K-WANG

YOKOGAWA DO30G Dissolved Oxygen Sensor

YOKOGAWA DO30G Dissolved Oxygen Sensor

Equipment Overview and Adaptation System

The core positioning of DO30G dissolved oxygen sensor is based on the principle of primary battery method, used for continuous measurement of dissolved oxygen concentration in water, suitable for environmental protection, water treatment and other scenarios. It needs to be combined with a supporting analyzer/converter to form a complete system and cannot be used alone.

Model coding rules

Standard model format: DO30G-NN-50-XX-YY, the meanings of each part are as follows:

-NN: Fixed suffix, no special meaning

-50: Permeable membrane thickness, fixed at 50 μ m

-XX: Cable length, optional -03 (3m), -05 (5m), -10 (10m), -15 (15m), -20 (20m)

-YY: Cable terminal types, - PN (pin type), - FK (fork type), - FL (M4 ring type), - FM (M3 ring type)

Key technical specifications

Specification category specific parameter remarks

Measurement parameter measurement range: 0-20 ppm, 0-20 mg/L, 0-100% (saturation). Specific ranges need to be set in the converter

Repeatability: 0.1 mg/L or 3% FS (whichever is greater) with sensor error included

Temperature compensation error: ± 3% FS (± 5 ℃ variation within 0-40 ℃) including sensor error

Response time: ≤ 2 minutes (90% response) including sensor error

Environmental requirements for measuring solution temperature: 0-40 ℃ (maximum value) Exceeding the range affects accuracy

Measure solution pressure: conventional 0-30 kPa, maximum 100 kPa, depth not exceeding 3m

Measure solution flow rate: ≥ 20 cm/s to prevent errors caused by bubble retention

Structural Material Sensor Unit: Hard PVC, Stainless Steel Resistant to Conventional Corrosion

Permeable membrane: Fluororesin (FEP) with a thickness of 50 μ m, requiring regular inspection

O-ring: Nitrile rubber sealing function, it needs to be replaced synchronously when replacing the membrane

Cable: heat-resistant flexible PVC, shielding design length 3-20m, terminal type selected according to requirements

Temperature compensation built-in RTD: PT1000 has a resistance of approximately 1097 Ω at 25 ℃, used to correct the effect of temperature on dissolved oxygen

The basic weight is 0.3 kg+0.12 × N kg (N is the length of the cable), and the total weight of a 5m cable is approximately 0.9 kg

Installation process and precautions

Pre-installation preparation

Remove protective cap: There is a black rubber protective cap on the tip of the sensor. It is forbidden to forcefully pull or twist it to remove it (which may cause the film to stretch/break). The correct way is to insert a 0.1-0.2mm thin rod and leave an air gap before pulling it out, or slowly rotate it clockwise to remove it (see Appendix 1 for details).

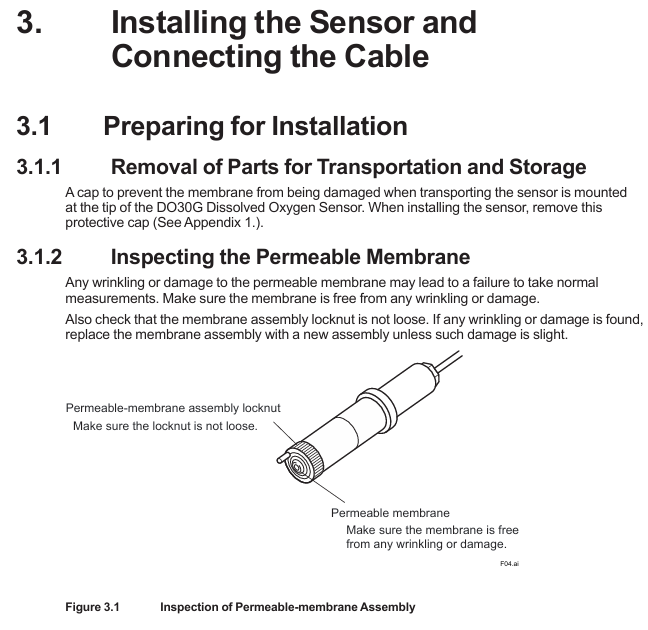

Check the permeable membrane: visually confirm that the membrane is not wrinkled or damaged, and that the membrane component lock nut is not loose (looseness can cause electrolyte leakage and affect measurement).

