K-WANG

KOLLMORGEN IDC EC series electric cylinder

KOLLMORGEN IDC EC series electric cylinder

Product Overview

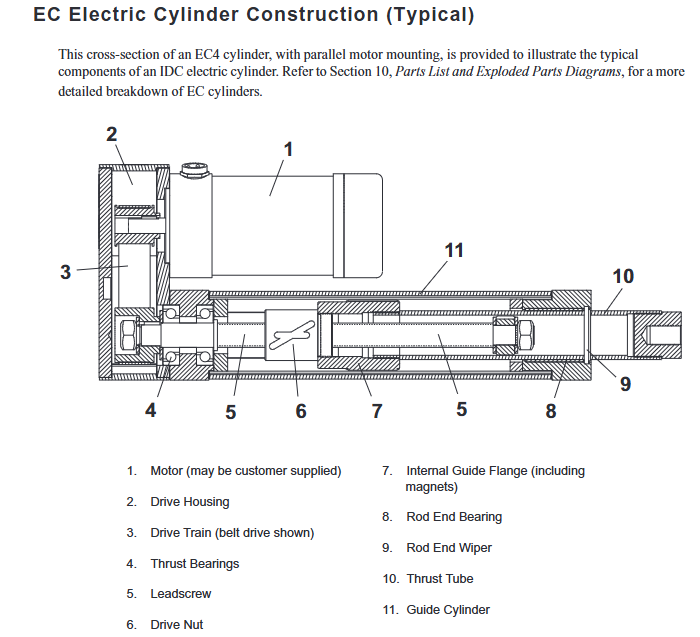

The IDC EC series electric cylinder includes four core models: EC2, EC3, EC4, and EC5, designed for precise control of linear thrust, speed, and position in the industrial, scientific, and commercial fields. It is an IDC high-performance electric cylinder product line, with the following core design highlights:

Structure: Adopting precision rolled ball screw (EC2/3 optional ACME screw), smooth transmission and precise positioning; Overall sealed design, standard IP54 protection, optional * * - PB protective boots achieve IP65 protection * *, preventing moisture and dry pollutants from entering;

Size: Complies with ISO6431 international standard, metric size, standard British/metric thread installation options;

Motor adaptation: Supports 24/160VDC brushed motors, 1.8 ° hybrid stepper motors, NEMA23/34/42 brushless servo motors, and can also be adapted to customer provided motors, with two installation methods: parallel/direct connection;

Core protection: All cylinder bodies come standard with ventilation pipe joints, and ventilation pipes need to be installed in specific scenarios to prevent internal pressure changes/pollutant intrusion.

Model Code and Configuration Rules

The EC series models are coded in combination, which can accurately identify all mechanical characteristics of the cylinder body through coding, and can also be customized according to coding requirements. The core coding dimensions and key configurations are shown in the table below:

table

Coding Dimension Core Options/Description Key Codes

Basic series four core models EC2/EC3/EC4/EC5

Motor type: DC brushed/stepper/brushless servo/customer provided D (24VDC)/H (160VDC)/P/S (stepper)/B (brushless)/X (self provided)

Transmission ratio belt/gear transmission, direct connection only 1:1 10 (1:1)/15 (1.5:1)/20 (2:1)/50 (5:1)/70 (7:1)/10L (direct connection)

Screw type ACME screw/ball screw, different lead 04A (4mm ACME)/05B (5mm ball)/10B/16A/25B/32B

The standard travel length is 50~1500mm, and it supports customized digital labeling in 1mm increments (unit: mm)

Installation methods: flange/fork/ear seat/ear shaft, etc. MF (flange)/MP (fork)/MS (ear seat)/MT (ear shaft)

Rod end type thread/fork/spherical joint FT (internal thread)/MT (external thread)/FC (fork)/FS (spherical)

Optional accessories include brake/encoder/potentiometer/protective boots, etc. - BS (screw brake)/- BM (motor brake)/- EMK (encoder)/- L (potentiometer)/- PB (protective boots)

Core Performance Parameters

The performance parameters of the four models differ significantly, with load capacity, no-load speed, and repeat positioning accuracy as the core distinguishing indicators. There are slight differences in performance when the same model is adapted to different motors. The core parameters are shown in the table below (with maximum values indicated):

table

Model Maximum Load Capacity Maximum Idle Speed Repetitive Positioning Accuracy Adaptation Screw Type Travel Range (mm)

