K-WANG

YOKOGAWA SC4AJ Conductivity Sensor

YOKOGAWA SC4AJ Conductivity Sensor

Equipment foundation and adaptation system

1. Core positioning and application scenarios

SC4AJ is a compact sensor designed specifically for low conductivity solutions, suitable for industries such as semiconductors, power, and pharmaceuticals that require high purity (such as ultrapure water detection). It needs to be paired with a specific analyzer/converter to form a complete detection system. The compatible equipment and corresponding manual information are as follows:

Corresponding manual number for supporting equipment type

FLXA202, FLXA21 2-wire analyzer IM 12A01A02-01E

FLXA402 4-wire converter IM 12A01F01-02EN, IM 12A01F03-01EN, etc

SC450G Conductivity Converter IM 12D08N05-01E

SA11 Smart Adapter IM 12A06S01-00EN-P

2. Equipment core classification and parameters

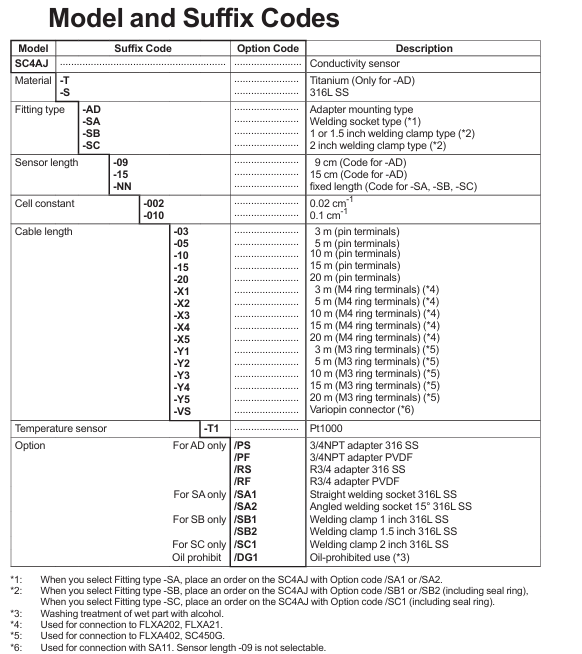

SC4AJ is classified into models based on electrode material, installation method, and battery constant. The core differences focus on adaptation scenarios and measurement ranges. The specific classifications are as follows:

Classification dimensions, specific types, key parameters/characteristics

Electrode material titanium (- T) is only suitable for adapter installation type (- AD), with strong corrosion resistance

316L stainless steel material (- S) is compatible with all installation methods and has strong universality

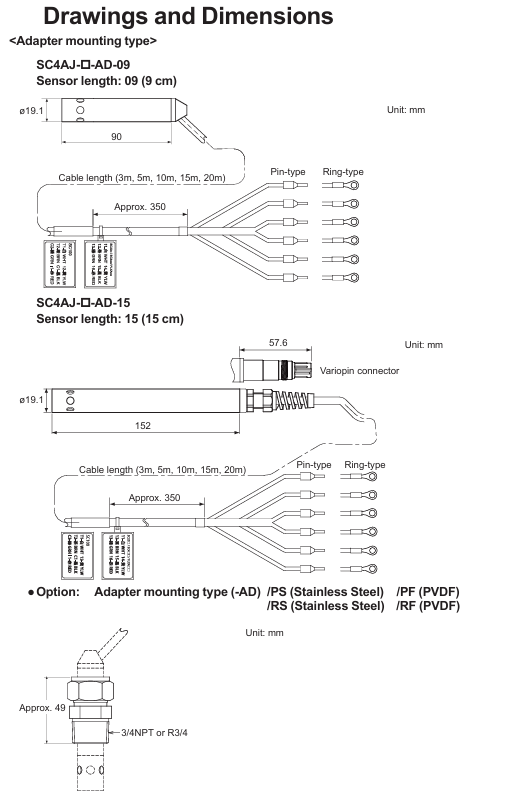

Installation method: Adapter installation type (- AD) with 3/4NPT or R3/4 adapter (stainless steel/PVDF material), sensor length 9cm/15cm

Welding socket type (- SA) requires straight type (/SA1) or 15 ° angle type (/SA2) welding socket, with fixed sensor length

