K-WANG

YOKOGAWA CW500 Power Quality Analyzer

YOKOGAWA CW500 Power Quality Analyzer

Instrument positioning and core use

CW500 is a portable power quality analyzer that can accurately measure voltage, current, power, harmonics, and power quality events (sudden rise/fall/interruption, transient overvoltage, impulse current, flicker, etc.). It supports various wiring systems from single-phase two wire to three-phase four wire, and is widely used in power quality assessment and problem solving in factory distribution systems, new energy power stations, data centers, and other scenarios.

Core difference models: divided into two categories: with Bluetooth function (- B1, only applicable in Japan, the United States, and Canada) and without Bluetooth function (- B0). The power cord is configured according to regional standards (such as GB standards, VDE standards, etc.), and the corresponding model needs to be selected according to the usage region.

Open box inspection and accessory instructions

1. Packaging content confirmation

After unboxing, it is necessary to verify the instrument model and suffix code (such as power cord standard, Bluetooth function) to ensure consistency with the order. The core accessories are shown in the table below:

Serial number, accessory name, model/specification, quantity description

1 set of voltage probe 98078, including 4 red, white, blue, and black wires (with crocodile clip), to match the terminals according to the wiring color

According to regional standards (such as UL/CSA for - B and GB for - H), one cord with a maximum rated voltage of 250V (125V for some models) needs to be matched with local power grid standards

3 USB cables L3064AD 1 for connecting PC and instrument, supporting data transmission and remote control

4 AA alkaline batteries (LR6) with 6 spare power supplies, with a full charge range of about 3 hours (when the backlight is turned off)

5 SD memory cards 97060 (2GB), 1 card for storing measurement data, supporting FAT16 format

6 portable cases 93046 1 protective instrument from impact and dust

7 Input Terminal Board -1 piece selected by wiring color (6 types), pasted on the top terminal area of the instrument

8 ID tags with 8 colors (red/blue/yellow, etc.) are pasted on both ends of the probe, corresponding to the terminal colors, to avoid wiring errors

9 CDs -1 sheet including application software and electronic manual (PDF)

1 set of 10 manuals including IM CW500-02EN, quick start guide, installation manual, and safety manual

2. Optional accessories (purchased separately)

It mainly includes current clamp probes with different ranges (2A~3000A, such as 2A for 96060 and 3000A for 96066), power adapters (98031, CW500 specific), banana head DIN adapter cables (99073), etc. The appropriate probe should be selected according to the measurement current range.

Safety regulations and operational limitations

1. Safety symbols and warnings

Warning: Refers to the risk of fatal/serious injury, such as prohibition of use in explosive environments, prohibition of unauthorized disassembly of instruments, and power-off and removal of probes before replacing batteries.

CAUTION: It involves the risk of minor injury or equipment damage, such as avoiding short circuits at the metal end of the probe, measuring beyond the range for a long time, and using in humid environments.

Protection level: Double insulation design, measurement category in accordance with IEC61010 standard, voltage limits for different categories are as follows:

CAT IV: 300VAC (applicable to power input terminal)

CAT III: 600VAC (applicable to distribution panels, circuit breakers)

CAT II: 1000VAC (suitable for household appliances and portable tools)

2. Operating environment restrictions

Environmental conditions: working temperature 0~45 ℃, relative humidity ≤ 85% (no condensation); Storage temperature -20~60 ℃, altitude ≤ 2000m, indoor use.

Electromagnetic compatibility: Class A industrial equipment may cause radio interference when used in residential areas, and users need to solve the interference problem themselves; Compliant with standards such as EN 61326-1 and EN 55011 Class A.

Instrument structure and functional layout

1. Name and function of core components

(1) Front panel

Component Function Description

Display screen 3.5-inch color TFT LCD (320 × 240 pixels), displaying measurement data, waveforms, vector graphics, etc

Function keys (F1~F4) execute menu options at the bottom of the screen, such as "Zoom", "Trend", "Customize"

The PRIMT SCREEN key saves the current screen as a BMP file to the SD card

Press and hold the DATA HOLD/KEY LOCK key for 2 seconds to lock all keys, then press and hold again to unlock; Short press to maintain display (measurement continues)

Press and hold the power button to turn on/off, and the interface from the last shutdown will be displayed after turning on

LCD key switches backlight switch, adjusts contrast and brightness

START/STOP key to start/stop data recording, status LED: green light constantly on indicates recording, green light flashing indicates standby

