldnetwork I/O) System General Specification Manual" (document number: GS 33K50F10-50E) released by Yokogawa Electric Corporation is the 8th edition updated in September 2014. Its core purpose is to guide the module selection, system deployment, installation, debugging, and compliance verification of the system in the CENTUM VP (Vnet/IP) integrated production control system. The FIO system, as a field I/O solution, focuses on the acquisition and control of industrial field signals. It is interconnected with field control units (FCUs) through multiple buses and is suitable for process control needs in industries such as petrochemicals, power, and pharmaceuticals.

System architecture and core components

(1) Overall architecture design

The FIO system adopts a layered architecture of "FCU+node unit+bus", which realizes reliable interconnection between on-site signals and control units, supports dual redundancy configuration (power module, bus interface module, I/O module), and ensures high availability operation of industrial sites. The system can achieve chain or star topology expansion through the optical ESB bus relay unit (ANT10U), adapting to centralized and distributed deployment scenarios.

(2) Classification and specifications of core components

1. On site Control Unit (FCU)

FCU is the system control core, responsible for receiving on-site signals from FIO node units and executing control logic. The specific model and characteristics are as follows:

Model series type installation method adaptation bus core characteristics

AFV30 (S/D) standard/dual redundant 19 inch rack mounted ESB bus and optical ESB bus support node expansion package, connecting up to 13 node units

AFV40 (S/D) standard/dual redundant integrated ESB bus with cabinet, optical ESB bus. A single cabinet can install up to 11 node units and relay units

AFV10 (S/D) standard/dual redundant 19 inch rack mounted ESB bus, ER bus miniaturization design, suitable for small and medium-sized control scenarios

2. Node unit

Node units are interface carriers for on-site I/O signals, integrating power modules, bus interface modules, and I/O modules. They are divided into three categories according to the adapted bus:

Node unit type, model series, redundancy support, adaptation to bus core usage

ESB bus node unit ANB10 (S/D) single/dual redundant ESB bus close range (≤ 10m) on-site signal acquisition and transmission

Optical ESB bus node unit ANB11 (S/D) single/dual redundant optical ESB bus long-distance (up to 50km) anti-interference signal transmission

ER bus node unit ANR10 (S/D) single/dual redundant ER bus medium short distance (≤ 185m) economical signal transmission

3. Relay unit

Model Name Core Function Adaptation Scenarios

ANT10U optical ESB bus relay unit optical ESB bus chain/star expansion, amplifying optical signals for cross plant and long-distance node interconnection

4. Bus interface module

Used to achieve bus interconnection between FCU and node units, the key models and characteristics are as follows:

Model name adaptation bus core parameter installation requirements

EC401 ESB bus coupler module ESB bus single module can connect up to 9 node units AFV30 /AFV40 /AFV10 , which need to be installed in slots 7/8

EC402 2-port ESB bus coupler module, with 9 node units connected to each of the upper and lower ports of the ESB bus, is only compatible with AFV30/AFV40

The EB401 ER bus interface main module ER bus supports dual redundant communication. The single module is installed in odd numbered slots, and the slot on the right side needs to be left blank

ANT401/ANT411 Optical ESB Bus Relay Main Module Optical ESB Bus Transmission Distance 5km/5-50km Only compatible with AFV30 /AFV40

ANT502/ANT512 optical ESB bus relay module cooperates with the main module to achieve long-distance expansion, pre installed in the ANB11 node unit

Detailed Explanation of Bus System Specifications

The FIO system supports three types of buses: ESB, optical ESB, and ER, adapting to different distance and bandwidth requirements. The core specifications are as follows:

(1) ESB bus (AFV full series FCU adaptation)

Application scenario: Close range interconnection between FCU and local node units;

Transmission parameters: speed of 128 Mbps, bus topology, dual redundancy support;

Transmission medium: dedicated cable (YCB301), maximum transmission distance of 10m;

Connection capacity: AFV30 /AFV40 (LFS1700 database) up to 3 node units, with a maximum of 13 after expansion; AFV10 (LFS1500 database) has a maximum of 3 node units, and can be expanded to a maximum of 9.

(2) Optical ESB bus (AFV30 /AFV40 adaptation)

Application scenario: Long distance, anti-interference node interconnection;

Transmission parameters: speed of 128 Mbps, chain/star topology, dual redundancy support;

Transmission medium: Quartz single-mode fiber (JIS C6835 SSMA-9.3/125), LC interface, 2-core;

Transmission distance: 10m without relay, up to 50km with ANT411 relay;

Connection capacity: Share node unit quota with ESB bus.

(3) ER bus (AFV10 adaptation)

Application scenario: Medium to short distance economic interconnection;

Transmission parameters: speed of 10 Mbps, bus topology, dual redundancy support;

Transmission medium: coaxial cable (YCB141/YCB311), which needs to be interconnected through YCB147/YCB149 bus adapters;

Transmission distance: YCB141 has a maximum length of 185m; when using mixed cables, it is necessary to meet the requirement of "YCB141 length+(185/500) × YCB311 length ≤ 185m";

Connection capacity: up to 3 node units for AFV10 (LFS1500 database), up to 14 after expansion, and up to 8 node units for a single bus.