Welding clip type (- SB/- SC) - SB compatible 1/1.5 inch clip (/SB1//SB2), - SC compatible 2-inch clip (/SC1), including sealing ring

Battery constant 0.02 cm ⁻¹ (-002) measurement range 0-0.5 μ S/cm to 0-200 μ S/cm, suitable for extremely low conductivity solutions

0.1 cm ⁻¹ (-010) measurement range 0-5 μ S/cm to 1 mS/cm, suitable for low conductivity solutions

Cable terminal pin type/M4 ring type/M3 ring type/Variopin pin type compatible with multiple devices; M4 ring adapter FLXA202/FLXA21; M3 ring adapter FLXA402/SC450G; Variopin compatible with SA11

3. General technical specifications

Temperature and pressure: The electrode has a conventional temperature of 0-110 ℃ (can be steam sterilized at 135 ℃ for 30 minutes) and a pressure of 0-1 MPa; The tolerance range of the bracket varies with the material (stainless steel 316L has higher temperature resistance, PVDF has lower temperature resistance, please refer to the temperature pressure curve for details)

Contact fluid material: main body (316L stainless steel/titanium), O-ring (FKM fluororubber, EPDM EPDM EPDM), adapter (PVDF or 316L stainless steel)

Temperature compensation: Built in Pt1000 temperature sensor to calibrate the effect of temperature on conductivity

Protection restriction: The sensor mold and metal joint are not waterproof and cannot be immersed in process water

Safety regulations and usage restrictions

1. Core security principles

Prohibited unauthorized operation: Only use according to the instructions in the manual, unauthorized modification of the device will result in loss of protective function; Repairs require Yokogawa certified spare parts, unauthorized modifications are prohibited

Static electricity and explosion prevention: The flow of ultrapure water in plastic pipes may generate static electricity, and it is necessary to avoid the sensor conducting static electricity and damaging the converter circuit; Must comply with explosion-proof standards such as IEC 60079-11 and GB 3836.4-2010 (TIIS certified models cannot be connected), and if necessary, affix a "simple equipment" label

Temperature limit: The maximum process temperature needs to be determined based on the supporting analyzer (FLXA202/FLXA21) and temperature level (T1-T6). For example, under T6 level, the maximum process temperature at 40 ℃/60 ℃ ambient temperature is 49 ℃; At T5 level, the ambient temperature is 95 ℃ at 40 ℃ (note that the upper limit of T5 level is 100 ℃)

2. Manual usage guidelines

It needs to be handed over to the end user and properly stored, and unauthorized copying/dissemination is prohibited; Yokogawa reserves the right to improve manuals and equipment without prior notice

The manual only describes the device functions and does not guarantee adaptation to specific user scenarios; The equipment is provided as is, and Yokogawa is not responsible for unforeseeable direct/indirect losses

Installation and Wiring Guide

1. Core installation requirements

Installation principle: Ensure uniform composition and no dead zone when the solution flows through the sensor; The sensor needs to be submerged above the outlet to ensure continuous liquid flow between the electrodes; Reserve maintenance space for easy disassembly and release of process pressure; Confirm that the pressure at the installation site is within the tolerance range of the sensor and adapter

Steps for different installation methods:

Adapter installation type (- AD): Assemble in the order of "nut → adapter support (stainless steel adapter) → adapter → sealing ring → sensor body", tighten the nut with a torque of about 190 N · m (tighten with fingers and then use a wrench to tighten 1.25 turns)

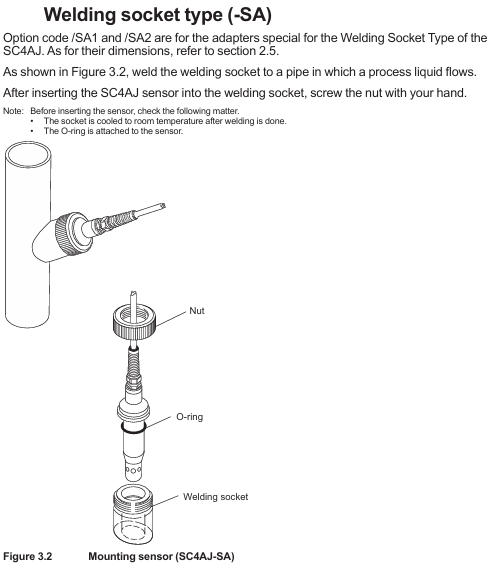

Welding socket type (- SA): First weld the welding socket to the process pipeline (cool to room temperature), insert the sensor into the socket after installing the O-ring, and fix it by hand tightening the nut

