K-WANG

Yokogawa DL350 Scope Order Communication Interface

Yokogawa DL350 Scope Order Communication Interface

Overview

This document is the Yokogawa DL350 Scope Order Communication Interface User Manual (6th edition, released in April 2024), which focuses on the Ethernet and USB communication interface functions of the device. It provides detailed guidance for users to complete interface configuration, remote control programming, and status monitoring. At the same time, it provides a supporting document system, technical support channels, and version revision records to ensure that users can safely and efficiently operate the device remotely through the communication interface.

Safety regulations and symbol explanations

(1) Warning symbols and their meanings

The manual adopts a three-level warning system and provides French reference to ensure clear safety guidance in multilingual scenarios

Warning: Operations that may cause serious or fatal injuries, such as operating high-voltage circuits without grounding, using equipment in flammable environments, etc., must strictly follow preventive measures.

CAUTION: Indicates operations that may cause minor injury or equipment/data damage, such as wet hand operation interfaces, improper cable connections, etc.

Note: Key information indicating the correct operation of the device, such as communication interfaces that cannot be used simultaneously, command execution sequence requirements, etc.

Equipment symbol: The "manual reference required" symbol marked on the equipment indicates that the operation needs to refer to the manual for special guidance to avoid missing key steps.

(2) Core Security Guidelines

Scope of use: The communication interface is only used to connect with a PC for remote control, and it is strictly prohibited to use it beyond the designated range; The equipment complies with measurement category II of IEC 61010-031 standard and cannot be used in category III/IV scenarios. When paired with equipment of different categories, the lower category shall prevail.

Grounding requirements: The oscilloscope protection grounding terminal must be reliably grounded, and the probe grounding wire must be connected to the grounding potential. Double grounding can effectively prevent the risk of electric shock.

Environmental restrictions: The working environment must meet the temperature range of 0-50 ℃, humidity range of 20% -80% RH (non condensing), and storage environment temperature range of -40~71 ℃; It is strictly prohibited to use in damp, dusty, flammable/explosive gas environments. The working altitude should not exceed 2000m, and the storage altitude should not exceed 15000m.

Equipment status: If any signs of damage such as damaged interface cables or exposed metal are found, immediately stop using and contact the dealer for repair; It is strictly prohibited to disassemble or modify communication interface components. Yokogawa shall not be held responsible for any malfunctions caused by unauthorized modifications.

Communication interface function and configuration

(1) Ethernet interface

1. Core features and parameters

Function: Supports remote reception of device setting instructions, acquisition of measurement data (such as waveform data, panel configuration) and status information (such as device error codes, operating status), and remote transmission of measurement results and status bytes.

Technical specifications: 1 RJ-45 port, compliant with IEEE 802.3 standard, maximum data rate of 100Mbps, communication protocol is TCP/IP; The transmission rate of waveform data varies depending on the data format. For example, the transmission of byte data for 1 million data points takes about 100ms, while ASCII data takes about 30s.

2. Connection and configuration

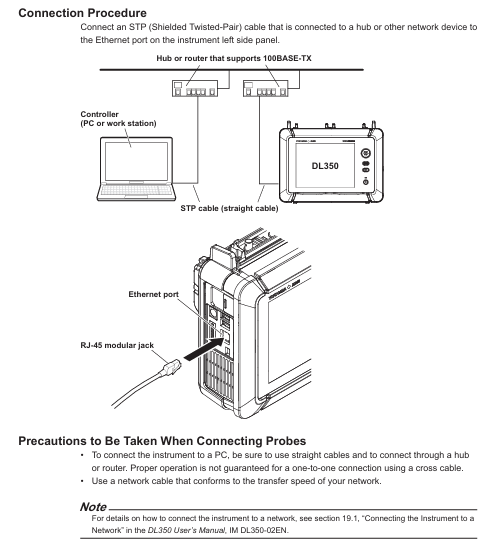

Hardware connection: Use shielded twisted pair (STP) to connect the Ethernet port on the left panel of the device to the hub/router, and then connect to the PC; direct cables are required, and it is not recommended to directly connect the PC to the device through crossover cables.

Parameter settings: TCP/IP parameters (IP address, subnet mask, default gateway) and network timeout time need to be configured. Set the timeout period through the device menu "Utility>Network>VXI11" to ensure stable communication during remote control.

3. Remote/Local Mode Switching

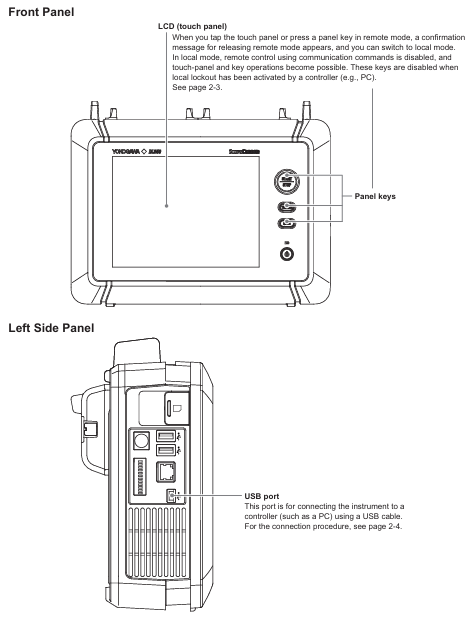

Switching logic: When the PC sends the "COMMunicate: REMote ON" command, the device enters remote mode, and "Remote" is displayed at the top of the screen. At this time, touch panel/button operations can only trigger the "Release Remote Mode" confirmation pop-up window; Send "COMMunicate: REMote OFF" or click "OK" in the pop-up window to switch back to local mode.