I/O module classification and core parameters

The FIO system I/O modules cover four categories: analog, digital, communication, and turbine machinery. They support isolation switch type and built-in isolation grid type, and are compatible with various field signals. The core classifications and parameters are as follows:

(1) Analog I/O module

It includes three types: non isolated, isolated, and channel isolated, supporting current, voltage, TC/mV, and RTD/PAT signals. Representative models are as follows:

Model Name Channel Number Signal Type Isolation Characteristics Power Consumption (5V DC/24V DC) Explosion proof Support

AAI141 analog input module 16 4-20 mA non isolated 310 mA/450 mA CSA/FM spark free type

AAV141 analog input module 16 1-5 V non isolated 350 mA/- CSA/FM spark free type

AAI143 analog input module 16 4-20 mA isolated 230 mA/540 mA Type i (intrinsic safety type)

AAI543 analog output module 16 4-20 mA isolated 230 mA/540 mA Type i (intrinsic safety type)

AAT141 TC/mV input module 16 TC (J/K/E, etc.), -100-150 mV isolated 450 mA/- CSA/FM spark free type

AAR181 RTD input module 12 Pt100 Ω isolated 450 mA/- CSA/FM spark free type

ASI133 built-in isolation barrier analog input module 4-20 mA isolation 150 mA/450 mA Type i (intrinsic safety type)

AST143 built-in isolation barrier TC/mV input module 16 TC, -100-150 mV isolation 150 mA/80 mA Type i (intrinsic safety type)

(2) Digital I/O module

Supports DC, AC, and relay outputs, partially compatible with NAMUR standards. Representative models are as follows:

Model Name Channel Number Signal Type Isolation Characteristics Power Consumption (5V DC) Explosion proof Support

ADV151 digital input module 32 24 V DC isolated 500 mA CSA/FM spark free type

ADV551 digital output module 32 24 V DC isolated 700 mA CSA/FM spark free type

ADV141 digital input module 16 100-120 V AC isolated 500 mA CSA/FM spark free type

ADR541 relay output module 16 24-110 V DC/100-240 V AC isolated 780 mA CSA/FM spark free type

ASD143 built-in isolation barrier digital input module 16 NAMUR compatible isolation 150 mA Type i (intrinsic safety type)

ASD533 built-in isolation barrier digital output module 8 U>12 V (I=40 mA) isolation 150 mA Type i (intrinsic safety type)

(3) Communication module

Support multiple industrial communication protocols to achieve interconnection with third-party devices:

Model Name Port Number Communication Protocol Rate Power Consumption (5V DC)

ALR111 serial communication module 2 RS-232C 1200 bps-115.2 kbps 500 mA

ALR121 serial communication module 2 RS-422/RS-485 1200 bps-115.2 kbps 500 mA

ALE111 Ethernet Communication Module 1 Ethernet 10 Mbps 500 mA

ALF111 Foundation Fieldbus Module 4 FF-H1 31.25 kbps 500 mA

ALP111/ALP121 PROFIBUS-DP module 1 PROFIBUS-DP -700 mA

(4) Turbomachinery specialized module

Suitable for turbomachinery control scenarios, the core models are as follows:

Model Name Channel Number Function Power Consumption (5V DC) Environment Support

AGS813 servo module 12 servo control 500 mA G3 support

AGP813 high-speed protection module 26 device security protection 900 mA G3 support

(5) Compatible module

Designed for upgrading the CENTUM V, CENTUM-XL, and µ XL systems, it can reuse existing cables. Representative models include AAP149 (pulse input), AAP849 (pulse input/analog output), and ADV859-ADV569 (ST compatible digital I/O).

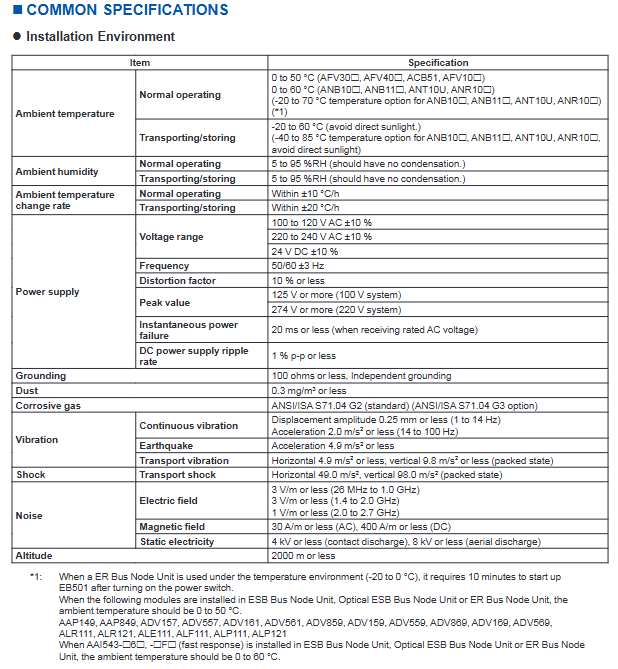

Environmental and power specifications

(1) Environmental requirements

Environmental parameters, working status, transportation/storage status, special instructions