Welding clamp type (- SB/- SC): First weld the flange to the pipeline, insert the sensor into the flange after installing the sealing ring, and fix it with a special fixture

2. Wiring requirements

Wiring logic: Connect according to the cable end identification and the terminal number of the analyzer/converter, for example, connect the temperature sensor wire (brown/black/red) to the corresponding temperature terminal, and the electrode wire (green/yellow) to the corresponding electrode terminal; Variopin terminal (- VS) needs to be connected to SA11 adapter

Cable specifications: Cable length 3-20m (selected according to the order), avoid contact with high-temperature components, and ensure that the insulation resistance meets the requirements after wiring (such as 1000-1137 Ω between terminals 11-12 and>100 M Ω between terminals 11-13)

Operation and maintenance process

1. Preparation and calibration before operation

Pre operation inspection: Confirm that the cable connection is correct, the solution is leak free, the temperature/pressure is within the range, and the solution level reaches the outlet height

Battery constant setting: The factory calibrated battery constant on the cable label needs to be input into the matching analyzer/converter (refer to the corresponding equipment manual for operation steps)

Calibration requirements: Use a standard solution with known conductivity for calibration (the conductivity of the standard solution should be close to that of the test liquid). Before calibration, the sensor should be equilibrated with the temperature of the solution, and the temperature should be measured using a calibration thermometer

2. Core maintenance operations

(1) Sensor cleaning

Choose the cleaning method based on the type of pollutant, and prohibit mixing hydrochloric acid with chlorine containing solvents (to avoid producing toxic chlorine gas):

Scale and hydroxides: Clean with 5-10% hydrochloric acid solution

Organic dirt (oil, grease): Wipe with ethanol or acetone

Algae/bacteria: Clean with chlorine containing solution (household bleach)

Conventional pollution: cleaning with hot water and household detergent

After cleaning, visually inspect the sensor for any damage or deformation

(2) Abnormal judgment

After the sensor dries, measure the resistance between the terminals with a digital multimeter. If it exceeds the following range, it needs to be replaced:

Terminal combination (non VS) Variopin terminal combination (- VS) standard resistance at room temperature

11-12 E-F 1000-1137 Ω

11-13, 13-15, 12-15 E-C, C-A, F-A>100 M Ω

13-14, 15-16 C-D, A-B < 10 Ω

3. Spare parts information

Core spare parts need to be matched according to the installation method, and common spare parts are as follows:

Type description corresponding to spare part number

K9670MA SA (non VS) O-ring

K9670VY SA (- VS) O-ring set

K9670MK-SB sealing ring (compatible/SB1//SB2)

K9670MP SC sealing ring (compatible/SC1)

K9670MT/MU-AD 3/4NPT stainless steel/PVDF adapter

K9670ME/MD-SA straight/angle welding socket and installation nut

- YOKOGAWA

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Energy and Gender

- Covid-19

- man-machine

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- Sewage treatment

- cement

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- Automobile market

- xYCOM

- Motorola

- architecture

- Industrial information

- New energy

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

-

GE Hydran M2-X Enhanced Monitoring

-

ABB REG316 1mrk000809-GA Numerical Generator Protection

-

ABB RED670 1MRK004810 Line differential protection

-

GE SR750-P5-G5-S5-HI-A20-R-E Feeder protection system

-

ABB PFTL301E-1.0KN 3BSE019050R1000 PillowBlock Load cells

-

Kollmorgen S33GNNA-RNNM-00 - Brushless Servo Motor

-

Kollmorgen 6sm56-s3000-g-s3-1325 - Servo Motor

-

Kollmorgen AKM52K-CCCN2-00 - Servo Motor

-

Kollmorgen PSR3-230/75-21-202 - Power Supply

-

Kollmorgen akm24d-anc2r-00 - Servo Motor

-

Kollmorgen AKM22E-ANCNR-00 - Servo Motor

-

Kollmorgen S60300-550 - Servo Drive

-

Kollmorgen B-204-B-21 - Servomotor

-

Kollmorgen AKM21E-BNBN1-00 - Servo Motor

-

Kollmorgen TT2953-1010-B - DC Servo Motor

-

Kollmorgen pa8500 - Servo Power Supply

-

Kollmorgen BDS4A-210J-0001-207C2 - Servo Drive

-

Kollmorgen TTRB1-4234-3064-AA - DC Servo Motor

-

Kollmorgen MH-827-A-43 - Servo Motor

-

Kollmorgen AKM24D-ACBNR-OO - Servo Motor

-

Kollmorgen 00-01207-002 - Servo Disk DC Motor

-

Kollmorgen AKM21C-ANBNAB-00 - Servo Motor

-

Kollmorgen PSR3-208/50-01-003 - Power Supply

-

Kollmorgen 6SM56-S3000 - Servo Motor

-

Kollmorgen DBL3H00130-B3M-000-S40 - Servo Motor

-

Kollmorgen 6SN37L-4000 - Servo Motor

-

Kollmorgen AKM65K-ACCNR-00 - Servo motor

-

Kollmorgen 6SM56-L3000-G - Servo Motor

-

Kollmorgen AKMH43H-CCCNRE5K - Servo Motor

-

Kollmorgen PSR4/52858300 - Power Supply

-

Kollmorgen KBM-79H03-E03 - Direct Drive Rotary Motor

-

Kollmorgen AKM33E-ANCNDA00 - Servo Motor

-

Kollmorgen U9M4/9FA4T/M23 - ServoDisc DC Motor

-

Kollmorgen AKM13C-ANCNR-00 - Servo Motor

-

Kollmorgen AKM43L-ACD2CA00 - Servo Motor

-

Kollmorgen AKM54K-CCCN2-00 - Servo Motor

-

Kollmorgen M-605-B-B1-B3 - Servo Motor

-

Kollmorgen AKD-P00606-NBAN-0000 - Rotary Drive

-

Kollmorgen 6SM-37M-6.000 - Servo Motor

-

Kollmorgen A.F.031.5 - Sercos Interface Board

-

Kollmorgen 918974 5054 - Servo PWM

-

Kollmorgen U12M4 - ServoDisc DC Motor

-

Kollmorgen AKD-B00606-NBAN-0000 - Servo Drive

-

Kollmorgen MV65WKS-CE310/22PB - Servo Drive

-

Kollmorgen 65WKS-CE310/22PB - Servo Drive

-

Kollmorgen EM10-27 - Module

-

Kollmorgen S64001 - Servo Drive

-

Kollmorgen CR03200-000000 - Servo Drive

-

Kollmorgen 6SM57M-3000+G - Servo Motor

-

Kollmorgen BDS4 - Servo Drive

-

Kollmorgen AKD-P00306-NBEC-000 - Servo Drive

-

Kollmorgen AKD-B01206-NBAN-0000 - Servo Drive

-

Kollmorgen STP-57D301 - Stepper Motor

-

Kollmorgen 6SM37L-4.000 - Servo Motor

-

Kollmorgen 44-10193-001 - Circuit Board

-

Kollmorgen PRDR9SP24SHA-12 - Board

-

Kollmorgen PRD-AMPE25EA-00 - Servo Drive

-

Kollmorgen DBL3N00130-0R2-000-S40 - Servo Motor