Principles for selecting measurement points

Uniform solution composition: avoid areas with frequent bubbles and stagnant water (to prevent fluctuations in measurement values).

Stay away from high velocity sand containing solutions: prevent sand particles from wearing down the permeable membrane.

Depth ≤ 3m: meets the pressure tolerance range (maximum 100 kPa).

Bracket selection and installation | Bracket type | Material/structure | Applicable scenarios | Installation points |

| Sensor tilted installation (anti bubble attachment), cleaning tube connected to water/air source for automatic cleaning|

cable connection

Match the converter according to the terminal number, taking FLXA402 as an example:

Temperature sensor (Pt1000): Connect terminal 11 (T1) and terminal 12 (T2) of the cable to the corresponding temperature terminals of the converter.

Electrode signal: Connect the 13 terminal (IE, anode) and 15 terminal (RE, cathode) of the cable to the corresponding electrode terminals of the converter.

Shielded wire: Connect to the shielded terminal of the converter to reduce interference.

Attention: Cable terminals must not be contaminated with water, and protection should be taken when not connected temporarily.

Maintenance and troubleshooting

Daily maintenance (regular inspection)

Permeation membrane cleaning: During each calibration, rinse the membrane surface with clean water, and wipe stubborn dirt with neutral detergent (do not scrape with hard objects to avoid membrane damage).

Membrane module lock nut inspection: Each calibration confirms that the lock nut is not loose, and if it is loose, it needs to be tightened; If there is still an abnormal display after tightening (such as extremely low measurement values), the electrolyte needs to be replaced.

Fault handling process

Troubleshooting steps and solutions

Abnormal measurement values (low/fluctuating) 1. Check if the membrane is damaged/wrinkled; 2. Check if the lock nut is loose; 3. Check if the electrolyte has deteriorated. 1. Replace the membrane module and electrolyte; 2. Tighten the nut lock; 3. Replace the electrolyte

If the temperature compensation fails and the resistance between terminals 11-12 of the measurement cable (standard value of 1097 Ω at 25 ℃) is abnormal, replace the sensor

Unable to zero/span 1. Replace membrane module+electrolyte and retry; 2. If the corrosion of the lead electrode is still ineffective, replace the sensor (lead electrode has a lifespan of 3-4 years)

Steps for replacing electrolyte and membrane components

Safety reminder: The electrolyte is KOH alkaline solution. If it comes into contact with the skin/eyes, rinse immediately with water and do not leave any residue in the syringe.

Steps:

Remove the sensor and clean the wet area;

Release the lock nut and remove the membrane component and old O-ring;

Empty the old electrolyte (tilt sensor, use a syringe to blow air from the injection port to assist in emptying);

Polishing silver electrode: Dip a damp gauze into aluminum oxide powder and gently wipe it (to avoid excessive polishing and prevent damage to the epoxy material), then clean the remaining powder;

Install a new O-ring, inject 8ml of new electrolyte (Yokogawa specific, model K9171DN), and reserve 1ml of air;

Install a new membrane component: Drop 1 drop of electrolyte on the surface of the silver electrode to prevent bubbles, lightly press the membrane component and tighten the locking nut (do not rotate the membrane component);

Rest: After replacement, it is necessary to rest for more than half a day before adjusting the zero/span (negative values may be displayed in the initial 10 minutes, which is a normal phenomenon).