Temperature standard: 0-50 ℃ (AFV series)/0-60 ℃ (node unit); Wide temperature options: -20-70 ℃ Wide temperature options: -40-85 ℃ ER node unit -20-0 ℃ Start up requires 10 minutes of preheating

Humidity 5-95% RH (no condensation) 5-95% RH (no condensation)-

Temperature change rate ± 10 ℃/h ± 20 ℃/h-

Vibration 1-14Hz: displacement ≤ 0.25mm; 14-100Hz: acceleration ≤ 2.0 m/s ² Earthquake: horizontal ≤ 4.9 m/s ²; Vertical ≤ 9.8 m/s ² in packaging state

Dust ≤ 0.3 mg/m ³ --

Corrosive gas standard: ANSI/ISA S71.04 G2; Option: G3--

Electromagnetic environment electric field ≤ 3 V/m (26MHz-2GHz); Magnetic field ≤ 30 A/m (AC)/400 A/m (DC) --

Static protection contact discharge ≤ 4 kV; air discharge ≤ 8 kV --

Altitude ≤ 2000 meters --

(2) Power specifications

Communication input: 100-120 V AC (± 10%) or 220-240 V AC (± 10%), frequency 50/60Hz (± 3Hz), distortion ≤ 10%, peak value ≥ 125 V (100V system)/274 V (220V system);

DC input: 24 V DC (± 10%), ripple rate ≤ 1% p-p;

Instantaneous power outage tolerance: ≤ 20ms (under rated AC voltage);

Grounding requirements: independent grounding, grounding resistance ≤ 100 Ω.

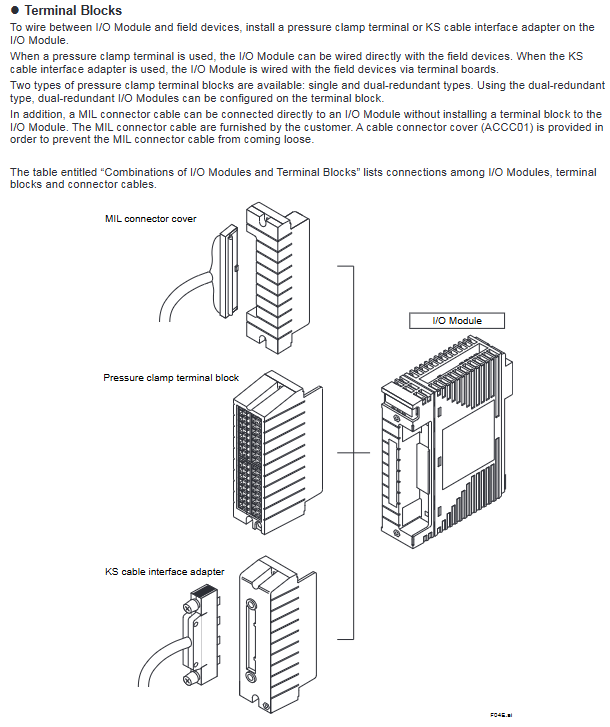

Connection method and terminal configuration

(1) Signal connection method

The module supports three connection methods to adapt to different on-site wiring requirements:

Pressure clamping terminal: directly connected to on-site equipment, supporting single/double redundant terminal blocks (such as ATA4S/ATA4D);

Special cable: Connect the terminal board through KS cable interface adapter, and some modules can be directly wired (such as YCB331/YCB337);

MIL connector cable: No terminal block required, directly connected to the module, equipped with anti loosening sheath (ACCC01).

(2) Compatibility of key module connections

Module type pressure clamping terminal dedicated cable MIL connector cable

Analog I/O (AAI141/AAI543) Support Support Support

Digital I/O (ADV151/ADV551) supports partial support

Communication module (ALF111/ALP111) partially supported but not supported

Built in isolation barrier module (ASI133/ASD143) is not supported

Compatibility module (AAP149/ADV859) is not supported

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Industrial information

- xYCOM

- Motorola

- architecture

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

ABB REF610 Protection and Control Relay

-

ABB DSQC633 Robot Control Interface Module

-

ABB DSQC332A Robot Control Module

-

ABB F362 Industrial Interface Module

-

ABB SK616001-A Industrial Control Module

-

ABB 3HAC0977-1 Robot Control Interface Module

-

ABB S503X Industrial Protection and Switching Device

-

ABB BC25 Industrial Automation Communication Interface

-

ABB DSQC504 Robot Servo and Control Module

-

ABB DSQC509 Robot I/O and Control Interface Module

-

ABB DSQC346B Robot Motion Control Board

-

ABB 3HAB8859-1/03A Industrial Robot Control Interface Board

-

ABB 3HAB9271-1/01B Robot Controller Communication Module

-

ABB 3HAC5497-1 Robot Control Processing Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923