K-WANG

Watlow PM PLUS ™ PID/Integrated Limit Controller

Watlow PM PLUS ™ PID/Integrated Limit Controller

Product Core Overview

Watlow PM PLUS ™ It is an enhanced PID/integrated limit controller that optimizes user experience and functional scalability while being compatible with the previous generation EZ-ZONE PM controller. The product is positioned as an industrial grade temperature and process control, supporting single/dual PID control loops and integrating functions such as limit control, timing, and curve programming. It is widely used in semiconductor manufacturing, chemical reactions, equipment heating, and other scenarios. Its core advantages include Bluetooth wireless configuration, intuitive touch operation, support for multiple communication protocols, and comprehensive security authentication, which can adapt to the precise control needs in complex industrial environments.

Core features:

Compatibility and Upgradeability: Fully compatible with the wiring and parameter settings of EZ-ZONE PM, can be replaced without hardware modification, and upgraded with smooth touch keyboard, multilingual display (English/German/Spanish) and other operations.

Control capability: Supports PID (including P/PI/PD mode), switch control, curve programming (4 curves, a total of 40 steps), equipped with TRU-TUNE+adaptive algorithm and automatic tuning function to improve dynamic control accuracy.

Communication and wireless functions: Supports Bluetooth (via EZ-LINK mobile application), Modbus RTU/TCP, EtherNet/IP, DeviceNet and other protocols, allowing remote configuration of parameters and monitoring, reducing on-site wiring dependence.

Safety and Certification: Certified by UL, CSA, CE, RoHS, FM, etc., some models support Class 1, Zone 2 hazardous environments, integrate limit control and multiple alarms to ensure equipment and personnel safety.

Product model and core configuration

(1) Model classification and structure

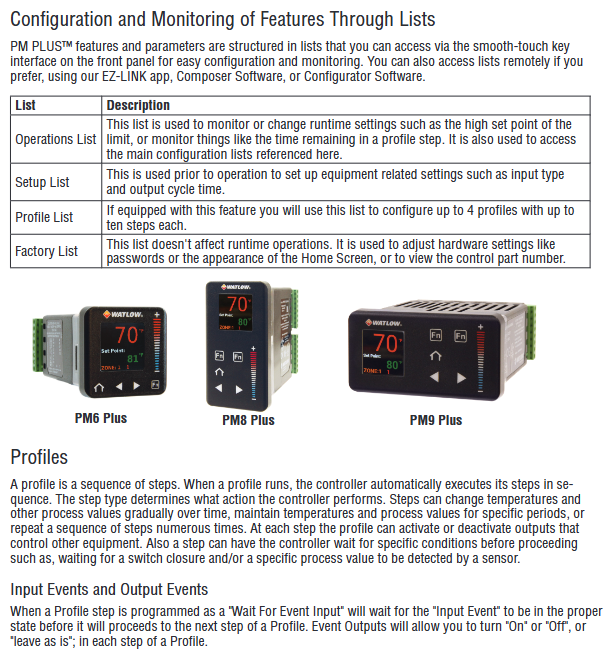

The product is divided into three series based on installation size and function. The core model parameters are defined by a 14 digit configuration code, and the key dimensions are as follows:

Classification, specific specifications, applicable scenarios

Installation size: 1/16 DIN (PM6), 1/8 DIN vertical (PM8), 1/8 DIN horizontal (PM9). Different panel space requirements, 1/16 DIN is suitable for compact scenarios, and 1/8 DIN is suitable for multi parameter display requirements

Core function - PID basic type (C/R/T/J/N): including universal input, curve programming (some models), and timing function

-Integrated limit type (L/M): Additional support for sensor backup, over limit protection, output 4 fixed limit control - Basic type: Single heating/cooling control

-Integrated type: Scenarios that require dual safety protection (such as high-temperature furnaces and hazardous material heating)

The power supply and I/O power supply can be selected from 100-240V AC or 20-28V AC/12-40V DC. The digital I/O supports 2-point or 6-point expansion to adapt to the global power grid. Multiple I/O point models can be connected to external trigger signals (such as emergency stop and start switches)