EC2 3230N(740lbs) 840mm/s(33in/s) 0.13mm(0.005in) 04A/05B/16B 50~750, customizable

EC3 7200N(1620lbs) 930mm/s(36.5in/s) 0.025mm(0.001in) 04A/05B/10B/16B 50~1000, customizable

EC4 12000N(2700lbs) 1330mm/s(52.5in/s) 0.025mm(0.001in) 10B/25B 50~1500, customizable

EC5 25000N(5620lbs) 1330mm/s(52.5in/s) 0.013mm(0.0005in) 10B/32B 50~1500, customizable

Note: Customized travel for all models can be designed in increments of 1mm and adapted to different controllers (such as D2200/SmartStep/B8961).

Installation and commissioning specifications

Basic installation requirements

The installation structure should be able to bear three times the rated load of the cylinder body and have sufficient rigidity to prevent deformation of the cylinder body/support components;

The cylinder body must be parallel to the direction of load movement, and different installation methods correspond to different alignment accuracy requirements. When the deviation exceeds the limit, it will cause premature wear of internal components;

When using pivot installation (MP2/MP3/MT4)+pivot rod end (FS2/FC2), the cylinder body extension does not exceed 95% of the full stroke, improving system rigidity;

All installation surfaces must be flat and clean, and flat installation models (MF1/MF2/MF3/MS1/MS6) must be rigidly fixed.

Rod end installation and torque limitation

When installing the load, it is necessary to use the hexagonal plane of the thrust tube to prevent it from rotating, and it is strictly prohibited to exceed the maximum torque limit, otherwise it will damage the internal guide flange. The torque limits for each model are as follows:

table

Model: Clockwise maximum torque, counterclockwise maximum torque

EC2 68N-m(50ft-lbs) 27N-m(20ft-lbs)

EC3 88N-m(65ft-lbs) 41N-m(30ft-lbs)

EC4/5 163N-m(120ft-lbs) 68N-m(50ft-lbs)

Accuracy of cylinder body and load alignment

Different installation methods correspond to parallel/vertical alignment deviation limits. It is necessary to operate according to the specifications to allow the cylinder body to self align before tightening the screws. The core limits are as follows:

Flange/Fork/Ear Shaft Installation (MF/MP/MT): It is required that the installation surface has a vertical deviation of EC2 (0.03mm), EC3 (0.04mm), and EC4/5 (0.05mm) from the direction of load movement;

Ear seat/side hole installation (MS1/MS2/MS6): It is required that the deviation of the installation surface parallel to the direction of load movement increases with the increase of stroke, with a maximum deviation of 0.62mm for a stroke of 1500mm.

Installation of limit sensors

To prevent the cylinder block from hitting the hard limit, a position sensor (limit switch) must be installed, and the core requirements are:

Sensor types: PSR (mechanical spring), PSN/PSP (Hall effect), IP67 protection, PSR compatible with 8-120VAC/DC, PSN/PSP compatible with 5/12/24VDC;

Installation requirements: A deceleration distance should be reserved on the inner side of the hard limit, with a sensor spacing of ≥ 38.1mm (1.5 inches) and a tightening fixture screw torque of ≤ 7.0oz in;

Wiring specification: different sensors correspond to different wiring colors, shielded wires need to be reliably grounded, and PSP sensors are not compatible with IDC controllers.

Application Key Limitations

Column Load Limitation

When the screw is subjected to axial pressure, there is a critical load for instability. Exceeding this value will cause the screw to permanently bend. The maximum column load of different stroke/screw types varies significantly. The core rule is:

EC5 all specifications, 32B lead screw without column load limit;

As the stroke increases, the column load limit of other models significantly decreases, such as EC3 1000mm stroke 04A screw with a maximum column load of 4650N;

Customized trips can refer to the column load limit for the next shorter standard trip, or consult IDC engineers.

Critical speed limit

When the screw rotates, there is a resonance critical speed, and continuous overspeed can cause severe vibration and bending of the screw. The core requirements are:

The critical speed of different screw types/strokes varies, for example, the critical speed of EC5 32B screw 600mm stroke is 1333mm/s, and the critical speed of 1500mm stroke is reduced to 1120mm/s;

The IDC programmable controller can set the maximum speed parameter and force the speed to not exceed the critical value.

3.5.3 Duty cycle limitation

The duty cycle is the percentage of working time within a 10 minute cycle divided by the total cycle time, with a core limit of:

Ball screw cylinder body: 100% duty cycle rated;

ACME screw cylinder body: maximum 60% duty cycle;

The motor itself also has a duty cycle limit, which should be referred to in the motor manual. Exceeding the duty cycle can cause overheating and damage to the motor/internal components.

Environmental and Protection Requirements

Working temperature: -30 ℃~70 ℃ (-22 ℉~158 ℉), ventilation pipes must be installed when it is below 2 ℃ (35 ℉);

Pollution prevention: The standard version only protects against slight water mist. External protective covers are required for contact with corrosive/pressurized liquids, and * * - PB protective boots * * are required for contact with abrasive particles;

Ventilation pipe installation: - PB protective boots must be installed for work below 2 ℃ in dusty environments. EC2/3 uses 1/4 inch inner diameter pipes, EC4/5 uses 3/8 inches, and EC4/5 with - PB uses 3/4 inches.

Optional accessory specifications and installation

The EC series supports multiple customized accessories, all of which are factory pre installed/optional. The core accessory parameters are as follows:

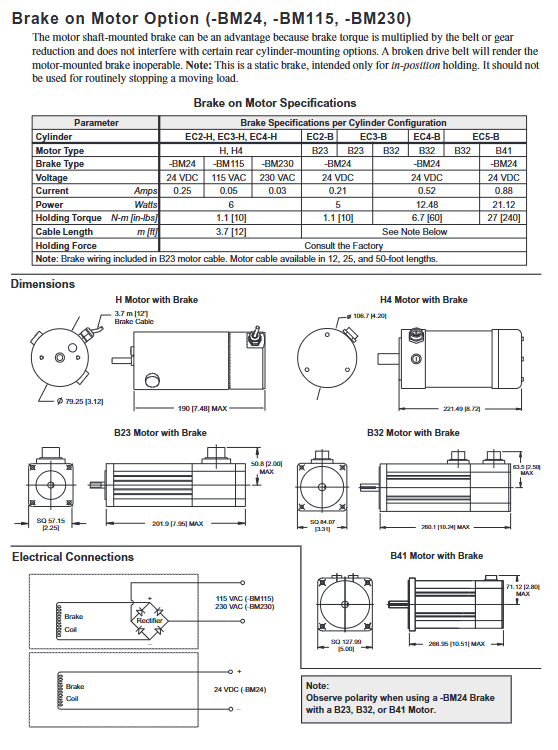

Brakes (- BS/- BM)

Only used for static positioning, not for braking motion loads, divided into screw end (- BS) and motor end (- BM), core parameters:

table

Type Voltage Options Core Performance Applicable Scenarios

-BS (screw end) 24VDC/115/230VAC EC2 maximum 3600N retention force, EC5 maximum 24800N requires high retention force, which does not affect the installation of the cylinder body at the rear end

-BM (motor end) 24VDC/115/230VAC brake torque is amplified by the transmission ratio. If the belt breaks, it will fail. There are installation restrictions at the rear end of the cylinder body, and there is no need for excessive positioning force

Encoder (- EM/- EMK)

Incremental rotary encoder for position feedback, core parameters:

-EM: 500 lines/rev, 2000 pulses/rev after orthogonal output;

-EMK: 1000 lines/rev, 4000 pulses/rev after orthogonal output;

The brushless servo motor (B23/B32/B41) comes standard with a 2000 line/rotary encoder and outputs 8000 pulses/revolution;

Power supply: 5VDC ± 5%, maximum speed 6000~12000rpm, cable length 3.7m (12ft).

Linear Potentiometer (- L)

Built in cylinder body, linear displacement through simulated voltage feedback, 0% stroke corresponds to 0VDC, 100% stroke corresponds to supply voltage, core parameters:

Resistance value: 50mm stroke 3000 Ω, 600mm stroke 7000 Ω, tolerance ± 20%~30%;

Non linearity: maximum ± 1%, not recommended for use in high vibration environments;

Power supply: External DC power supply, with brown (+VDC), black (feedback), and blue (GND) wiring.

Protective Boots (- PB)

Realize IP65 protection level, wrap the thrust tube/oil scraping sealing surface to prevent moisture and dry particles from entering. All models are optional and need to be used in conjunction with the vent pipe after installation.

Daily Maintenance and Factory Services

Maintenance Classification and Operating Scope

On site routine maintenance: only belt tensioning, screw/gear lubrication, motor small gear alignment, and replacement of vulnerable parts (belt/rod end) are allowed;

Factory services: complex operations such as screw modification, transmission ratio replacement, accessory installation (- BS/- L), internal component maintenance, etc. must be returned to the factory.

Core maintenance cycle and specifications

Lubrication cycle:

ACME lead screw (EC2/3): 200000 inch stroke re lubricated;

Ball screws (all models): Re lubricate with a stroke of 1000000 inches;

Lubricants: NLGI grade 2 synthetic lithium grease is used for ball screws, NLGI grade 2 synthetic grease containing PTFE is used for ACME screws, and NLGI grade 2 synthetic lithium based composite extreme pressure grease is used for gears.

Belt tension inspection: The maximum deflection of the transmission belt is ≤ 3.17mm (0.125 inches), and if it exceeds the tolerance, the motor position needs to be adjusted for tension.

Gear mesh clearance: After the motor small gear meshes with the intermediate gear, it needs to be retracted by 0.076~0.203mm (0.003~0.008 inches) to ensure the mesh clearance.

Hardware torque: All maintenance operations require tightening screws according to standard torque, such as M10X1.5 screws with a maximum torque of 41N-m (362.86in-lbs).

Customer provided motor installation

Support the adaptation of customer provided motors, core steps:

Install the pulley/pinion/coupling, apply Loctite 680 (green), and tighten the screws with Loctite 262 (red);

Adjust the spacing between pulleys/small gears according to specifications (such as EC2 pulley spacing of 11.63mm);

Belt transmission requires tensioning the belt, gear transmission requires centering the mesh clearance, and direct transmission requires alignment with the coupling;

Tighten the motor mounting screws to ensure that the motor flange is in contact with the mounting plate.

Troubleshooting

The manual provides clear fault symptoms, causes, and solutions for the four major types of faults in electric cylinder machinery, motion, positioning, and accessories. The core faults and troubleshooting ideas are as follows:

Abnormal noise/jamming/shaking: mostly caused by poor alignment between the cylinder body and load, excessive side load, insufficient lubrication, foreign object intrusion. If the side load exceeds the limit, the load needs to be reduced, and foreign object intrusion/internal component damage needs to be returned to the factory for inspection;

Motor not turning/abnormal speed: The motor is not connected/damaged, the load exceeds the limit, the belt slips/breaks, the gear mesh is poor, the belt slips and needs to be re tensioned, and the gear is damaged and needs to be returned to the factory;

Inaccurate positioning/backdrive: large load changes, controller parameter errors (screw lead/transmission ratio), improper sensor position, insufficient brake retention force, need to correct controller parameters and adjust sensor position;

Accessory failure: Sensor/encoder wiring error/damage, brake overload/wiring error, wiring needs to be checked, damaged accessories need to be replaced, brake overload needs to be reduced.

Components

Parts List: Provides a complete list of 63 components and exploded diagrams for the EC series, divided into four types: EC2/3, EC4/5, and parallel/direct motor installation. Accessories can be ordered through IDC authorized dealers;

Warranty policy: 1-year original factory warranty. From the date of shipment, free repair/replacement is provided for faults caused by material/process defects. Faults caused by human misuse, improper installation, or improper maintenance are not covered by warranty.

- YOKOGAWA

- Reliance

- ADVANCED

- SEW

- ProSoft

- WATLOW

- Kongsberg

- FANUC

- VSD

- DCS

- PLC

- man-machine

- Covid-19

- Energy and Gender

- Energy Access

- Renewable Integration

- Energy Subsidies

- Energy and Water

- Net zero emission

- Energy Security

- Critical Minerals

- A-B

- petroleum

- Mine scale

- Sewage treatment

- cement

- architecture

- Industrial information

- New energy

- Automobile market

- electricity

- Construction site

- HIMA

- ABB

- Rockwell

- Schneider Modicon

- Siemens

- xYCOM

- Yaskawa

- Woodward

- BOSCH Rexroth

- MOOG

- General Electric

- American NI

- Rolls-Royce

- CTI

- Honeywell

- EMERSON

- MAN

- GE

- TRICONEX

- Control Wave

- ALSTOM

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bentley

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- schneider

- Foxboro

- KB

- REXROTH

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- XP POWER

- Baldor

- Meggitt

- SHINKAWA

- Other Brands

-

ABB 216AB61 Industrial Control Module for Automation Systems

-

ABB 5SHX1060H0003 High Power Thyristor Module for Industrial Power Control

-

ABB 07KT97H3 PLC Central Processing Unit for Industrial Automation

-

ABB 3BHB005171R0101 Power Semiconductor Module for Industrial Power Systems

-

KEBA E-SP-CCEC/A/22 - Keyboard Panel

-

KEBA ERHL33 - Module

-

KEBA K-FTC-AN/B - Control Panel Board

-

KEBA DO321 1914D-0 - Digital Output Module

-

KEBA T70Q - Teach Pendant

-

KEBA BL272/A / BL272/B - Bus Coupling Module

-

KEBA T70R - Teach Pendant

-

KEBA PRONET-E-20A-K - Servo Drive

-

KEBA T55-RA0-AU0-LK - Mobile HMI KeTop

-

KEBA DO-272/A - Digital Output Module

-

KEBA PS240/A - Power Supply Module

-

KEBA 2134-00393 - Module Code

-

KEBA E-10-ANALOG-SU - Analog Card

-

KEBA 1904D-0 / D1458E - E-10 Analog Card

-

KEBA FM265A - Function Module

-

KEBA CR17910086 - Controller Board

-

KEBA C5G-TP5WC2 - Robot Teach Pendant

-

KEBA PD242A - Power Supply Module

-

KEBA DI-325 - Digital Input Card

-

KEBA C2-TM-240/A - Digital Input Module

-

KEBA D1547C - I/O Bus Coupling Board

-

KEBA CR-092 - Interface Module

-

KEBA 3HAC023195-003 - IRC5 Teach Pendant Cable

-

KEBA KETOP-T150-MA0 - Mobile HMI

-

KEBA KC-P30-EC24011 - Control Module

-

KEBA 1770B-1 - E-8-THERMO Card

-

KEBA T20T-T00-AR0-CE6 - KeTop Terminal

-

KEBA D1633C-1 - CPU Card

-

KEBA HT401-232-8/0 - Teach Pendant

-

KEBA AO-570 - Analog Output Module

-

KEBA T10-mAb-DMV - Handheld Terminal

-

KEBA C70-rqa-AK0-Le - KeTop Teach Pendant

-

KEBA 1918F-0 - Digital Output Board

-

KEBA T10-mAa-DMV - Handheld Terminal

-

KEBA HT2-SCHLUSSELS - Key Switch for HT2

-

KEBA T100-003-CES - HMI Terminal

-

KEBA GVME610IO - I/O Module

-

KEBA HT501-231 - Teach Pendant

-

KEBA E-CG-CONTROL - Graphic Control Card

-

KEBA D1420F - F-SIC-1 Circuit Board

-

KEBA E-ANA-SUB2 - Analog Sub-module

-

KEBA HT401-222-4 - Teach Pendant

-

KEBA II030 - Input Module

-

KEBA T155-M10-AN0-W - KeTop Mobile HMI

-

KEBA CP088-B - Processor Module

-

KEBA HT40123280 - Operating Terminal

-

KEBA HT4222 - Handheld Terminal

-

KEBA H24025369 - Replacement Part

-

KEBA H24024891 - Replacement Part

-

KEBA SR161 - Analog Input Card

-

KEBA 1762A - E-CRT/EL Circuit Board

-

KEBA T50-011-CES-CE5 - Operator Terminal

-

KEBA E-CON-ELD/B/15 - Control Panel

-

KEBA E-8-THERMO - Thermocouple Card

-

KEBA 330/A-1211-20 - Axis Module

-

KEBA T55-maw-AU0-CE6 - Mobile HMI

-

KEBA C150-110-AK0-N - KeTop HMI

-

KEBA HT4-20656 / HT4-221 - Handheld Terminal

-

KEBA 18658-1 - Analog Board

-

KEBA LM64P89 - LCD Display Screen

-

KEBA E-CPU-88-A - CPU Board

-

KEBA D-CE/59718/15 - Control Board

-

KEBA KC-P30-ES2400E2-E00 - Control Module

-

KEBA 3HAC12929-1 - Teach Pendant SX TPU

-

KEBA E-CON-CC100/A - Control Panel Engel

-

KEBA T200-M01-P20-WES7 - Panel PC Windows Embedded

-

KEBA KC-P30-ES2400B2-M0R - KeControl C3 Module

-

KEBA E8ANALOGC - Analog Card

-

KEBA E-CPU-88-B - CPU Board

-

KEBA T55-raw-AU0-CE6 - Mobile HMI

-

KEBA D1633C - CPU Board

-

KEBA T55-MAW-Au0-CE6 - Mobile HMI

-

KEBA 3HAC11266-4 - Teach Pendant Cable

-

KEBA T20e-m00-Br0-C - Handheld Terminal

-

KEBA E-3-ACU-INC - Controller Board

-

KEBA E-PS-24V - Power Supply Module 24V

-

KEBA C55-2aw-1U0-R - Control Unit

-

KEBA T70-qqu-Aa0-LK - KeTop Teach Pendant

-

KEBA PS244 - Power Supply Module

-

KEBA ECPU186B - CPU Circuit Board

-

KEBA E-8-ANALOG/C - Analog Input Card Engel

-

KEBA AT-4041 - KeControl C3 Controller

-

KEBA T50-ADP - Adapter Module

-

KEBA CP088/D - Control Processor Module

-

KEBA CU312 - Central Unit Module

-

KEBA K2-400 SC440/A - Communication Module

-

KEBA CU212 - Power Supply Module

-

KEBA T20T-T00-AR0-C - KeTop Handheld Terminal

-

KEBA HT4014X20B21572 - Teach Pendant

-

KEBA HT4010V4X201K4 - Operating Terminal

-

KEBA HT401/NC-4X20/20844 - Handheld Terminal

-

KEBA RS-091 / RS091A - Remote Station Module

-

KEBA E8THERMOA - Thermocouple Input Card

-

KEBA TI-570 - Temperature Input Module

-

KEBA C35E 10m/79421/02 - KeTop Teach Pendant

-

KEBA T40-001/58599/06 - Teach Pendant

-

KEBA CR17910087 C5G-GTP5 - Controller Board

-

KEBA T20E-R00-AR0-C - Handheld Terminal

-

KEBA 3HAC023195-001 /02 - Teach Pendant Unit

-

KEBA AR281 - Analog Input Module Engel

-

KEBA D3-DA330/A-0611-20 - D3 Axis Module

-

KEBA CU313 / C-SICU313KEB - Control Unit

-

KEBA k2-700 - Kemro Control System

-

KEBA CU211 - Central Unit Power Supply Module

-

KEBA C5G-TP5WC - Robot Teach Pendant

-

KEBA C100D-CE - Control Panel

-

KEBA D3-DR361/D-6341-30 - D3 Drive Module

-

KEBA D3-DP/A-1000-0 - D3 Supply Module

-

KEBA SXTPU-21664 - Teach Pendant Unit

-

KEBA T70-rqa-AK0-LK - KeTop Touch Screen Glass Panel

-

KEBA C10-1aa-abb - Control Terminal

-

KEBA T50-T41-CPU - CPU Module

-

KEBA 3HAC023195-001 - IRC5 Sx TPU 2 Teach Pendant Controller

-

KEBA D3-DA 330/A-1211-00 - D3 Axis Module

-

KEBA K2-200 250/X (71580) - Processor Module

-

KEBA O70-bra-A0a-F - Operator Panel

-

Creative Duster Vinyl Brush - Record Stylus Cleaner Brush

-

KEBA 3HAC12929-1/04 - Touch Panel Touchscreen Glass Replacement

-

KEBA OP350/Y-1016 - Keyboard Membrane Protective Film K2-200

-

KEBA DO 321/B - Digital Output Card

-

KEBA DI 325/B - Digital Input Module

-

KEBA E-16-DIGOUT-PLUS (D1456E-2) - Digital Output Board

-

KEBA AI 240/A (068370) - Kemro K2-200 Analog Input Module

-

KEBA TM 220/A (066676) - Kemro K2-200 Module

KONG JIANG

Add: Jimei North Road, Jimei District, Xiamen, Fujian, China

Tell:+86-15305925923