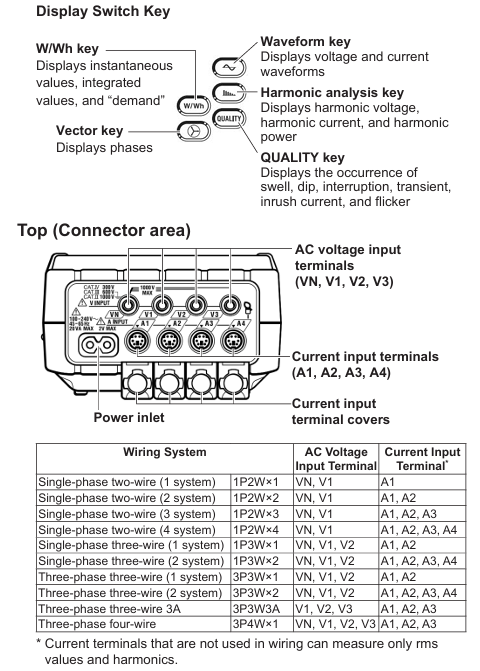

(2) Top terminal area

Voltage input terminals: VN (neutral wire), V1/V2/V3 (phase wire), supporting single-phase to three-phase wiring.

Current input terminals: A1/A2/A3/A4, connected to clamp probes. Unused current terminals can only measure effective values and harmonics.

Power interface: Connect a dedicated power cord and support wide voltage input of 100-240VAC.

(3) Side and back

Side: SD card slot (supporting 2GB SD card), USB Type-B interface (connected to PC), analog input terminal (2-channel, ± 11VDC, monitoring temperature sensor and other signals), digital output terminal (open collector, outputting low level when power quality event triggers).

Back: Battery cover (6 AA batteries), instrument serial number label (to be provided when contacting the dealer).

2. Probe and wiring identification

Voltage probe: equipped with a safety barrier (to avoid finger crossing), connected to the tested circuit at the crocodile clip end, and connected to the instrument voltage terminal at the other end. It needs to be matched with the ID marked color (such as red connected to V1, blue connected to VN).

Clamp probe: The direction of the arrow should be consistent with the current flow direction (otherwise the polarity of the active power will reverse), supporting a range of 2A~3000A. When connecting, it should be aligned with the arrow mark on the instrument current terminal.

Basic operation process

1. Power supply mode setting

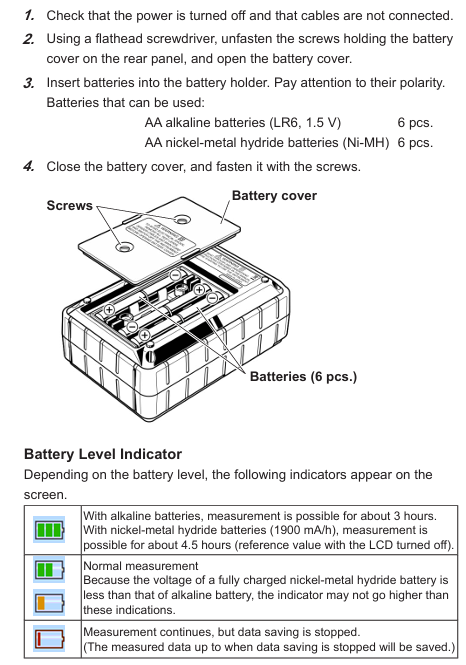

(1) Battery powered

Confirm that the instrument is powered off, use a Phillips screwdriver to open the back battery cover, and insert 6 AA alkaline batteries (or nickel hydrogen rechargeable batteries) according to polarity.

Close the battery cover and tighten the screws. After turning on, the battery icon will be displayed at the top of the screen, with 4 bars indicating full charge and 1 bar indicating low battery (needs to be replaced in a timely manner).

Attention: Nickel hydrogen batteries need to be charged with a dedicated charger, and the instrument does not support charging function; Long term disuse requires removing the battery to avoid leaking and damaging the instrument.

(2) AC power supply

Confirm that the instrument is powered off, connect one end of the power cord to the top power interface of the instrument, and plug the other end into a socket that meets local standards (100-240VAC, 50/60Hz).

After booting up, the AC power icon is displayed at the top of the screen, with a maximum power consumption of approximately 7VA.

2. Preparation before measurement

(1) Paste terminal board and ID mark

Select the input terminal board that matches the wiring color from the accessories (such as TYPE 1: VN=blue, V1=red, V2=green), clean the top terminal area of the instrument, and paste it.

Paste the ID tag on both ends of the probe to ensure consistency with the terminal color (such as connecting the red probe to the V1 terminal), to avoid wiring errors.

(2) SD card installation

Open the side SD card slot cover, insert the SD card face up (hear a "click" sound to indicate installation), and close the slot cover.

