K-WANG

Watlow Ceramic Fiber Heater

Watlow Ceramic Fiber Heater

Product Core Overview

The Watlow ceramic fiber heater is a radiation type heater designed specifically for high-temperature scenarios. The core consists of an alumina silica ceramic fiber insulation layer and built-in heating elements, which have the characteristics of low quality, high insulation, and strong thermal shock resistance. Its maximum working temperature can reach 2200 ° F (1204 ° C), with a power density range of 5-30 W/in ² (0.8-4.6 W/cm ²). It only works through radiation heat transfer and can directly adapt to common power supply voltages without the need for transformers. It is widely used in industrial scenarios such as high-temperature furnaces, metal melting, semiconductor processing, and glass ceramic processing.

Core advantages:

High temperature adaptation: far exceeding the temperature limit of traditional heaters, suitable for extreme working conditions of 815-1204 ° C.

Efficient and energy-saving: Low quality insulation materials (10-15 lb/ft ³ density) heat up rapidly, and energy is concentrated on the load rather than self loss.

Flexible structure: Supports various forms such as flat, semi cylindrical, and fully cylindrical, and can customize multi-faceted integrated structures to adapt to complex installation environments.

Durable and reliable: inorganic adhesive and ceramic coating design, resistant to thermal cycling and chemical corrosion (except hydrofluoric acid, phosphoric acid, and strong alkali).

Core product configuration and features

(1) Types and differences of heating elements

The heater provides 5 core component configurations, suitable for different power densities and application scenarios:

Component type, structural characteristics, key advantages, power density improvement, applicable scenarios

Embedded Sined components are embedded inside ceramic fibers, divided into flat/V-shaped insulation with large thickness and strong thermal stability. The V-shaped insulation is 27% higher than the flat insulation in medium high temperature and medium power density scenarios, suitable for large-sized flat/semi cylindrical devices

Exposed Sined components are exposed on the surface of ceramic fibers, and the temperature difference between the flat/V-shaped components and the cavity is small, resulting in a long lifespan. The V-shaped components have a 20% increase in surface area and large inner diameter compared to flat components, and require rapid heating scenarios

Embedded Coil: a coil element embedded in complex curved surfaces, suitable for fitting small customized chambers, operating under high voltage, low current, low power density, and low duty cycle conditions, suitable for small tube furnaces

(2) Product Form and Specifications

Basic form

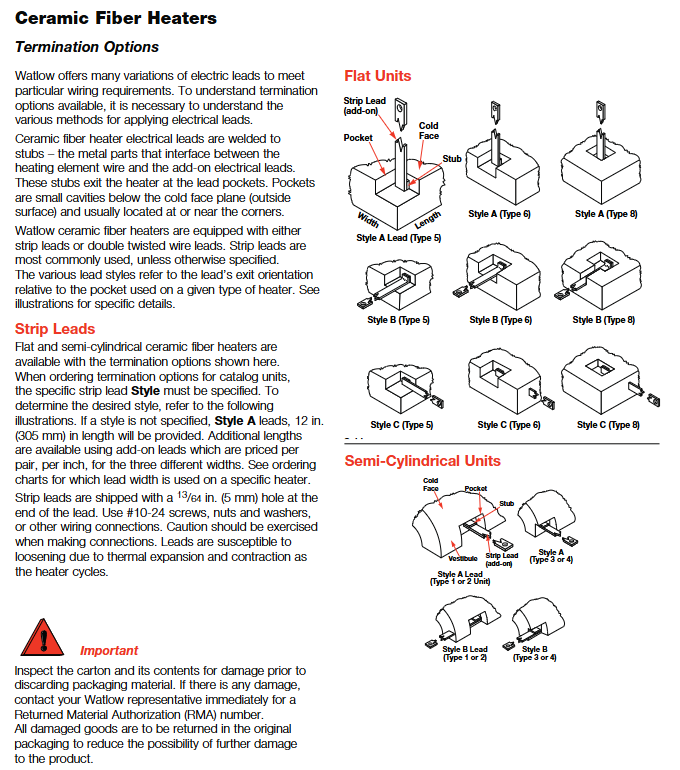

Flat panel: Supports four types: Type 5 (full heating), Type 6 (side insulation), Type 7 (end insulation), and Type 8 (full edge insulation), with sizes ranging from 4 × 6 in to 36 × 36 in.

