K-WANG

Westinghouse ePX3500 Electric High Voltage Cleaning Machine

Flow parameters: maximum water flow rate of 1.76 US GPM (6.66 LPM), rated water flow rate of 1.2 US GPM (4.54 LPM).

Power parameters: Input 120V AC, 60Hz, 13A, equipped with Class A GFCI leakage protection plug, double insulation design.

Applicable water source: Only cold water (tap water) is supported, and the use of hot water, lake water, pool water, etc. is prohibited. The water source pressure should not exceed 150 PSI.

Westinghouse ePX3500 Electric High Voltage Cleaning Machine

Core parameters and product configuration

1. Key specifications

Pressure parameters: maximum pressure 2500 PSI, rated pressure 2000 PSI.

Flow parameters: maximum water flow rate of 1.76 US GPM (6.66 LPM), rated water flow rate of 1.2 US GPM (4.54 LPM).

Power parameters: Input 120V AC, 60Hz, 13A, equipped with Class A GFCI leakage protection plug, double insulation design.

Applicable water source: Only cold water (tap water) is supported, and the use of hot water, lake water, pool water, etc. is prohibited. The water source pressure should not exceed 150 PSI.

2. Core configuration

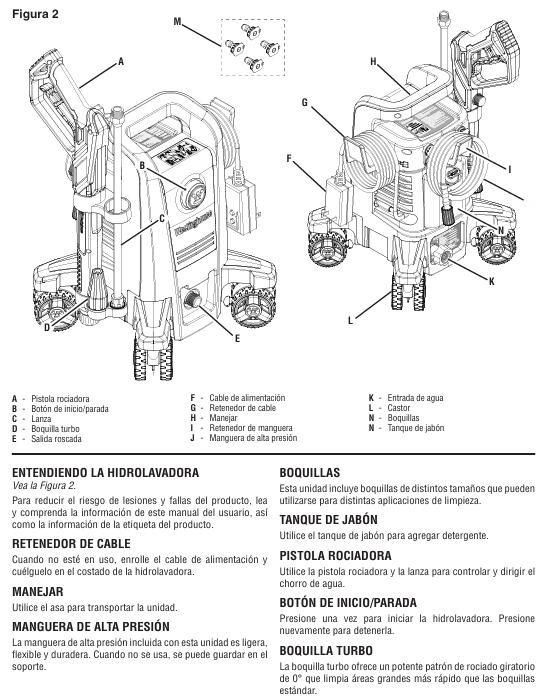

Cleaning accessories: 0 ° turbine nozzle (high-pressure cleaning), 15 °/25 ° nozzle (medium pressure cleaning), soap nozzle (low-pressure spraying).

Body components: high-pressure hose, spray gun, extension rod, soap box, roller (easy to move), cable storage rack, hose storage rack.

Safety configuration: trigger safety lock (to prevent accidental contact), GFCI leakage protection (to be tested monthly), 20A circuit breaker (overload protection).

Core functions and usage scenarios

1. Core functions

Multi scenario cleaning: By changing the nozzle to meet different needs, high-pressure nozzles can remove stubborn stains and paint peeling, medium pressure nozzles are suitable for brick and stone roads, and soap nozzles can be used with specialized cleaning agents to clean vehicles, doors, and windows.

Automatic start stop: When the trigger is triggered, the machine starts and automatically stops when released, reducing energy consumption and wear.

Convenient operation: The roller design is easy to move, components can be quickly assembled and disassembled, and cables and hoses have dedicated storage structures.

2. Applicable and taboo scenarios

Applicable for cleaning hard surfaces such as vehicles, decks, sidewalks, fences, and exterior walls of buildings.

Taboo: Do not directly spray personnel, animals, electrical equipment, glass (easily broken); Do not use in damp environments, flammable dust/liquid areas; Not suitable for cleaning medical equipment or precision instruments.