The new SD card needs to be formatted on the instrument (through the SETUP menu), as formatting on a PC may result in abnormal recording; Stop recording before removing the SD card to avoid data damage.

3. Wiring and measurement startup

Taking the "three-phase four wire (3P4W)" wiring as an example, the process is as follows:

Power off confirmation: Ensure that the tested circuit is powered off, remove the instrument power supply and probe.

Voltage wiring: Connect the voltage probe crocodile clip to VN (neutral wire) and V1/V2/V3 (phase wire) respectively, and insert the other end of the probe into the instrument VN and V1/V2/V3 terminals.

Current wiring: Clamp the clamp probe on the outside of the V1/V2/V3 phase line (arrow pointing towards the current flow direction), and insert the probe plug into the A1/A2/A3 terminals accordingly.

Power on and setup: Press and hold the power button to turn on the device, press the SETUP button to enter "Basic Setup", select the wiring system as "3P4W", confirm the voltage range (default 600V), and current clamp model (e.g. 96064 is 500A).

Start recording: Press the START button, the status LED green light stays on, the screen displays "REC", and start recording measurement data; Press the STOP button to stop recording, and the data will be automatically saved to the SD card.

4. Data display and operation

(1) Key function key operation

W/Wh key: Switch between displaying instantaneous values (voltage, current, power), integrated values (electrical energy Wh, varh), and demand values (DEM Target/Guess/Max).

Vector key: Display voltage/current vector diagram, check if the wiring phase is correct (e.g. three-phase voltage phase difference should be 120 °).

Waveform key: Display real-time voltage/current waveforms, switch channels using the directional keys, and adjust the time scale by pressing the F2 key (e.g. 5ms/div).

Harmonic key: displays the harmonic analysis results (1st to 50th harmonics), including THD (total harmonic distortion) and the percentage of voltage/current for each harmonic.

QUALITY key: displays the record of power quality events, such as the occurrence time and value of sudden rise (default 110% rated voltage), sudden drop (default 90% rated voltage), and interruption (default 10% rated voltage).

Core functions and technical parameters

1. Measurement function and scope

Measurement parameter range/range accuracy (typical values)

Voltage (RMS) 600.0V/1000V ± 0.2% reading ± 0.2% range (sine wave, 40~70Hz)

Current (RMS) 2A~3000A (depending on clamp probe) ± 0.2% reading ± 0.2% range+probe accuracy

Active power 2000W~3000kW ± 0.3% reading ± 0.2% range (power factor=1, sine wave)

Frequency 10.00~99.99Hz ± 2dgt (40~70Hz, V1 range 10%~110%)

Harmonic (1~50 times) THD 0.0%~100.0% complies with IEC61000-4-30, Class 3 accuracy

Flashing Pst (short-term) and Plt (long-term) comply with IEC61000-4-15, with a reading of ± 10%

2. Data recording and storage

Record interval: adjustable from 1 second to 30 minutes, supporting manual/continuous/timed recording modes.

Storage media: Built in 4MB flash memory (used without SD card), 2GB SD card (default accessory), saved in CSV format, supports PC analysis later.

Event recording: Automatically record events such as sudden rise, sudden drop, interruption, transient overvoltage, surge current, etc. The trigger threshold can be customized (such as a sudden rise threshold of 110% of the rated voltage).

Common Problems and Maintenance

1. Troubleshooting

Possible causes and solutions for the fault phenomenon

If there is no response when starting up, the battery is dead or the installation is reversed. If the power cord has poor contact, replace the battery and confirm the polarity. Check the power cord connection

No measurement data, probe not connected properly, wiring error, improper range setting. Reconnect the probe, check the terminal color and wiring diagram, and confirm that the range covers the measured value

SD card cannot be read, unformatted, damaged, poor contact. Format SD card on the instrument (SETUP → Save → Format), replace SD card

Record if the SD card is full or the battery is low, delete useless data or replace the SD card, connect to AC power or replace the battery during the recording process

2. Daily maintenance

Calibration cycle: It is recommended to calibrate once a year. You can contact the authorized service center of Yokogawa or refer to the "User Calibration Manual" on the official website for self calibration (standard calibration source is required).

Probe maintenance: Regularly check whether the insulation layer of the probe is damaged and whether the metal end is oxidized; The voltage probe crocodile clip needs to be cleaned to ensure good contact.

Instrument cleaning: Wipe the outer shell with a dry soft cloth and avoid using corrosive solvents such as alcohol and gasoline; If there is dust in the terminal area, it can be blown clean with compressed air.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923