Output types support switch DC, mechanical relay (5A), SSR (0.5A), NO-ARC relay (15A), universal process output (0-10V/4-20mA) - NO-ARC relay: high-power resistive load (such as large heaters)

-Universal process output: signal retransmission to recorder or PLC

(2) Core hardware specifications

Category detailed parameters

Input Characteristics - Universal Input: Thermocouple (J/K/T/E, etc.), RTD (100 Ω/1k Ω), Process Signal (0-20mA/0-10V)

-Input accuracy: ± 0.1% range (typical value), temperature stability ± 100ppm/° C

-Sensor backup: supports dual sensor switching, automatically switches to backup sensor in case of failure

Output Capacity - Maximum Output: 15A NO-ARC Relay (AC Load Only)

-Process output: 0-10V (minimum 1k Ω load) or 4-20mA (maximum 800 Ω load), accuracy ± 20 μ A/± 10mV

Environmental adaptability - Operating temperature: 0-65 ° C (non condensing)

-Protection level: Front panel IP67/IP4X (indoor)

-Anti interference: Compliant with IEC 61000-4 series standards, anti-static and radio frequency interference resistant

Installation and wiring specifications

(1) Installation requirements

Panel opening and fixing

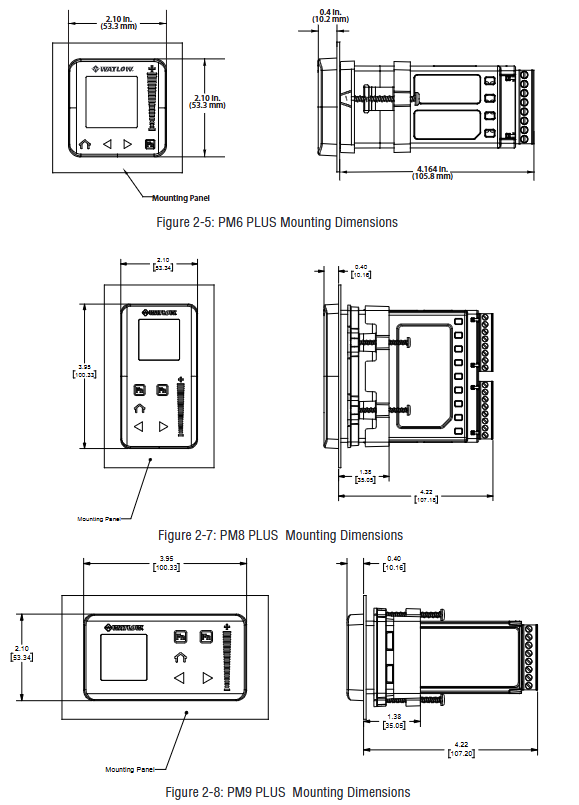

Size standards: 1/16 DIN (PM6) opening 45 × 45mm, 1/8 DIN (PM8/9) opening 45 × 92mm (vertical)/92 × 45mm (horizontal).

Installation steps: Remove the terminal and fixing ring → Insert the controller from the front of the panel → Align the fixing ring and tighten the screws (torque 3-4 in lbs) → Reinstall the terminal.

Environmental restrictions: Avoid corrosive gases and high vibration environments, install vertically to ensure heat dissipation, and reserve a spacing of ≥ 30mm for parallel installation of multiple units.

Power supply and wiring safety

Power adaptation: High power models (1/2) are connected to 100-240V AC, while low-power models (3/4) are connected to 20-28V AC/12-40V DC, and must match the power type indicated on the equipment label.

Wiring specifications: Wire specifications are 12-30 AWG, terminal torque is 5.0 in lb, unused terminals need to be empty, analog input and power/digital signals need to be isolated and wired to avoid grounding loops.

Attention to hazardous environments: Class 1, Zone 2 models (with "12" at the end of the configuration code) require the use of explosion-proof switches. It is prohibited to plug or unplug wiring when powered on, and replacement parts must comply with hazardous environment certification.

(2) Key wiring example

Sensor wiring

Thermocouple: Connect the negative electrode (usually red) to the S1/S2 terminal, and the extension wire should be consistent with the thermocouple material (such as K-type extension wire for K-type).

RTD: 2/3 wire system, 3-wire system needs to ensure that the resistance of the three leads is consistent (≤ 20 Ω), S1 is connected to a white lead to compensate for the lead resistance.

Process signal: 4-20mA signal connected to+R1/- S1 terminal, 0-10V signal connected to+T1/- S1 terminal, requiring separate shielded wiring.

Output and communication wiring

NO-ARC relay: only connected to AC loads (85-264V AC), load current ≤ 15A, prohibited from series use, cycle time ≥ 5 seconds.

Communication wiring: RS-485 uses twisted pair cables (T+/R+connected to B, T -/R - connected to A), and a 120 Ω terminal resistor needs to be added at the end of the bus. The distance between the communication line and the power line should be ≥ 305mm.

Digital I/O: 2-point I/O model (configuration code 2/4) supports dry contact or 3-36V DC input, 6-point I/O model (configuration code C/D/M/N) expandable switch output, with a maximum load of 1.5A per channel.

Operating interface and core functions

(1) User interface

Touch buttons and display

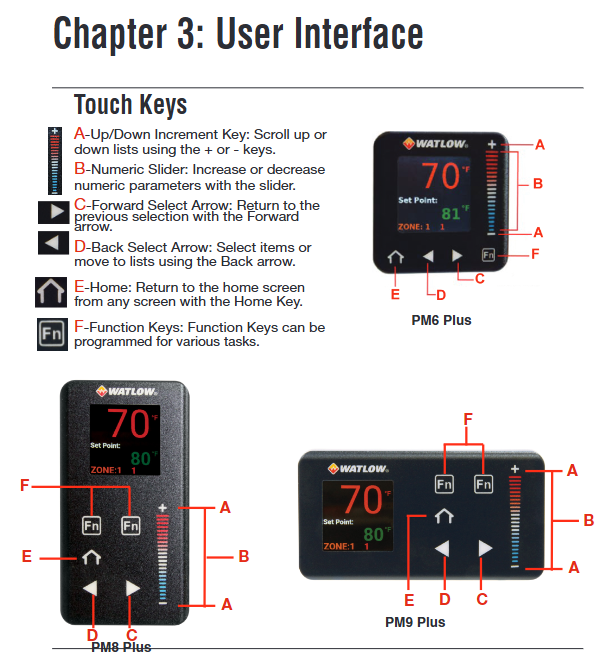

Key functions: Home button (return to home page), left and right buttons (menu navigation), increase and decrease buttons (parameter adjustment), custom function buttons (F1/F2, can set start/stop curves, reset alarms, etc.).

Display mode: default display of process values (such as temperature), set values, and regions, supporting 4 themes (such as white background, high contrast blue background), customizable display parameters (such as output power, remaining time).

Message prompt: Automatically switch display in case of alarm/error, such as "Limit High" or "Input Error". The lock alarm can be cleared by pressing the home button.

Menu Structure

Operations List: Real time monitoring and adjustment of operating parameters (such as set values, manual power).

Setup: Configure basic parameters such as input type, control algorithm, alarm threshold, etc.

Profile: Edit curve steps (heating/holding/waiting for events).

Factory List: Calibration, password locking, factory reset (permission required).

(2) Core function operation

PID control and tuning

Auto tuning: Enter "Operations - Autotune" and select "Yes". The controller aims to achieve 90% of the set value and automatically calculates parameters such as proportional band and integration time. During the tuning period, it outputs 100% power and ensures load safety.

TRU-TUNE+adaptive: enabled in the "Setup Control Loop", automatically optimizes PID parameters by monitoring process value fluctuations, suitable for scenarios with dynamic load changes (such as batch production).

Manual tuning: If the automatic tuning effect is not good, you can manually adjust the Heat Prop. Band and Time Integral. It is recommended to set the integration time to 0 first and gradually reduce it after stabilization to eliminate static errors.

Curve Programming (Ramp/Soak)

Curve configuration: Enter the "Profile List", each curve supports 10 steps, including Time/Ramp Rate, Soak, Wait for Event/Process, Jump, etc.

Example: Set the target temperature for "Step 1 (heating up)" to 150 ° C for 30 minutes; Step 2 (insulation) lasts for 60 minutes; Set 'Step 3' to 'Hold' to maintain the final temperature.

Startup method: It can be remotely started through function keys, numerical input, or communication. It can pause/resume during operation. If the restart time is ≤ the set "Power Off Time" after power failure, the curve can be continued.

Alarm and limit control

Alarm configuration: Supports 4 alarm channels, including process alarm (fixed threshold), deviation alarm (relative set value), and can be set to lock/non lock, shield (not triggered temporarily when starting/set value changes).

Limit control: The integrated limit model (L/M) supports high/low limit, and automatically cuts off the output when it exceeds the limit. It needs to be manually reset (through buttons, digital inputs, or communication), and outputs 4 fixed limit dedicated.

Current monitoring: Equipped with a current transformer (CT) input, it can detect open/short circuits in the heater, trigger the "Heater Error" alarm, and protect the load and controller.

Communication and Remote Configuration

(1) Communication Protocol and Settings

Protocol configuration key points applicable scenarios

Bluetooth (EZ-LINK application) devices can be paired through Bluetooth after being powered on, supporting parameter reading and writing, alarm viewing, curve downloading, and quick on-site configuration without the need for physical wiring, reducing wiring costs

Modbus RTU baud rate 1200-19200bps, addresses 1-247, supports function codes 03 (read register), 06 (write single register), and 16 (write multiple registers) to connect PLC or HMI and achieve multi device networking

EtherNet/IP supports DHCP or fixed IP, with a maximum of 40 members in the I/O assembly, capable of real-time transmission of process values and control commands in industrial Ethernet environments, requiring high-speed data exchange

DeviceNet node address 0-63, baud rate 125/250/500kbps, supports implicit/explicit communication, compatible with Rockwell and other brands of PLCs, suitable for device layer networking

(2) Remote configuration process (using Bluetooth as an example)

Download the EZ-LINK app (supports iOS/Android), turn on the controller Bluetooth ("Setup - Global - Bluetooth" set to "On").

Search for and pair devices within the application, enter "Parameter Configuration", and modify input types (such as thermocouple J-type), PID parameters, and alarm thresholds.

Save parameters to the device or local (supports 2 sets of user configurations), monitor process values and output power in real-time during operation, and receive alarm push notifications.

Maintenance and troubleshooting

(1) Daily maintenance

Regular inspection: monthly cleaning of panels and heat sinks, quarterly tightening of terminals (to avoid cold flow loosening), annual calibration of input/output (via the "Factory Calibration" menu, requiring a standard signal source).

Parameter backup: Save the configuration to User Set 1/2 through "Setup - Global - Save Settings As" to avoid resetting after a malfunction.

Firmware Upgrade: Supports firmware upgrade through communication port. The latest firmware and upgrade tool must be downloaded from the Watlow official website. Power off is prohibited during the upgrade process.

(2) Common fault handling

Possible causes and solutions for the fault phenomenon

No display/output power supply not connected, fuse burned out, loose terminals. Check the power supply voltage and fuse (Slot C terminal 98/99), re tighten the terminals, and replace the fuse (matching model required)

The temperature cannot reach the set value due to heating output fault, improper PID parameters, sensor error check output wiring and load, re perform automatic tuning, calibrate sensor offset ("Setup - Analog Input - Calibration Offset")

Alarm cannot be cleared. Alarm not cleared, alarm locked, parameter error confirmation process value returned to safe range. Clear it through "Operations - Alarm - Clear Alarm" and check the alarm type configuration

Communication failure: Address/baud rate mismatch, wiring error, interference with unified device communication parameters. Check RS-485 polarity (A/B lines), route away from power lines, and add terminal resistors

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923