Complete operation process (assembly → use → shutdown → maintenance)

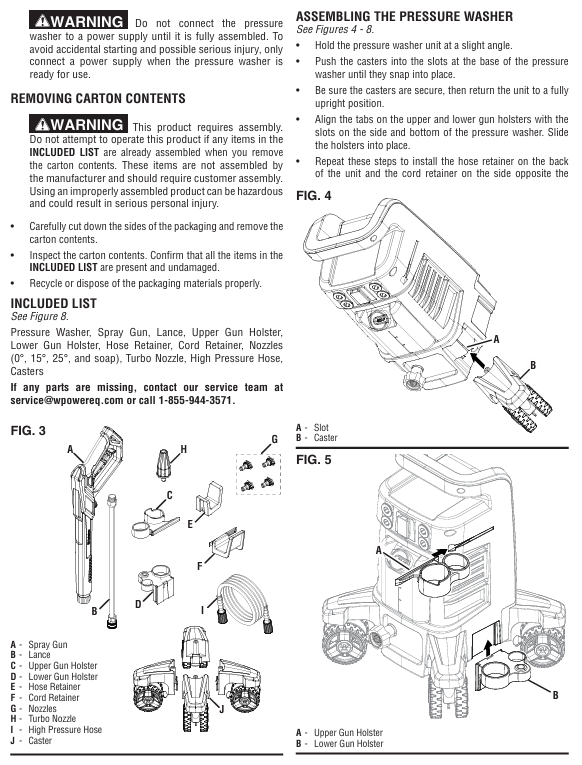

1. Assembly steps (completed within 10 minutes)

Install the roller: Tilt the body, align the roller with the bottom slot, and push it in firmly until you hear a "click" sound, ensuring that the roller is securely installed (you can gently shake it for testing).

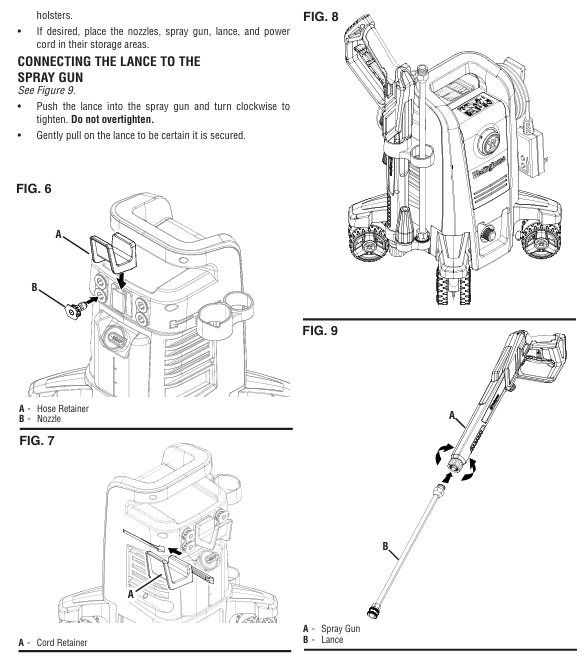

Fixed storage components: Align the spray gun storage rack, hose storage rack, and cable storage rack with the reserved card slot on the body, slide them into place, and tighten the fixing screws (if any).

Connect high-pressure hose:

Take out the high-pressure hose, align one end with the water outlet of the machine body, press the hose buckle and push it in, and tighten the locking ring clockwise.

Align the other end with the spray gun interface, press the buckle and tighten it, gently pull the hose to confirm a secure connection.

Connect water source:

Check if the filter inside the water inlet of the aircraft is intact and unobstructed (if there are impurities, rinse with clean water).

Connect one end of the garden hose to the faucet and the other end to the water inlet of the machine. Tighten the buckle clockwise and turn on the faucet to test for water leakage.

Assemble spray gun and nozzle:

Insert the extension rod into the spray gun interface, tighten clockwise (do not apply excessive force to avoid damaging the thread), and gently pull to confirm fixation.

Select the desired nozzle, align it with the front end interface of the extension rod and press it. Once you hear the snap sound, it will be installed in place; Press the buckle and pull out the nozzle during disassembly.

2. Usage steps (divided into regular cleaning and cleaning with cleaning agents)

(1) Regular cleaning (without cleaning agents)

Preparation before startup:

Turn on the faucet to ensure smooth water flow and no impurities.

Unlock the safety lock of the spray gun trigger, press the trigger to release the air and residual impurities in the pipeline until there are no bubbles in the continuous water flow, and then lock the safety lock.

Insert the power plug into the grounding socket and ensure that the plug is dry.

Startup and Cleaning:

Press the "start stop button" on the machine body, and the machine will automatically stop after running for 1-2 seconds (the automatic start stop function is normal).

Unlock the trigger safety lock, press the trigger, the machine starts and sprays high-pressure water flow to start cleaning.

Cleaning technique: Starting from the bottom of the surface, clean upwards in a left-right translation to avoid water flow from top to bottom (which may leave water marks); For stubborn stains, the distance between the nozzle and the surface can be shortened (but not less than 15cm), or the 0 ° turbine nozzle can be replaced.

Shutdown operation:

Release the trigger, the machine will automatically stop, and lock the trigger safety lock.

Turn off the faucet and press the trigger to release any residual pressure in the system.

Disconnect the power supply, wrap the cable around the storage rack, wrap the high-pressure hose around the hose storage rack, and place the spray gun into the storage rack.

(2) Cleaning with cleaning agent

Preparation: Pour the specialized cleaning agent for the high-pressure cleaning machine into the soap box in proportion and cover the box tightly.

Replace nozzle: After turning off the power and releasing the pressure, remove the current nozzle and install the soap nozzle.

Cleaning operation:

Turn on the water source and power, press the trigger, and wait for 3-5 seconds (to allow the cleaning agent to be sucked into the pipeline) until the water flow contains the cleaning agent.

Spray at a uniform speed onto the dry surface, ensuring even coverage of the cleaning agent, and let it sit for 1-2 minutes (do not dry out).

Turn off the power, replace with a 25 ° nozzle, turn on the water source and power, rinse the surface with clean water until there is no residue of cleaning agent.

Follow up processing: Empty the soap box, pour in clean water, install a soap nozzle, press the trigger to flush the pipeline for 1 minute to avoid blockage caused by residual cleaning agents.

3. Daily maintenance and regular maintenance

(1) Maintenance after each use (completed within 5 minutes)

Cleaning nozzle: Remove the nozzle, use specialized cleaning tools or fine needles to clean impurities (such as mud, residue of cleaning agent) in the nozzle hole, and then rinse with clean water.

Cleaning the inlet filter: Unscrew the inlet connector, remove the filter, rinse it with clean water, and reinstall it to ensure that the filter is not damaged (missing the filter can cause impurities to enter the pump body and cause wear).

Drain residual water from the pipeline: Turn off the water source, press the trigger to release residual water, disconnect the high-pressure hose and garden hose, tilt the machine body to drain the accumulated water in the inlet.

Cleaning the body: Wipe the dust and stains on the surface of the body with a damp cloth, do not rinse the body with high-pressure water flow (to avoid water ingress to electrical components), and do not use corrosive cleaning agents such as gasoline and solvents.

(2) Regular maintenance (monthly/every 20 hours of use)

Check the high-pressure hose: Check whether the hose is damaged, bulging, loose joints, and whether the sealing ring is aging (if there is water leakage, replace the sealing ring or hose).

Lubrication sealing ring: Apply a small amount of non water soluble grease (such as Vaseline) on the sealing ring of the high-pressure hose joint and spray gun interface to extend the service life of the sealing ring.

Test GFCI plug: Follow the steps of "leakage protection maintenance" mentioned earlier to ensure that the protection function is normal.

Check nozzle wear: If the nozzle hole becomes larger and the spraying direction deviates, it indicates that it has been worn and needs to be replaced (wear can cause a decrease in pressure and cleaning efficiency).

(3) Long term storage and maintenance (not used for more than one month)

Thoroughly clean: Follow the "maintenance after each use" steps to clean the nozzle, filter screen, and pipeline, ensuring that there is no residual cleaning agent.

Drain water: Disconnect all pipelines, press the trigger to release residual water in the pump body, and tilt the machine body for multi angle drainage.

Pump body protection: It is recommended to use commercial pump body protectants (operate according to the instructions) to prevent the pump body seals from drying out and rusting inside.

Storage requirements:

Store in a dry, ventilated, and heated room with a temperature not lower than 4.5 ℃ (to prevent residual moisture from freezing and expanding, which may cause the pump body to crack).

