K-WANG

Watlow Power Series microprocessor based SCR power controller

Watlow Power Series microprocessor based SCR power controller

Product Core Overview

The Watlow Power Series is a microprocessor based silicon controlled rectifier (SCR) power controller designed specifically for industrial heater control. It supports various configurations such as single-phase, three-phase two bridge arm, three-phase three bridge arm, and single-phase multi zone. The current rating is 65-250A (at 50 ° C environment), and the voltage is compatible with 24-600V AC. It has multiple control methods such as zero crossing trigger and phase angle control. It integrates heater diagnosis, current limitation, alarm and other functions, and is widely used in industrial heating, heat treatment, semiconductor manufacturing and other scenarios. The product complies with UL 508, CE certification, IP00 protection level, pollution level 3, provides a 3-year warranty, supports Modbus RTU communication and signal retransmission function, and balances stability and flexibility.

Core advantages:

Multi configuration adaptation: covering single-phase, three-phase, and multi zone control, meeting the needs of different load types (resistive, transformer coupled loads).

Intelligent control function: supports zero crossing (fixed/variable time base), phase angle control, built-in soft start, current limit, heater drying and other functions to protect the load and optimize the control effect.

Comprehensive diagnosis and alarm: equipped with multiple alarms such as heater open circuit, over temperature, phase imbalance, etc., supporting locked/non locked modes, combined with SCR short circuit detection and fuse protection, to enhance system safety.

Flexible expansion: optional communication module (RS-232/485), signal retransmission function, supports remote monitoring and parameter configuration.

Core functions and features

(1) Control method

Zero crossing control (Burst Firing)

Fixed time base: 1-second or 4-second cycle, output power is distributed based on the complete power cycle, low noise, suitable for resistive loads (such as nickel chromium heaters).

Variable time base: dynamically adjusts the on-off cycle, with fast response speed, supports line voltage compensation, and adapts to scenarios that require precise power regulation.

DC contactor mode: Only 0% or 100% output, trigger threshold 2.0V/3.5V (voltage input), 5.0mA/8.0mA (current input), suitable for simple switch control.

Phase Angle Control

Based on partial conduction of the power cycle, power regulation is achieved, with built-in soft start (adjustable from 0-120 seconds) and support for current limitation (requiring heater diagnostic function). It is suitable for transformer coupled loads and nonlinear loads that require soft start.

The maximum rate of change can be adjusted (0.1-100%/0.1 seconds) to avoid load damage or fuse tripping caused by sudden changes in current.

(2) Key functions

Heater diagnosis and protection

Heater drying: suitable for single-phase and three-phase three bridge arm configurations, slowly heating to remove heater moisture, avoiding damage caused by direct full power start-up, and supporting overcurrent trip protection.

Current limitation: Effective in phase angle control mode, the maximum allowable current can be set to prevent overload.

Fault detection: Detect faults such as open circuit, short circuit, out of tolerance, SCR short circuit, phase imbalance, etc. of the heater, and trigger corresponding alarms.

Alarm and safety functions

Alarm types: including 10+types of alarms such as heater open circuit, over temperature, line voltage loss, frequency abnormality, communication watchdog, etc., supporting four configurations: standard, lockout, mute, lockout+mute.

Alarm output: Single channel electromagnetic relay (Form C contact), rated 3A@250V AC or 30V DC, supports energized or de energized state configuration when powered on.

Hardware protection: Built in semiconductor fuse (to be matched with specified models, such as Bussmann 170M series), supporting 200kA short-circuit current rating (SCCR).

Communication and signal retransmission

Communication: Supports RS-232/485 interface, Modbus RTU protocol, baud rate 1200-19200bps, can connect up to 247 devices (requiring repeaters).

Signal retransmission: optional 0-10V DC or 4-20mA output, adjustable load current, power and other parameters, suitable for external devices such as recorders and PLCs.

Installation and wiring

(1) Installation requirements

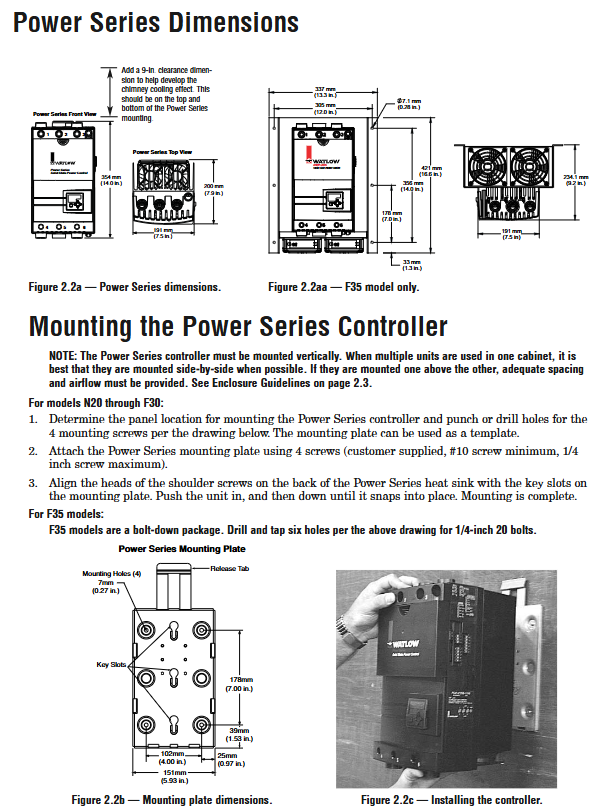

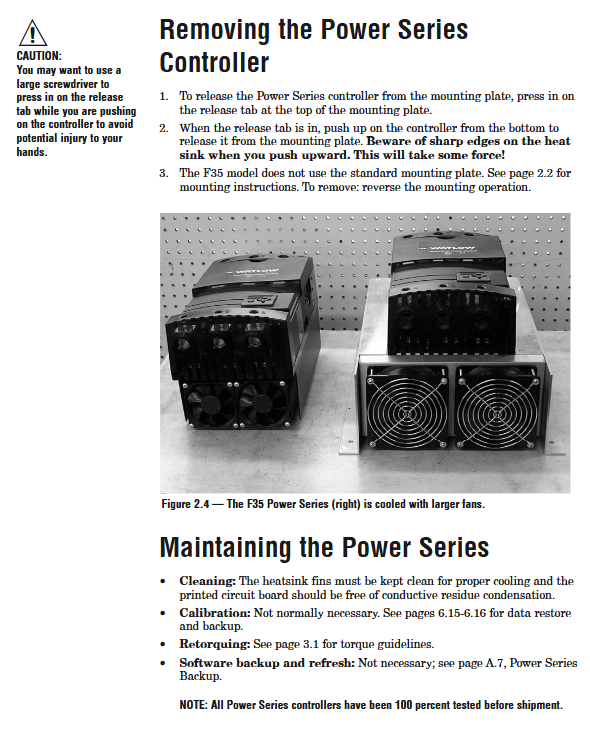

Installation method: Panel installation (N20-F30 model) or bolt fixation (F35 model), must be installed vertically to ensure heat dissipation. When multiple units are installed in parallel, heat dissipation space must be reserved.

Environmental restrictions: Working environment temperature 0-60 ° C (fan cooling)/0-65 ° C (natural cooling), relative humidity 0-90% (no condensation), avoid corrosive and high humidity environments.

Cooling requirements: Calculate the cooling demand based on power loss (1.25W/ampere/control bridge arm), and use fans, eddy current coolers, or air conditioners for cooling to ensure that the temperature inside the chassis does not exceed 50 ° C.

(2) Wiring specifications

Power and load wiring

Wire specifications: Select 6 AWG-250 MCM copper wire based on the current, with a terminal torque of 180 in lbs (20 Nm) and a wire bending radius of 2.0-8.5 inches (depending on the current specifications).

Fuse selection: Semiconductor fuses (such as Watlow 0808 series) should be used, and the specific model should be matched according to the rated current of the controller (such as 65A corresponding to 100A fuses).

Grounding requirements: The specifications of the grounding wire should be consistent with the power line, connected to a grounding terminal with sufficient current carrying capacity, and comply with NEC and local electrical regulations.

Signal wiring

Input signal: Supports 0-10V DC voltage input (input impedance 11k Ω) or 4-20mA current input (input impedance 100 Ω), and high and low trigger points can be configured through parameter settings.

Communication wiring: RS-485 uses differential signals (485 T/R+, 485 T/R -), RS-232 supports signal transmission and reception, and shielded wires are grounded at one end to reduce interference.

Retransmission signal: 4-20mA output load maximum 800 Ω, 0-10V output load minimum 1k Ω, separate wiring is required to avoid signal interference.

(3) Typical configuration wiring

Single phase: L1 is connected to the power supply, the load is connected to the output terminal and internal busbar, and the reference terminal is connected to the neutral wire or another phase wire as needed.

Three phase two bridge arm: Only switch between L1 and L3 phases, L2 is directly connected through an internal busbar, suitable for delta or ungrounded wye loads.

Three phase three bridge arm: Switch all three phases, support grounded wye loads, and ensure that the phase rotation is clockwise from A-B-C.

Multi zone: Each zone is independently wired and shares alarm output, avoiding phase conflicts between different zones (such as 180 ° inversion).

Operation and Configuration

(1) Operation interface

Display and buttons: dual four digit display (parameter values displayed on the upper screen and parameter names displayed on the lower screen), including increase and decrease keys, left and right keys, and home keys, supporting menu navigation, parameter adjustment, and alarm clearing.

Menu structure: divided into display loop (monitoring parameters), settings page (configuration control mode, alarm, communication), factory page (calibration, data backup), supporting menu locking function to prevent misoperation.

(2) Core parameter configuration

control parameters

Control algorithm: Choose zero crossing (fixed/variable time base), phase angle control, or DC contactor mode.

Soft start time: adjustable from 0-120 seconds, phase angle control mode is enabled by default to avoid starting surge current.

Current limit: Only the phase angle control mode is effective, and it needs to be paired with a heater diagnostic function to set the maximum allowable current (0-load rated current).

Heater diagnostic parameters

Drying time: 0-9999 minutes. Exceeding the set current (HbOC parameter) during the drying process will trigger a trip.

Load tolerance: Set high and low current thresholds (effective for power above 20%), triggering an alarm if the range is exceeded.

Alarm and communication parameters

Alarm configuration: Select the global alarm mode (standard/lockout/mute) or configure each alarm type separately, and set the alarm relay status (triggered by power on/off).

Communication parameters: Configure device address (1-247), baud rate, watchdog timeout (0-9999 seconds). If enabled, no communication will trigger an alarm.

(3) Calibration and maintenance

Analog input calibration: Calibrate the high and low points of voltage/current input on the factory page to ensure signal accuracy.

Retransmission calibration: Calibrate 4-20mA or 0-10V output signals to match the range of external devices.

Data backup: Supports configuration parameter backup, recovery, and factory reset, and can be backed up by system and region classification to avoid parameter loss.

Troubleshooting and Maintenance

(1) Common fault handling

Possible causes and solutions for the fault phenomenon

No output, no display. The power supply is not connected, the fuse is blown, and the display module has poor contact. Check the power wiring and fuse, unplug the display module again, and if it is ineffective, return it to the factory for repair

The heater does not generate heat, the load wiring is disconnected, the control algorithm is set to "OFF", and the input signal is abnormal. Check the load and input wiring, confirm the control algorithm configuration, and monitor the input signal ([In] parameter) through display loop monitoring

Frequent tripping of fuses due to mismatched rated values, insufficient heat dissipation, and short circuits in the heater. Replace the corresponding type of fuse, optimize the heat dissipation of the chassis, and check the insulation and wiring of the heater

Phase angle control error [hCYL] caused by inductive load resulting in half cycle loss, low reactance delay setting increasing [rdLy] parameter (0-500) until the error disappears

Communication failure address/baud rate mismatch, wiring error, watchdog timeout. Unified communication parameters, check RS-485 differential wiring to shorten communication interruption time

(2) Daily maintenance

Regular inspection: Re tighten the terminals every 3-6 months (to avoid looseness caused by cold flow), clean the heat sink fins, and ensure no dust accumulation.

Fuse replacement: Only use designated models (such as Watlow 0808 series or Bussmann 170M series), disconnect the power and tighten according to the specified torque during replacement.

Calibration cycle: It has been calibrated at the factory and does not require frequent calibration on site. If the sensor or input module is replaced, the analog input needs to be recalibrated.

Typical application scenarios

Recommended configuration for application areas, matching core functions

Industrial resistive heater control single-phase/three-phase zero crossing control with low noise and stable power output, suitable for nickel chromium, iron chromium aluminum heaters

Transformer coupling load (such as silicon carbide rod heater) three-phase three bridge arm phase angle control soft start+current limitation to avoid load impact damage

Multi zone heating system (such as oven multi temperature zone) single-phase multi zone configuration independently controls the power of each zone, shares alarms and communication, saving installation space

Remote monitoring scenario (such as chemical reaction kettle) with communication and retransmission function Modbus remote configuration, retransmitting load current/power to the monitoring system

Wet environment heater (such as food processing) single-phase+heater drying function to dry and remove moisture, avoiding short circuit when the heater is started

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923