Core spare parts list

DOX8A Maintenance Kit (Style B): Designed specifically for DO30G, it includes the following items:

Item Name Specification/Quantity Usage

Replace 50mL of electrolyte (model K9171DN) with 8ml each time

Replace damaged/contaminated membranes with 3 sets of membrane components and O-rings (model K9171HM)

500g of zero calibration reagent (sodium sulfite) (model L9920BR) is used to prepare a zero calibration solution (50g is required for 1L)

Inject 5ml (with needle, model L9827NH/L9827NG) of electrolyte into the syringe

200mL beaker (model L9825AF) for draining electrolyte/calibration purposes

30g of silver electrode polishing powder (model K9088PE) is used to polish silver electrodes, with approximately 0.5g used each time

Spare parts: membrane module lock nut (model K9171CH), spare sensor (to avoid measurement interruption caused by sudden failure).

Key issue

Question 1: How long does it take to replace the permeation membrane and electrolyte of DO30G sensor? What safety and operational details should be paid attention to when replacing?

answer:

Replacement cycle: It is recommended to replace the electrolyte every 6-8 months or immediately when the sensor cannot be adjusted for span; The permeable membrane and electrolyte should be replaced synchronously. If the membrane is damaged, wrinkled, or severely contaminated, it needs to be replaced in advance.

Safety details: The electrolyte is KOH alkaline solution. If it comes into contact with the skin, rinse immediately with clean water. If it enters the eyes, rinse and seek medical attention. Do not leave any residue in the syringe;

Operation details: When injecting electrolyte, add 8ml (Yokogawa specific model K9171DN) and reserve 1ml of air to prevent abnormal pressure; Before installing the membrane module, one drop of electrolyte should be dropped on the surface of the silver electrode to avoid the formation of bubbles between the membrane and the electrode; Do not rotate the membrane component when tightening the nut to prevent membrane wrinkling.

Question 2: There are three commonly used mounting brackets for DO30G sensors (PH8HG, PB350G, DOX8HS). How to choose according to the actual scenario? What are the core advantages and installation requirements of each bracket?

answer:

Selection of bracket type scene based on core advantages and installation requirements

PH8HG catheter measurement solution has no bubbles or pollutants (such as clear water tank), PVC material is corrosion-resistant, simple structure, low cost, and needs to be fixed on a pipeline with an outer diameter of 60.5mm. The sensor is suspended in a 2m long catheter

The PB350G floating ball bracket measures the solution level with large fluctuations and a small amount of flocculent substances (such as sedimentation tanks). The floating ball changes with the liquid level, and the sensor is always immersed in the solution; The wet part is smooth and not easy to hang flocs. The bracket is fixed on the 50A pipeline (outer diameter 60.5mm) or horizontal plane, and the float does not deviate from the measurement point

The DOX8HS immersion bracket measurement solution is prone to contamination (such as industrial wastewater) and needs to be regularly cleaned and installed at a 45 ° angle to prevent bubble adhesion; Support automatic cleaning with water/air spray to reduce the need for manual maintenance by connecting to a clean water/air source. The sensor is tilted and fixed to ensure that the cleaning spray port is aligned with the membrane surface

Question 3: When the DO30G sensor displays abnormal measurement values (such as continuous low or large fluctuations), how to gradually investigate the cause of the fault and solve it?

Answer: Troubleshooting should be carried out according to the following steps, with priority given to handling simple faults:

Check the condition of the permeable membrane: visually inspect the membrane for any damage, wrinkles, or severe contamination (such as oil stains or sediment). If there is, replace the membrane module (model K9171HM)+electrolyte; If the pollution is minor, clean with clean water and neutral detergent and try again;

Check the locking nut of the membrane module: confirm whether the locking nut is loose (looseness can cause electrolyte leakage, and the measured value is low). If it is loose, tighten it. If it is still abnormal after tightening, replace the electrolyte;

Check the status of the electrolyte: observe whether the electrolyte is turbid or discolored (normally clear), and replace it if it deteriorates;

Check temperature compensation: Use a multimeter to measure the resistance between terminals 11-12 of the cable (standard value of 1097 Ω at 25 ℃). If the resistance is abnormal, the sensor RTD is faulty and needs to be replaced;

Check the lead electrode: If the above steps are ineffective, it may be due to long-term corrosion failure of the lead electrode (with a lifespan of 3-4 years), and the sensor needs to be replaced as a whole.

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector