K-WANG

Westinghouse DS/DSL series low-voltage power circuit breakers

Breaking capacity DS series 30000-65000A; DSL series 200000A DSL relies on built-in current limiting components to enhance breaking capacity, suitable for high short-circuit current scenarios

Amptector II-A (standard type) and Amptector I-A (with grounding protection) solid-state trip units with adjustable parameters, high repeatability, and no mechanical wear

Operation modes: manual (spring energy storage), electric (motor energy storage+remote control). The electric type supports emergency manual energy storage to deal with control power failures

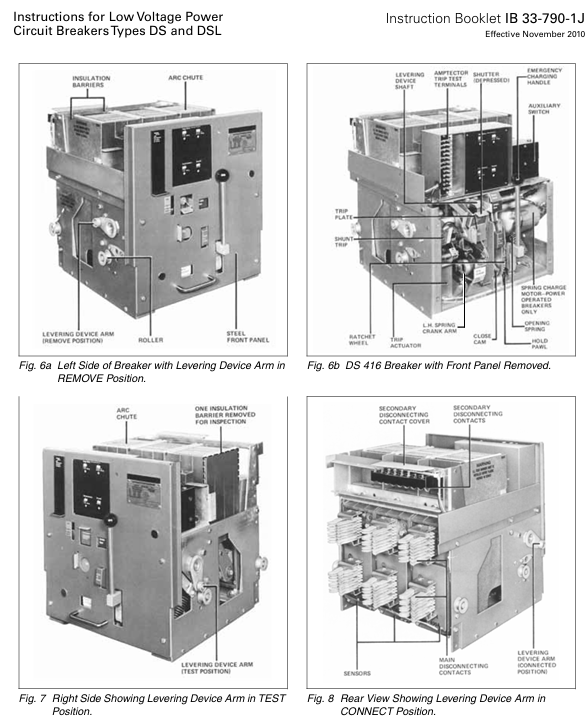

Installation forms include drawer style (mainstream) and fixed drawer style, which support four working positions for extraction, disconnection, testing, and connection, making maintenance convenient

Environmental adaptability operating temperature -20~+40 ℃, humidity ≤ 95% (no condensation). Keep away from dust and corrosive gases to avoid insulation aging

Westinghouse DS/DSL series low-voltage power circuit breakers

Detailed explanation of core product information

1. In depth analysis of technical parameters

Category parameter details note explanation

Voltage and current voltage range 208-600Vac, continuous current 50-4000A DSL series supports up to 600Vac, sensors can be replaced to adapt to different current levels

Breaking capacity DS series 30000-65000A; DSL series 200000A DSL relies on built-in current limiting components to enhance breaking capacity, suitable for high short-circuit current scenarios

Amptector II-A (standard type) and Amptector I-A (with grounding protection) solid-state trip units with adjustable parameters, high repeatability, and no mechanical wear

Operation modes: manual (spring energy storage), electric (motor energy storage+remote control). The electric type supports emergency manual energy storage to deal with control power failures

Installation forms include drawer style (mainstream) and fixed drawer style, which support four working positions for extraction, disconnection, testing, and connection, making maintenance convenient

Environmental adaptability operating temperature -20~+40 ℃, humidity ≤ 95% (no condensation). Keep away from dust and corrosive gases to avoid insulation aging

2. Product classification and core differences

(1) DS series (basic type)

Core features: No built-in current limiting components, simple structure, high cost-effectiveness, breaking capacity of 30000-65000A.

Mainstream models:

DS-206/206S: Frame current 800A, DS-206S is an upgraded version (with a breaking capacity of 42000A, better than DS-206's 30000A).

DS-416/416S/420: Frame current 1600A (416/416S), 2000A (420), 416S breaking capacity 65000A.

DS-632/840: Frame current 3200A (632), 4000A (840), suitable for large capacity distribution systems.

Applicable scenarios: Conventional industrial power distribution, commercial buildings, and situations with small fault currents (≤ 65000A).

(2) DSL series (current limiting enhanced type)

Core features: Equipped with a built-in current limiter, the breaking capacity has been increased to 200000A, which can quickly cut off large short-circuit currents and protect downstream equipment.

Mainstream models: DSL-206 (800A), DSL-416 (1600A), DSL-632/840 need to be used with an independent fuse car.

Applicable scenarios: Industrial scenarios with high short-circuit currents such as chemical and metallurgical industries, or critical distribution circuits that require enhanced protection.

(3) Fuse Trucks

Core features: Independent drawer design, equipped with Class L current limiting fuse, used in series with DS-632/840 circuit breaker.

Mainstream models: DS-3200 (3200A), DS-4000 (4000A), with fuse indicator.

Applicable scenario: Distribution systems that require graded protection, which achieve selective tripping through the combination of fuses and circuit breakers.

3. Function analysis of the trip unit

(1) Amptector II-A (Standard Type)

Adjustable parameters:

Long delay: Current 0.5-1.25 times the rated value of the sensor, time 8-36 seconds (at 6 times the rated current).

Short delay: current 4-10 x sensor rated value, time 0.18-0.5 seconds.

Instantaneous: current 4-12 times the rated value of the sensor, without delayed tripping.

Core function: Covering basic protection against overload and short circuit, supporting three combination modes: DU (long delay+instantaneous), SE (long delay+short delay), and TR (triple protection).

(2) Amptector I-A (optional)

Additional features: Added ground fault protection (adjustable current, delay of 0.22-0.5 seconds), trip indicator (overload/short circuit/ground fault indication separately).

Applicable scenarios: Ground fault sensitive scenarios (such as humid environments and places with high personal safety requirements).

Safety operation standards (including risk avoidance)

1. Personnel and Qualification Requirements

Operation qualification: Only personnel with low voltage distribution operation qualification are allowed to install and maintain, and they need to be familiar with equipment structure, interlocking mechanism, and electric shock risk.

Protective equipment: Insulated gloves and goggles must be worn during operation, insulated shoes must be worn, and slippers, bare feet, or loose clothing are prohibited (to avoid getting caught up in mechanical parts).

Prohibited behavior: Unauthorized personnel are prohibited from operating; It is prohibited to dismantle the arc extinguishing chamber and insulation barrier during equipment operation; Prohibit blocking or modifying interlocking devices (which may cause equipment misoperation and lead to accidents).

2. Installation and wiring safety

Pre installation inspection:

Check the nameplate parameters (voltage, current, breaking capacity) to match the system, and confirm that the circuit breaker is not damaged during transportation (contacts, arc extinguishing chamber, interlocking components are intact).

The drawer type circuit breaker needs to check that the guide rail and rocker are not deformed, and that the energy storage spring is not fatigued or corroded.

Wiring specifications:

Main circuit wiring: The tightening torque meets the requirements (copper bars/cables need to be crimped to the terminals) to avoid loosening and heating; The cross-sectional area of the three-phase wires is consistent, and the phase correspondence is correct.

Control circuit wiring: The electric operation type needs to be connected to a compliant control power supply (AC120/240V or DC48/125/250V), and the connection between the trip unit and the actuator should be firm with correct polarity (otherwise the protection function will fail).

Grounding requirements: The circuit breaker frame must be reliably grounded with a grounding resistance of ≤ 4 Ω to avoid electric shock caused by leakage.

3. Operation and operational safety

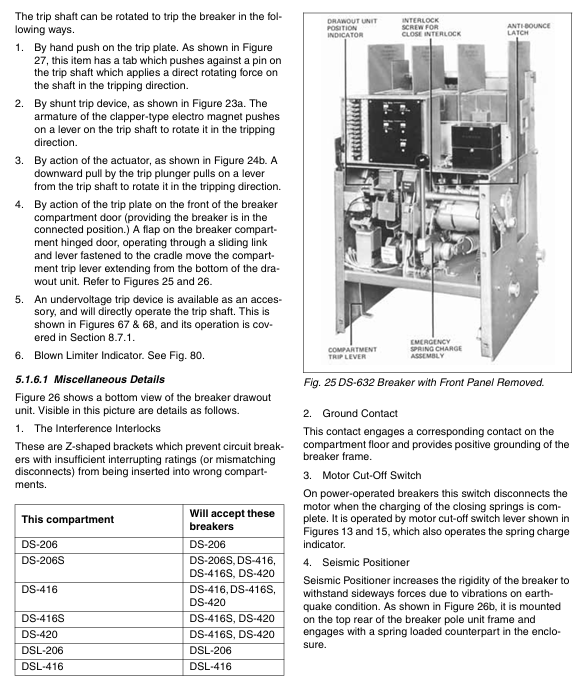

Working position operation:

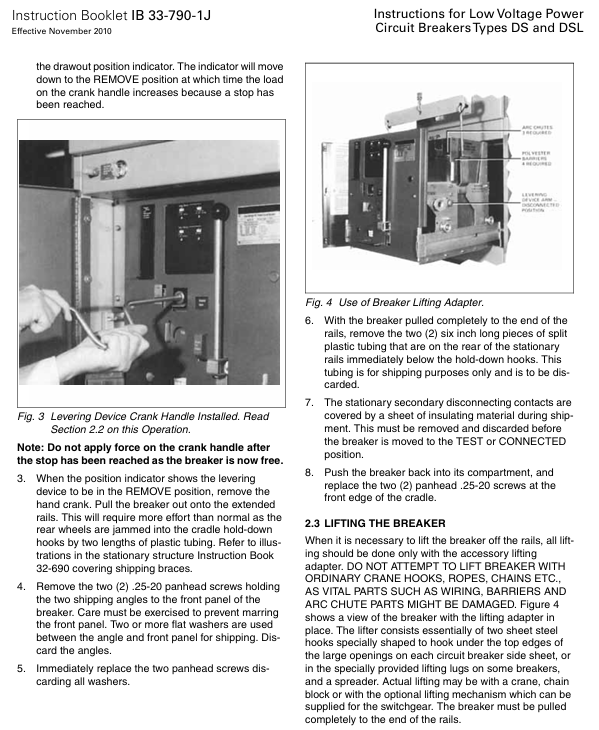

Remove position: only used for maintenance or replacement. The energy storage spring must be released first, and all power sources must be disconnected. It is forbidden to remove it while it is still live.

Disconnect position: Both the main and auxiliary contacts are disconnected, which can be locked to prevent misoperation and is used for isolation and maintenance.

Test position (TEST): The auxiliary contact is connected, which can test the closing/tripping action and tripping function. The main circuit is not powered.

CONNECT: Normal operating position, it is necessary to confirm that the mechanical stop is in place, the interlocking device is locked, and it is prohibited to switch positions in the closed state.

Energy storage and closing operation:

Manual energy storage: DS-206 and other models require a single stroke downward pull on the energy storage handle, while DS-416 and above require multiple presses on the ratchet wheel. After energy storage is completed, there will be a "click" sound and the spring energy storage indicator light will light up.

Electric energy storage: After connecting to the control power supply, the circuit breaker will automatically store energy in the test/connection position. In case of energy storage failure, emergency manual energy storage can be used.

Closing taboos: Do not close with load; Do not repeatedly close the circuit when the short circuit fault has not been resolved; Do not close the circuit with current exceeding the nameplate.

Fault handling safety:

Troubleshooting after tripping: Overload tripping requires reducing the load, short-circuit tripping requires troubleshooting for line faults, grounding faults require checking the grounding circuit, and DSL series requires confirming whether the current limiting element is blown.

Emergency stop: In the event of a serious malfunction, emergency stop can be achieved through the panel trip button or remote trip signal, and forced locking and closing are prohibited.

4. Environment and Protection Safety

Operating environment: It is necessary to maintain dryness, cleanliness, good ventilation, avoid dust, oil mist, corrosive gases (such as chlorine and ammonia), and prevent contact oxidation and insulation aging.

Temperature control: When the ambient temperature exceeds 40 ℃, it is necessary to reduce the capacity (reduce the capacity by 10% for every 10 ℃ increase), and avoid direct sunlight or proximity to heat sources.

Moisture prevention measures: Insulation inspection should be strengthened in humid environments, and insulation resistance should be measured regularly (main circuit ≥ 1M Ω, control circuit ≥ 2M Ω).

Complete operation process (installation → debugging → maintenance)

1. Installation process (drawer style as an example)

Guide rail preparation: Open the circuit breaker cabinet door, unfold the built-in guide rail to a horizontal position, and ensure that the guide rail is not deformed or stuck.

Remove transportation fixing: Remove the transportation bracket and plastic protective cover on the circuit breaker, and check that the energy storage spring is not preloaded (released during transportation).

Push in the circuit breaker: Align the circuit breaker with the guide rail, slowly push it into the extraction position, insert the joystick and rotate it clockwise to switch to the disconnection position, test position, and connection position in sequence. Each position needs to be confirmed to be mechanically locked in place (with a "click" sound).

Wiring operation:

Main circuit: Connect the incoming and outgoing copper bars according to the phase, tighten the bolts (refer to the equipment manual for torque), and check the balance of the three-phase resistance.

Control circuit: Connect control power supply, remote closing/tripping signal, tripping unit power supply, check wiring diagram to avoid reverse polarity connection.

Grounding: Connect the grounding terminal of the circuit breaker frame reliably to the cabinet grounding bar.

Insulation test: Use a 500V megohmmeter to measure the insulation resistance of the main circuit. A resistance of ≥ 1M Ω is considered qualified, otherwise moisture or wiring faults need to be investigated.

2. Debugging process

Energy storage testing:

Manual energy storage: Operate the energy storage handle, confirm that the energy storage is completed, and the spring energy storage indicator light will turn on, and the closing mechanism can operate normally.

Electric energy storage: Connect the control power supply, the circuit breaker automatically stores energy, observe that the energy storage motor runs normally, and the energy storage time is ≤ 30 seconds.

Closing/tripping test (test position):

Manual closing: Press the closing button to close the circuit breaker, the closing indicator light will light up, and the contacts will be closed in place; Press the trip button, the circuit breaker trips, the trip indicator light lights up, and the action is smooth without any jamming.

Electric closing/tripping: Through remote control signal testing, confirm that the action response is timely (≤ 0.5 seconds) and there is no misoperation.

Release unit test:

Long delay test: Use a dedicated testing kit to input 1.25 times the rated current of the sensor and verify that the trip time meets the set value (8-36 seconds).

Short delay test: Input 6 times the rated current of the sensor and verify the trip time of 0.18-0.5 seconds.

Instantaneous test: Input 10 times the rated current of the sensor to verify instantaneous tripping.

Grounding fault test (I-A type): Input the set grounding current, verify the delayed tripping and indicator action.

Interlocking function test:

Attempt to switch to the open position while in the closed state, and confirm that the interlock prevents action.

Extract the position and attempt to store energy, confirming that the energy storage mechanism is interlocked and locked.

Padlock test: Hang the lock in the tripped position and confirm that it cannot be closed.

3. Daily maintenance and regular maintenance

(1) Daily maintenance

Cleaning: Use a dry cloth to wipe the dust on the surface of the circuit breaker, and use compressed air (pressure ≤ 0.4MPa) to blow and sweep the arc extinguishing chamber vent and contact area. Do not use solvents for cleaning.