-

Kollmorgen S406BA-SE - Servo Drive

-

Kollmorgen AKD-P00607-NBEI-0000 - Servo Drive

-

Kollmorgen AKD-P01207-NBEC-0000 - Servo Drive

-

Kollmorgen CR03550 - Servo Drive

-

Kollmorgen VSA24-0012/1804J-20-042E - Servo Drive

-

Kollmorgen N2-AKM23D-B2C-10L-5B-4-MF1-FT1E-C0 - Actuator

-

Kollmorgen 04S-M60/12-PB - Servo Drive

-

Kollmorgen H33NLHP-LNW-NS50 - Stepper Motor

-

Kollmorgen A-78771 - Interlock Board

-

Kollmorgen AKM43E-SSSSS-06 - Servo Motor

-

Kollmorgen AKD-P00607-NBEC-0000 - Servo Drive

-

Kollmorgen E21NCHT-LNN-NS-00 - Stepper Motor

-

Kollmorgen cr10704 - Servo Drive

-

Kollmorgen d101a-93-1215-001 - Motor

-

Kollmorgen BDS4A-203J-0001-EB202B21P - Servo Drive

-

Kollmorgen MCSS23-6432-002 - Connector

-

Kollmorgen AKD-P01207-NACC-D065 - Servo Drive

-

Kollmorgen CK-S200-IP-AC-TB - I/O Adapter and Connector

-

Kollmorgen CR10260 - Servo Drive

-

Kollmorgen EC3-AKM42G-C2R-70-04A-200-MP2-FC2-C0 - Actuator

-

Kollmorgen BDS5A-206-01010-205B2-030 - Servo Drive

-

Kollmorgen s2350-vts - Servo Drive

-

Kollmorgen AKM24D-ANC2DB-00 - Servo Motor

-

Kollmorgen E31NCHT-LNN-NS-01 - Stepper Motor

-

Kollmorgen PRD-0051AMPF-Y0 - Servo Board

-

Kollmorgen TB03500 - Module

-

Kollmorgen 60WKS-M240/06-PB - Servo Drive

-

Kollmorgen M21NRXC-LNN-NS-00 - Stepper Motor

-

Kollmorgen H-344H-0212 - Servo Motor

-

Kollmorgen MCSS08-3232-001 - Connector

-

Kollmorgen AKM33H-ANCNC-00 - Servo Motor

-

Kollmorgen PA-2800 - Power Supply

-

Kollmorgen MTC308C1-R1C1 - Servo Motor

-

Kollmorgen PRDR0091300Z-00 - Capacitor Board

-

Kollmorgen BDS4A-206J-0024/01502D79 - Servo Drive

-

Kollmorgen S20330-VTS - Servo Drive

-

Kollmorgen S20250-CNS - Servo Drive

-

Kollmorgen SBD2-20-1105-WO - Servo Drive Board

-

Kollmorgen M405-C-A1--E1 - Servo Motor

-

Kollmorgen PRD-PB805EDD-00 - Servo Drive

-

Kollmorgen 6SM57S-3.000-J-09-HA-IN - Servo Motor

-

Kollmorgen AKM33H-ANCNDA-00 - Servo Motor

-

Kollmorgen PCB-00030200-04 - PCB

-

Kollmorgen H22SSLB-LNN-NS-02 - Stepper Motor

-

Kollmorgen BJRL-20012-110001 - Module

-

Kollmorgen BDS4A-206J-0001404A - Servo Drive

-

Kollmorgen H-342-H-0802 - Servo Motor

-

Kollmorgen CR10561 - Servo Drive

-

Kollmorgen BDS5A-206-00010-205B2-030 - Servo Drive

-

Kollmorgen BDS5A-206-00010-207B-2-030 - Servo Drive

-

Kollmorgen mcss08-3224-001 - Connector

-

Kollmorgen M-207-B-23-B3 - Servo Motor

-

Kollmorgen PRD-0041200Z-S0 - Encoder/Resolver Card

-

Kollmorgen MH-225-G-61 - Motor

-

Kollmorgen MT308B1-T1C1 - Servo Motor

-

Kollmorgen BDS4A-240J-0001604C83 - Servo Drive

-

Kollmorgen 6SM57-S-3000 - Servo Motor

-

Kollmorgen N-T31V-15-5B-6-MF3-FT1E-C251 - Actuator

-

Kollmorgen PRD-0051AMPA-X0 - Servo Board

-

Kollmorgen CF-SS-RHGE-09 - Cable

-

Kollmorgen DIGIFAS7204 - Servo Drive

-

Kollmorgen S30101-NA - Servo Drive

-

Kollmorgen DIGIFAS7201 - Servo Drive

-

Kollmorgen PRD-0051AMPA-Y0 - Servo Board

-

Kollmorgen AKM23D-EFCNC-00 - Servo Motor

-

Kollmorgen SE10000 - Servo Drive

-

Kollmorgen PSR4/5A-112-0400 - Power Supply

-

Kollmorgen AKM31H-ANCNC-01 - Servo Motor

-

Kollmorgen M-203-B-93-027 - Servo Motor

-

Kollmorgen CP-SS-G1HE-05 - Connector