Disassemble the nozzle, spray gun, and extension rod, clean them and place them in the storage rack. Wrap the high-pressure hose and cable neatly to avoid squeezing or bending.

Stay away from flammable materials, high temperature sources (such as heating, stoves), and corrosive gas environments.

Common troubleshooting (quick problem-solving)

Possible causes and solutions for fault phenomena

The machine cannot start. 1. The power supply is not connected properly or the GFCI plug is not reset; 2. The system pressure has not been released; 3. Motor malfunction: 1. Check if the plug is securely plugged in and press the GFCI "RESET" button; 2. Press the trigger of the spray gun to release pressure; 3. If it still cannot be started, contact after-sales service

There is power supply but no water flow/intermittent water flow. 1. The water source is not turned on or the water pressure is insufficient; 2. The inlet filter is clogged; 3. nozzle blockage; 4. Hose bending/leakage 1. Turn on the faucet and ensure that the water source pressure is ≥ 20 PSI; 2. Disassemble and clean the inlet filter screen; 3. Clean or replace the nozzle; 4. Sort out the hoses and check if the joints are tightened

Insufficient pressure: 1. nozzle wear or blockage; 2. Low water source pressure; 3. Aging of hoses (internal collapse); 4. Wear of pump body seal 1. Clean or replace the nozzle; 2. Change the water source (such as taking water from a bucket and switching to tap water); 3. Replace the high-pressure hose; 4. Contact after-sales service for pump body maintenance

Leakage at the connection point: 1. Damaged or missing sealing ring; 2. The joint is not tightened; 3. Damaged hose: 1. Replace the sealing ring with the corresponding specification; 2. Tighten the joint clockwise (do not apply excessive force); 3. Damaged hoses need to be replaced immediately

The machine will automatically stop after running for 2 seconds. The automatic start stop function is normal (if the trigger is not pressed, the pump will stop after the priming is completed). Pressing the trigger of the spray gun can start it without maintenance; If the machine stops frequently after pressing the trigger, check if the nozzle is blocked or if the pipeline is stuck

The trigger cannot be locked, and the safety lock is stuck or damaged. Check if there are impurities stuck in the safety lock, rinse with clean water, and try to operate it; If it still cannot be locked, the trigger assembly of the spray gun needs to be replaced

GFCI plug frequently trips 1. Circuit leakage; 2. The specifications of the extension cable do not match; 3. Internal electrical failure of the machine: 1. Stop using and check if the plug and cable are damaged; 2. Replace the extension cable that meets the requirements; 3. If it still trips, contact after-sales maintenance for repair

Maintenance and Storage

1. Daily maintenance

After each use: empty the soap box, inject clean water and rinse the pipeline through the soap nozzle; Clean the nozzle (use specialized tools or fine needles to remove blockages); Clean the inlet filter screen.

Regular maintenance: monthly testing of GFCI leakage protection; Regularly inspect high-pressure hoses and sealing rings (lubricated with non water soluble grease), and replace hoses immediately if they are damaged (non repairable).

2. Storage requirements

Environmental conditions: Store in a dry, heated indoor environment with a temperature not lower than 4.5 ℃ (to prevent the pump body from freezing and cracking), away from flammable materials and high temperature sources.

Preparation before storage: Disconnect all pipelines and drain any residual water from the pump body; Disassemble the nozzle and spray gun, clean and store them; Use pump body protector (optional) to extend the lifespan.

Common troubleshooting

Possible causes and solutions for the fault phenomenon

After starting up, there is no water flow. The water source is not turned on, the inlet filter is blocked, the hose is bent to open the water source, the filter is cleaned, and the hose is straightened

Insufficient pressure/intermittent discharge nozzle blockage, insufficient water source pressure to clean nozzle, replacement of qualified water source

The sealing ring at the connection is damaged/missing due to water leakage, the thread is not tightened, replace the sealing ring, and tighten the connection again

The automatic start stop function of the machine stops after running for 2 seconds (without pressing the trigger) and can be started by pressing the trigger, no maintenance is required

GFCI plug cannot reset due to circuit leakage, plug damage and stop using. Contact after-sales service to replace the plug

The spray gun cannot lock the trigger and the safety lock is faulty. Check if the safety lock is stuck and if it is damaged, it needs to be replaced

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923