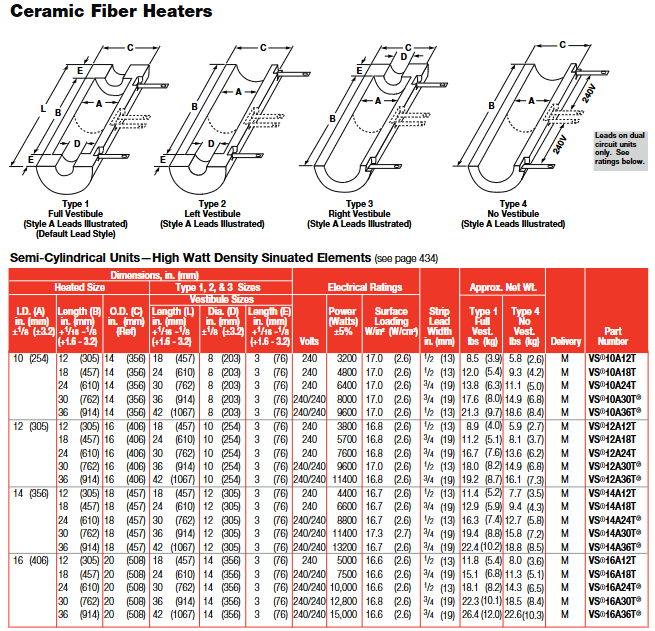

Semi cylindrical: Type 1 (full vestibule), Type 2 (left vestibule), Type 3 (right vestibule), Type 4 (no vestibule), with an inner diameter of 1/2 inch to 8 inches and a length of 6-42 inches.

Full cylindrical shape: with an inner diameter of 1/2 inch to 8 inches and a length of 6-12 inches, suitable for small tube heating scenarios.

Customized molding: It can mold box shaped structures with up to five integrated sides, supporting complex curve and polygon designs.

Key specification parameters

Voltage: Standard 60/120/240 VAC (± 5%), customizable up to 600 VAC or three-phase wiring scheme.

Power: 60-11500 W per unit, supporting multiple units for combined expansion. High power density models (suffix "T") have a power density of 14.6-17.2 W/in ².

Dimensional tolerance: Heating area ± 1/16 in (± 1.6 mm), outer diameter ± 1/8 in (± 3.2 mm), wall thickness standard 2 ± 1/4 in (51 ± 6 mm).

(3) Core functions and protection

high-temperature stability

Within 24 hours of first use (1600-2200 ° F), there may be a shrinkage of ≤ 4%, which can be compensated for by factory pre firing treatment or on-site filling of ceramic fiber cotton gaps.

Ceramic fiber material does not contain organic binders, and there is no smoke or combustion risk when heated to 300 ° F (150 ° C) for the first time.

Auxiliary function options

High emissivity coating: Black surface coating (part number CFBSC) with an emissivity close to 1.0, improving radiative heat transfer efficiency.

Thermocouple installation: Supports embedded ceramic tubes (0.140-0.265 in inner diameter), can be arranged close to components, and accurately monitors hot spot temperatures.

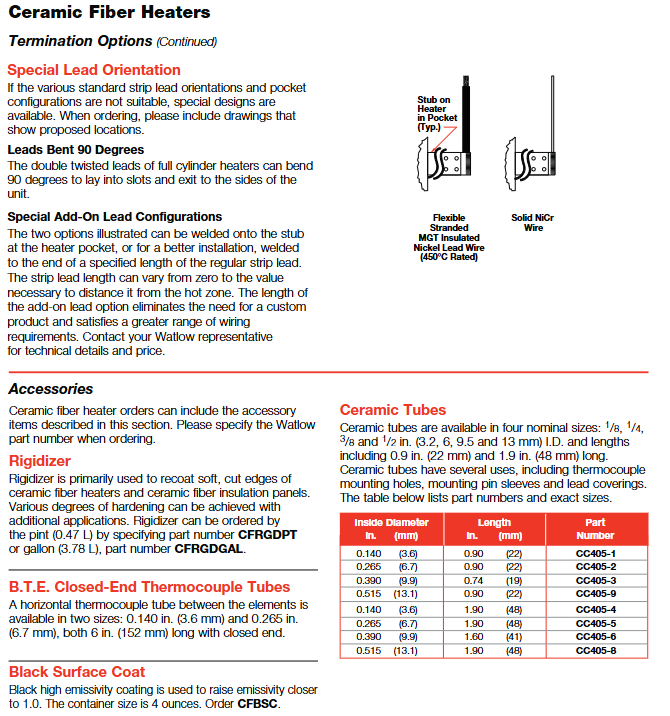

Lead protection: Provides options such as ribbon leads (601 alloy 600), flexible leads (nickel material), etc. The lead length can be adjusted from 0-42 inches, and is equipped with ceramic sleeves to protect against high temperature oxidation.

Installation and usage specifications

(1) Key installation requirements

Fixed method: Priority should be given to mechanical fixation such as pins, clamps, and overlapping edge clamping to avoid adhesion (which cannot adapt to the thermal expansion and contraction of metal structures).

Heat dissipation and insulation: A backing insulation blanket (recommended density of 6 lb/ft ³, part number CFBLKT series) is required to improve energy efficiency and reduce external surface temperature (external temperature can be controlled within 450 ° F under 2200 ° F conditions).

Space reservation: When installing multiple units, a shrinkage gap should be reserved, and the gap should be filled with loose ceramic fibers after the first use.

Environmental protection: Avoid contact with pollutants such as oil and lubricants. Ceramic fiber porosity is greater than 90%, and the infiltration of pollutants can damage heating elements.

(2) Wiring and safety regulations

Lead wire treatment: The lead wire should be kept away from high temperature areas and connected by crimping. Regularly check for looseness caused by thermal expansion and contraction.

Temperature control: Low quality fast response thermocouples must be used (recommended distance from heating surface ≤ 1/16 in) to avoid self damage of the heater due to lack of temperature control.

Fault protection: Equipped with semiconductor fuses (such as Bussmann 170M series), with a short-circuit current rating (SCCR) of 200kA, in compliance with UL 508 safety standards.

(3) Maintenance and Repair

Cleaning: Regularly clean the surface dust with compressed air to avoid accumulation that affects heat dissipation.

Repair: Minor mechanical damage can be repaired using a specialized repair kit (CFPATCHKIT), which includes ceramic fiber powder and black coating. The use of non original adhesives is prohibited.

Replacement: If the heating element is damaged, the entire heater needs to be replaced, and the built-in element cannot be repaired separately.

Selection and Accessories

(1) Selection of core dimensions

Temperature and power density matching: Under high temperature conditions (>1800 ° F), the power density needs to be reduced to avoid exceeding performance limits (refer to the product performance curve to ensure that the operating conditions fall within a safe zone).

Form adaptation: Select flat/cylindrical/customized type according to the shape of the equipment chamber. For semi cylindrical equipment with an inner diameter greater than 5 inches, V-shaped sine elements are preferred.

Voltage and wiring: The 240V standard model adopts dual element parallel connection, and can be customized with 480V/277V or three-phase internal wiring schemes.

(2) Key accessories

Accessory type, function, usage, recommended model

Insulation blanket enhances insulation effect and reduces external temperature CFBLKT1/4 (6mm thick) and CFBLKT1 (25mm thick)

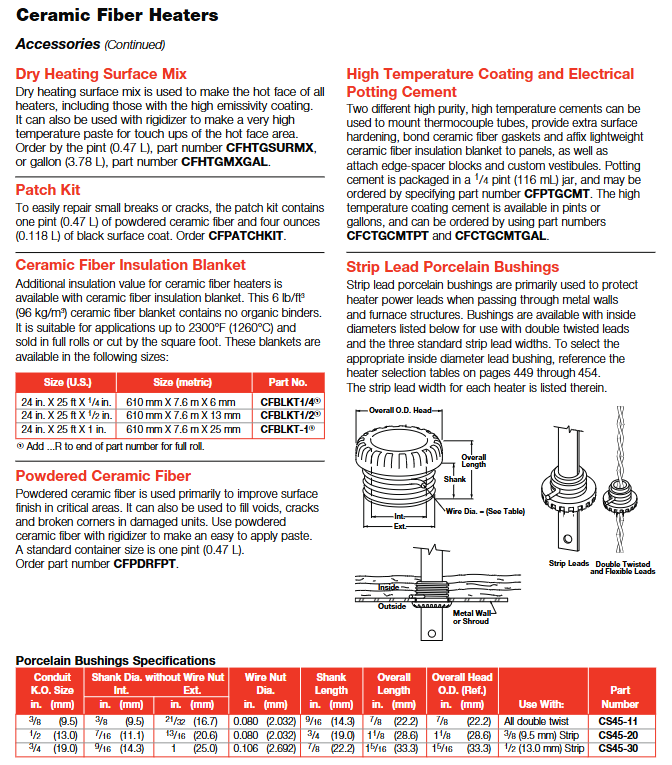

Thermowell fixed thermocouple, electrically isolated CC405 series (inner diameter 3.6-13.1mm)

Hardening agent repairs cutting edges, enhances surface hardness CFRGPPT (pint pack), CFRGDGAL (gallon pack)

Ceramic sleeve protection lead or fixing pin CC405-1 (3.6mm inner diameter), CC405-9 (13.1mm inner diameter)

Repair kit for small area damage CFPATCHKIT (including ceramic powder and coating)

Typical application scenarios

Recommended Configuration Core Value for Industry Application Scenarios

Metal processing melting furnace, insulation furnace, metal transmission line semi cylindrical/customized forming heater, high emissivity coating, high temperature resistance, fast heating, suitable for metal high-temperature processing needs

Semiconductor wafer processing equipment, CVD reactor flat embedded coil components, precise temperature control, low pollution, strong thermal stability, avoiding affecting process accuracy

Glass ceramic glass forming furnace, ceramic sintering furnace, fully cylindrical/multi-faceted integrated molding, high power density bonding chamber structure, uniform radiation, improving product consistency

Laboratory and R&D small-scale experimental furnaces, analytical instruments, small-sized fully cylindrical (inner diameter 3/4-2 in) rapid heating and cooling, suitable for frequent start stop test scenarios

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923