Mode restriction: In remote mode, if the PC sends the ": Communicate: LOCKout ON" command, the local operation will be locked and can only be released through the PC command; When switching between two modes, the current device settings will be retained without the need for reconfiguration.

(2) USB interface

1. Core features and parameters

Function: Consistent with Ethernet interface function, supports remote command reception, data transmission, and status monitoring, but requires additional driver installation.

Technical specifications: 1 Mini Type B port, compliant with USB 2.0 standard, device in self powered mode; Only supports Windows 8.1/10/11 system PC, requires installation of Yokogawa USB driver (YKMUSB) and communication library (TMCTL); The waveform transmission rate is slightly higher than Ethernet, with a byte data transmission time of about 700ms for 1 million data points and about 25s for ASCII data.

2. Connection and configuration

Hardware connection: Use a USB Mini B cable to connect the USB port on the left panel of the device to the PC. If multiple devices are connected through a USB hub, connect the DL350 to the hub port near the PC to avoid signal attenuation; Do not plug or unplug USB cables within 20-30 seconds after the device is turned on (not fully started) to prevent damage to the device.

Parameter setting: Set "USB Function" to "TMC" through the device menu "Utility>System>Others". After setting, restart the device to take effect; PC requires the installation of corresponding drivers, which can be obtained through the official website or by contacting distributors. The use of third-party USB drivers is prohibited.

3. Remote/Local Mode Switching

Switching logic: Completely consistent with the Ethernet interface, confirm the switch through PC commands or local pop ups, and retain the current settings when switching modes.

Exclusive restriction: Ethernet and USB interfaces cannot be used simultaneously. When one interface is enabled, the other interface will be automatically disabled.

Fundamentals of Programming and Instruction System

(1) Core Programming Concepts

1. Message format

Program message: sent from a PC to a device, containing one or more instruction units separated by semicolons, and ending with a termination symbol (NL, ^ END, or NL ^ END); Each instruction unit consists of "program header+space+program data", such as "ACQuire: MODE NORMal" (set the acquisition mode to normal mode).

Response message: returned by the device to the PC, corresponding to the query instruction in the program message, in the format of "response header+space+response data" (some queries only return data), terminated with NL ^ END at the end; If the program message contains multiple queries, the response will be returned in the order of the queries.

2. Data type

Supporting multiple data formats to adapt to different control requirements, the key types and descriptions are as follows:

Example of Data Type Format Explanation

Decimal numbers (<Decimal>) consist of integers (NR1), fixed-point numbers (NR2), and floating-point numbers (NR3). The device can receive any format, and the response is uniformly set to NR3 with a sampling rate of "TIMebase: SRATE 1E6"

Physical quantities (such as<Voltage>/<Time>) are numerical values prefixed with units or multiples, and units/prefixes are not case sensitive. Set the timeline as "TIMebase: TDIV 1US"

Register>supports decimal, hexadecimal (# H), octal (# Q), and binary (# B), and responds by uniformly setting events in decimal: "STATus: EESE # H01"

Pre defined mnemonic for character data (<Character data>), to be selected from options, case insensitive setting coupling method: "CHANnel1: COUPling AC"

Boolean value (<Boolean>) supports ON/OFF or numerical values (0=OFF, non-zero=ON), and the response uniformly uses 0/1 to open the channel display: "CHANnel1: DISPlay ON"

The string (<String data>) needs to be enclosed in single/double quotation marks. If it contains quotation marks, two consecutive setting labels should be entered: "CHANnel1: LABel" CH1_TEST "

Block data (<Block data>) 8-bit binary data, formatted as "# N+N bit data length+data byte sequence", only used to respond to waveform data response: "# 800000010ABCDEFGHIJ"

(2) Instruction system

The manual divides instructions into 37 command groups, covering full remote control functions such as device acquisition, analysis, display, and triggering. The core command groups and functions are as follows:

Command Group Core Instruction Function Description

ACQuire Group: ACQuire: MODE, ACQuire: LENGTH Set/query waveform acquisition mode (normal/average/envelope), recording length (oscilloscope mode)

ANALysis Group :ANALysis:HARMonic:FREQuency、:ANALysis:HARMonic:RESult? Configure harmonic analysis frequency, query harmonic RMS/power analysis results (such as total distortion rate, active power)

CHANnel Group: CHANnel<x>: COUPling, CHANnel<x>: SCALe sets channel input coupling (AC/DC/GND), screen display upper and lower limits, supports voltage, temperature, strain and other modules