Check:

Appearance: The contacts are not eroded or deformed, the arc extinguishing chamber is not damaged or carbonized, and the interlocking components are not loose.

Indicator lights: The status of energy storage, closing, and tripping indicator lights is consistent with the actual situation.

Wiring: There is no looseness, heating or discoloration in the wiring of the main circuit and control circuit.

Functional testing: Manually close/trip once each to verify smooth operation; Test GFCI leakage protection function (once a month).

(2) Long term storage and maintenance (not used for more than 3 months)

Preparation before storage:

Release the energy storage spring and disconnect the main circuit and control circuit wiring.

Clean the surface and interior of the circuit breaker, apply rust inhibitor (metal parts), and cover with a dust cover.

Remove easily aging components (such as rubber seals) and store them separately.

Storage environment: dry, ventilated, temperature -10~+30 ℃, avoid direct sunlight and humidity.

Pre activation check:

Remove the dust cover, clean the equipment, and inspect the components for rust and deformation.

Install the sealing ring and manually operate the closing/tripping mechanism more than 5 times.

Conduct insulation and functional tests, and only after passing the tests can it be put into use

Common troubleshooting (quick problem-solving)

Possible causes and solutions for fault phenomena

Unable to store energy 1. Interlock not unlocked (not in test/connection position); 2. The energy storage mechanism is stuck (due to foreign objects/insufficient lubrication); 3. Spring fatigue or fracture; 4. Fault in electric energy storage motor: 1. Switch to the test/connection position; 2. Clean up foreign objects and apply lubricating grease; 3. Replace the energy storage spring; 4. Check the motor power supply and winding, replace if there is a fault

Unable to close after energy storage 1. Trip mechanism not reset; 2. The closing interlock is not unlocked; 3. Fault in closing electromagnet (electric type); 4. Contact stuck. 1. Manually reset the trip mechanism; 2. Confirm that the circuit breaker is in the correct position and the padlock has been removed; 3. Check the power supply and winding of the electromagnet; 4. Clean the foreign objects on the contact and check the contact stroke

Immediately trip after closing: 1. Overload (load current exceeding the set value); 2. Short circuit fault (line/equipment short circuit); 3. The tripping parameter is set too small; 4. Grounding fault (I-A type); 5. Under voltage trip not reset. 1. Reduce the load and check the current; 2. Check the short circuit point, repair it, and then close it again; 3. Adjust the trip parameters (such as increasing the long delay current); 4. Check the grounding circuit and eliminate faults; 5. Reset the undervoltage trip device and check the control voltage

No indication after disconnection. 1. Trip indicator malfunction; 2. Power failure of the trip unit; 3. Mechanical indicator rod stuck. 1. Replace the trip indicator; 2. Check the power supply of the trip unit and tighten the wiring; 3. Clean up foreign objects on the indicator rod and apply lubricating grease

The release unit has no response. 1. Control power failure; 2. Loose wiring of the trip unit; 3. Sensor damage; 4. Fault in the trip unit: 1. Check the voltage of the control power supply; 2. Tighten the connection terminals of the release unit; 3. Test the sensor output signal and replace it if it is damaged; 4. Use a testing kit to detect the trip unit, and replace it if there is a malfunction

DSL series current limiting element fuse 1. Short circuit current exceeds the breaking capacity of the circuit breaker; 2. Aging of current limiting components; 3. The trip unit did not operate. 1. Investigate the short circuit fault and reduce the short circuit current; 2. Replace the current limiting component (requires original factory accessories); 3. Calibrate the trip unit to ensure normal operation

Contact heating and discoloration: 1. Loose wiring; 2. Insufficient contact pressure; 3. Contact oxidation and erosion; 4. Overload operation: 1. Re tighten the wiring and apply conductive paste; 2. Replace the contact pressure spring; 3. Polish or replace the contacts; 4. Reduce load and avoid overload

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923