TRIGger Group: TRIGger: MODE, TRIGger: LEVel Configure trigger mode (single/repeated), trigger level, supports multiple trigger types such as edge, pulse width, etc

WAVeform Group :WAVeform:SEND? 、 WAVeform: FORMat queries waveform data and sets data transmission format (byte/word/ASCII)

SYSTem Group :SYSTem:CLOCk:DATE、:SYSTem:BATTery:REMain? Set device date and time, check battery remaining level

Common Command Group *IDN? 、 *CLS, OPC standard IEEE 488.2 command, query device model, clear status register, mark operation completed

Status monitoring and troubleshooting

(1) Status reporting mechanism

The device achieves status monitoring through status bytes, registers, and queues. The core components include:

Status byte: 8-bit binary data, reflecting the overall operating status of the device, such as bit0 indicating operation completion and bit5 indicating error occurrence.

Standard event register: records device standard events (such as operation completion, query errors), which can be enabled through "* ESE" and queried and cleared through "* ESR?".

Extended event register: records device specific events (such as collection completion, trigger occurrence), enabled through the "STATus: EESE" setting, cleared through the "STATus: EESR?" query.

Output and Error Queue: The error queue stores the latest error code and description, which can be queried through "STATus: ERRor?"; The output queue stores non error messages, which can be set to be stored or not through ": STATus: QENable".

(2) Common problem solving

Troubleshooting steps for problem types and phenomena

Communication connection issue: Ethernet/USB cannot establish a connection. 1. Check if the cable connection is secure, and confirm if the Ethernet IP address is in the same network segment; 2. USB needs to confirm whether the driver is installed correctly and whether the device's "USB Function" is set to "TMC"; 3. Restart the device and PC and try again

Instruction execution problem: Sending instructions without response or error. 1. Check the instruction syntax (such as case and parameter range), refer to Chapter 4 of the manual to confirm the instruction format; 2. Confirm that the device is in remote mode and there is no local lock; 3. Check the communication timeout setting. If the data volume is large, the timeout time can be extended

Data transmission issue: waveform data transmission interruption or distortion. 1. Confirm that the transmitted data format is consistent with the supported format of the device (such as byte/word/ASCII); 2. Ethernet needs to check network bandwidth to avoid transmitting large amounts of data simultaneously; 3. USB requires the use of short distance cables to reduce signal attenuation

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

- other brands

-

ABB NPCT-01C Process Control Terminal – Industrial Automation Interface

-

ABB 216DB61 AC Motor Protection Relay – Reliable Motor Safety and Control

-

ABB 216AB61 AC Motor Protection Relay – Industrial Motor Safety

-

ABB 5SHX1060H0003 High Voltage Circuit Breaker – Reliable Industrial Protection

-

ABB 3BHB003154R0101 AC Drive Module – Industrial Automation Solutions

-

ABB UAD149A0011 Industrial Excitation Control Module for Advanced Drive Systems

-

ABB UAD149 Excitation Control Unit

-

ABB PFEA113-20 Tension Measurement Module

-

ABB GDD471A001 Drive Control Board

-

ABB UCD224A103 Control Unit Module

-

ABB PDD205A1121 Power Drive Control Module

-

ABB DSPC454 Processor Module

-

ABB 81EU01E-E Excitation Control Module

-

ABB TK457V050 Control Cable Assembly

-

ABB DSRF197K01 I/O Interface Module

-

ABB TK802F Communication Cable Assembly

-

ABB 3BHE039203R0101 Control Interface Module

-

ABB 3BHB004027R0101 Power Control Board

-

ABB 3BHB003154R0101 Power Control Board

-

ABB PM864AK01-eA AC 800M Processor Unit

-

ABB CI868K01-eA Communication Interface Module

-

ABB 5SHY35L4520 IGCT Power Semiconductor Module

-

ABB UNS0119A-P V101 Control Interface Module

-

ABB GCC960C103 Control Communication Board

-

ABB GVC736CE101 Voltage Control Module

-

ABB PCD244A101 Control Processor Module

-

ABB GFD212A Ground Fault Detection Module

-

ABB PPD513 A2A‑11165 Industrial Automation Controller

-

ABB PDD200A101 Digital Processing Device

-

ABB SPIET800 Industrial Automation Interface Module

-

ABB SPAD346C3 Protection and Automation Device

-

ABB FPX86-9329--C Power Interface Board

-

ABB ARCOL0339 Precision Power Resistor

-

ABB 5SDF0860H0003 Phase Control Thyristor Module

-

ABB KUC720AE01 Drive Control Module

-

ABB UFC718AE01 Control Interface Unit

-

ABB 5SHX2645L0004 IGCT Power Semiconductor Module

-

ABB SPHSS03 High-Speed Signal Processing Module

-

ABB CB801 Communication Backbone Module

-

ABB DSAI130D Analog Input Module

-

ABB 086345-504 Industrial Interface Control Module

-

ABB PFCL201C 10KN Tension Measurement Module

-

ABB 3HAC17484-8108 Industrial Control Module

-

ABB 5SHY3545L0009 IGCT Power Semiconductor Module

-

ABB NPCT-01C Control Processing Module

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923